Combined FCCL material having electromagnetic shielding function and manufacturing method therefor

A technology of electromagnetic shielding and manufacturing methods, applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, electrical components, etc., can solve the problems of increasing the overall thickness of product modules, unfavorable thinning of electronic products, and increasing costs, so as to improve the overall Production and assembly efficiency, solving EMI problems, and reducing the thickness of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

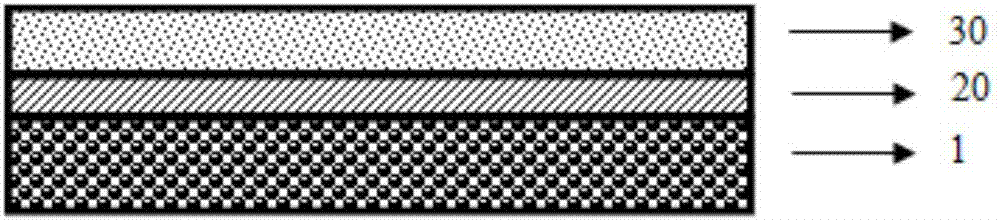

[0049] According to the manufacturing method described in the present invention, a new type of composite FCCL material with electromagnetic shielding function is prepared with a single-sided copper-clad structure, that is, a layer of copper foil material is laminated on the base layer of magnetic glue, and a prepreg is used for bonding in the middle. The prepared material contains both soft magnetic material magnetic glue and conductive material copper.

[0050] The thickness of the magnetic glue used is 40μm, and the magnetic permeability is 200 (@3MHz) (that is, the magnetic permeability is 200 at the frequency of 3MHz); the metal conductive foil used is electrolytic copper foil, and the thickness of the copper foil is 18um; the thickness of the prepreg used is 32um. The preparation method specifically includes the following steps:

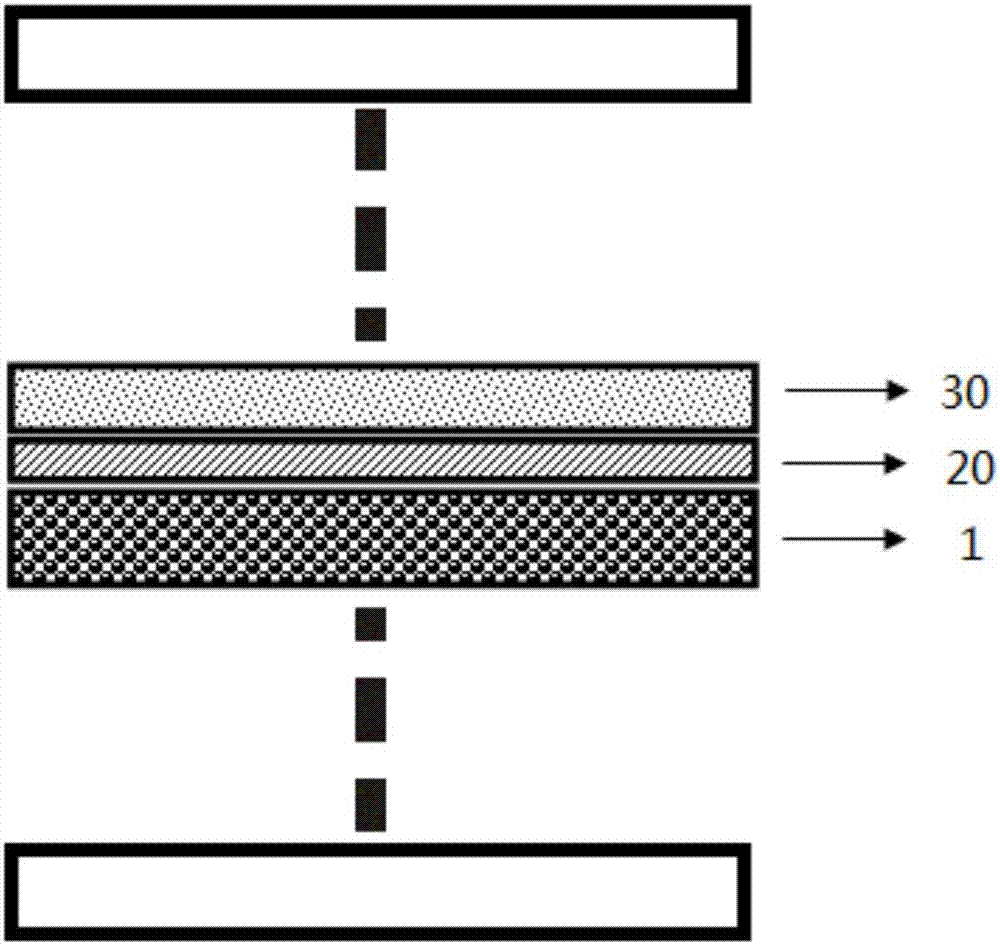

[0051] 1) After cleaning the surface of the base magnetic adhesive layer and copper foil layer, stack the magnetic adhesive, prepreg, and coppe...

Embodiment 2

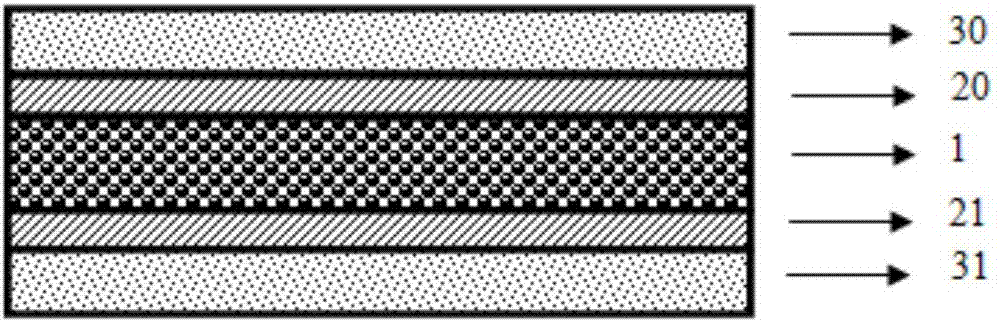

[0057] A novel composite FCCL material with electromagnetic shielding function is prepared according to the manufacturing method of the present invention, that is, a layer of copper foil material is laminated on both sides of the magnetic glue base layer, and acrylic is used in the middle. Adhesive for bonding.

[0058] The thickness of the magnetic glue used is 30 μm, and the magnetic permeability is 200 (@3MHz); the electrolytic copper foil is used, and the thickness of the two layers of copper foil is 12um; the acrylic thermosetting adhesive is used, and the film thickness is 12um.

[0059] 1) After cleaning the surface of the base magnetic adhesive layer and copper foil layer, stack copper foil, adhesive film, magnetic adhesive, adhesive film and copper foil layer by layer to form a unit, with kraft paper and other materials between the two units, multiple The units are stacked into a lamination mold.

[0060] 2) Pre-pressing in the mold: Before pre-pressing in the mold, ...

Embodiment 3

[0065] According to the manufacturing method described in the present invention, a kind of asymmetric special composite FCCL material with electromagnetic shielding function is prepared, that is, a layer of PI base material is compounded with a thermosetting adhesive on the magnetic adhesive base layer as an insulating composite layer, and a prepreg is used on one side Use thermosetting adhesive on the other side, and then cover the two sides with copper foil of different thickness. The overall structure is: 35um copper foil, 20um prepreg, 30um magnetic glue, 12um thermosetting adhesive, 12um PI film, 12um thermosetting adhesive, 12um copper foil.

[0066] The thickness of the magnetic glue used is 30μm, the magnetic permeability is 200(@3MHz); the electrolytic copper foil is used, and the thickness of the two layers of copper foil is 12um and 35um respectively; the acrylic thermosetting adhesive is used, and the film thickness is 12um.

[0067] 1) After cleaning the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com