Zinc oxide desulfurization method suitable for zinc smelting system

A zinc oxide, zinc smelting technology, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of inability to comprehensively recycle desulfurization products, pipeline blockage, low desulfurization rate, etc., to achieve low desulfurization cost, not easy to block. , the effect of high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

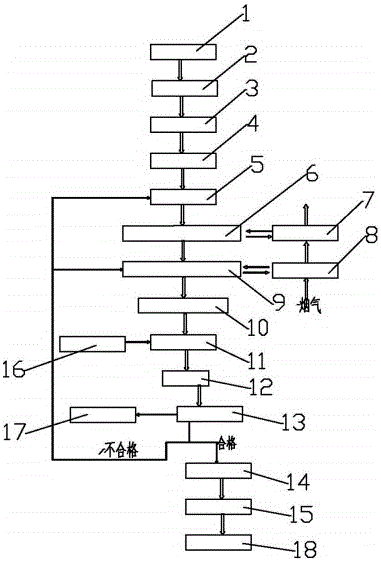

[0022] Such as figure 1 Shown, a kind of zinc oxide desulfurization method applicable to zinc smelting system, the steps of this method are as follows:

[0023] Step 1), the intermediate product zinc oxide powder produced by the rotary volatilization kiln of the zinc smelting system is transported to the zinc oxide intermediate silo 2 through the gasification jet pump 1, and then passed through the belt scale 3 installed at the lower part of the intermediate silo 2 and screw feeding The machine 4 sends the zinc oxide powder to the slurry mixing tank 5, and in the slurry mixing tank 5, the zinc oxide powder and water are mixed to form a suspension, and after stirring, a washing liquid is obtained;

[0024] Step 2), the washing liquid prepared in the pulp mixing tank 5 is poured into the circulation tank 9 of the first-level power wave scrubber and the circulation tank 6 of the second-level power wave scrubber through the delivery pump, and then passed through the first-level po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com