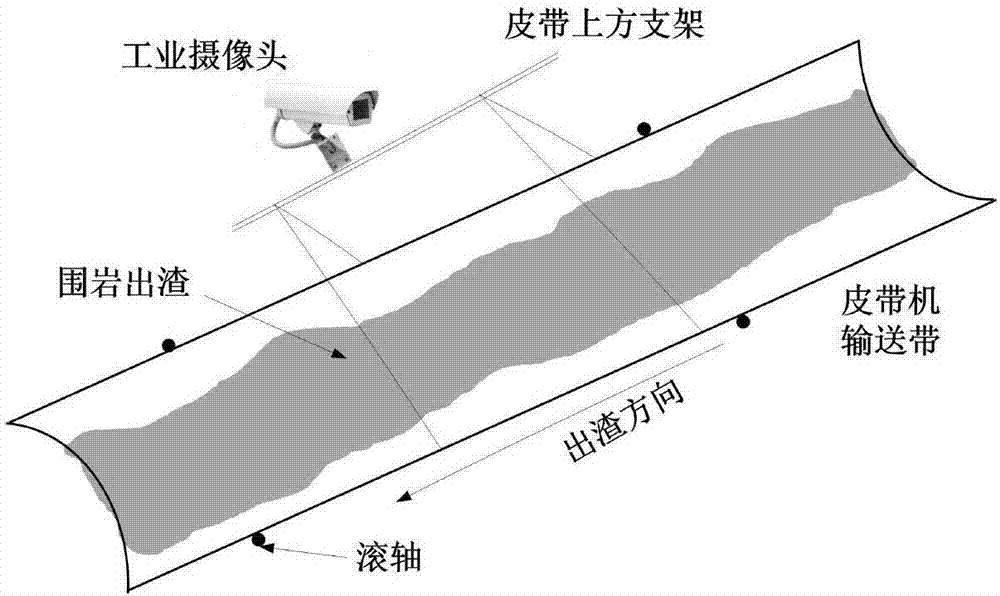

Machine vision-based discharged ballast monitoring method for heading machine

A technology of machine vision and roadheading machine, applied in the direction of instruments, computer parts, image data processing, etc., can solve problems such as inaccurate monitoring, achieve the effects of reducing labor costs, avoiding inaccurate monitoring, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

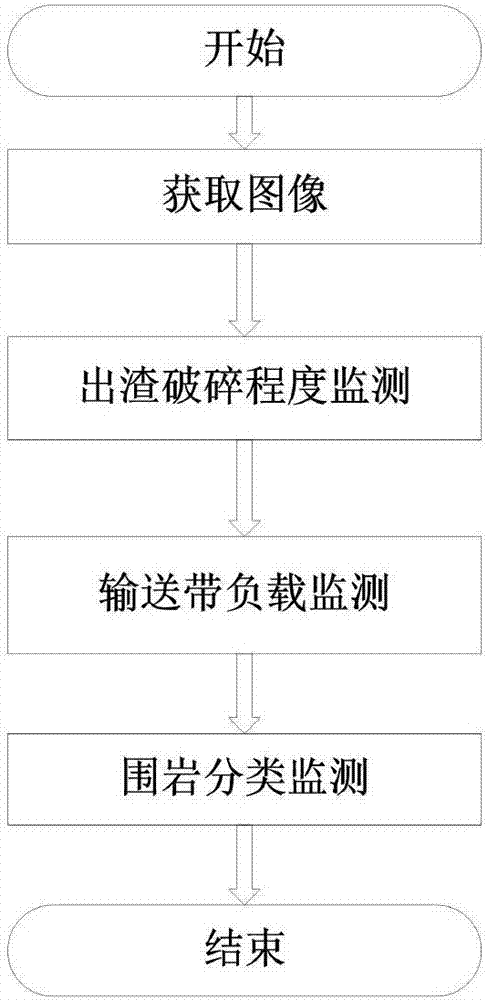

Method used

Image

Examples

Embodiment

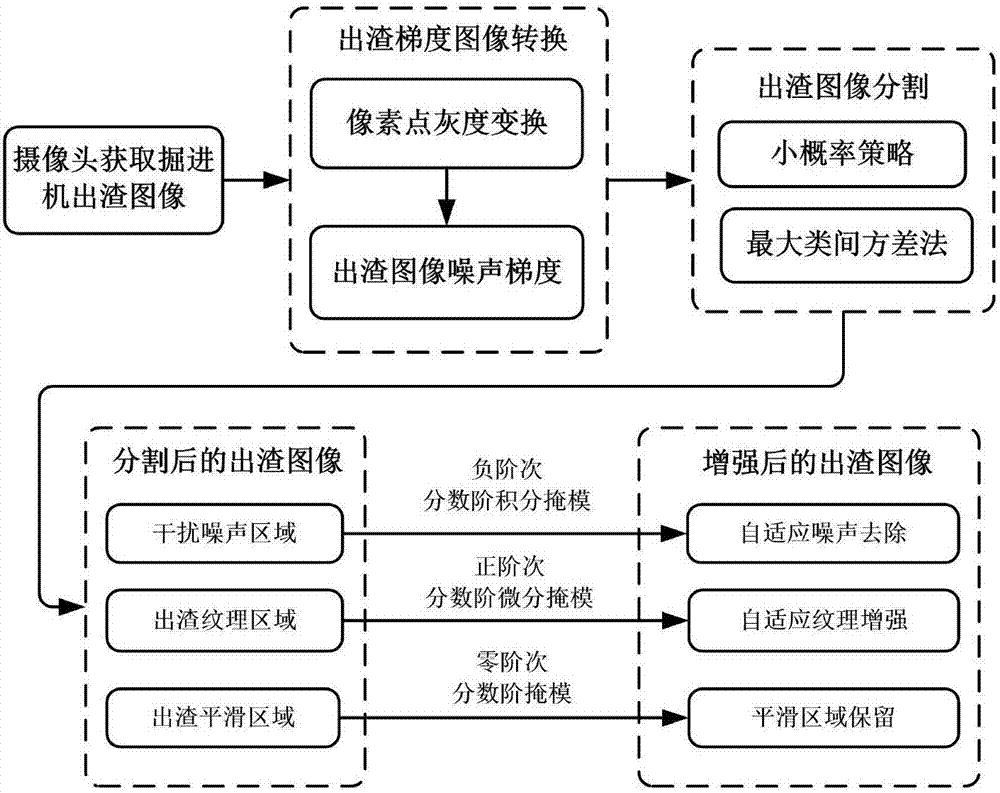

[0052] The visual technology used in the process of processing video images mainly involves the following types of technologies: 1) image enhancement: fractional image enhancement algorithm, which enhances the edge information of the detection target for easy extraction; 2) image contour extraction: extracts the detection target 3) K-means clustering algorithm: extract image features and classify images; 4) Image straight line detection: detect the boundary line between the conveyor belt and the slag discharge area to obtain the detection area , reduce the interference caused by the environment, improve the processing speed, etc.

[0053] OpenCV image processing API function library and VS2010 integrated development environment: OpenCV is an open source image processing function library, developed by C and C++ language, including image processing library and machine vision algorithm library, which can be used across platforms, provided by OpenCV The function can facilitate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com