Method for producing 2-propenyl ethanoate

A technology of allyl acetate and acetic acid, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, and can solve the problem of low selectivity and yield of allyl acetate and the unit consumption of allyl acetate products High, low utilization of reactants, etc., to achieve the effect of increasing selectivity and yield, improving utilization of reactants, and suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0046] Taking the 100,000 tons / year allyl acetate plant as the benchmark, the benchmark plant adopts a commonly used fixed-bed reactor type, the technology without recirculation flow, and the product unit consumption, selectivity and yield of the benchmark plant are benchmark values of 1, investigate the embodiment The ratio of the incremental value of the reference device to the reference value can be easily understood to see the implementation effect of the method of the present invention.

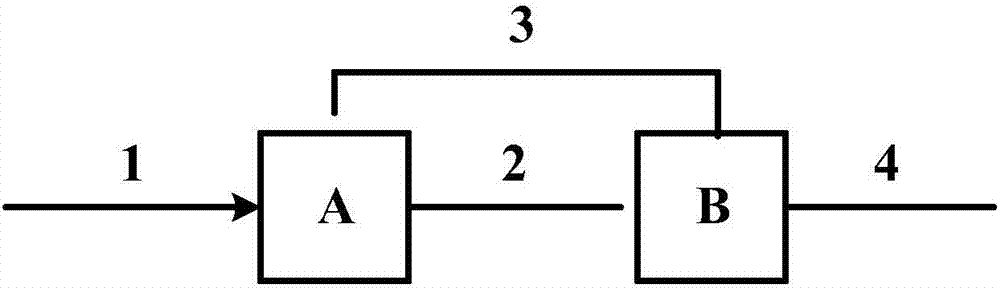

[0047] according to figure 1 Described inventive method, implementation result is as shown in table 1.

[0048] Table 1

[0049] Example

Embodiment 5~8

[0051] Taking the 100,000 tons / year allyl acetate plant as the benchmark, the benchmark plant adopts a commonly used fixed-bed reactor type, the technology without recirculation flow, and the product unit consumption, selectivity and yield of the benchmark plant are benchmark values of 1, investigate the embodiment The ratio of the incremental value of the reference device to the reference value can be easily understood to see the implementation effect of the method of the present invention.

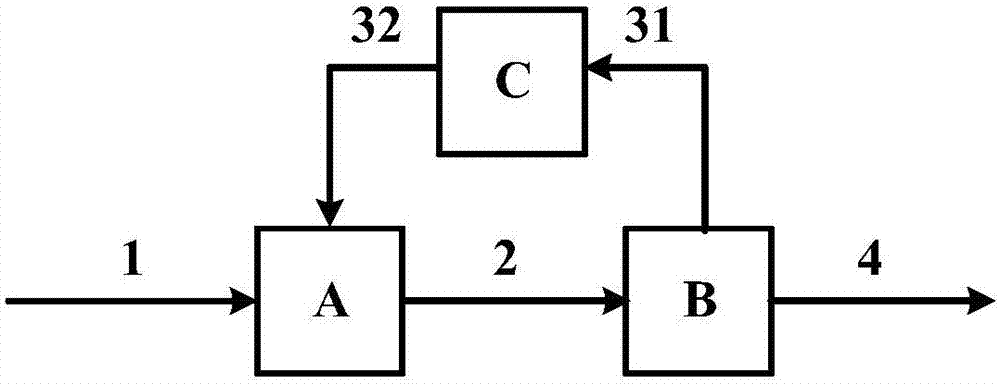

[0052] according to figure 2 Described inventive method, implementation result is as shown in table 1. From Table 2, it can be seen that the main technical index unit consumption, selectivity and yield are close to those of Examples 1~4, mainly because figure 2 and figure 1 Compared with that, the booster equipment is only added, and the reaction conditions are not changed.

[0053] Table 2

[0054] Example

Embodiment 9~20

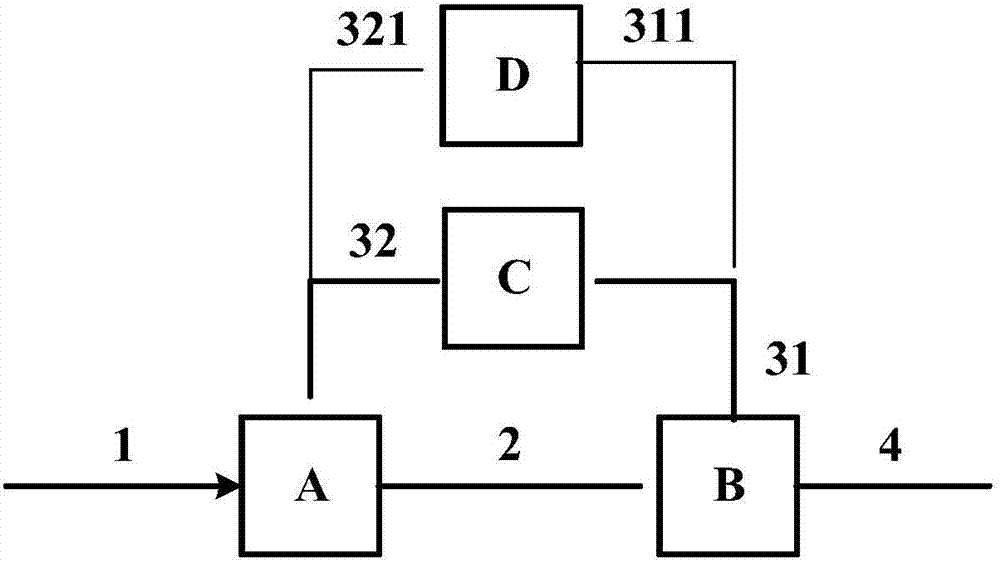

[0056] according to image 3 Described inventive method, implementation result is as shown in table 2. "Refining / recycling" in the table indicates the ratio of the mass flow rate of stream 321 to stream 32.

[0057] Table 2

[0058] parameter

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com