Composite fast forming production device and preparation method

A composite material and production device technology, applied in the directions of additive manufacturing, manufacturing tools, additive processing, etc., can solve problems such as poor strength, limited application of molded parts, etc., to improve mechanical properties, meet the convenience of design concepts, and improve product mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

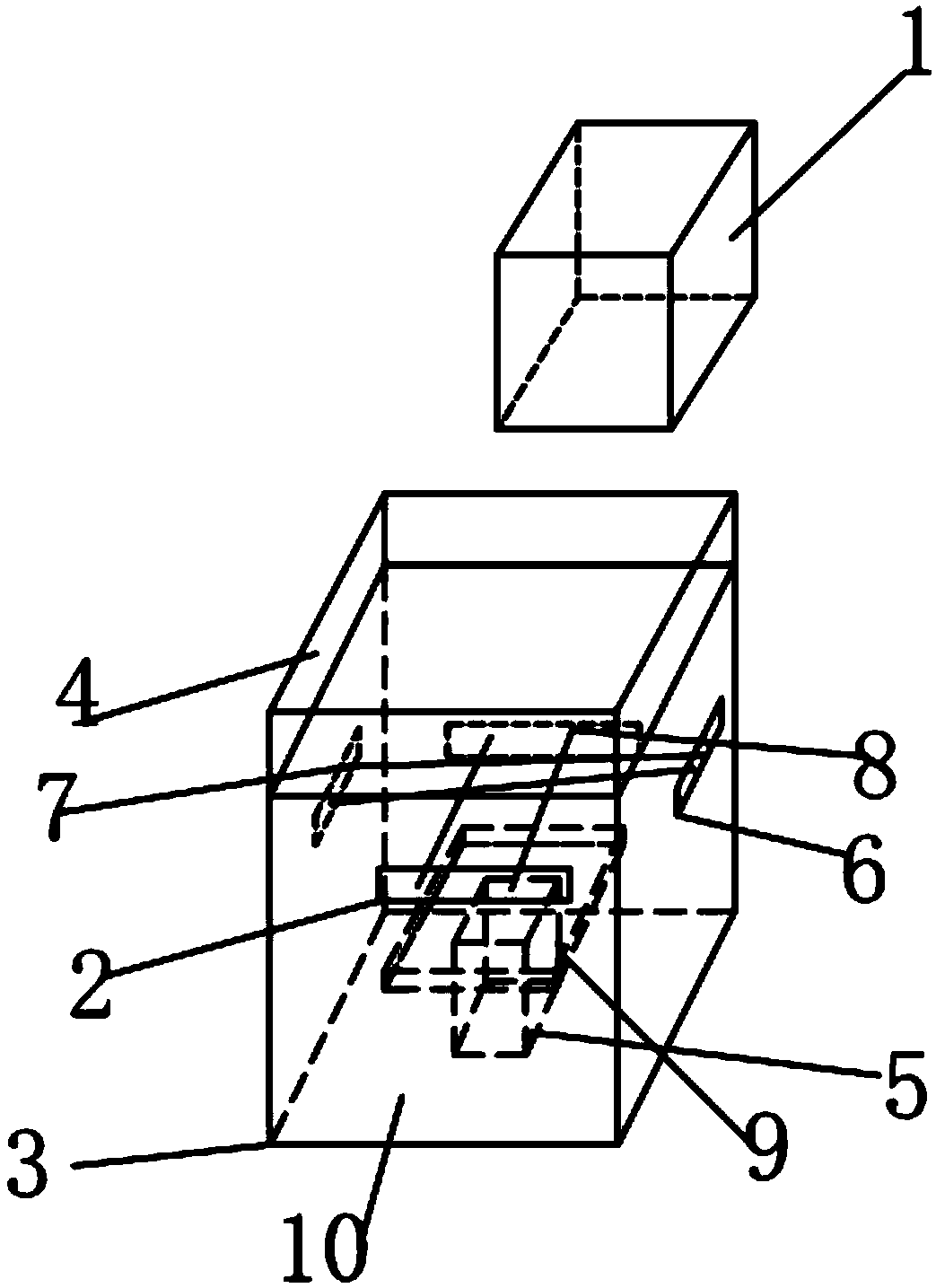

[0014] A composite material rapid prototyping production device of the present embodiment, such as figure 1 As shown, it includes a loom frame (not shown in the figure), and an ultraviolet light emitter 1 and a light-curing 3D printer 3 are sequentially installed on the loom frame from top to bottom; the light-curing 3D printer 3 The inner bottom surface is a liquid storage tank 10; the above left and right inner walls of the photo-curing 3D printer 3 are respectively provided with a row of horizontal pick-up holes 6 at the same height; the photo-curing 3D printer 3 is above the front and rear inner walls The same height is provided with a row of vertical pick-up holes 2 respectively; The passing weft inserter is located at the same height; the inner bottom surface of the liquid holding tank 10 below the horizontal direction picking hole 6 and the vertical direction picking hole 2 is equipped with a lifting device 5 made of an electric motor and a threaded rod. A printing pl...

Embodiment 2

[0019] A composite material rapid prototyping production device of the present embodiment, such as figure 1As shown, it includes a loom frame (not shown in the figure), and an ultraviolet light emitter 1 and a light-curing 3D printer 3 are sequentially installed on the loom frame from top to bottom; the light-curing 3D printer 3 The inner bottom surface is a liquid storage tank 10; the above left and right inner walls of the photo-curing 3D printer 3 are respectively provided with a row of horizontal pick-up holes 6 at the same height; the photo-curing 3D printer 3 is above the front and rear inner walls The same height is provided with a row of vertical pick-up holes 2 respectively; The passing weft inserter is located at the same height; the inner bottom surface of the liquid holding tank 10 below the horizontal direction picking hole 6 and the vertical direction picking hole 2 is equipped with a lifting device 5 made of an electric motor and a threaded rod. A printing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com