Elastic hook-and-loop fastener

An adhesive buckle and elastic technology, applied in the direction of fasteners, household components, clothing, etc., can solve the problem of lack of elasticity, and achieve the effect of good strength, functional safety and superior performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

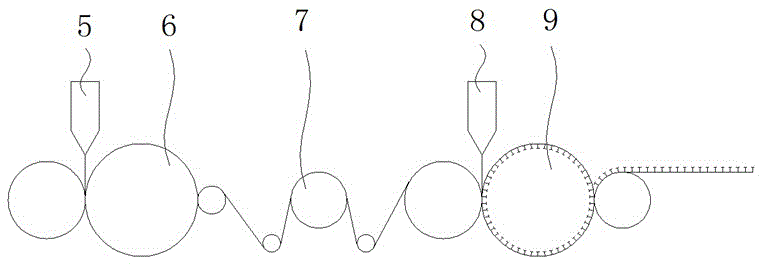

[0028] A method for preparing an elastic adhesive fastener, comprising the following steps:

[0029] Step 1: The elastic material of material A is formed into a base film 1 through a first extruder (5) and a tape casting machine (6);

[0030] Step 2: The substrate film 1 passes through the tractor (7) and then goes to the second forming station;

[0031] Step 3: The material B engineering material above the second molding station is extruded by the second extruder (8) and compounded with the film formed in the previous process;

[0032] Step 4: The material is formed into an adhesive fastener after passing through the forming roller (9).

[0033] The elastic material of material A in step 1 includes, but is not limited to, one or more of polyurethane elastomers, styrene elastomers, polyolefin elastomers, and polyester thermoplastic elastomers.

[0034] In step 3, the material B engineering material includes but is not limited to one of polyamide-nylon, polycarbonate, polypro...

Embodiment example 1

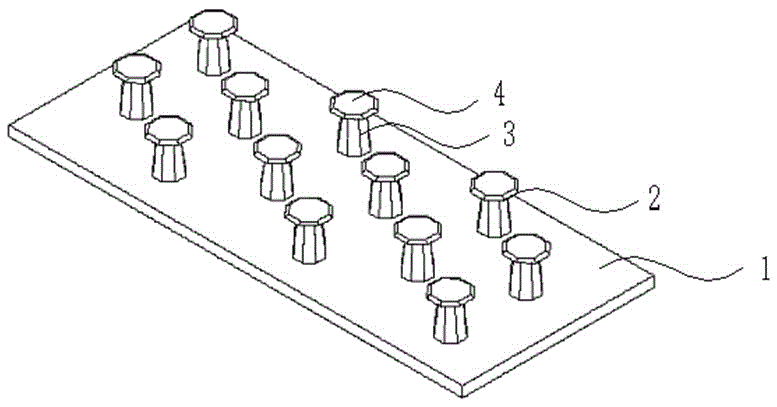

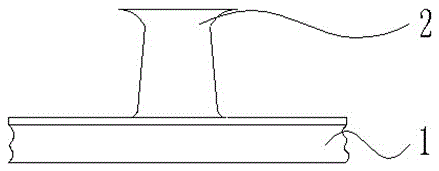

[0037] According to the above preparation method, the substrate film 1 is made of styrene-based elastomer with a thickness of 85 microns, and the raised mushroom head 2 is made of polypropylene material with a height of 0.28 mm and a diameter of 0.16 mm. The density is 300 per square centimeter, the cover is a regular octagon, and the diameter of the inscribed circle is 0.295 mm.

[0038] Performance test method: refer to ASTM D5169-1998, ASTM D5170-1998

[0039] Instrument: Material tensile machine, MTS, EMT2502-B

[0040] Materials: Bonded fasteners and rings of the present invention (from Xiamen Yanjiang New Material Co., Ltd.)

[0041] Test Results

[0042] Adhesive fasteners

[0043] Softness Test Method

[0044] Since there is no standard softness test method for adhesive fasteners, refer to GB / T 8942-2016 "Determination of Paper Softness", QB / T 1060-2012 "Softness Tester"

[0045] Instrument: computer softness tester, YY-RRY1000, Hangzhou Yante Technology ...

Embodiment example 2

[0055] Such as Figure 4 As shown, another preparation method of elastic bonded fasteners:

[0056] Material A uses polyurethane elastomer, material B uses engineering material polypropylene, and the ratio of material A to material B is 40:60. After being extruded through two extruders on the left and right, they are compounded into two layers at the material composite mold. The film is then formed into an elastic adhesive fastener by a forming device. The substrate film 1 has a thickness of 70 microns, and the raised mushroom head 2 has a height of 0.2 mm and a diameter of 0.14 mm. The density of the raised mushroom heads 2 on the base film 1 is 400 per square centimeter. The cover is circular and has a diameter of 0.23 mm. Referring to the test method of ASTM D5169-1998 and ASTM D5170-1998, using the adhesive fastener of the present invention and the ring of Xiamen Yanjiang New Material Co., Ltd., the peel force is 2.5N and the dynamic shear force is 42N. Referring to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com