Preparation method of green tea

A technology of green tea and tea leaves, which is applied in the field of green tea preparation, can solve the problems of poor taste or shape, poor shape of tea leaves, weak tea fragrance, etc., and achieve the effect of complete shape, complete shape of tea leaves and strong aroma of tea leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

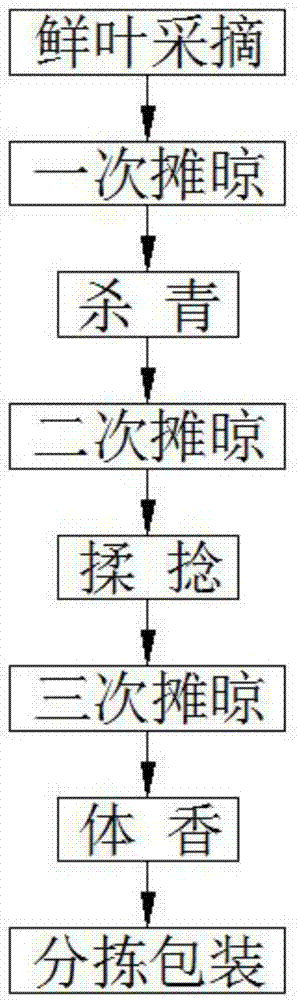

[0023] Such as figure 1 As shown, a method for preparing green tea includes the following steps:

[0024] 1) Picking fresh leaves: Pick the brightly colored tea leaves from the tea tree and place them in a bamboo basket to collect fresh leaves;

[0025] 2) One-time spreading and drying: Place the collected fresh leaves in a bamboo dustpan and spread and dry for 5 hours;

[0026] 3) Finishing: the fresh leaves after being spread and dried once are laid flat on the belt conveyor and continuously processed by the curing machine to make the curing material, and the curing temperature is 280°C;

[0027] 4) Second spreading and drying: Place the curing material prepared in step 3) in a bamboo dustpan and spread and dry for 2 hours, so that the leaves of the tea can absorb the residual moisture in the leaf stalk after curing;

[0028] 5) Twisting: Place the greening material after the second spreading in step 4) in the bamboo dustpan. The operator presses on the greening material with one han...

Embodiment 2

[0034] Such as figure 1 As shown, a method for preparing green tea includes the following steps:

[0035] 1) Picking fresh leaves: Pick the brightly colored tea leaves from the tea tree and place them in a bamboo basket to collect fresh leaves;

[0036] 2) One-time spreading and drying: Place the collected fresh leaves in a bamboo dustpan and spread and dry for 4 hours;

[0037] 3) Finishing: the fresh leaves after being spread and aired once are spread flat on the belt conveyor and continuously processed by the finishing machine to make the finishing material, and the finishing temperature is 180°C;

[0038] 4) Second spreading and drying: Place the curing material prepared in step 3) in a bamboo dustpan and spread and dry for 2 hours, so that the leaves of the tea can absorb the residual moisture in the leaf stalk after curing;

[0039] 5) Kneading: Place the green material after the second spreading in step 4) in the bamboo dustpan. The operator presses on the green material with on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com