A kind of hot-in-place recycling equipment for multi-stage asphalt pavement

A technology of asphalt pavement and recycling equipment, which is applied in the direction of roads, roads, road repairs, etc., and can solve the problems of asphalt loss of activity and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

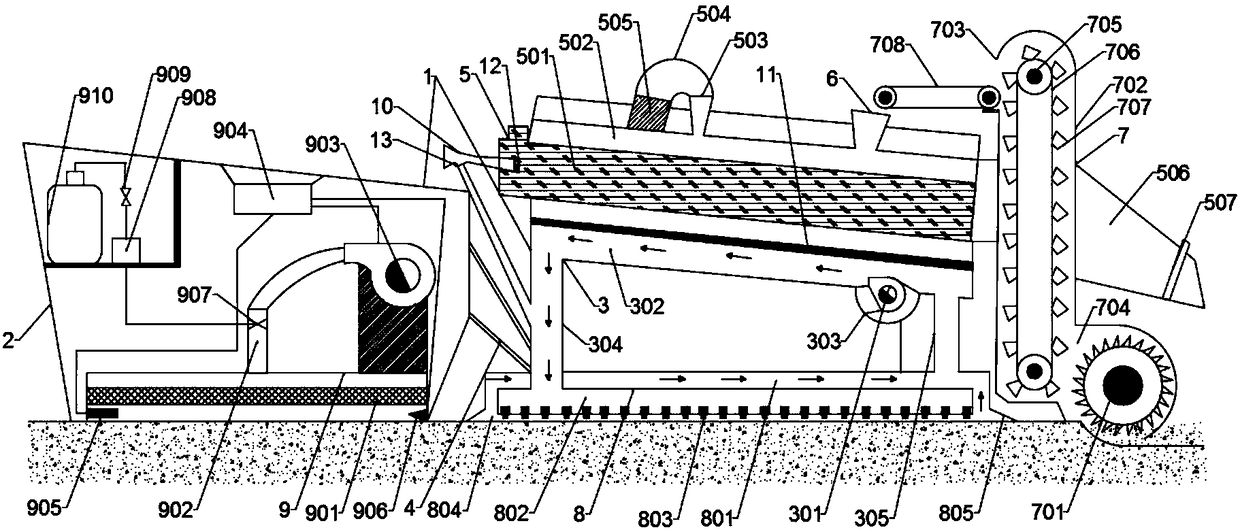

[0035] Such as figure 1As shown, the present invention provides a technical solution: a multi-stage asphalt pavement hot-in-place regeneration equipment, including a vehicle body support 1, the vehicle body support 1 is divided into two sections, one of which is a solid steel support 2, and the other section It is a hollow steel pipe support 3, one end of the steel support 2 and one end of the steel pipe support 3 are fixedly connected by several connecting rods 4;

[0036] The top of the steel pipe support 3 is fixedly equipped with a burner 5, and the top of the burner 5 is provided with an old material addition port 6, which is used to add the milled road asphalt into the burner for high temperature melting, and the burner 5 The right end of the steel pipe support 3 is connected with a milling material lifting device 7, a second blower 301 is installed in the steel pipe support 3, a hot air spray device 8 is connected to the lower end of the steel pipe support 3, and a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com