Heating solid-phase synthetic method of polypeptides

A solid-phase synthesis and condensation technology, applied in the preparation methods of peptides, chemical instruments and methods, peptides, etc., to achieve the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

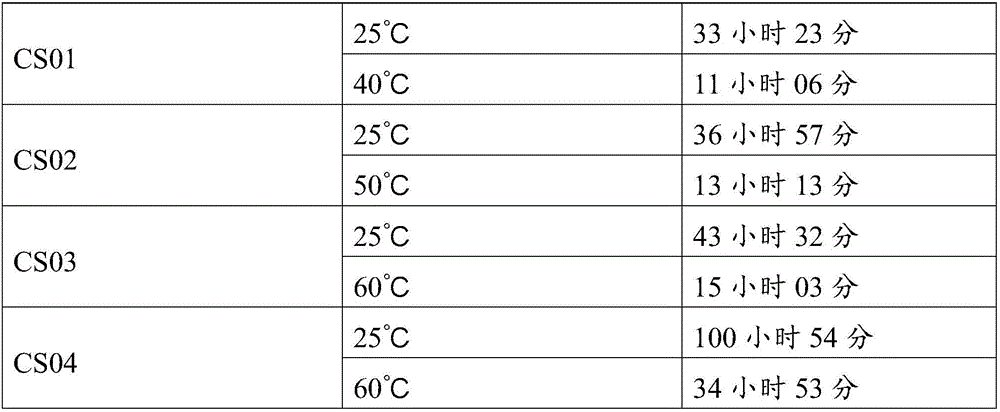

[0041] Embodiment 1: the preparation method of Ala-Ala-Lys-Lys-Ala-Ala-Lys-Lys-Ala-Lys (CS01)

[0042] (1) Heating and condensing amino acids: add polypeptide resin, Fmoc-protected amino acids, condensing agents and solvents to the reactor, heat to the reaction temperature, and the reaction time is 10-30min. After the reaction, use N,N- Wash the resin 3 times with dimethylformamide, each elution time is 20-40s;

[0043] In this embodiment, the reactor is a 3-channel reactor;

[0044] Polypeptide resin is Wang resin in the present embodiment;

[0045] Condensing agent is DIC / HOBt in the present embodiment;

[0046] The solvent in this example is N,N-dimethylformamide.

[0047] (2) Removal of Fmoc by heating: add 20% piperidine / N,N-dimethylformamide solution of deprotecting agent, heat to reaction temperature, reaction time 2-5min, after the reaction is completed, use N at the reaction temperature , washing the resin once with N-dimethylformamide, and then washing the resin ...

Embodiment 2

[0056] Embodiment 2: the preparation method of Ile-Asp-Leu-Leu-Gln-Gly-Arg-Thr-Arg-Asn-Arg-Cys (CS02)

[0057](1) Heating and condensing amino acids: add polypeptide resin, Fmoc-protected amino acids, condensing agents and solvents to the reactor, heat to the reaction temperature, and the reaction time is 10-30min. After the reaction, use N,N- Wash the resin 3 times with dimethylformamide, each elution time is 20-40s;

[0058] In this embodiment, the reactor is a 3-channel reactor;

[0059] Polypeptide resin is chlorine resin in the present embodiment;

[0060] Condensing agent is DIC / HOAt in the present embodiment;

[0061] The solvent in this example is N,N-dimethylformamide.

[0062] (2) Removal of Fmoc by heating: add 20% piperidine / N,N-dimethylformamide solution of deprotecting agent, heat to reaction temperature, reaction time 2-5min, after the reaction is completed, use N at the reaction temperature , washing the resin once with N-dimethylformamide, and then washing...

Embodiment 3

[0072] The preparation method of Ala-Tyr-Arg-Ala-Ile-Arg-His-Ile-Pro-Arg-Arg-Ile-Arg-Gln (CS03)

[0073] (1) Heating and condensing amino acids: add polypeptide resin, Fmoc-protected amino acids, condensing agents and solvents to the reactor, heat to the reaction temperature, and the reaction time is 10-30min. After the reaction, use N,N- Wash the resin 3 times with dimethylformamide, each elution time is 20-40s;

[0074] In this embodiment, the reactor is a 3-channel reactor;

[0075] In this embodiment, the polypeptide resin is an amino acid resin;

[0076] Condensing agent is DIEA / HBTU in the present embodiment;

[0077] The solvent in this example is chloroform.

[0078] (2) Removal of Fmoc by heating: add 20% piperidine / N,N-dimethylformamide solution of deprotecting agent, heat to reaction temperature, reaction time 2-5min, after the reaction is completed, use N at the reaction temperature , washing the resin once with N-dimethylformamide, and then washing the resin o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com