Dynamic load simulation test device and test method thereof

A simulation test and dynamic load technology, applied in the field of mechanical experiments, can solve the problems of high manufacturing cost, large floor space, incapable of real-time and stepless adjustment of load value, etc., to achieve the goal of reducing experiment cost and floor space, and improving accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

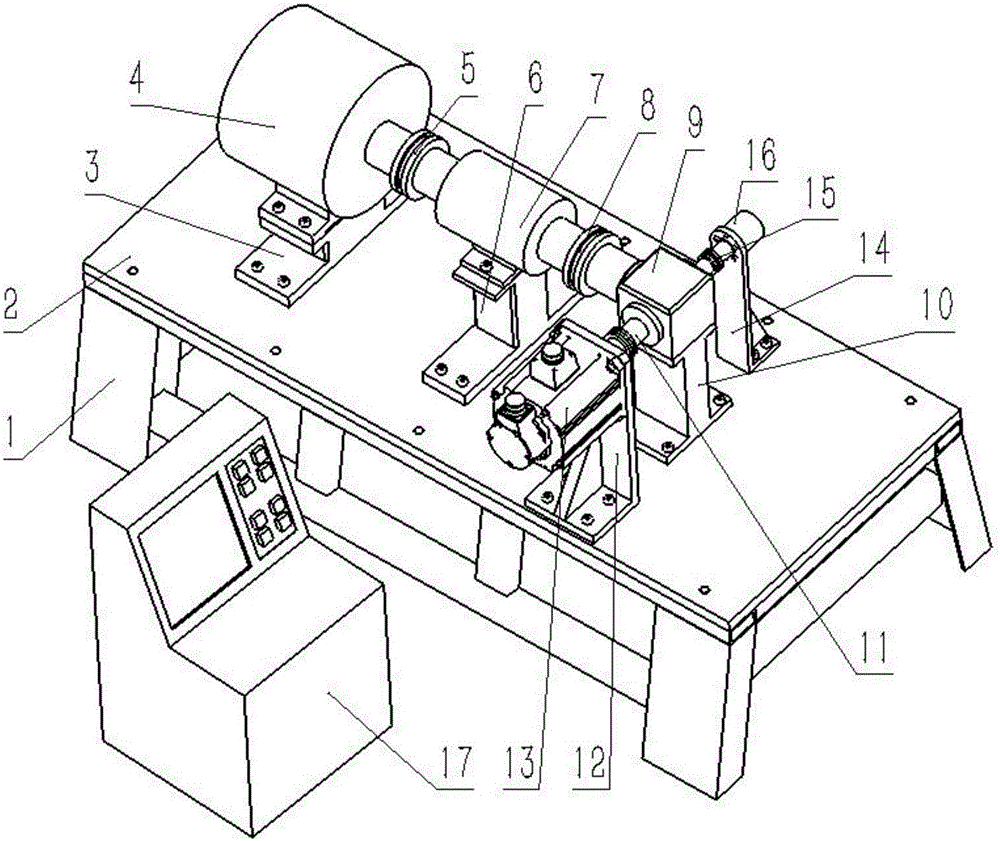

[0017] Such as figure 1 As shown, the dynamic load simulation test device of the present invention includes: an installation base 1, a workbench 2, a measured object support 3, a measured object 4, a first shaft coupling 5, a torque sensor support 6, a torque sensor 7, Second coupling 8, servo commutator bracket 10, servo commutator 9, third coupling 11, servo motor bracket 12, servo motor 13, fourth coupling 15, acceleration sensor bracket 14, acceleration sensor 16. Measurement and control system 17.

[0018] In the present invention, the installation base 1 is a trapezoidal frame, which is welded by a plurality of channel steels and square steels, and a plurality of light holes are processed around the upper surface; a workbench 2 is installed on the upper surface. The workbench 2 is a rectangular steel plate with threaded holes processed in the middle and around the steel plate; the workbench 2 is installed on the installation base 1 by screws, and various supports are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com