Single aspherical lens for LD and fiber coupling

An aspheric lens and fiber coupling technology, applied in the field of optical components, can solve the problems of complex device structure, low coupling efficiency, increased cost, etc., and achieve the effects of high coupling efficiency, low reflection loss and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

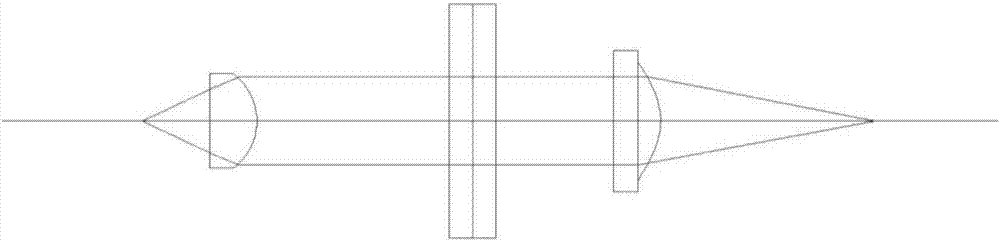

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

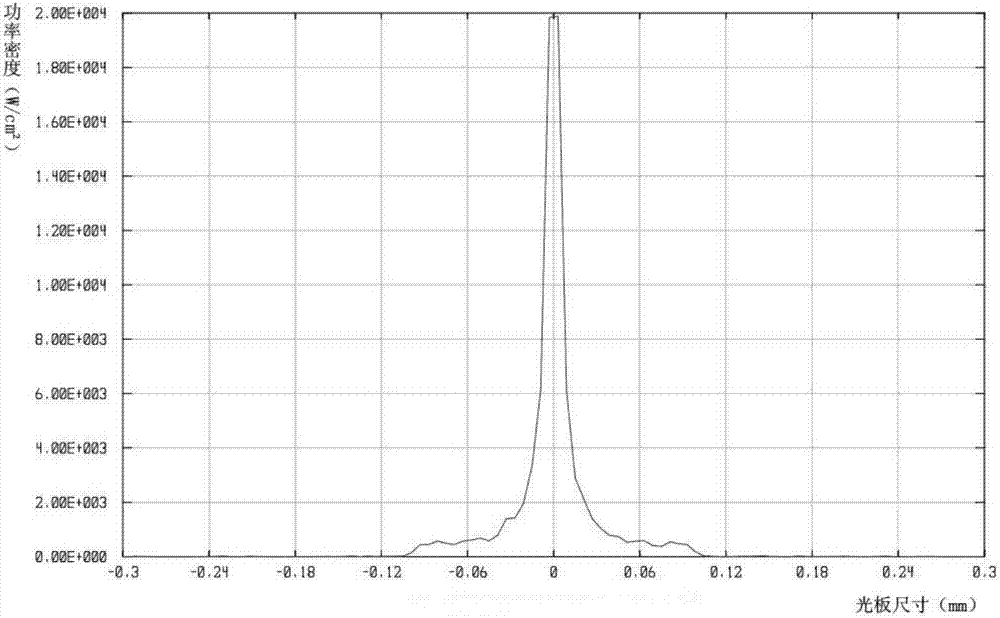

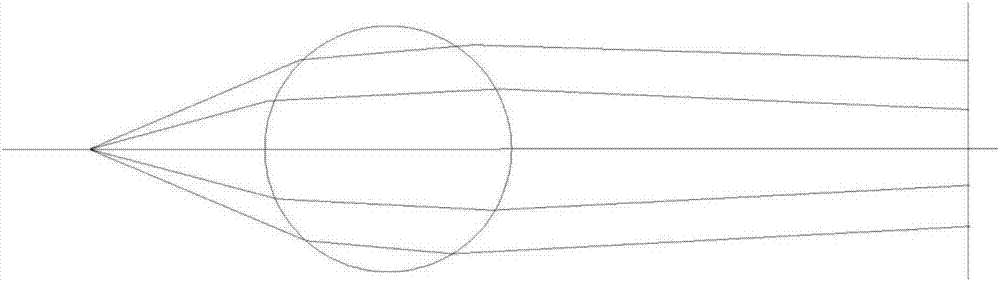

[0030] Such as Figure 4 and Figure 5 As shown, the present invention is used for the single aspheric lens of LD and optical fiber coupling, comprises two aspheric curved surfaces, it is characterized in that: the aspheric surface expression that the section curve of aspheric mirror is made up of quadratic term and high order term is :

[0031]

[0032] Among them, c represents the curvature of the quadric surface of the aspheric mirror, r represents the radius, k represents the constant of the quadric surface, and A is the coefficient of the higher order term. In order to improve the fitting accuracy and reduce the fitting difficulty, we set c=0, k=0. Both surfaces are aspherical surfaces, and both conform to the above expressions.

[0033] In the present invention, the maximum divergence half angle that the lens can accept the LD light source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com