Control method of sectional warping machine

A slit warping machine and control method technology, applied in warping machines, manufacturing tools, textiles and papermaking, etc., can solve the problems of small torque, complex lines, uneven tension control, etc., to achieve accurate positioning and displacement, The device is small in size and good in stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

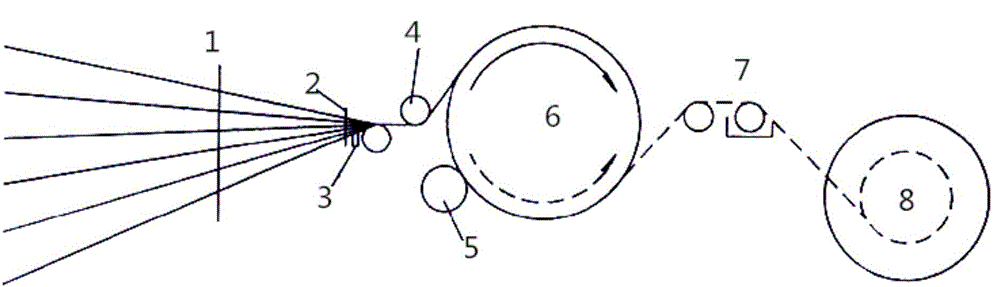

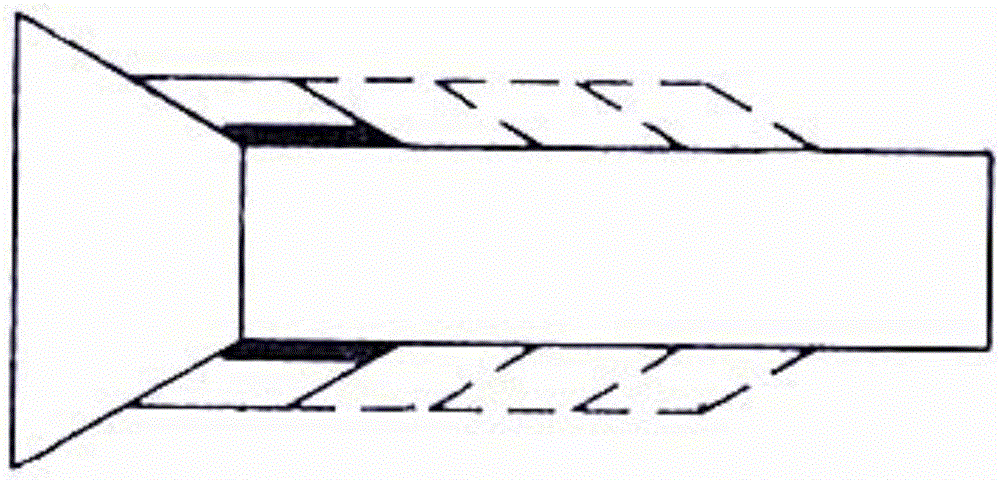

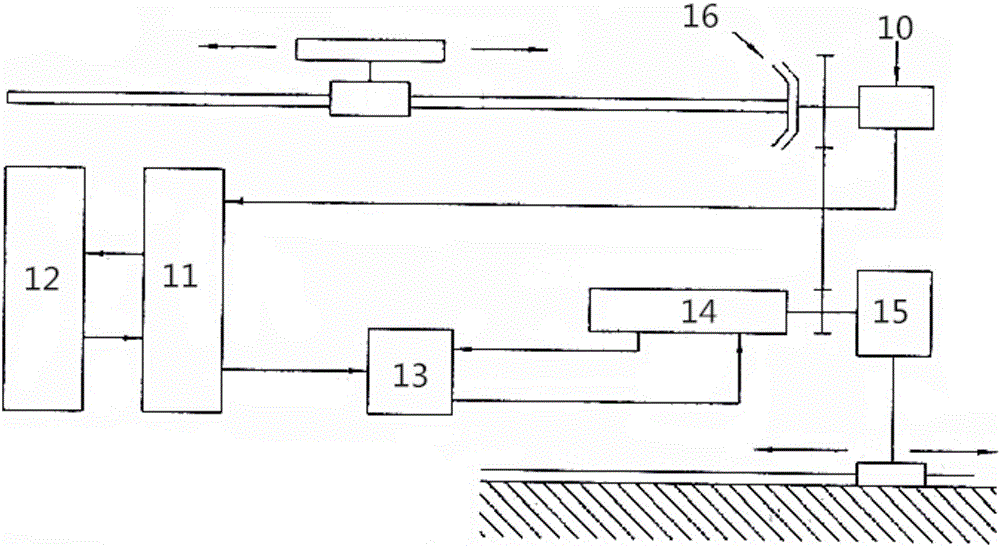

[0022] Such as figure 1 As shown, the section warping machine in the present embodiment includes the sub-skeined reed 1 arranged in sequence along the yarn conveying direction, the fixed width reed 2, the guide roller 4, the pressing roller 5, the cylinder 6, the guide roller 7, Wax roller 8 and weaving beam 9. Static elimination 3 is arranged between the sizing reed 2 and the guide roller 4, two guide rollers 4 are arranged above and below the yarn, and the pressing roller 3 is arranged below the cylinder 6. A shaft encoder is arranged on the roller shaft, and a thickness measuring sensor and a pressure sensor are also arranged on the roller. After the yarn is sorted by the split reed 1, the fixed width reed 2 and the yarn guide roller 4, several yarns are separated and wound on the large round drum in turn, and the yarn pressure roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com