Preparation of gas sensor based on screen printing technique

A screen printing, humidity sensor technology, applied in printing, instruments, printing devices, etc., to achieve the effect of low production equipment and environmental requirements, low production cost, and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

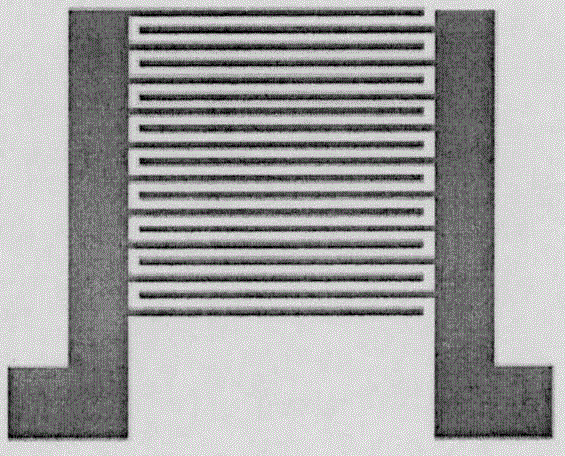

[0017] 1. Firstly, nano-silver interdigitated electrodes are printed on an insulating substrate by screen printing technology. The specific steps are as follows (1) drawing electrodes and making a screen; (2) optimizing the ratio of nano-silver ink; (3) cleaning the screen printing machine with alcohol; (4) cleaning and drying the PET substrate to be printed with water and absolute ethanol; (5) Print silver finger electrodes.

[0018] 2. Synthesis of flaky CuO powder: the production process is as follows: (1) Take 5 g of copper sulfate and dissolve it in 100 ml of water with magnetic stirring to obtain a copper sulfate solution; (2) Dissolve 3.2 g of sodium hydroxide powder in 50 ml of After dissolving in water by magnetic stirring, a sodium hydroxide solution was obtained, and its pH was measured to be 12. (3) Slowly add the sodium hydroxide solution obtained in step (2) to the solution (1), heat and stir with a magnetic force, the temperature is controlled at 80°C, and afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com