Preparation method and application of theta-AlF3 micro-nano-spherical catalyst

A technology of micro-nanospheres and catalysts, which is applied in the direction of physical/chemical process catalysts, dehydrohalogenation preparation, chemical instruments and methods, etc., which can solve the limitations of catalytic performance improvement, complex preparation methods, and difficulty in obtaining high-quality trifluoroethylene products, etc. problems, achieve the effects of shortening the fluorination time, high production efficiency, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

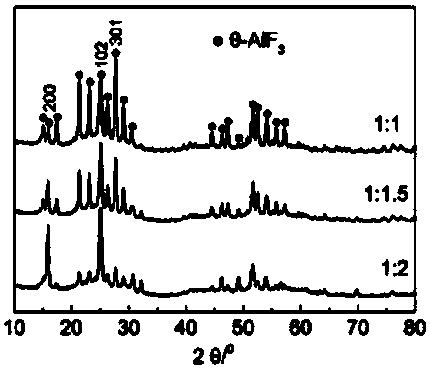

Embodiment 1

[0024] Take 6g of aluminum nitrate and 6g of PVDF, and dissolve them in 40mL of DMF under the condition of heating and stirring in a water bath at 70°C. After the dissolution is complete, a colorless and transparent gel-like precursor solution is formed, and the above-mentioned gel-like precursor solution is placed in a blast drying oven for 100 Dry at ℃ for 24 hours, remove the organic solvent, then calcinate the completely dried solid in a muffle furnace, the calcination temperature is 300 ℃, the heating rate is 5 ℃ / min, and keep at the calcination temperature for 12 hours, and finally cool naturally in the air atmosphere , that is, 1.9 g of aluminum fluoride was obtained, and then it was crushed to 20-40 mesh (0.45-0.9mm) after being pressed into a tablet at 15MPa to obtain a catalyst precursor.

Embodiment 2

[0026]Take 4g of aluminum nitrate and 6g of PVDF, and dissolve them in 40mL of DMF under the condition of heating and stirring in a water bath at 70°C. After the dissolution is complete, a colorless and transparent gel-like precursor solution is formed, and the above-mentioned gel-like precursor solution is placed in a blast drying oven for 120 Dry at ℃ for 36 hours, remove the organic solvent, then calcinate the completely dried solid in a muffle furnace, the calcination temperature is 390 ℃, the heating rate is 5 ℃ / min, and keep at the calcination temperature for 10 hours, and finally cool naturally in the air atmosphere , that is, 1.2g of aluminum fluoride is obtained, and then it is crushed to 20-40 mesh (0.45-0.9mm) after being pressed into a tablet at 15MPa to obtain a catalyst precursor.

Embodiment 3

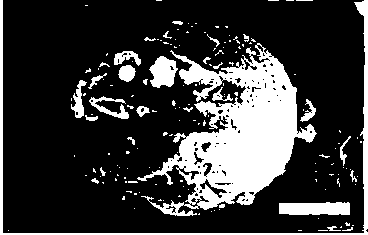

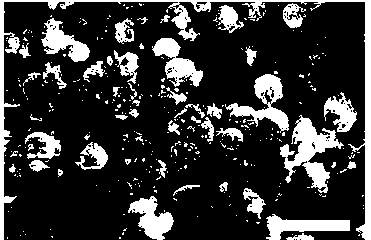

[0028] Take 3g of aluminum nitrate and 6g of PVDF, and dissolve them in 40mL of DMF under the condition of heating and stirring in a water bath at 70°C. After the dissolution is complete, a colorless and transparent gel-like precursor solution is formed, and the above-mentioned gel-like precursor solution is placed in a blast drying oven for 120 Dry at ℃ for 24 hours, remove the organic solvent, then calcinate the completely dried solid in a muffle furnace, the calcination temperature is 450 ℃, the heating rate is 10 ℃ / min, and keep at the calcination temperature for 5 hours, and finally cool naturally in the air atmosphere , that is, 0.8g of aluminum fluoride, 15MPa tablet molding and then crushing it to 20-40 mesh (0.45-0.9mm) to get the catalyst precursor, the scanning electron microscope (SEM) picture of the prepared aluminum fluoride is as follows Figure 2 shows. It can be seen from Fig. 2 that the morphology of the product is a uniform micro-nanosphere with a size of abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com