Process for efficiently purifying azadirachtin technical

A kind of technology of azadirachtin, which is applied in the direction of insecticide, animal repellent, botanical equipment and method, etc., can solve the problems of low content of azadirachtin, unfavorable storage, low content of extract, etc., and achieve the extraction rate High, avoid loss, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

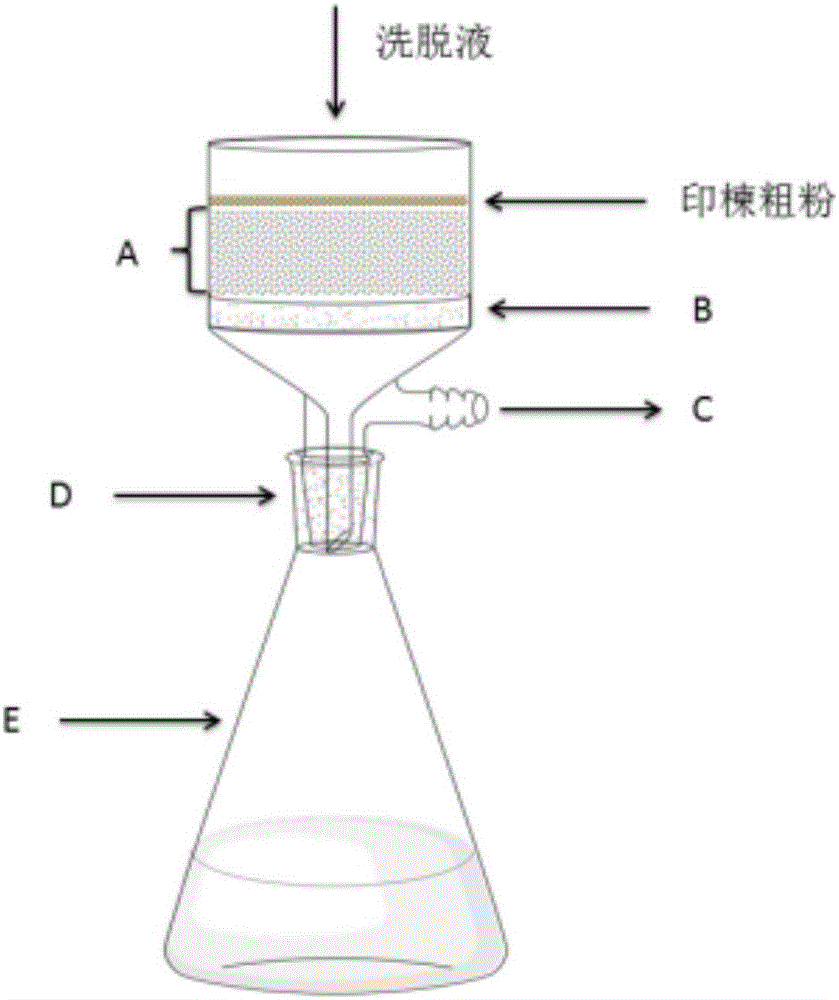

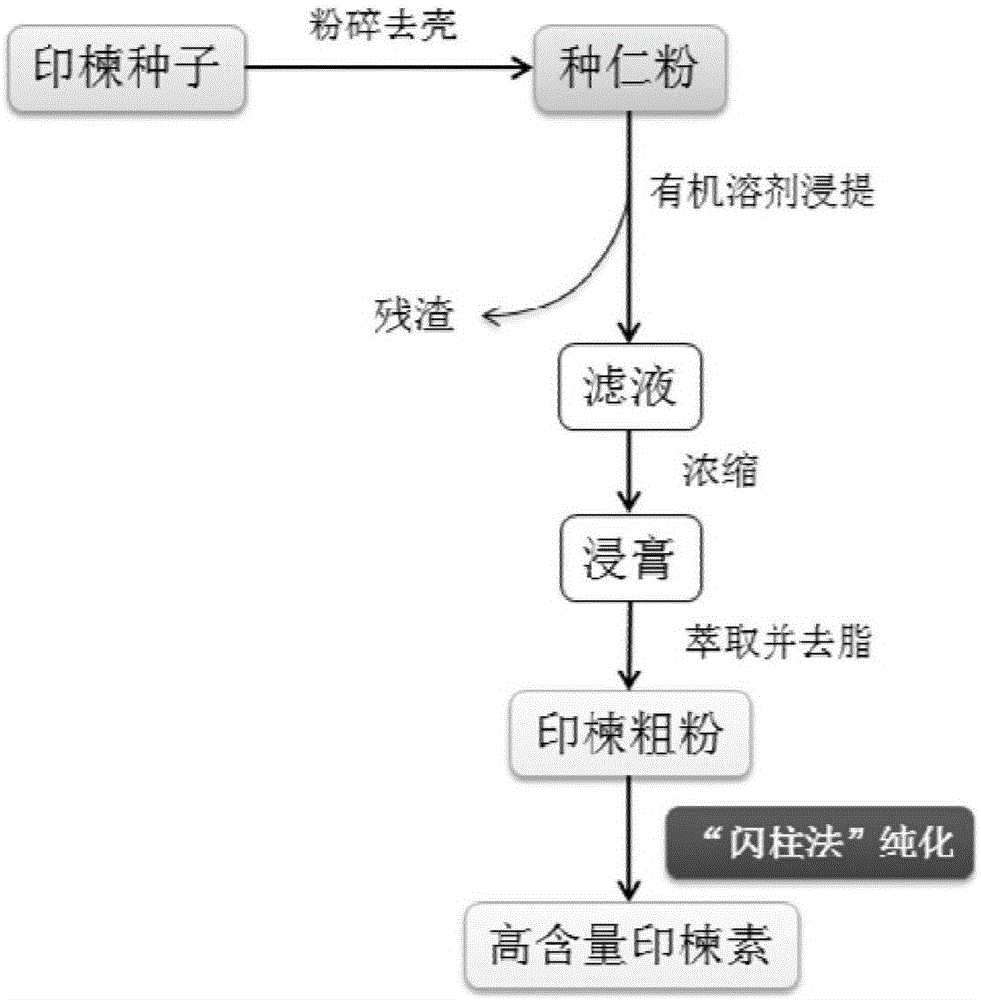

Method used

Image

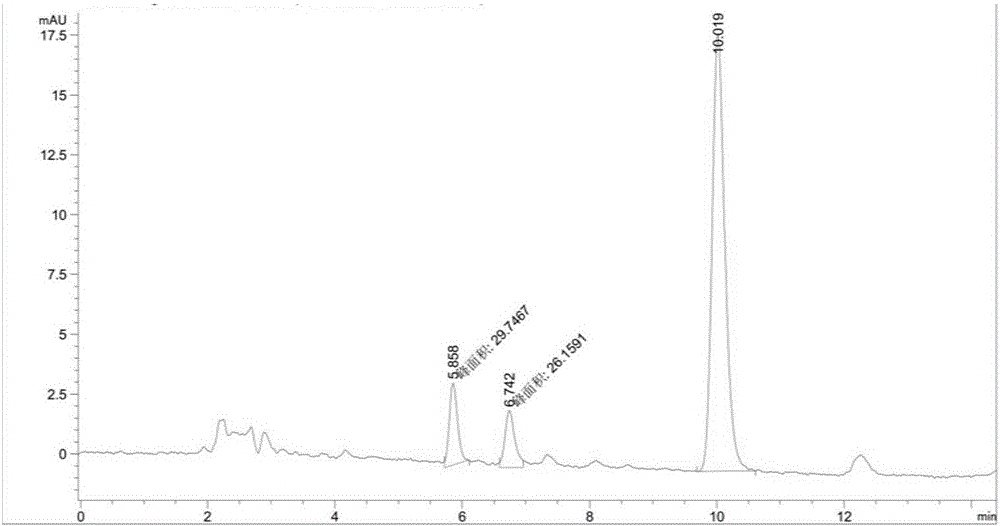

Examples

Embodiment 1

[0033] Grind the dried azadirachtin seed kernels with shells with a pulverizer, remove most of the shells with a 20-mesh sieve, take 700 g of powder, add 2 L of methanol, and stir mechanically for 3 hours at room temperature. Then stand still for 1 hour until the precipitation is complete, then filter and separate, and extract the filter residue with methanol for 1 to 2 times, collect the extract and concentrate in vacuum below 50°C to obtain neem concentrate.

[0034] Add an equal amount of ethyl acetate and 500 mL of saturated saline to the concentrate obtained in the previous step, mix and stir evenly, and then let stand for about 1 hour until ester-water is completely separated. The ethyl acetate layer was washed with saturated brine to remove organic acids, water-soluble proteins, polysaccharides, etc., and the aqueous layer was extracted once with ethyl acetate to increase the extraction rate of azadirachtin, and the ethyl acetate layer was collected and dried with anhydr...

Embodiment 2

[0037] Grind the dried azadirachtin seed kernels with shells with a pulverizer, remove most of the shells with a 20-mesh sieve, take 700 g of powder, add 2 L of methanol, and stir mechanically for 3 hours at room temperature. Then stand still for 1 hour until the precipitation is complete, then filter and separate, and extract the filter residue with methanol for 1 to 2 times, collect the extract and concentrate in vacuum below 50°C to obtain neem concentrate.

[0038] Add an equal amount of ethyl acetate and 500 mL of saturated saline to the concentrate obtained in the previous step, mix and stir evenly, and then let stand for about 1 hour until ester-water is completely separated. The ethyl acetate layer was washed with saturated brine to remove organic acids, water-soluble proteins, polysaccharides, etc., and the aqueous layer was extracted once with ethyl acetate to increase the extraction rate of azadirachtin, and the ethyl acetate layer was collected and dried with anhydr...

Embodiment 3

[0041] Grind the dried azadirachtin seed kernels with shells with a pulverizer, remove most of the shells with a 20-mesh sieve, take 700 g of powder, add 2 L of methanol, and stir mechanically for 3 hours at room temperature. Then stand still for 1 hour until the precipitation is complete, then filter and separate, and extract the filter residue with methanol for 1 to 2 times, collect the extract and concentrate in vacuum below 50°C to obtain neem concentrate.

[0042]Add an equal amount of ethyl acetate and 500 mL of saturated saline to the concentrate obtained in the previous step, mix and stir evenly, and then let stand for about 1 hour until ester-water is completely separated. The ethyl acetate layer was washed with saturated brine to remove organic acids, water-soluble proteins, polysaccharides, etc., and the aqueous layer was extracted once with ethyl acetate to increase the extraction rate of azadirachtin, and the ethyl acetate layer was collected and dried with anhydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com