A Multi-stage Tidal Energy Turbine Based on Real-time Adjustable Spindle Angle

A shroud, tidal energy technology, applied in mechanical equipment, hydroelectric power generation, ocean energy power generation, etc., can solve the problem that the water energy flowing through the runner cannot be well utilized, the design of the shroud attack angle is limited, and the real-time Adjust the shroud and other issues to achieve a significant energy enhancement effect, improve the inflow effect, and improve the effect of energy harvesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

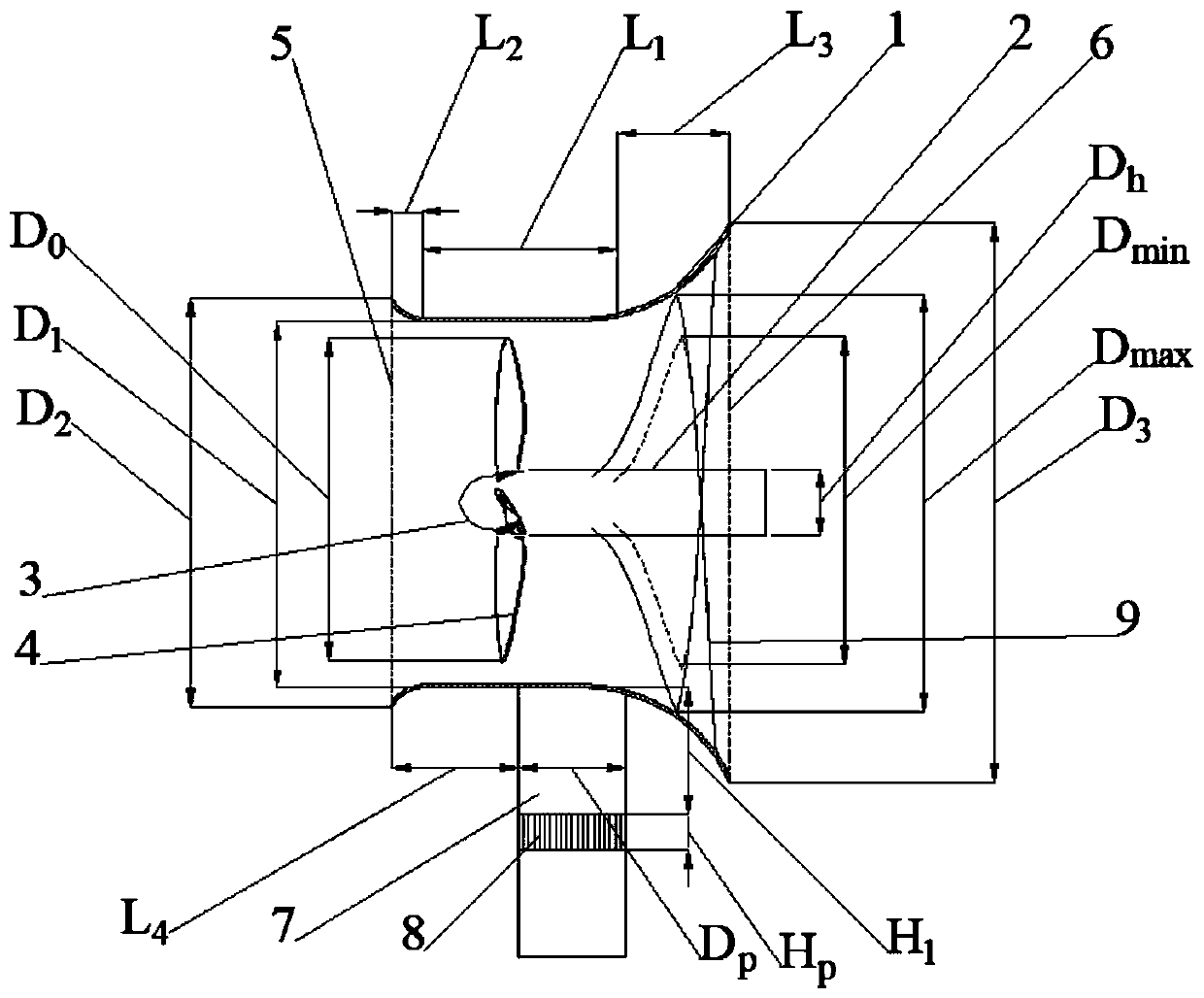

[0042] combine Figure 1 to Figure 10 , the present invention proposes a multi-stage tidal energy turbine based on the real-time adjustable deflector rotation angle, which includes a deflector 1, a hub 3 fixed on the rotating shaft 2, and a basic impeller fixed on the hub 3. The rotating shaft 2, the hub 3 and the basic impeller are all arranged in the shroud 1, which also includes a support shaft 7 with a real-time adjustable rotation angle of the shroud 1, and a hyperbolic helical helical blade 9 with a variable radius. The energy-increasing runner, the energy-increasing runner is located at the outlet end of the shroud 1, and the hyperbolic spiral blade 9 is gradually stretched along the axial direction of the rotating shaft 2 according to the helix of the hyperbolic spiral, It is in the shape of spatial intersecting twist and is evenly distributed on the circumferential inner wall of the rotating shaft 2, and the intersection of the cross-sections of the hyperbolic helical...

Embodiment 2

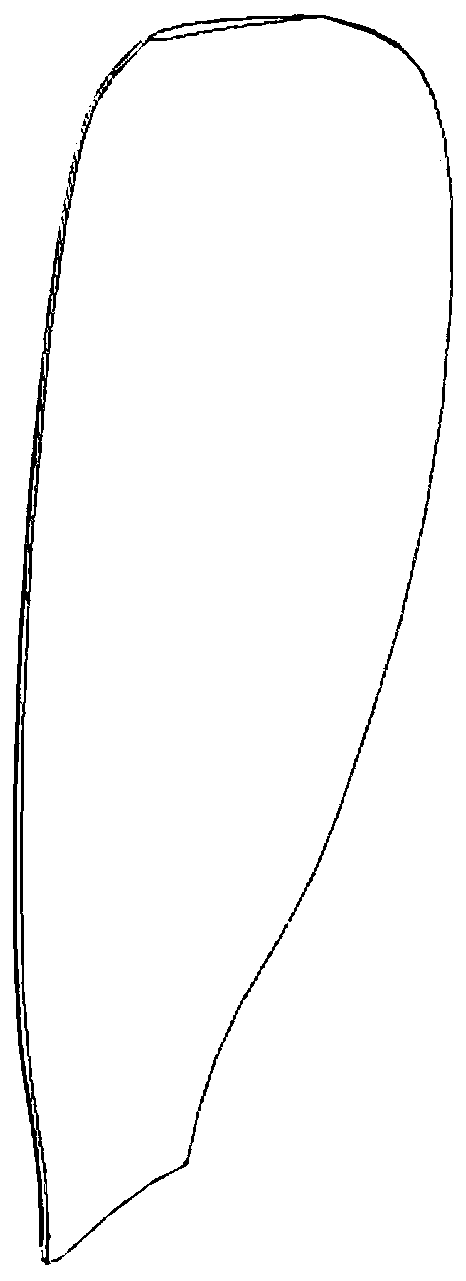

[0057] combine Figure 2 to Figure 5 The parameters of the installation angle of each section of the twisted blade 4 according to the present invention are shown in Table 3, and the parameters of the chord length of each section of the twisted blade 4 are shown in Table 4.

[0058] table 3:

[0059] Section number Installation angle(°) Section number Installation angle(°) 1002 40.14 1012 20.29 1003 38.23 1013 18.67 1005 35.27 1015 15.63 1006 32.69 1016 14.13 1007 30.23 1017 12.58 1008 27.94 1018 10.86 1009 25.81 1019 8.66 1010 23.84 1020 5.92

[0060] The installation angle from the blade root to the blade tip is fitted to the sixth power of the number of sections, and the installation angle fitting equation is:

[0061] Y=-9.21×10 -7 x 6 +8.33×10 -5 x 5 -3.71×10 -3 x 4 +8.39×10 -2 x 3 -0.899x 2 +2.06x+38.86;

[0062] Table 4:

[0063]

[0064]

[0065] The chord length of the distort...

Embodiment 3

[0068] combine figure 1 , the shape of the hub 3 of the present invention is a spherical convex, the length L of the hub 3 0 The length L of the middle section with the shroud 1 1 The ratio of 0.29 to 0.36, the length L of the inlet section of the shroud 1 2 The length L of the middle section with the shroud 1 1 The ratio of 0.08 to 0.15, the length L of the outlet section of the shroud 1 3 The length L of the middle section with the shroud 1 1 The ratio of 0.51 to 0.58, the diameter Dp of the support shaft 7 and the total length of the shroud 1 (L 1 +L 2 +L 3 ) ratio is 0.2 to 0.3, the distance from the center of the support shaft 7 to the front end of the shroud 1 (L 4 +0.5Dp) and the total length of the shroud 1 (L 1 +L 2 +L 3 ) ratio is 0.45 to 0.65, the distance H between the hydraulic turntable bearing 8 and the lower part of the shroud 1 1 The ratio to the diameter Dp of the support shaft 7 is 1.2-2.6, and the ratio of the height Hp of the hydraulic slewing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com