Compact adsorption refrigeration system

It is an adsorption refrigeration and compact technology, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc. It can solve the problems of inability to control the flow of hot water, inconvenient heating and desorption of the adsorption bed, and large equipment volume. The effect of small volume cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

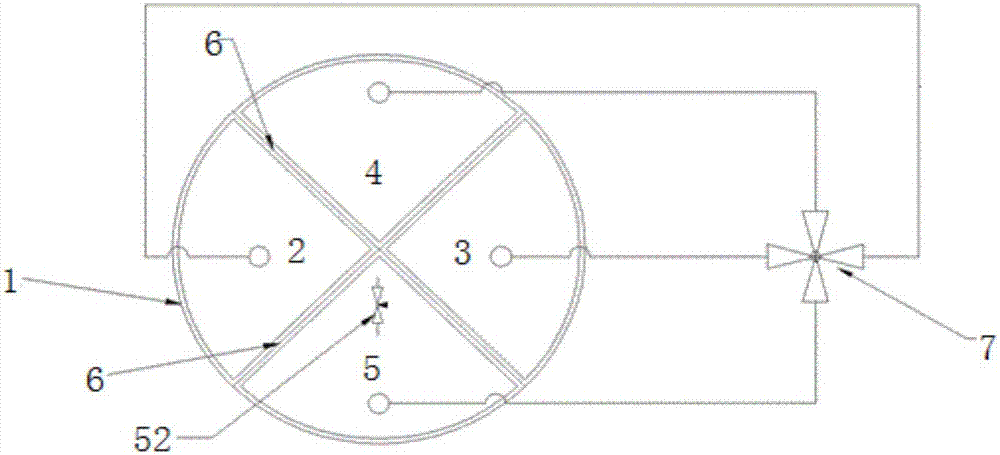

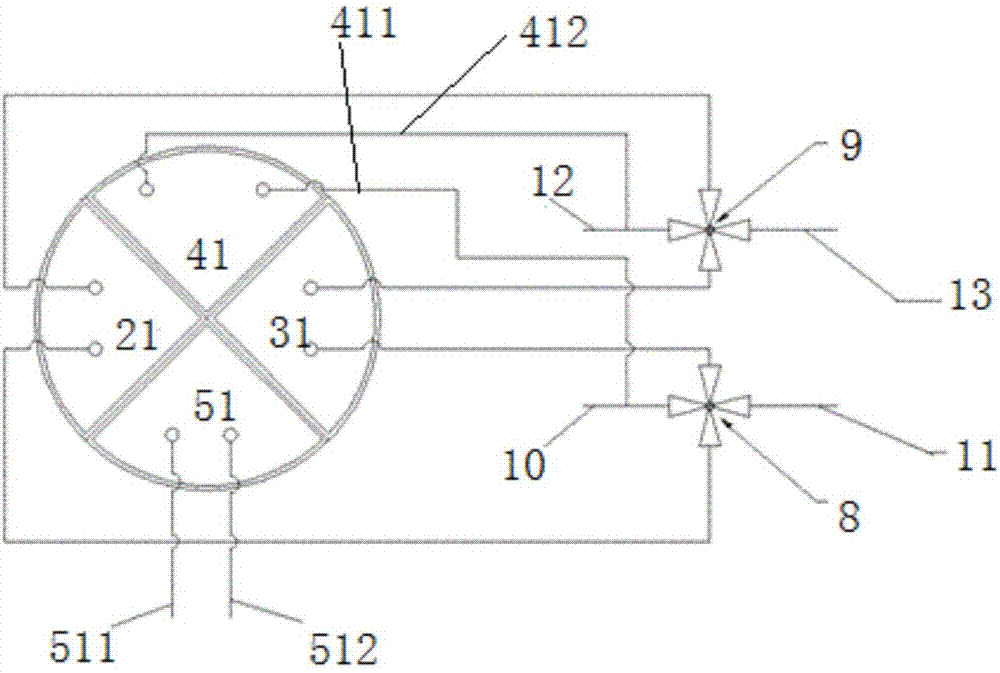

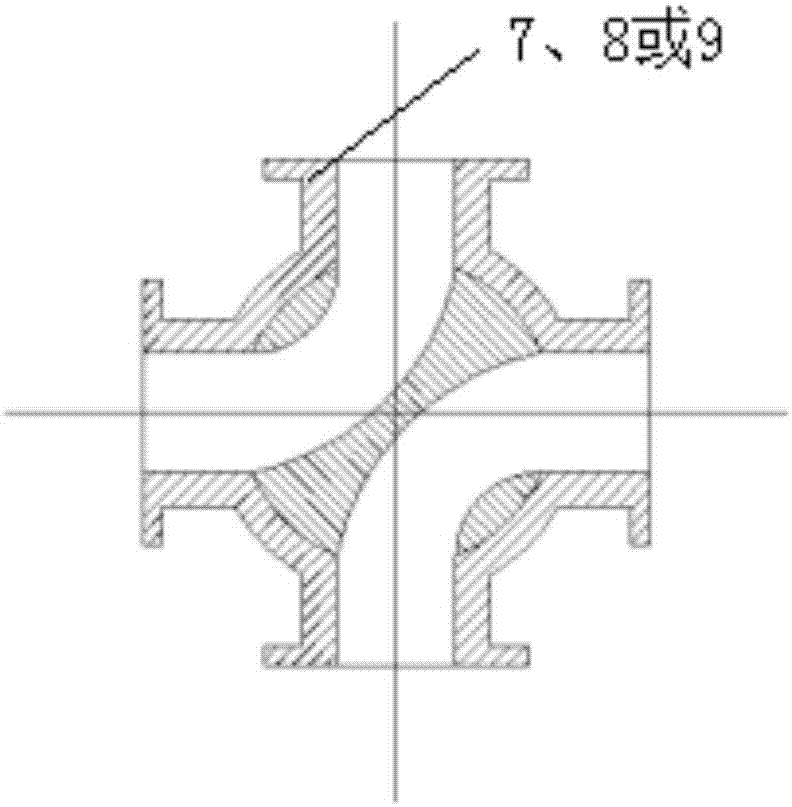

[0038] The invention discloses a compact adsorption refrigeration system, such as Figure 1-Figure 4 As shown, it includes container shell 1, partition plate 6, steam four-way valve 7, cold and heat source fluid inlet four-way valve, cold and heat source fluid outlet four-way valve 9;

[0039] The partition plate 6 divides the container shell 1 into 4 cavities. The first adsorption bed 21, the second adsorption bed 31, the evaporator 51, and the condenser 41 are respectively arranged in the 4 cavities. The first adsorption bed cavity 2, the second adsorption bed cavity 3, the evaporator cavity 5, and the condenser cavity 4;

[0040] The first adsorption bed cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com