Tailstock type vertical takeoff and landing unmanned aerial vehicle and flight control method

A technology for vertical take-off and landing of unmanned aerial vehicles, applied in the field of unmanned aerial vehicles, which can solve the problems of low flight speed, unable to take off and land normally, and low efficiency, and achieve the effects of aircraft safety, increased load, and flight safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

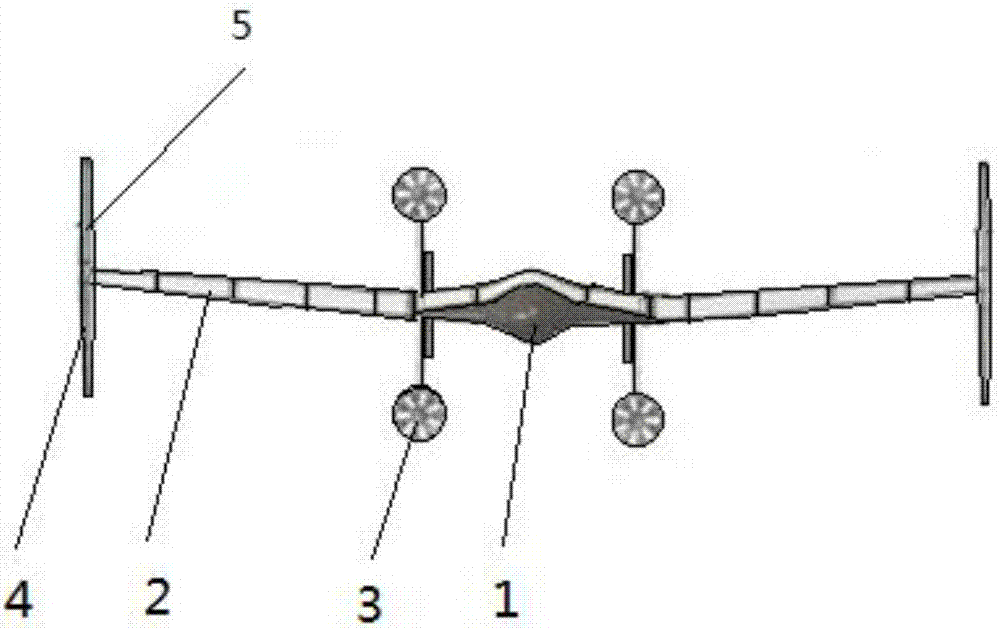

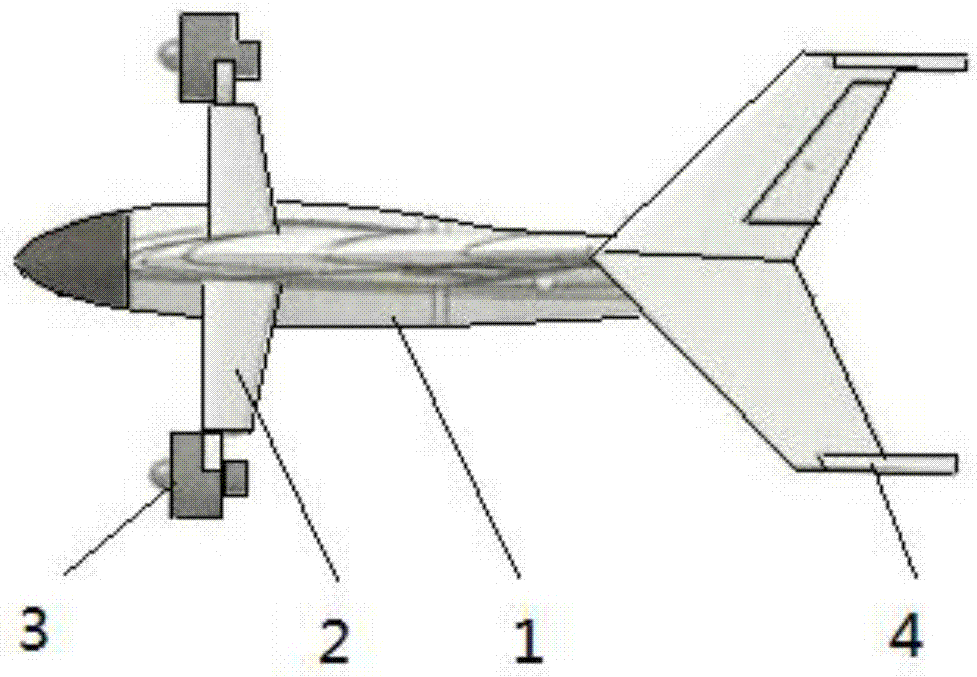

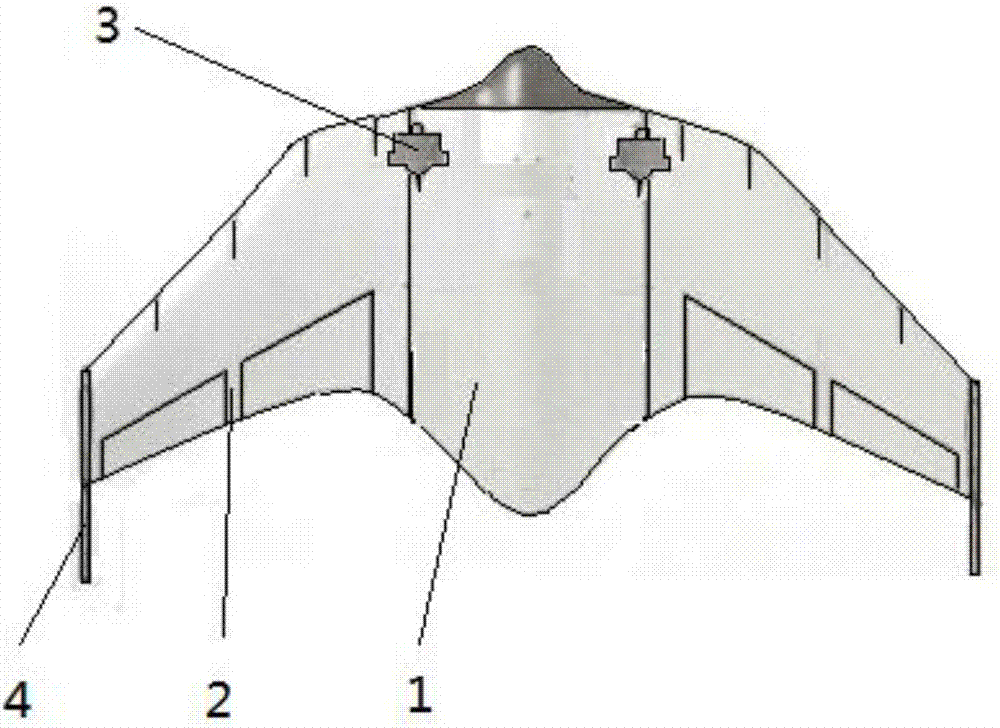

[0037] Refer to the attached Figure 1 to Figure 3 As shown, the present invention provides a tail-sitting vertical take-off and landing unmanned aerial vehicle, comprising wing-shaped fuselage 1, wings 2 on both sides of fuselage 1, four ducted propellers 3 on the upper and lower sides of fuselage 1 and machine The vertical tail 5 above the end of the wing 2 and the wingtip landing gear 4 below, the ducted propeller 3 is driven by a battery or an engine inside the fuselage 1 .

[0038] Further, the fuselage 1 is in the shape of a shuttle, and the width of the end of the connection between the wing 2 and the fuselage 1 is consistent with that of the fuselage 1 . The structure has the characteristics of large lift-to-drag ratio, excellent aerodynamic characteristics, and stable control.

[0039] Refer to the attached Figure 4 As shown, further, avionics equipment 6, said avionics equipment 6 includes GPS or Beidou multi-mode positioning and navigation 61, ultrasonic or optic...

specific Embodiment 2

[0041] According to the control method of any tail-mounted vertical take-off and landing UAV described in the present invention, the flight of the tail-mounted vertical take-off and landing UAV is divided into a take-off section, a take-off transition section, a level flight section, a landing transition section, and a landing section. part;

[0042] Take-off section: refer to the attached Figure 5 As shown, the UAV is set in the four-rotor flight mode, and takes off smoothly in a four-rotor manner through the four ducted propellers 3. At this time, the standard output power of the four ducted propellers 3 is determined according to the load of the UAV. There is no need to establish a speed advantage, hover when taking off to the set height H, and turn to the take-off transition section; the standard output power of the engine is the power when the engine pull is equal to the load of the drone;

[0043]Take-off transition section: refer to the attached Image 6 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com