Improved continuous linseed oil degumming process

A linseed oil and degumming technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of inability to produce high-quality linseed oil, prolong the processing cycle of linseed oil, reduce the gum content, etc., and achieve the improvement of the continuous degumming process route , Shorten the hydration treatment time and increase the treatment temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

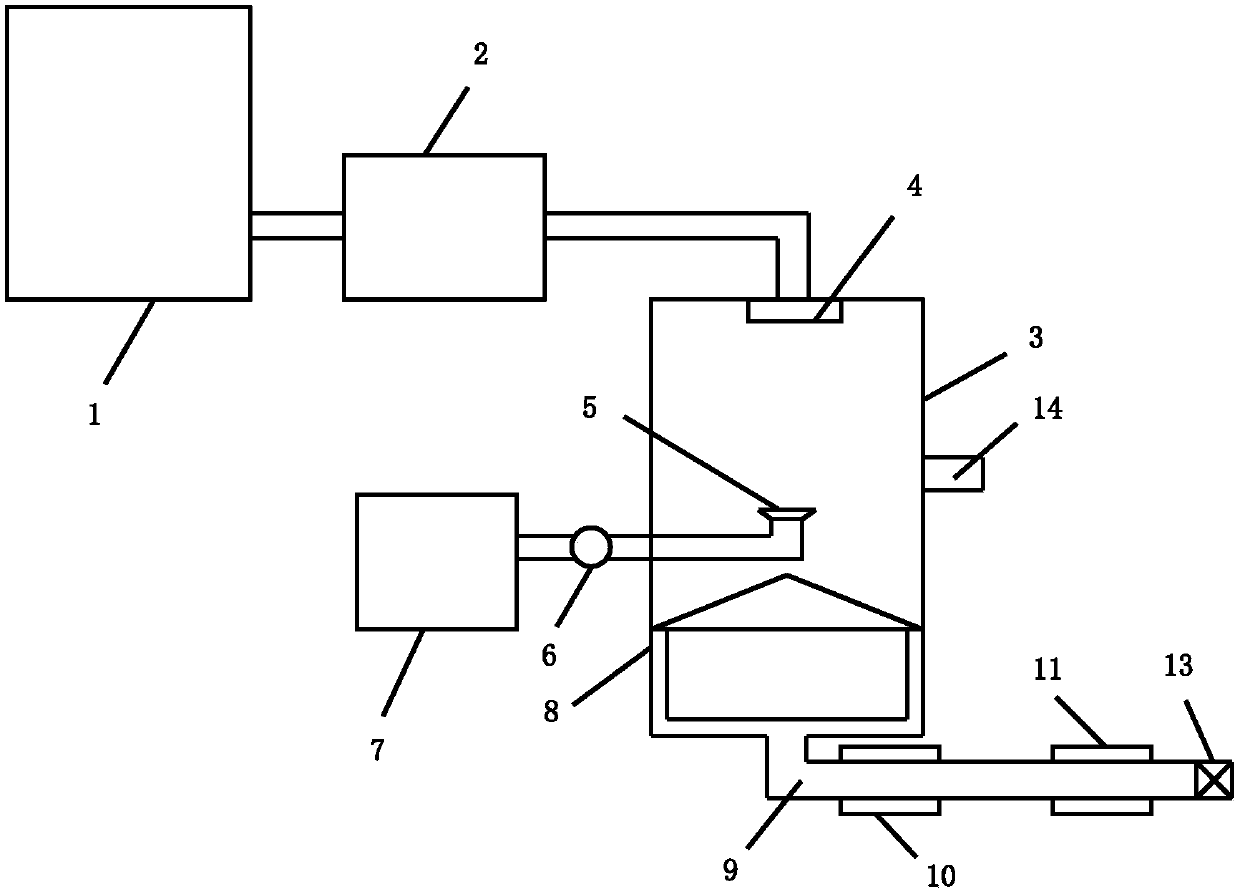

[0021] refer to figure 1 , an improved continuous linseed oil degumming process, characterized in that: a high-temperature stirring tank 1 is set, the crude oil is injected into the high-temperature stirring tank 1, and water is added, the amount of water added is 18g / Kg, pressurized to 0.5MPa, and then gradually heated to 120°C, carry out uniform stirring treatment for 10 minutes, then release the pressure, reduce the temperature to 85°C at the same time, add citric acid, the addition amount is 0.6g / Kg, and then carry out uniform stirring for 5 minutes;

[0022] The high-temperature stirring tank 1 is connected to the spray tank 3 through the buffer tank 2. The top of the spray tank 3 is provided with a spray head 4 connected to the buffer tank 2. The bottom of the spray tank 3 is provided with a high-pressure nozzle 5. The high-pressure nozzle 5 is pressurized The pump 6 is connected to the storage tank 7, the bottom surface of the spray tank 3 is conical, and the outer side...

Embodiment 2

[0042] This example is improved on the basis of Example 1. 0.5 wt% sodium alginate is added to the flocculant, which can improve the oxidation resistance of crude oil and reduce the loss rate.

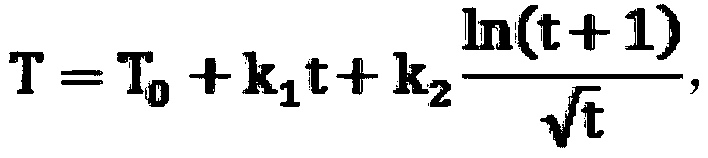

[0043]

Embodiment 3

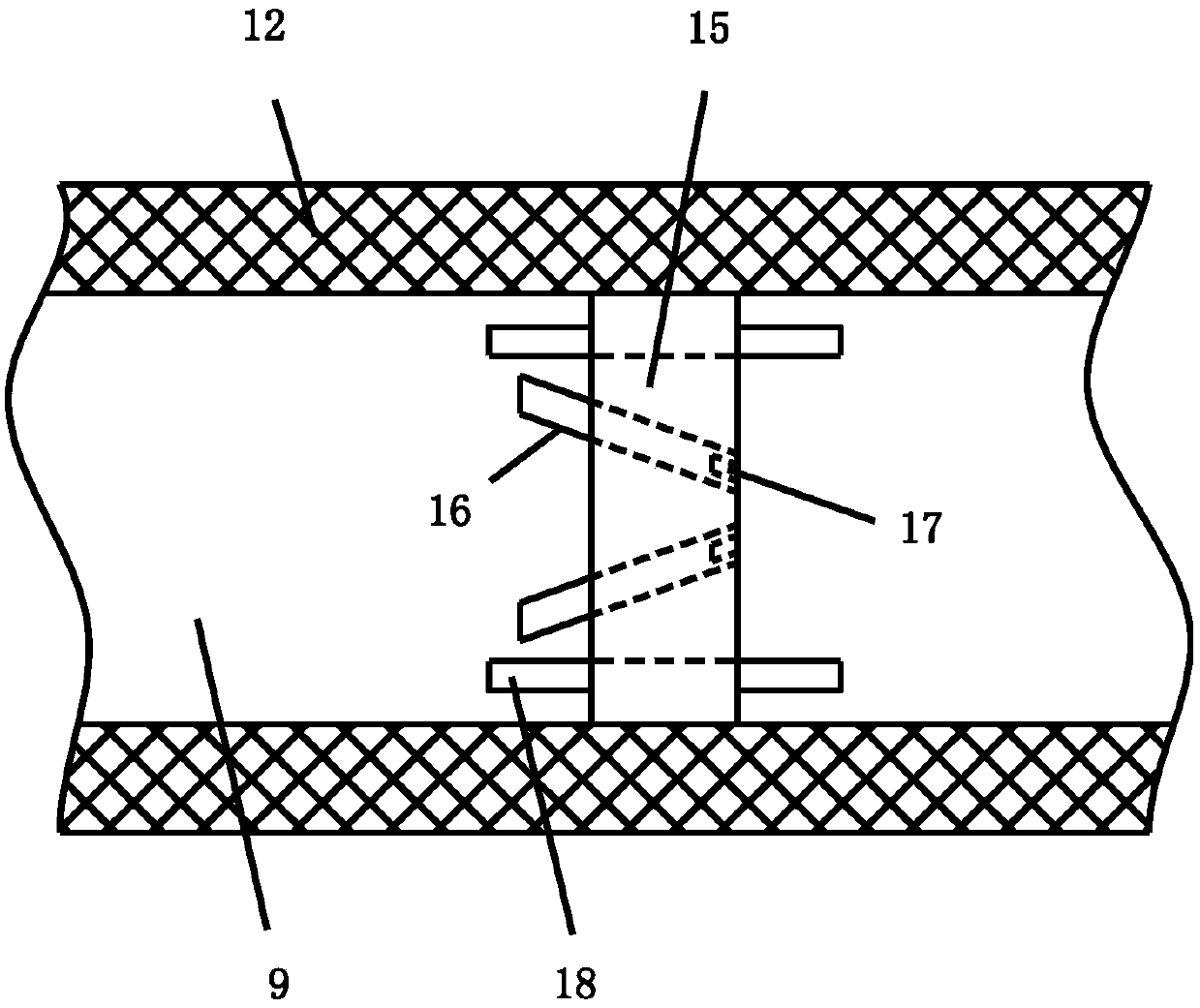

[0045] This embodiment is improved on the basis of Embodiment 1. refer to figure 2 , several guide rings 15 are fixed inside the wire mesh layer 12, and several guide plates 16 are evenly fixed inside the guide ring 15, and the angle between the guide plates 16 and the direction of the guide ring 15 is 20°. A groove 17 is arranged on the surface of the deflector 16 where the crude oil flows out. A baffle 18 is provided between the guide ring 15 and the wire mesh layer 12 . By adding the guide ring 15, the circulation uniformity of the crude oil flowing in the spiral channel 9 can be improved, thereby improving the filtration of the colloid precipitated in the crude oil by the wire mesh layer 12. The baffle 18 is used to reduce the disturbance of the crude oil fluid to the colloid attached to the surface of the wire mesh layer 12, so as to prevent the colloid from entering the crude oil fluid again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com