High-strength and low-thermal-conductivity precast brick

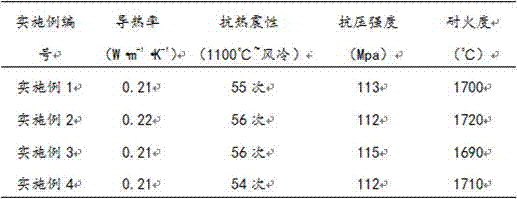

A low thermal conductivity, prefabricated brick technology, applied in the field of refractory materials, can solve the problems of high temperature on the outer wall of the kiln shell, difficult control of pouring quality, large thermal conductivity, etc., to improve thermal shock resistance, low thermal conductivity, good anti-corrosion Alkali corrosion resistance, effect of improving high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with specific embodiment, the present invention is described in further detail, and the present invention is not limited to these embodiments, and every example that adapts to the thinking of problem solving of the present invention is all within the scope of protection of the present invention:

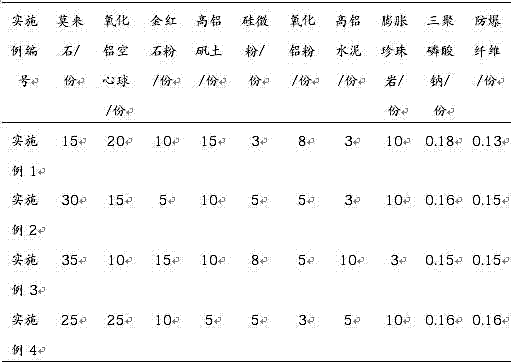

[0046] The prefabricated brick preparation process of embodiment 1~embodiment 4 is as follows:

[0047] ① Mixing: The main ingredients are prepared according to the formula, put in a mixer and stirred, then add additional materials to continue stirring, and continue to add magnesium chloride solution during the stirring process, wherein the magnesium chloride solution added in Examples 1~4 is 8 parts, 9 copies, 9 copies, 10 copies;

[0048] ② Forming: Add the stirred mixture into the mold, spread it out by its own weight and surface tension, and wipe off the excess mixture on the surface;

[0049] ③Conservation: Put the mold with the mixture in a constant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com