A steel plate cutting device

A steel plate and cutting machine technology, applied in the direction of sawing machine, sawing machine tool, metal sawing equipment, etc., can solve the problems of easy displacement and affecting the cutting quality of steel plate remaining materials, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

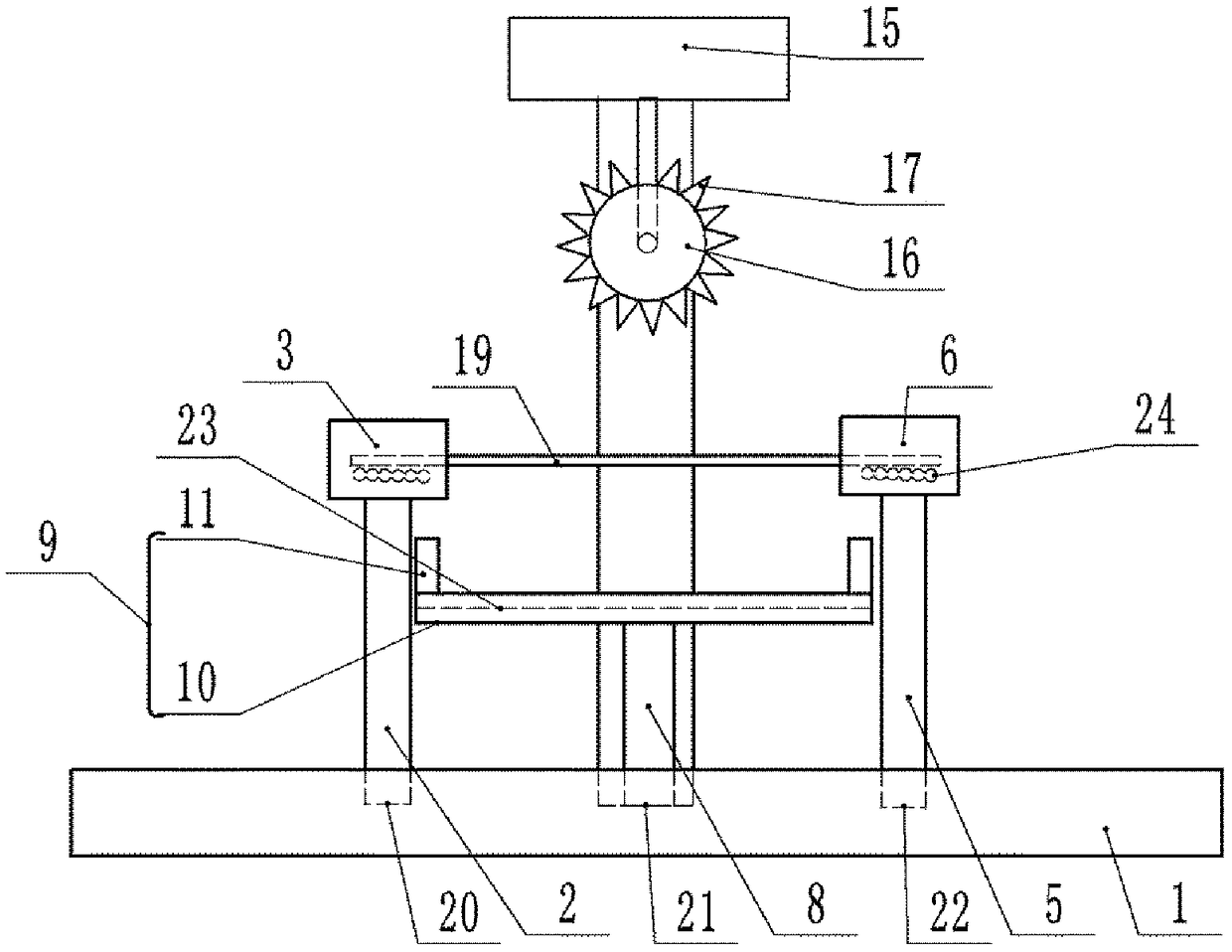

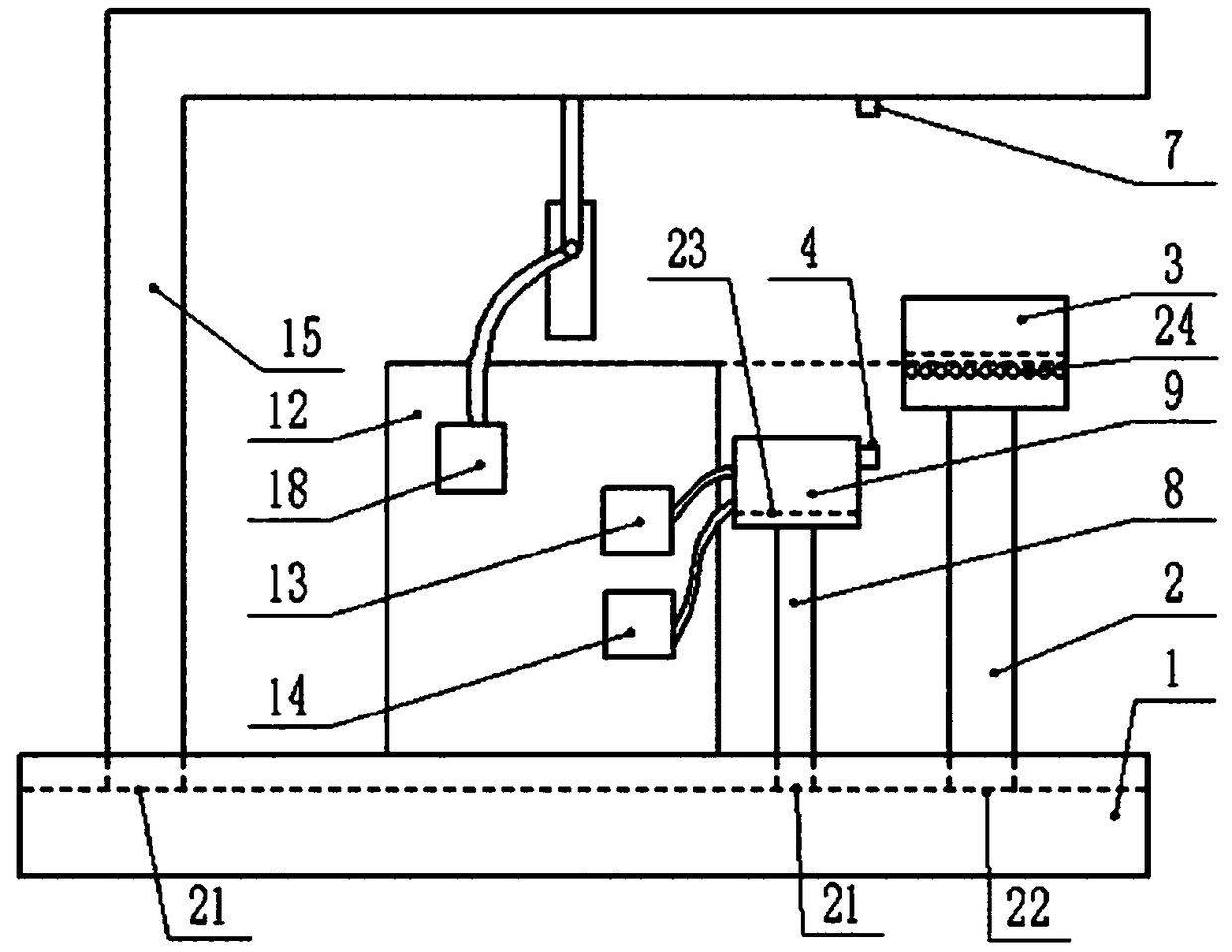

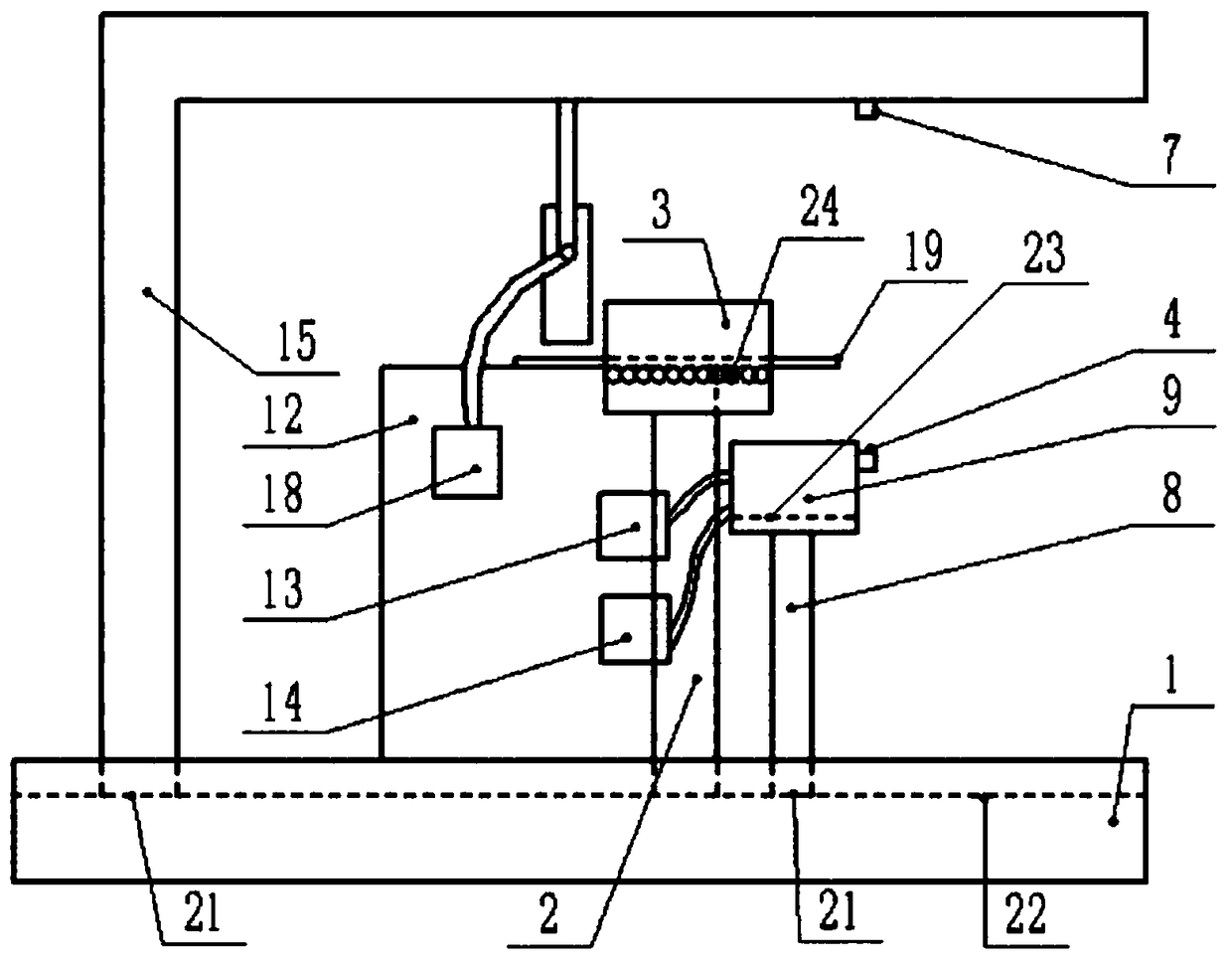

[0022] The reference numerals in the accompanying drawings of the description include: base 1, first telescopic rod 2, first clamp transmission device 3, infrared emitter 4, second telescopic rod 5, second clamp transmission device 6, infrared receiver 7, The third telescopic rod 8, splint 9, bottom plate 10, splint arm 11, cutting table 12, hot melt glue box 13, air-conditioning box 14, L-shaped arm bar 15, cutting knife 16, cutting knife teeth 17, hot air box 18, steel plate 19. The first chute 20 , the second chute 21 , the third chute 22 , the fourth chute 23 , and the roller set 24 .

[0023] Such as figure 1 As shown, a steel plate cutting machine includes a base 1, and the base 1 is provided with three chutes from left to right, namely the first chute 20, the second chute 21 and the third chute 22, the second chute Install the L-shaped arm bar 15 and the third telescopic link 8 on the slot 21. The L-shaped arm bar 15 transverse arm and the vertical arm are all adjustab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com