Manufacturing process of catalyst core of automobile exhaust catalyst

A manufacturing process, a technology for automobile exhaust, which is applied in the electronic control of exhaust treatment devices, diagnostic devices of exhaust treatment devices, and exhaust gas treatment. , can not respond to the working state of the catalyst in real time, etc., to achieve the effect of good catalytic effect, reasonable and novel structure design, and improved catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

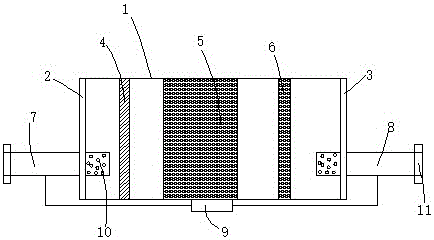

[0028] see figure 1 and figure 2 , the present invention provides an automobile exhaust catalyst, comprising: a housing 1, a front end cover 2 and a rear end cover 3 respectively arranged at the front end and the rear end of the housing 1, arranged at intervals from the front end to the rear end of the housing The turbulence plate 4, the catalyst core 5 and the particle filter 6, and the inlet pipe 7 and the outlet pipe 8 respectively inserted into the front end and the rear end of the housing 1, and the outer surface of the housing 1 A differential pressure sensor 9 is connected with the inlet pipe 7 and the outlet pipe 8;

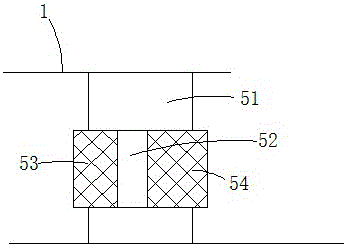

[0029] The catalyst core 5 includes: a fixing plate 51 fixed in the housing 1, a mounting hole 52 provided in the fixing plate 51, and first catalytic converters arranged at intervals along the axial direction of the mounting hole 52. The core 53 and the second catalytic core 54 , and the catalyst coating provided on the first catalytic core 53 and the...

Embodiment 2

[0034] A kind of manufacturing process of the catalytic converter core of automobile exhaust catalytic converter, the steps are as follows:

[0035] ①, structure and molding

[0036] The catalyst core includes a fixing plate fixed in the casing, a mounting hole arranged in the fixing plate, a first catalytic core and a second catalytic core arranged at intervals along the axial direction of the mounting hole, and Catalyst coating on the second catalytic core;

[0037] The material of the fixed plate is Q235 steel, and the mounting hole is formed by stamping;

[0038] The first catalytic core and the second catalytic core are prepared according to the prior art, and the catalyst coating is prepared and loaded according to the prior art;

[0039] ②, catalytic core pretreatment

[0040] Soak the first catalytic core and the second catalytic core in the pretreatment solution for at least 15 minutes, then take them out and dry them directly;

[0041] The pretreatment liquid is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com