A kind of cesium tungsten bronze modified powder and preparation method thereof

A technology of cesium tungsten bronze and modified powder, which is applied in the field of energy-saving PVB glue with external absorption and infrared absorption, and can solve the problems of UV discoloration resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

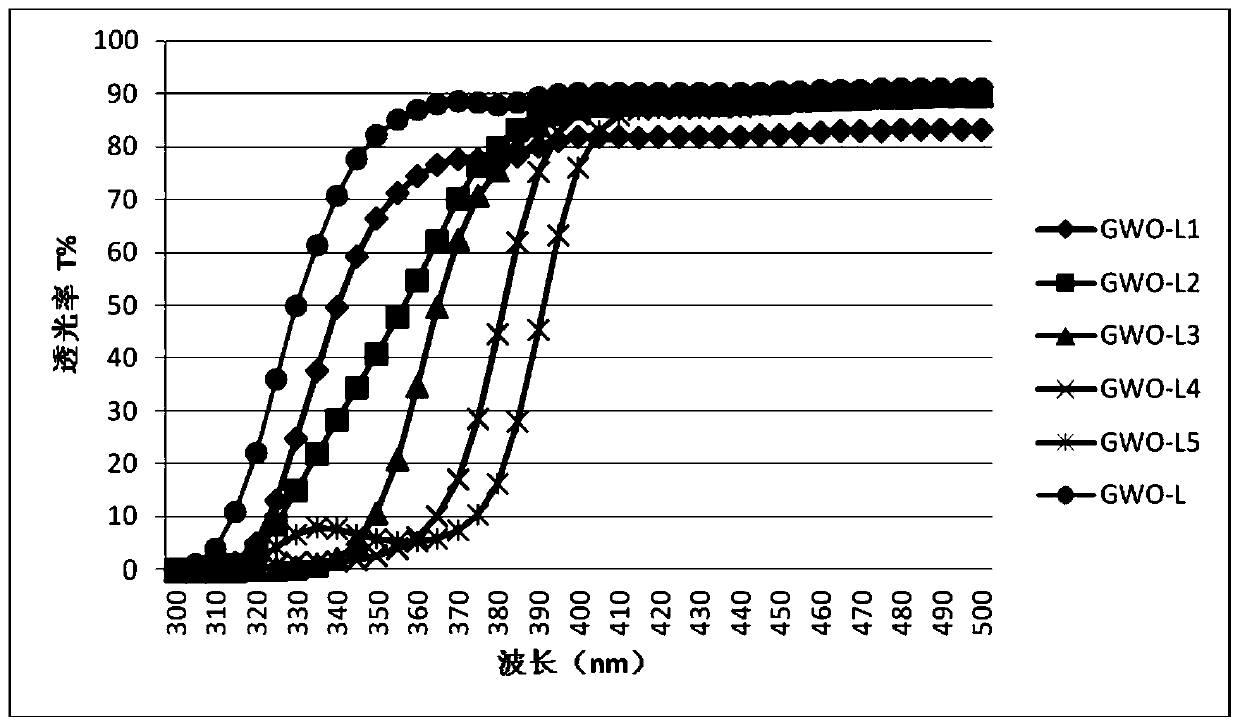

Image

Examples

Embodiment 1

[0038] (1) Preparation of a cesium tungsten bronze modified powder:

[0039] A. Place nano-tungsten trioxide with a reaction volume of 1mol and cesium hydroxide of 0.32mol, ammonia water of 2mol, and 0.01mol nano-nickel oxide in a closed reactor with stirring, and stir for 30 minutes under normal temperature conditions to make cesium hydroxide Dissolve in ammonia water and fully wet the nano-tungsten trioxide; then the reaction temperature is raised from room temperature to the melting point of cesium hydroxide 342.3°C, the heating rate is 50°C / h, and the temperature reaches 342.3°C for 1 hour, so that the cesium hydroxide melt is evenly adsorbed On the surface of nano-tungsten oxide; then the temperature is raised to 740°C at 50°C / h, and the temperature is kept at 740°C for 3 hours. The reaction formula is as follows:

[0040]

[0041] B. Take out the reaction product in step A, and then use Shanghai Huasan Powder Equipment Co., Ltd. model BPQ-50 jet mill for pulverizatio...

Embodiment 2

[0046] (1) Preparation of a cesium tungsten bronze modified powder:

[0047] A. Place nano-tungsten trioxide with a reaction volume of 1mol and cesium hydroxide of 0.32mol, ammonia water of 2mol, and 0.01mol nano-nickel oxide in a closed reactor with stirring, and stir for 30 minutes under normal temperature conditions to make cesium hydroxide Dissolve in ammonia water and fully wet the nano-tungsten trioxide; then the reaction temperature is raised from room temperature to the melting point of cesium hydroxide 342.3°C, the heating rate is 50°C / h, and the temperature reaches 342.3°C for 1 hour, so that the cesium hydroxide melt is evenly adsorbed On the surface of nano-tungsten oxide; then the temperature is raised to 740°C at 50°C / h, and the temperature is kept at 740°C for 3 hours. The reaction formula is as follows:

[0048]

[0049] B. Take out the reaction product in step A, and then use Shanghai Huasan Powder Equipment Co., Ltd. model BPQ-50 jet mill for pulverizatio...

Embodiment 3

[0054] (1) Preparation of a cesium tungsten bronze modified powder:

[0055] A. Place nano-tungsten trioxide with a reaction volume of 1mol and cesium hydroxide of 0.32mol, ammonia water of 2mol, and 0.01mol nano-nickel oxide in a closed reactor with stirring, and stir for 30 minutes under normal temperature conditions to make cesium hydroxide Dissolve in ammonia water and fully wet the nano-tungsten trioxide; then the reaction temperature is raised from room temperature to the melting point of cesium hydroxide 342.3°C, the heating rate is 50°C / h, and the temperature reaches 342.3°C for 1 hour, so that the cesium hydroxide melt is evenly adsorbed On the surface of nano-tungsten oxide; then the temperature is raised to 740°C at 50°C / h, and the temperature is kept at 740°C for 3 hours. The reaction formula is as follows:

[0056]

[0057] B. Take out the reaction product in step A, and then use Shanghai Huasan Powder Equipment Co., Ltd. model BPQ-50 jet mill for pulverizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com