Ore coarse crushing device for mineral product processing

A kind of ore and coarse crushing technology, applied in the field of ore coarse crushing device for mineral processing, can solve the problems of inability to diffuse dust and reduce dust, unfavorable environmental protection, poor ore crushing effect, etc., achieve ingenious structure, reasonable design, and improve crushing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of this patent is described in further detail below in conjunction with specific embodiments:

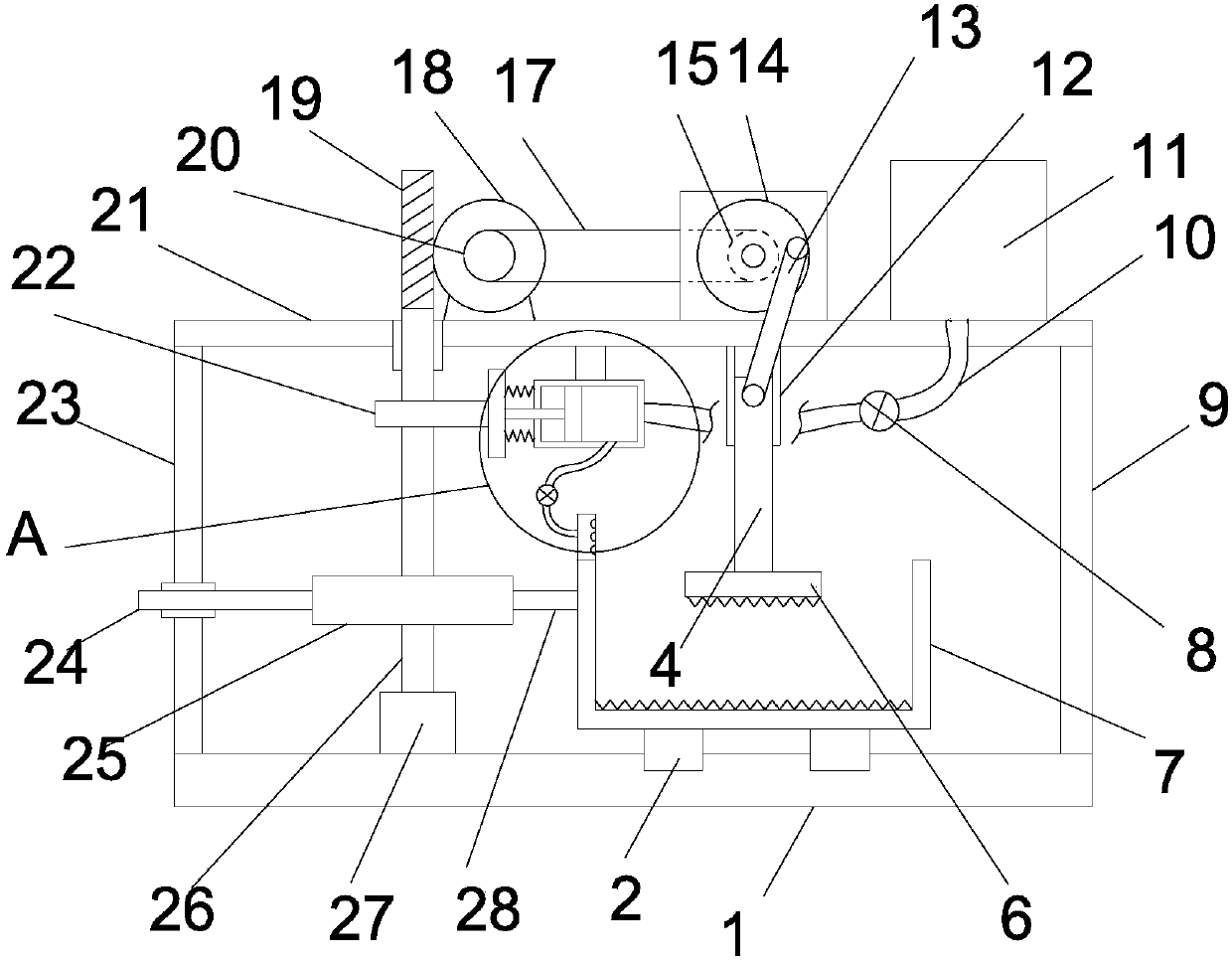

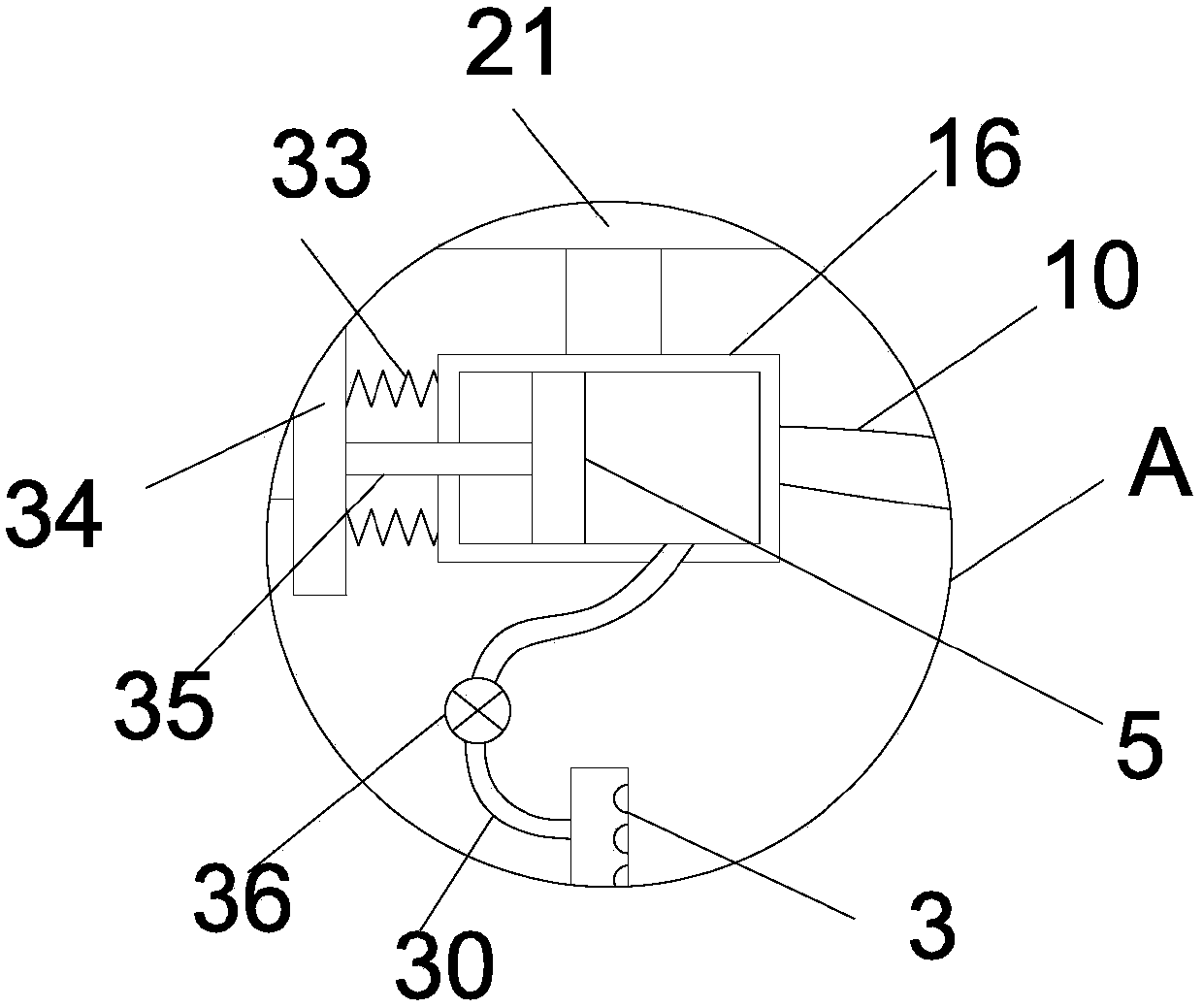

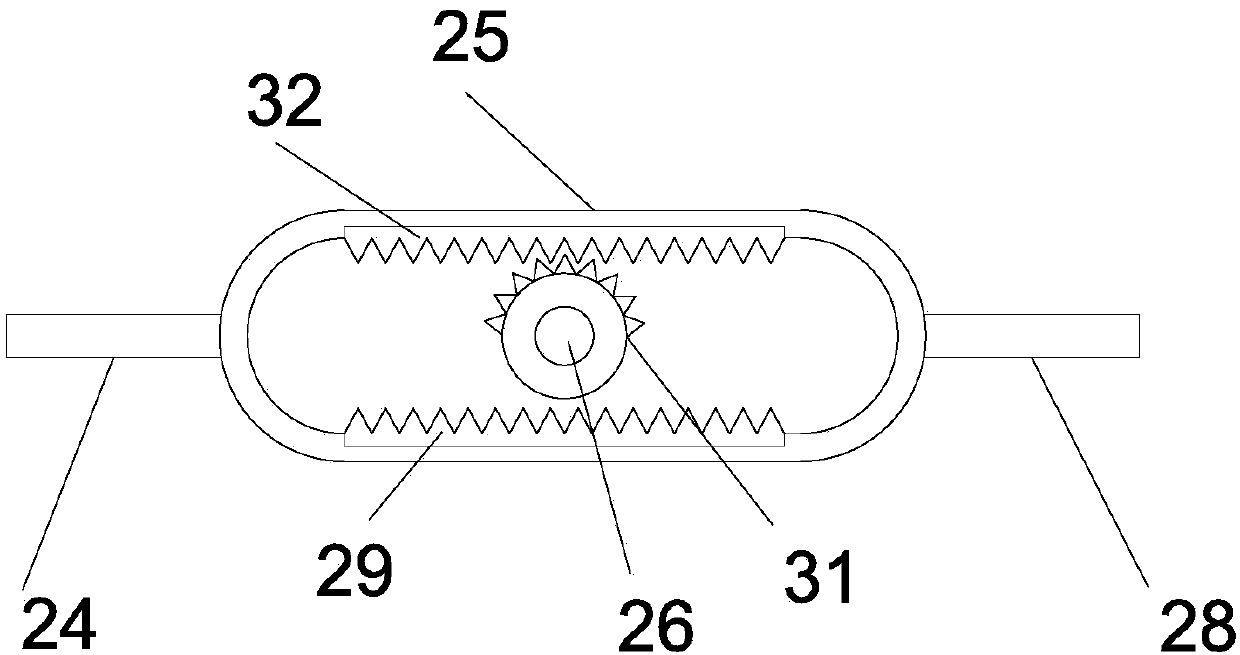

[0019] see Figure 1-3 , a coarse ore crushing device for mineral processing, comprising a bottom plate 1, a top plate 21, a worm wheel 18, a runner 14 and a water tank 11 are arranged on the top plate 21 from left to right; the top plate 21 is vertically provided with a limit Slideway 12, the vertical sliding type in limit slideway 12 is provided with slide bar 4, is connected with transmission rod 13 between slide bar 4 and runner 14, and described transmission rod 13 upper ends are hinged at runner 14 front edges, The lower end of the transmission rod 13 is hinged on the upper end of the slide bar 4. The driven pulley 15 is fixedly mounted coaxially on the runner 14, and the driving pulley 20 is fixedly mounted coaxially on the worm wheel 18. The driving pulley 20 and the driven pulley 15 is wound with a transmission belt 17, and the bottom surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com