Powder mixing machine

A mixer and powder technology, applied in mixers, feeds, dissolving and other directions, can solve the problems of high viscosity of coagulation, low mixing efficiency, easy to agglomerate, etc., and achieves wide application range, simple structure and easy manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

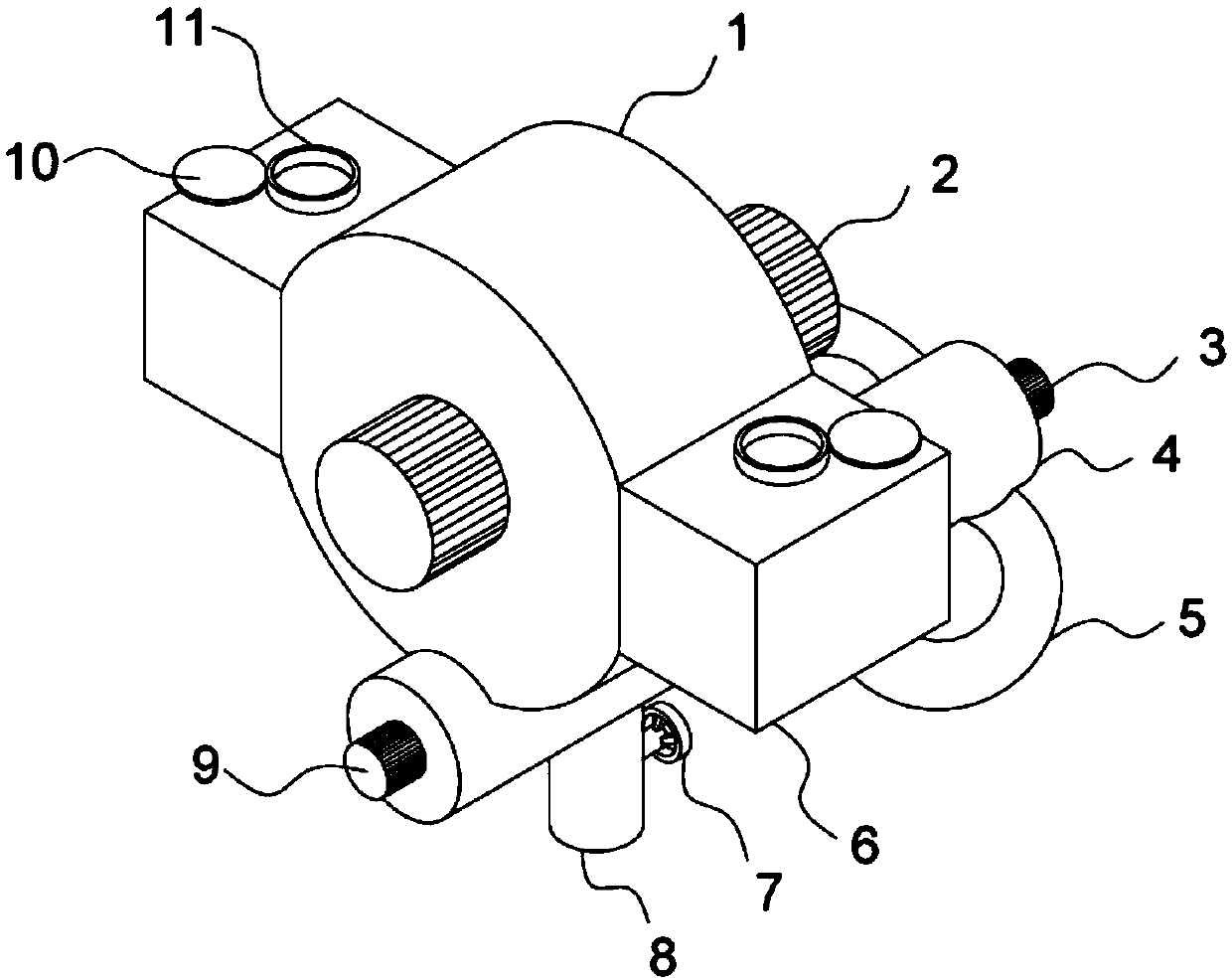

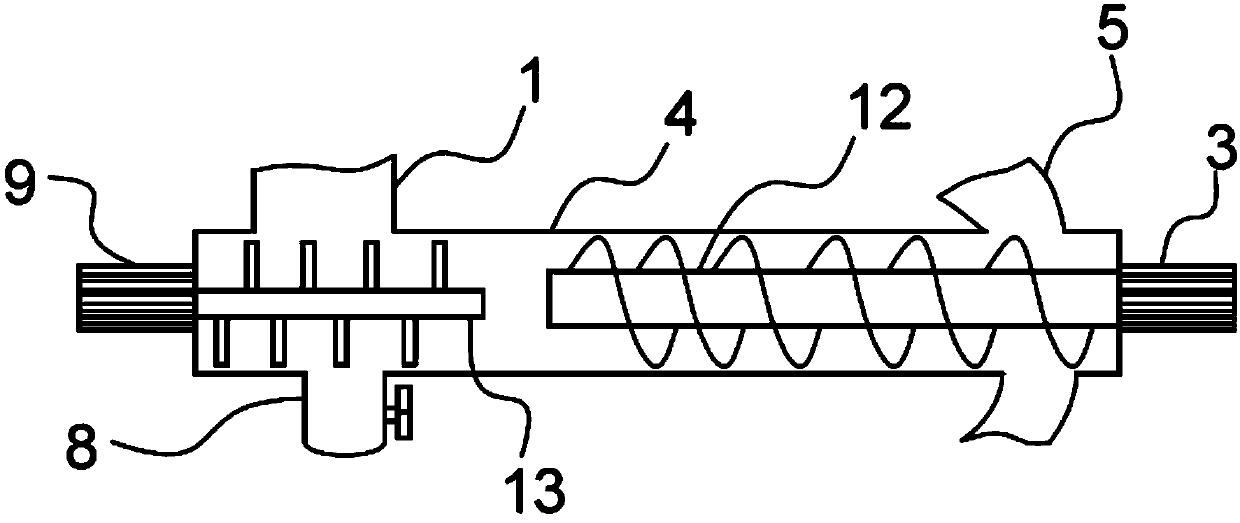

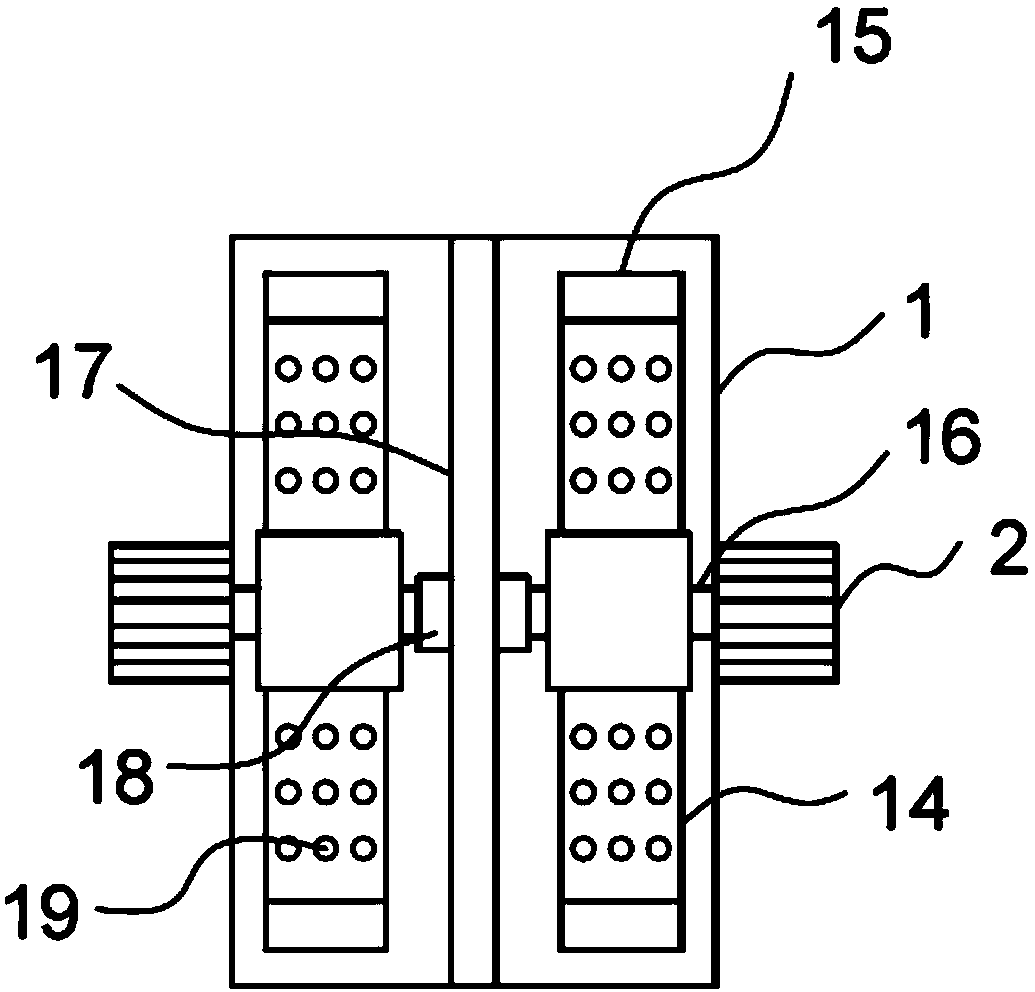

[0032] A powder mixer is used to mix feed powder in animal husbandry, comprising: a mixing cylinder 1, a drive motor 2 for driving a rotating shaft 16 is installed at both ends of the mixing cylinder 1, and the two sides of the mixing cylinder 1 are respectively fixed A mixing box 6 is connected, and the bottom of the mixing cylinder 1 is communicated with a conveying pipe 4; a straight plate 14 is fixedly mounted on a rotating shaft 16, and one end of the straight plate 14 is fixedly connected with a material shifting plate 15; the conveying pipe 4, its two ends A stirring motor 9 for driving the stirring shaft 13 and a conveying motor 3 for driving the conveying screw 12 are installed respectively, and the bottom of the conveying pipe 4 is communicated with a discharge pipe 8; The driven vibrating sieve plate 20, and the bottom outlet of the mixing box 6 communicates with one end side of the delivery pipe 4 through the return pipe 5; A sealing cover 10 is hinged.

[0033] S...

Embodiment 2

[0036] A powder mixer is used in the chemical industry to mix PVC powder, comprising: a mixing cylinder 1, the two ends of which are respectively equipped with drive motors 2 for driving the rotating shaft 16, and the two sides of the mixing cylinder 1 are respectively fixedly connected There is a mixing box 6, and the bottom of the mixing cylinder 1 is communicated with a conveying pipe 4; a straight plate 14 is fixedly mounted on a rotating shaft 16, and one end of the straight plate 14 is fixedly connected with a material pushing plate 15; the conveying pipe 4, its two ends are respectively A stirring motor 9 for driving the stirring shaft 13 and a conveying motor 3 for driving the conveying screw 12 are installed, and the bottom of the conveying pipe 4 is communicated with a discharge pipe 8; The vibrating sieve plate 20, and the bottom outlet of the mixing box 6 communicates with one end side of the delivery pipe 4 through the return pipe 5; the upper part of the mixing bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com