Executing system and control method for double-station press with machine-liquid mixing

A technology of execution system and control method, applied in the direction of presses, manufacturing tools, etc., can solve the problems of many conversion links of hydraulic presses, increase energy conversion links, waste of potential energy, etc., to ensure high-efficiency operation, ensure accurate stop, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

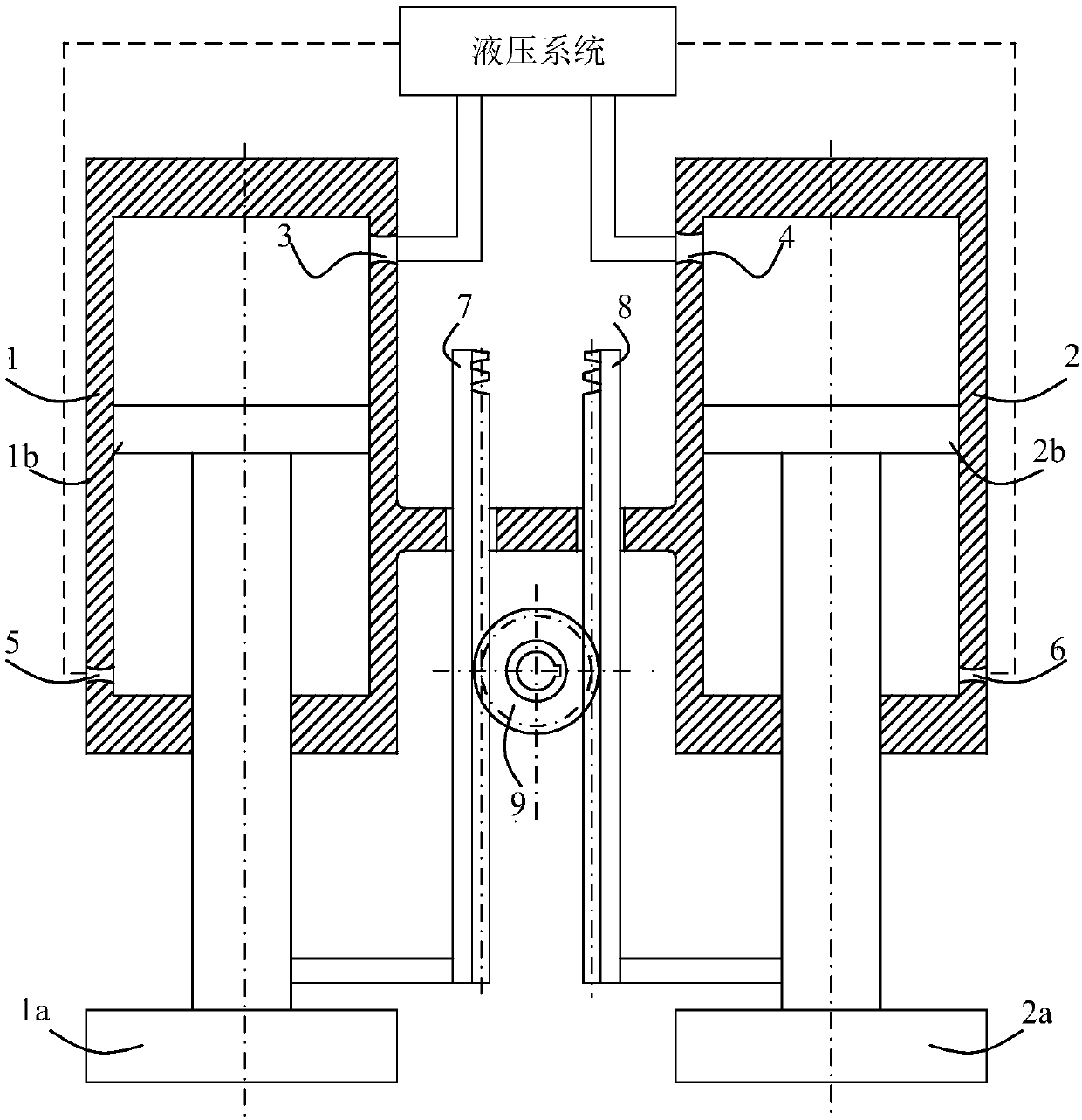

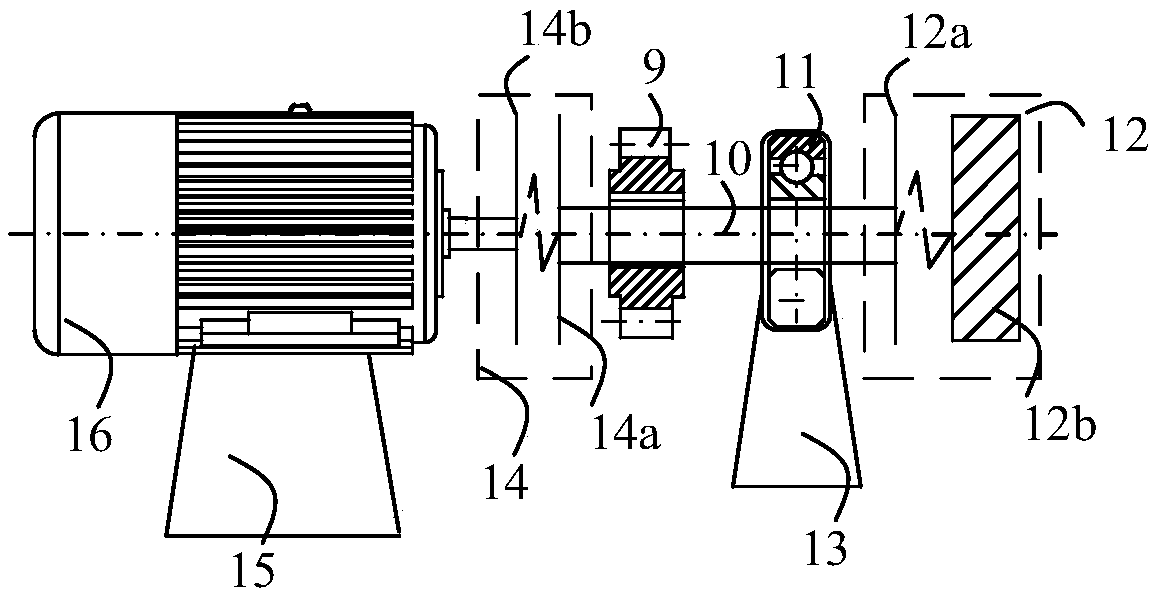

[0030] In this embodiment, the execution system of the machine-hydraulic mixed double-station press is to arrange two vertical hydraulic cylinders in the same press body, and the two hydraulic cylinders correspond to the workbenches at the corresponding positions to form the left and right sides. Working unit; a common mechanical drive unit and a hydraulic drive unit are set for the left and right working units; the mechanical drive unit forms a linkage structure with the moving parts of the two hydraulic cylinders outside the cylinder through a mechanical transmission structure, and the mechanical drive The unit realizes electric drive and reverse linkage of two hydraulic cylinders.

[0031] see figure 1 and figure 2 , the two hydraulic cylinders in this embodiment are respectively the first hydraulic cylinder 1 and the second hydraulic cylinder 2, which are symmetrically fixed in the body of the press and are in the same vertical plane. On the position between the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com