Heavy metal stabilizer for treating sludge, and use method thereof

A heavy metal stabilizer and sludge technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., to achieve reliable long-term stability, low cost, and simple use methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

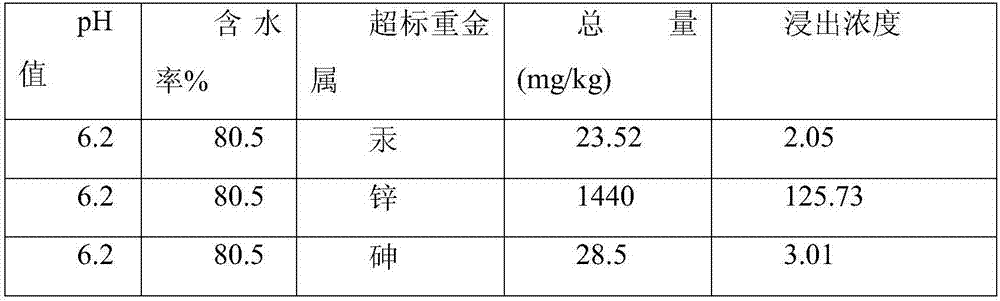

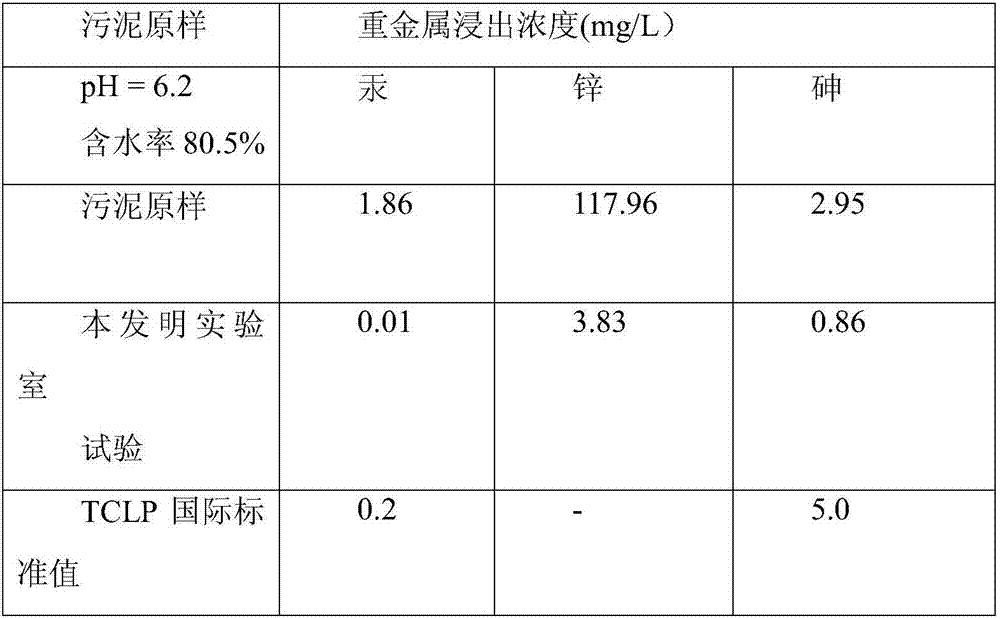

[0035] Table 1-1 shows that the TCLP results of a city sludge of A are high in mercury, zinc and arsenic leaching toxicity concentrations, and the mercury leaching toxicity concentration exceeds the TCLP international standard value of 0.2mg / L, and necessary stabilization treatment is required.

[0036] Table 1-1 The original sample data of a certain A municipal sludge (mg / L, leached by US TCLP method 1311)

[0037]

[0038] According to analysis judgments such as sludge original state property, pH value and experience, prepare a test heavy metal stabilizer formulation sample of following component and weight percent composition: phosphate (calcium magnesium phosphate fertilizer) 35.0%, calcium oxide 30%, and adsorbent ( activated carbon) 35.0%.

[0039] The test was carried out at one time, including a test formula sample and a dosage of 8.0%; the original test sludge was 120g, and all materials, including the original sludge and heavy metal stabilizer, were fully stirred ...

Embodiment 2

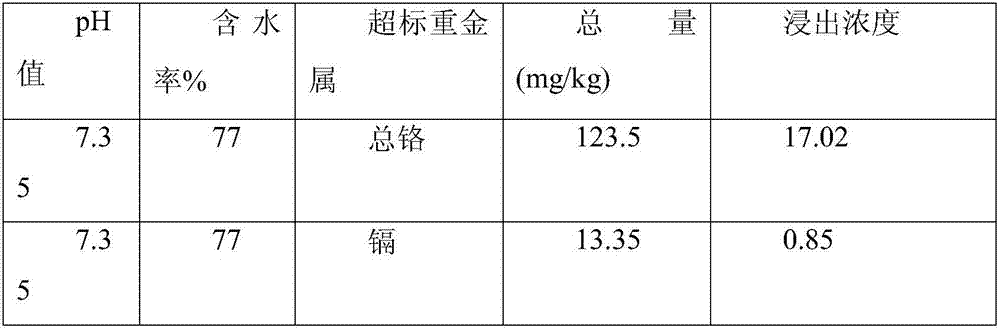

[0044] Table 2-1 shows the TCLP results of a certain B city sludge, which shows that the leaching toxicity concentration of total chromium and cadmium is very high, and the chromium leaching toxicity concentration exceeds the TCLP international standard value of 5.0mg / L, and necessary stabilization treatment is required.

[0045] Table 2-1: Data of a certain B city sludge (mg / L, leached according to US TCLP method 1311)

[0046]

[0047] According to the analysis and judgment of the original state of sludge, pH value and experience, a test heavy metal stabilizer formula sample composed of the following components and weight percentages is prepared: 30.0% of phosphate (GPS), 35% of calcium oxide, and adsorbent (activated alumina) 35.0%.

[0048] The test was carried out at one time, including a test formula sample and a dosage of 10.0%; the original test sludge was 120g, and all materials, including the original sludge and heavy metal stabilizer, were fully stirred and mixed...

Embodiment 3

[0053] The results of TCLP in a certain C city sludge are shown in Table 1, which shows that the lead leaching toxicity concentration is very high, exceeding the TCLP international standard value of 5.0mg / L, and necessary stabilization treatment is required.

[0054] Table 3-1: Data of the original sample of city sludge in a certain C (mg / L, leached according to US TCLP method 1311)

[0055]

[0056] According to analysis and judgment such as sludge original sample property, pH value and experience, prepare a test heavy metal stabilizer formulation sample of following components and weight percentage composition: phosphate (trisodium phosphate) 35.0%, magnesium oxide 35%, and adsorbent ( activated alumina) 30.0%.

[0057] The test was carried out at one time, including a test formula sample and a dosage of 5.0%; the original test sludge was 120g, and all materials, including the original sludge and heavy metal stabilizer, were fully stirred and mixed for about 15 minutes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com