Centralized-dispatching system and method for numerically-controlled machine tools in machining workshop

A technology of CNC machine tools and machining workshops, applied in the direction of comprehensive factory control, electrical program control, etc., can solve the problems of not considering stability, CNC machine tools cannot interact, and manufacturing resources are not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

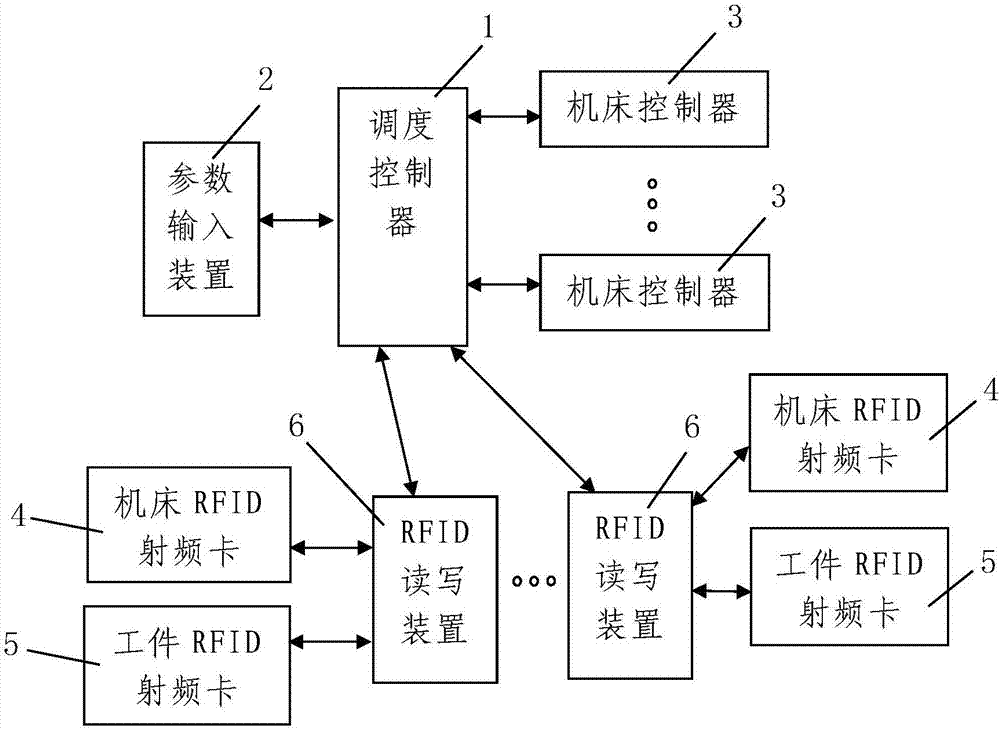

[0096] Such as figure 1 A centralized scheduling system for CNC machine tools in a processing workshop as shown, including a scheduling controller 1 for scheduling N CNC machine tools located in a processing workshop, a parameter input device 2 connected to the scheduling controller 1, and a parameter input device 2 for N said CNC machine tools A machine tool processing state monitoring device for monitoring the processing state of the machine tool, the dispatching controller 1 is connected to the machine tool controllers 3 of the N numerically controlled machine tools; The machine tool RFID radio frequency card 4; the machine tool processing state monitoring device is a fixed monitoring device or a mobile monitoring device, and the fixed monitoring device includes N machine tool monitors, each of which is for a machine tool monitor Describe the machine tool RFID radio frequency card 4 arranged on the numerical control machine tool and the RFID reading and writing device 6 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com