Surface-treated zinc-coated steel sheet and method for producing same

A galvanized steel sheet and surface treatment technology, which is applied to the manufacturing field of the above-mentioned surface treated galvanized steel sheet, can solve problems such as motor failure and motor vibration, and achieve improved oil repellency, area ratio, excellent oil repellency and resistance to dark spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

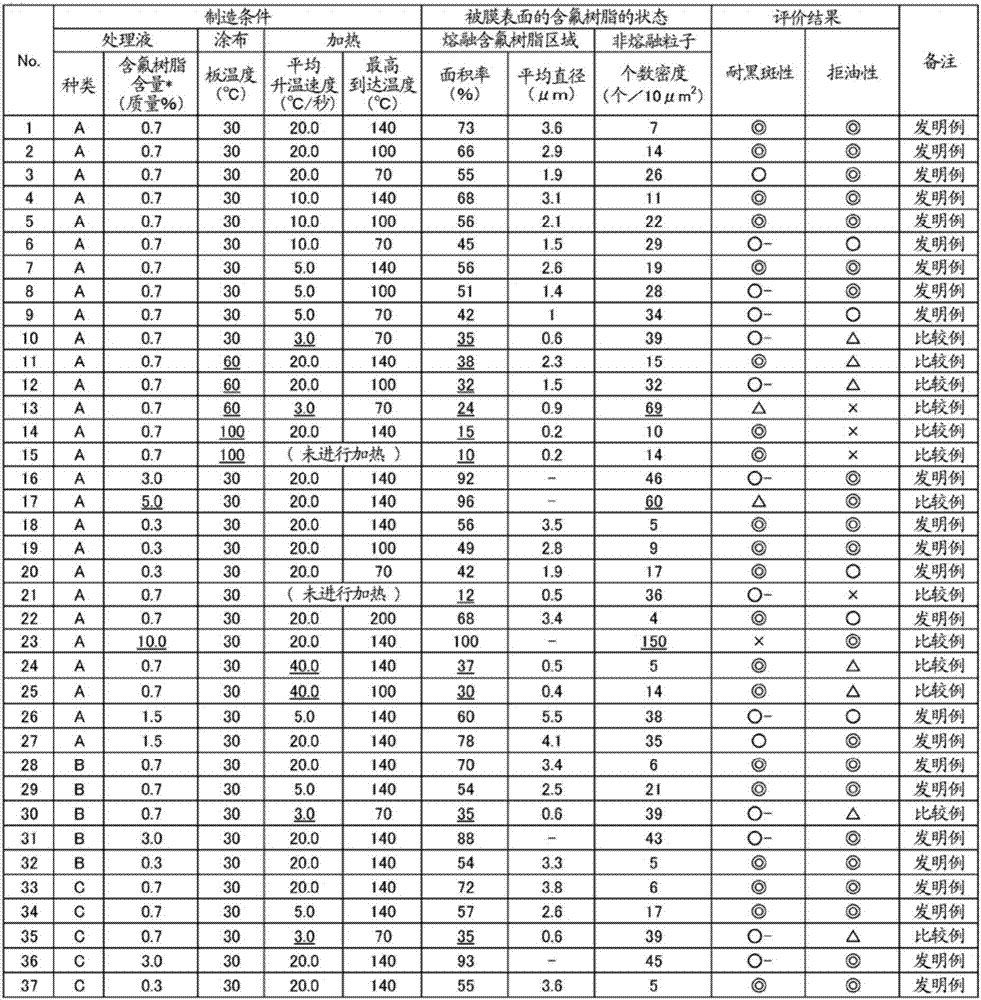

[0052] Hereinafter, a method for carrying out the present invention will be specifically described. In addition, the following description shows one preferable embodiment of this invention, and this invention is not limited at all by the following description.

[0053]

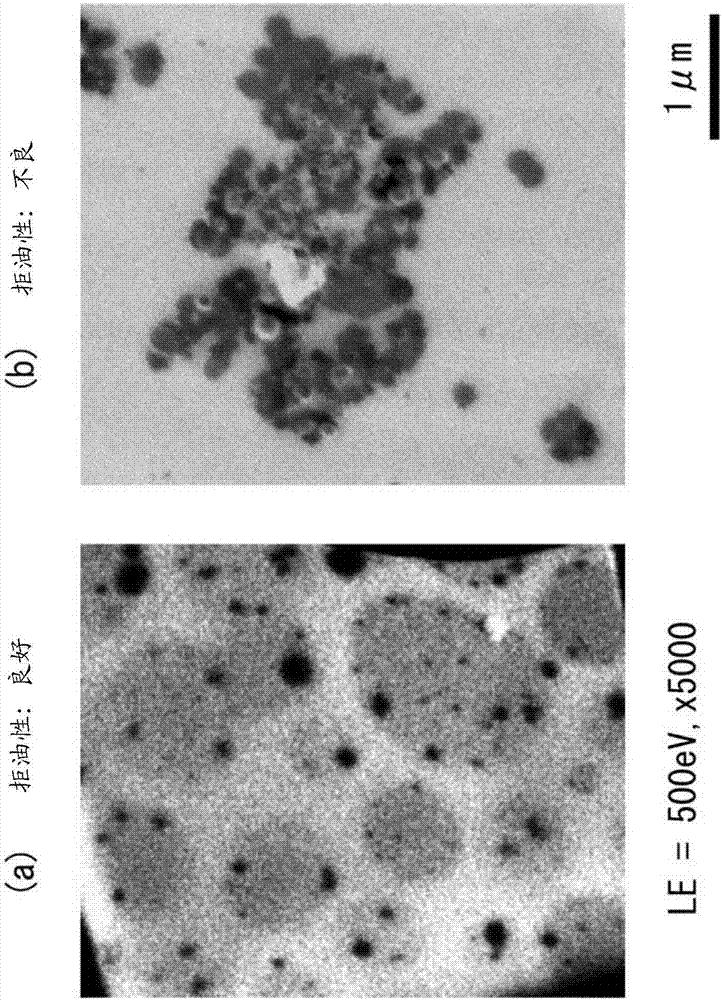

[0054] The surface-treated galvanized steel sheet of the present invention has a galvanized steel sheet and a surface-treated coating formed on the surface of the galvanized steel sheet and containing fluorine-containing resin particles.

[0055] [Galvanized steel sheet]

[0056] In the present invention, the base galvanized steel sheet is not particularly limited, and any steel sheet having a galvanized coating can be used. Here, the zinc-based coating includes any of zinc coating and zinc alloy coating. Examples of galvanized steel sheets that can be preferably used include galvanized steel sheets such as hot-dip galvanized steel sheets (GI), alloyed hot-dip galvanized steel sheets (GA), and electrogalva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com