Ti-containing WC powder based on mass directional adjustment and control, and preparation method and application thereof

A technology of powder and quality, which is applied in the field of powder metallurgy materials to achieve the effects of high sintering activity, enhanced process stability, and high quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

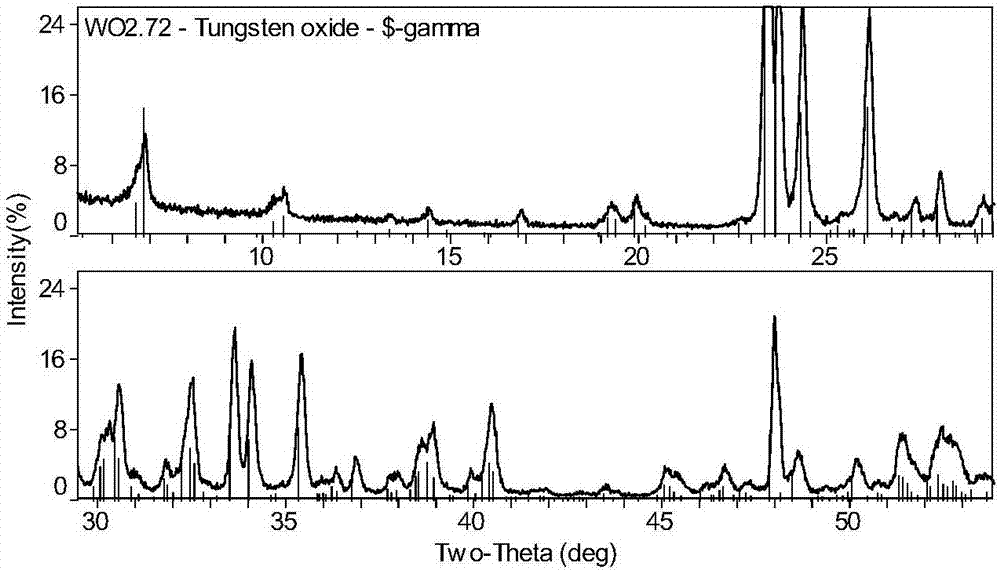

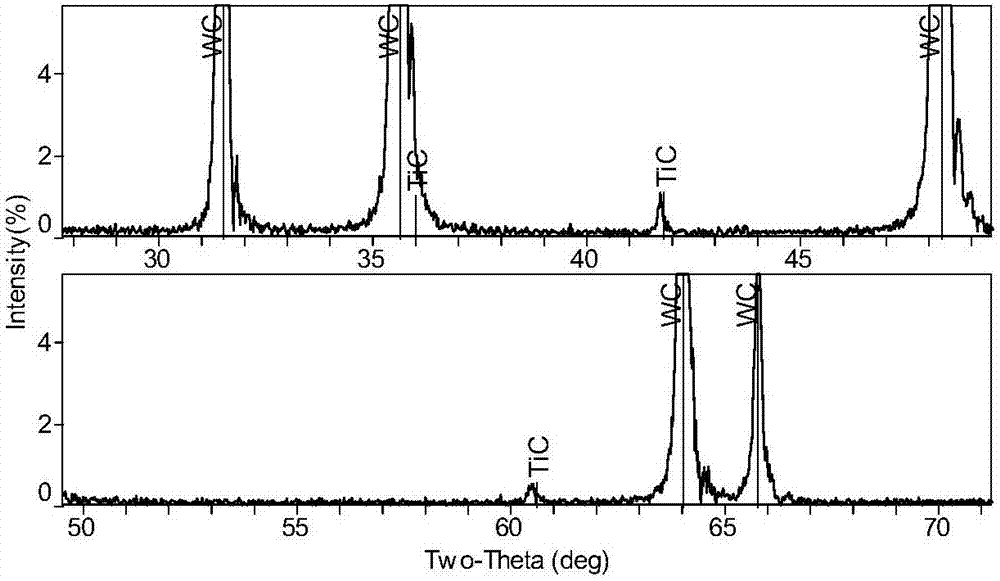

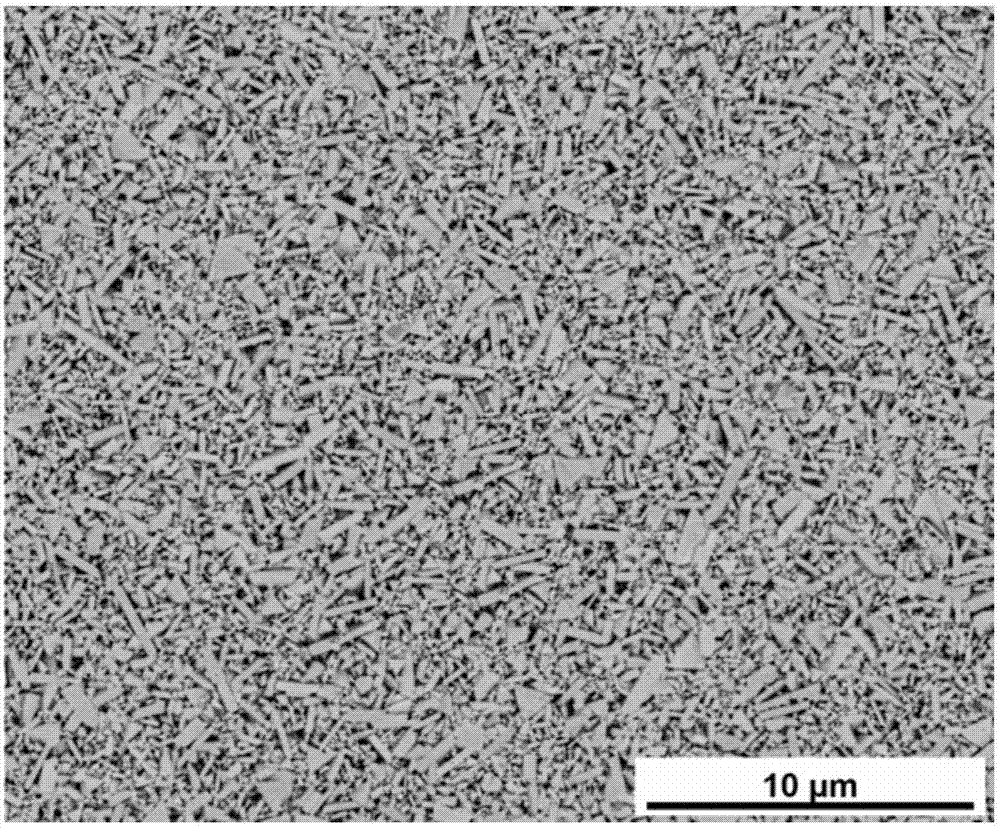

[0065] Select ammonium paratungstate with a Fibonacci particle size of 18 μm as the solid W source material, ammonium titanyl oxalate aqueous solution as the Ti source material, and calculate the material ratio based on the mass fraction of Ti in the Ti-containing WC powder being 0.4%, and the addition amount of fatty alcohol polyoxyethylene ether Dosing for 1% of the mass fraction of ammonium paratungstate; in equipment with an ultrasonic generator and stirring function, dilute ammonium titanyl oxalate and fatty alcohol polyoxyethylene ether solution with water to completely bury the ammonium paratungstate to achieve ammonium titanyl oxalate, Permeation and impregnation of ammonium paratungstate with fatty alcohol polyoxyethylene ether aqueous solution; the frequency of ultrasonic waves is 80kHz, the stirring speed is 80 rpm, and the mixing time is 4h. The aqueous mixture of ammonium titanyl oxalate, fatty alcohol polyoxyethylene ether and ammonium paratungstate was dried by a...

Embodiment 2

[0067] Select yellow tungsten with a Fibonacci particle size of 20 μm as the solid W source material, ammonium titanyl oxalate aqueous solution as the Ti source material, and calculate the material ratio according to the mass fraction of Ti in the Ti-containing WC powder as 0.3%, and the addition amount of fatty alcohol polyoxyethylene ether Dosing for 0.5% of the mass fraction of yellow tungsten; in equipment with ultrasonic generator and stirring function, dilute ammonium titanyl oxalate and fatty alcohol polyoxyethylene ether solution with water, so that the solution completely bury yellow tungsten, and realize titanyl oxalate Penetration and impregnation of yellow tungsten with ammonium and fatty alcohol polyoxyethylene ether aqueous solution; the frequency of ultrasonic waves is 80kHz, the stirring speed is 80 rpm, and the mixing time is 4h. A dynamic flash drying method is used to dry the aqueous mixture of ammonium titanyl oxalate, fatty alcohol polyoxyethylene ether and...

Embodiment 3

[0069] Select ammonium paratungstate with a Fibonacci particle size of 20 μm as the solid W source material, ammonium titanyl oxalate aqueous solution as the Ti source material, and calculate the material ratio according to the mass fraction of Ti in the Ti-containing WC powder as 0.23%, and the addition amount of fatty alcohol polyoxyethylene ether is The mass fraction of ammonium paratungstate is 0.8% for batching; in the equipment with ultrasonic generator and stirring function, dilute ammonium titanyl oxalate and fatty alcohol polyoxyethylene ether solution with water to completely bury the ammonium paratungstate to achieve ammonium titanyl oxalate, fat Penetration and impregnation of ammonium paratungstate with alcohol polyoxyethylene ether aqueous solution; the frequency of ultrasonic waves is 80kHz, the stirring speed is 80 rpm, and the mixing time is 4h. A dynamic flash drying method was used to dry the aqueous mixture of ammonium titanyl oxalate, fatty alcohol polyoxye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com