WiFi wireless remote control-type DC high-voltage power supply for cable fault detection equipment

A technology of DC high-voltage power supply and testing equipment, which is applied in general control systems, components of electrical measuring instruments, and measuring electricity, and can solve problems such as low safety factor, inability to use remote control, unfavorable cable maintenance and management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

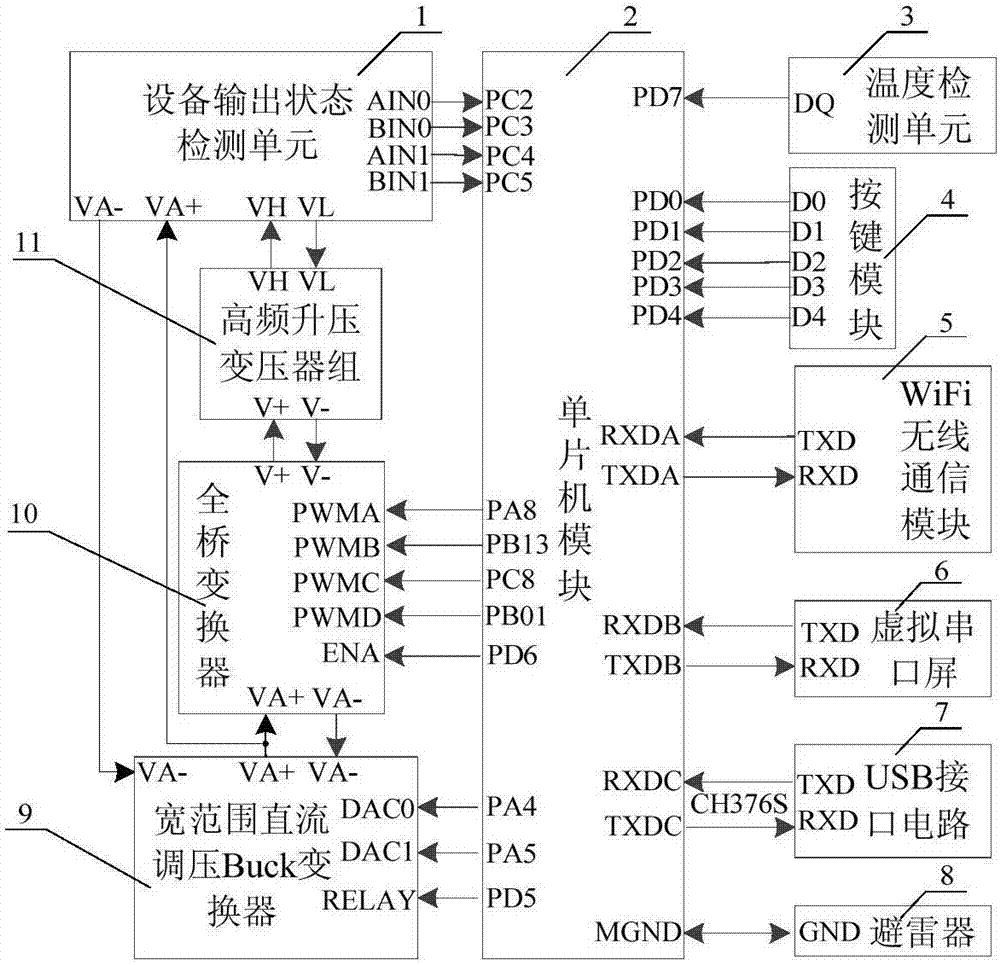

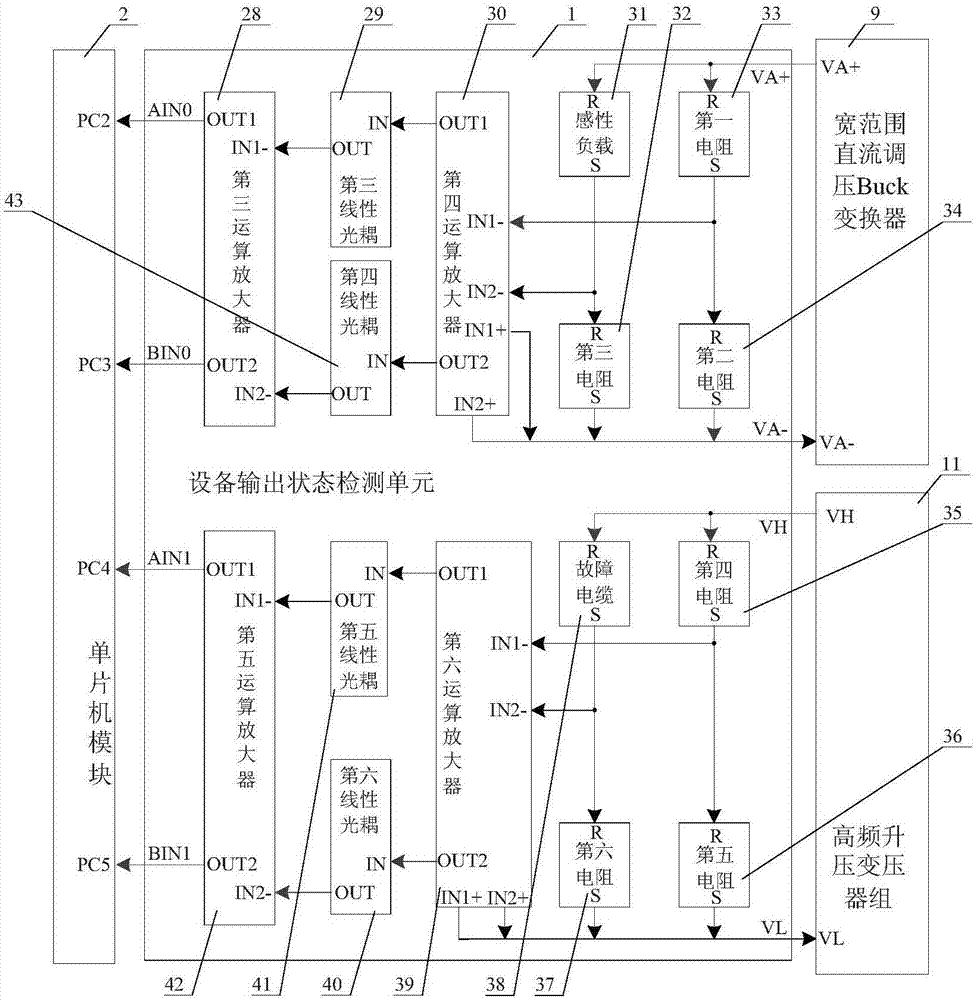

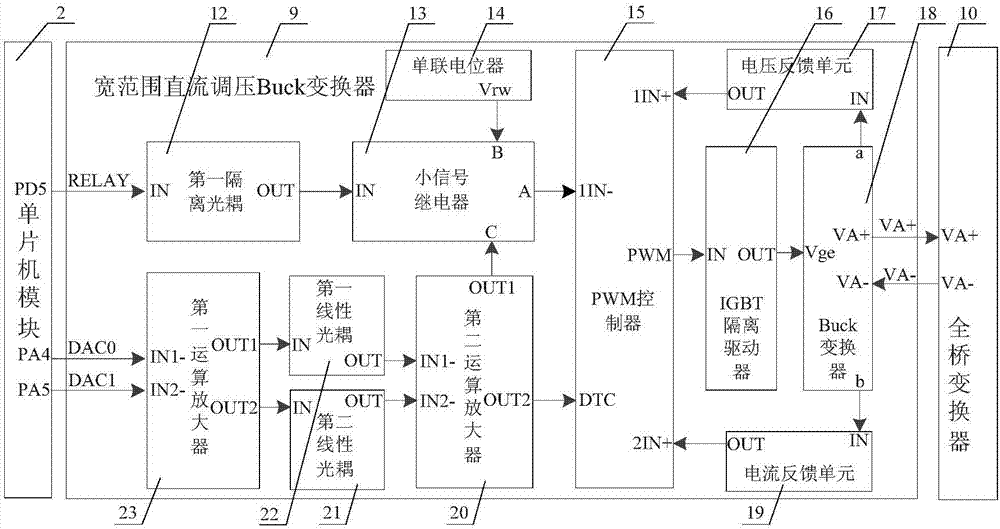

[0065] A WiFi wireless remote control DC high-voltage power supply for cable fault detection equipment. Such as figure 1 As shown, the WiFi wireless remote control type DC high-voltage power supply (hereinafter referred to as DC high-voltage power supply) for the cable fault detection equipment includes a device output state detection unit 1, a single-chip microcomputer module 2, a temperature detection unit 3, a button module 4, and a WiFi wireless communication module 5 , a virtual serial screen 6, a USB interface circuit 7, a lightning arrester 8, a wide-range DC voltage regulating Buck converter 9, a full-bridge converter 10 and a high-frequency step-up transformer group 11.

[0066] Such as figure 1 As shown, the input terminals PC2, PC3, PC4, and PC5 of the single-chip microcomputer module 2 are connected to the output terminals AIN0, BIN0, AIN1, and BIN1 of the device output state detection unit 1, and the input terminal PD7 of the single-chip microcomputer module 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com