Lubricating grease composition for concrete pump truck and preparation method of lubricating grease composition

A grease composition and a technology for a concrete pump truck are applied in the field of grease, which can solve the problems of poor compatibility, complex varieties, and failure of lubrication, and achieve the effects of simple process, reasonable price and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Formula: No. 3 lithium-based grease: 300g (30%), mineral base oil (lithium A1: viscosity of 70mm at 40°C 2 / s): 700g (70%), additives: solid wear reducing agent (light calcium carbonate) 10g (1%), rust inhibitor (barium petroleum sulfonate) 10g (1%).

[0023] Process: (1) Add 300g of No. 3 lithium base grease, mineral base oil (lithium A1 40°C viscosity is 70mm 2 / s): 700g was added to the reactor, stirred, and heated to 70°C;

[0024] (2) Add 10 g of light calcium carbonate and 10 g of barium petroleum sulfonate, continue to stir for 40 minutes, and squeeze oil three times to form a finished product.

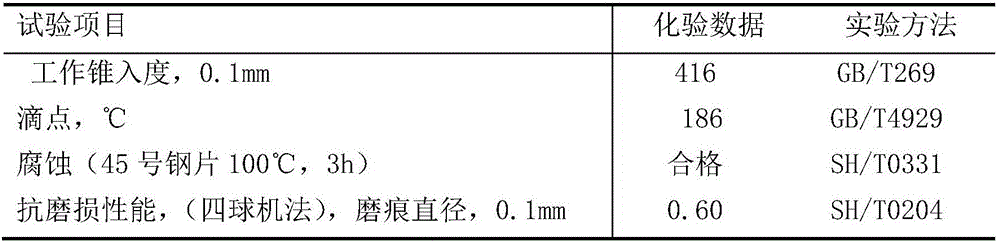

[0025] The performance of the lubricating grease that process formula of the present invention makes is listed in table 1

[0026] Table 1

[0027]

example 2

[0029] Formula: No. 3 lithium base grease 350g (35%), mineral base oil (lithium A1 + lithium A3 reconcile the viscosity of 90mm at 40°C 2 / s),: 650g (65%), additives: solid wear reducing agent (light calcium carbonate) 15g (1.5%), rust inhibitor (barium petroleum sulfonate) 10g (1%)

[0030] Process: (1) Add 350g of No. 3 lithium-based grease, mineral base oil (Lithium A1 550g, Lithium A3 50g): 600g into the reaction kettle, stir, and heat to 90°C;

[0031] (2) Add 15g of light calcium carbonate and 10g of barium petroleum sulfonate, continue to stir for 40 minutes, and squeeze oil twice to form a finished grease.

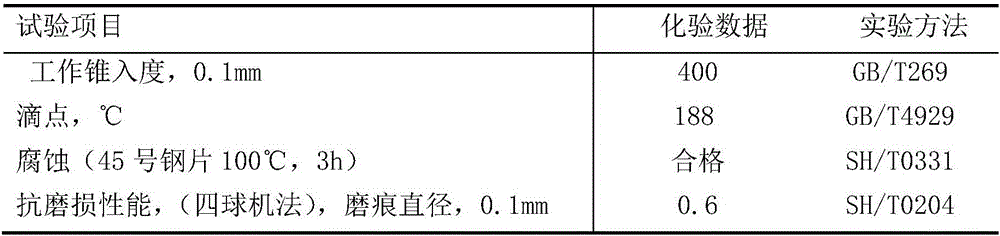

[0032] The performance of the lubricating grease that process formula of the present invention makes is listed in table 2

[0033] Table 2

[0034]

example 3

[0036] Formula: No. 3 lithium base grease 400g (40%), mineral base oil (lithium A3 40 ℃ viscosity is 150mm 2 / s): 600g (60%), additives: solid wear reducing agent (light calcium carbonate + modified nano-calcium carbonate) 15g (1.5%), rust inhibitor (barium petroleum sulfonate + sodium petroleum sulfonate) 10g ( 1%)

[0037] Process: (1) Add 400g of No. 3 lithium base grease, mineral base oil (lithium A3 40°C viscosity is 150mm 2 / s): 600g was added to the reactor, stirred, and heated to 80°C;

[0038] (2) Add 10 g of light calcium carbonate, 5 g of modified nano-calcium carbonate, 5 g of barium petroleum sulfonate, and 5 g of sodium petroleum sulfonate, continue to stir for 50 minutes, and press oil three times to form a finished grease.

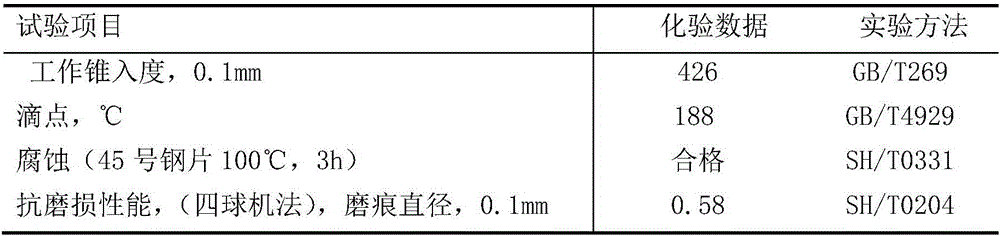

[0039] The performance of the lubricating grease that process formula of the present invention makes is listed in table 3

[0040] table 3

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com