Punch filling pile bottom cleaning method

A cast-in-place pile and bottom cleaning technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problem that the gravel slag and gravel cannot be completely removed from the pile hole, the reinforcement cage cannot be installed, and the depth of the pile hole is insufficient. and other problems to achieve the effect of ensuring civilized construction, short cleaning time and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

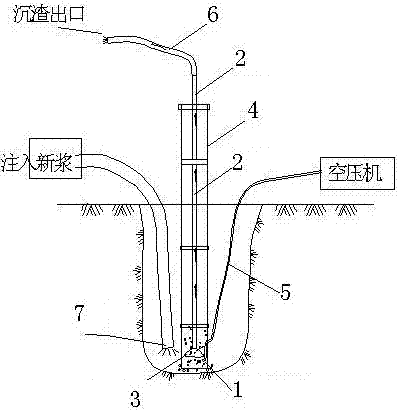

[0016] Such as figure 1 Shown is a method for clearing the bottom of a punching cast-in-situ pile, which includes: taking a section of concrete pouring conduit and welding a section of 20-25mm diameter elbow respectively on the inside and outside, and the two elbows are connected as the bottom section conduit 1;

[0017] Take a steel pipe 2 with a diameter of 50-80mm, weld a circular metal cover 3 at the end, the outer diameter of the metal cover is slightly smaller than the inner diameter of the concrete pouring conduit;

[0018] In addition, weld a steel plate on the top of a section of concrete pouring conduit, seal the top of the conduit, and open a hole at the top of the steel plate, the diameter of the hole is the same as that of the steel pipe in step 2, as the first section of conduit 4.

[0019] Install the conduit, after the cast-in-place pile has completed the pile hole, connect the hose 5 (the hose is connected to the air compressor) to the ventilating elbow of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com