A theta-alf 3 Preparation method and application of micro-nanosphere catalyst

A technology of micro-nanospheres and catalysts, which is applied in the direction of physical/chemical process catalysts, dehydrohalogenation preparation, chemical instruments and methods, etc., which can solve the limitations of catalytic performance improvement, complex preparation methods, and difficulty in obtaining high-quality trifluoroethylene products, etc. problems, achieve the effects of shortening the fluorination time, high production efficiency, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

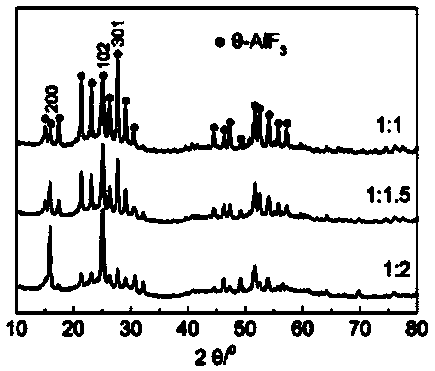

[0025] Take 6g of aluminum nitrate and 6g of PVDF, and dissolve them in 40mL of DMF under the condition of heating and stirring in a water bath at 70°C. After the dissolution is complete, a colorless and transparent gel-like precursor solution is formed, and the above-mentioned gel-like precursor solution is placed in a blast drying oven for 100 Dry at ℃ for 24 hours, remove the organic solvent, then calcinate the completely dried solid in a muffle furnace, the calcination temperature is 300 ℃, the heating rate is 5 ℃ / min, and keep at the calcination temperature for 12 hours, and finally cool naturally in the air atmosphere , that is, 1.9 g of aluminum fluoride was obtained, and then it was crushed to 20-40 mesh (0.45-0.9mm) after being pressed into a tablet at 15MPa to obtain a catalyst precursor.

Embodiment 2

[0027]Take 4g of aluminum nitrate and 6g of PVDF, and dissolve them in 40mL of DMF under the condition of heating and stirring in a water bath at 70°C. After the dissolution is complete, a colorless and transparent gel-like precursor solution is formed, and the above-mentioned gel-like precursor solution is placed in a blast drying oven for 120 Dry at ℃ for 36 hours, remove the organic solvent, then calcinate the completely dried solid in a muffle furnace, the calcination temperature is 390 ℃, the heating rate is 5 ℃ / min, and keep at the calcination temperature for 10 hours, and finally cool naturally in the air atmosphere , that is, 1.2g of aluminum fluoride is obtained, and then it is crushed to 20-40 mesh (0.45-0.9mm) after being pressed into a tablet at 15MPa to obtain a catalyst precursor.

Embodiment 3

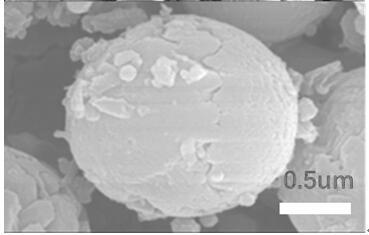

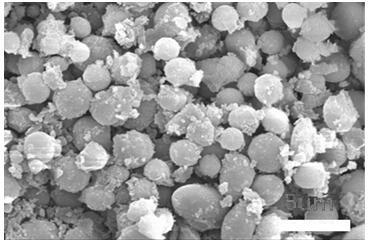

[0029] Take 3g of aluminum nitrate and 6g of PVDF, and dissolve them in 40mL of DMF under the condition of heating and stirring in a water bath at 70°C. After the dissolution is complete, a colorless and transparent gel-like precursor solution is formed, and the above-mentioned gel-like precursor solution is placed in a blast drying oven for 120 Dry at ℃ for 24 hours, remove the organic solvent, then calcinate the completely dried solid in a muffle furnace, the calcination temperature is 450 ℃, the heating rate is 10 ℃ / min, and keep at the calcination temperature for 5 hours, and finally cool naturally in the air atmosphere , that is, 0.8g of aluminum fluoride, 15MPa tablet molding and then crushing it to 20-40 mesh (0.45-0.9mm) to get the catalyst precursor, the scanning electron microscope (SEM) picture of the prepared aluminum fluoride is as follows Figure 2a with Figure 2b shown. from Figure 2a with Figure 2b It can be seen that the morphology of the product is a un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com