Novel micro-channel reactor

A microchannel reactor, a new type of technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the requirements of high flatness and smoothness of combined substrates, poor sealing performance of combined channels, increased Use cost and other issues to achieve the effect of low production cost and use cost, strong structural sealing, and not easy to swirl and leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

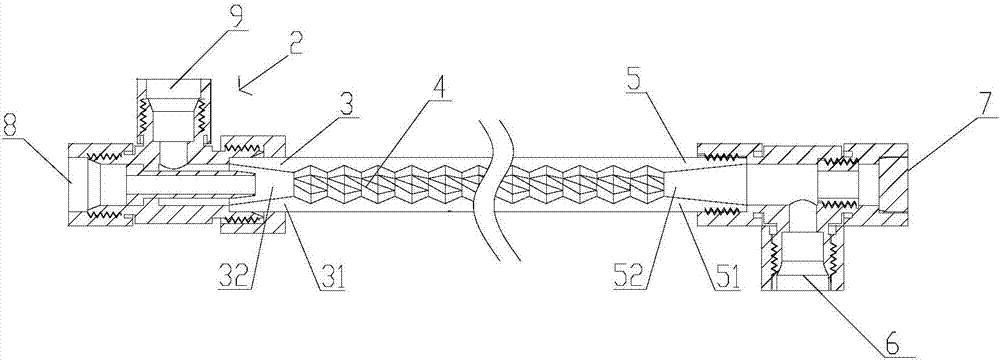

[0039] What needs to be explained here is that the orientation words left, right, up and down are based on figure 2 The views shown are defined by reference, and it should be understood that the use of said localizers should not limit the scope of protection claimed in this application.

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

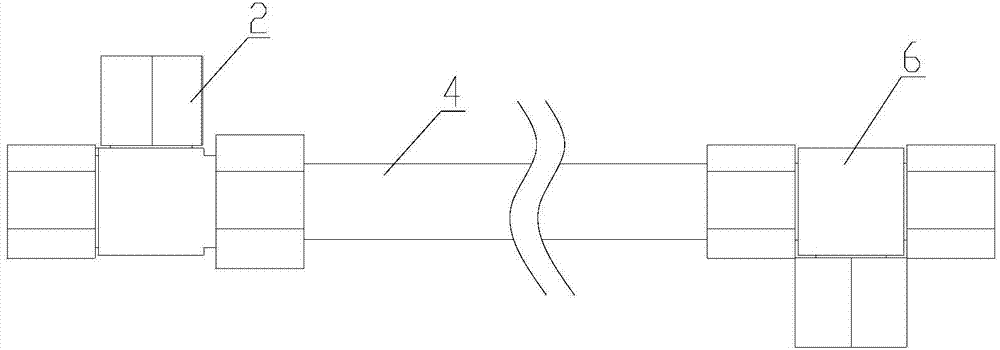

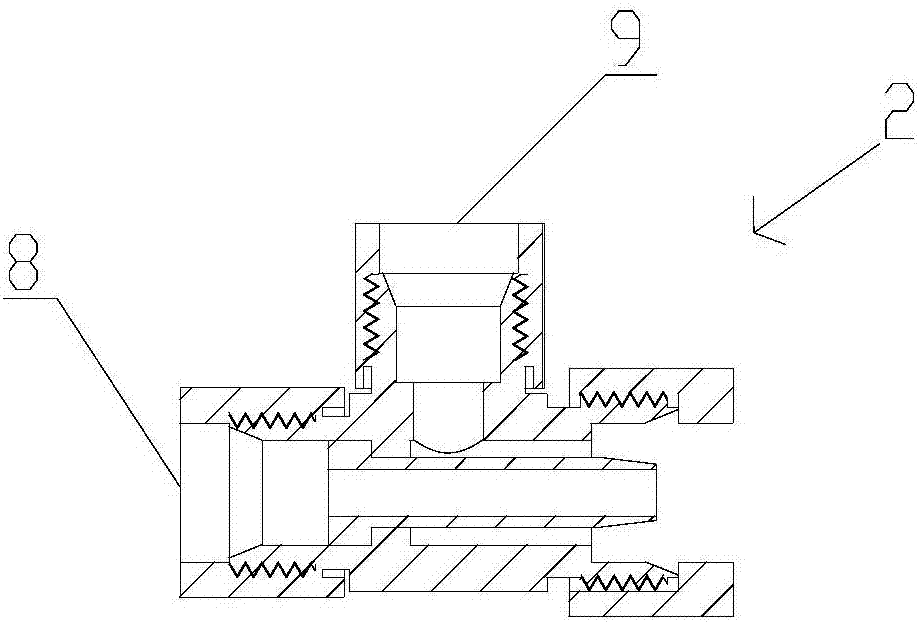

[0041] Such as Figure 1 to Figure 4 Shown, a kind of novel microchannel reactor, it comprises inlet valve 2, input mixing chamber 3, mixed reaction channel 4, output mixing chamber 5 and outlet valve 6; There is a first feed port 8 and a second feed port 9 communicated with each other, the outlet end of the feed port valve 2 is connected to one end of the mixing reaction channel 4 through the input mixing chamber 3, and the other end of the mixing reaction channel 4 One end communicates with the outlet valve 6 through the output mixing chamber 5;

[0042] The inpu...

Embodiment 2

[0049] On the basis of the above technical solutions, if Figure 5 As shown, the mixing reaction channel 4 has a mixing reaction channel housing 41, and a plurality of prismatic mixing reaction channel cavities 41a in a hexagonal cross-section that are successively connected to each other are arranged in the mixing reaction channel housing 41. The first mixing reaction channel teeth 42a are also fixed on the inner side walls of the two prismatic mixing reaction channel cavities 41a. In this way, the mixing reaction channel 4 with this structure is named KU1 type, the mixing reaction channel shell 41 is cylindrical or cuboid as a whole, and the inner diameter of the mixing reaction channel 4 is 0.4 mm to 12 mm.

[0050] The inside of the mixing reaction channel 4 is a continuous toothed rhomboid structure. When two streams of fluid pass through, under the action of the teeth 42a of the first mixing reaction channel, a rotating and colliding fluid is formed, and the continuous p...

Embodiment 3

[0052] On the basis of the above technical solutions, if Image 6 As shown, the mixing reaction channel 4 has a mixing reaction channel housing 41, and a plurality of elliptical mixing reaction channel cavities 41b with an elliptical cross-section connected in succession are arranged in the mixing reaction channel housing 41, and each of the On the inner side wall of the elliptical mixing reaction channel chamber 41b, a plurality of rectangular splitters 42b, a plurality of pyramidal splitters 43b and S-shaped special-shaped splitters 44b are distributed. In this way, the mixing reaction channel 4 with this structure is named KU2 type, the mixing reaction channel housing 41 is cylindrical or cuboid as a whole, and the inner diameter of the mixing reaction channel 4 is 0.4 mm to 12 mm.

[0053] The mixing reaction channel 4 is a separation channel formed by an ellipsoid. When the fluid passes through, under the action of the rectangular sub-fluid 42b, the pyramid sub-fluid 43b ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com