Light Source With Glass Housing

a glass housing and light source technology, applied in the field of light sources, can solve the problems of light extraction, reduced efficiency with which light may be extracted from the device, and large heat dissipation of light emitting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

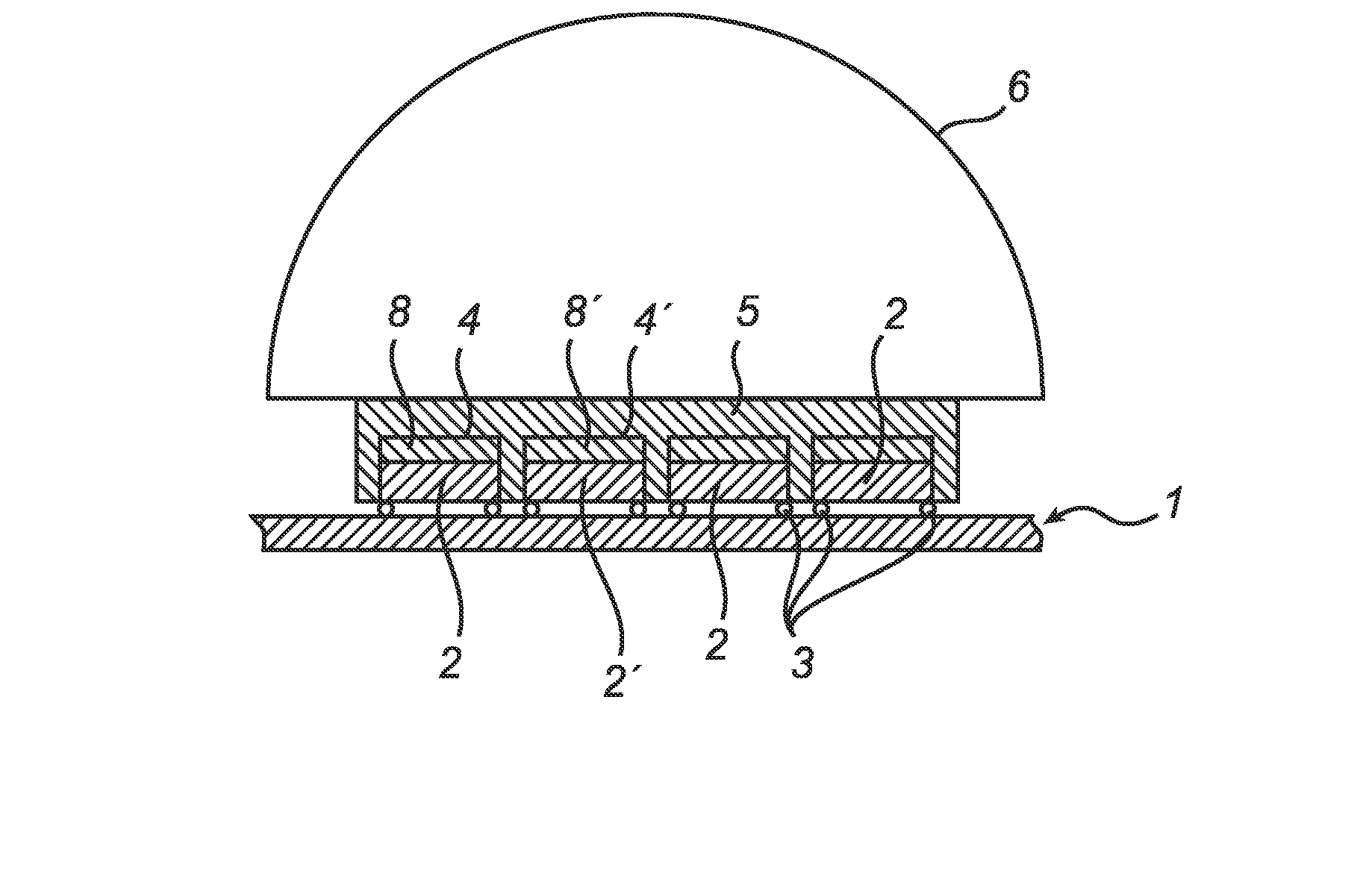

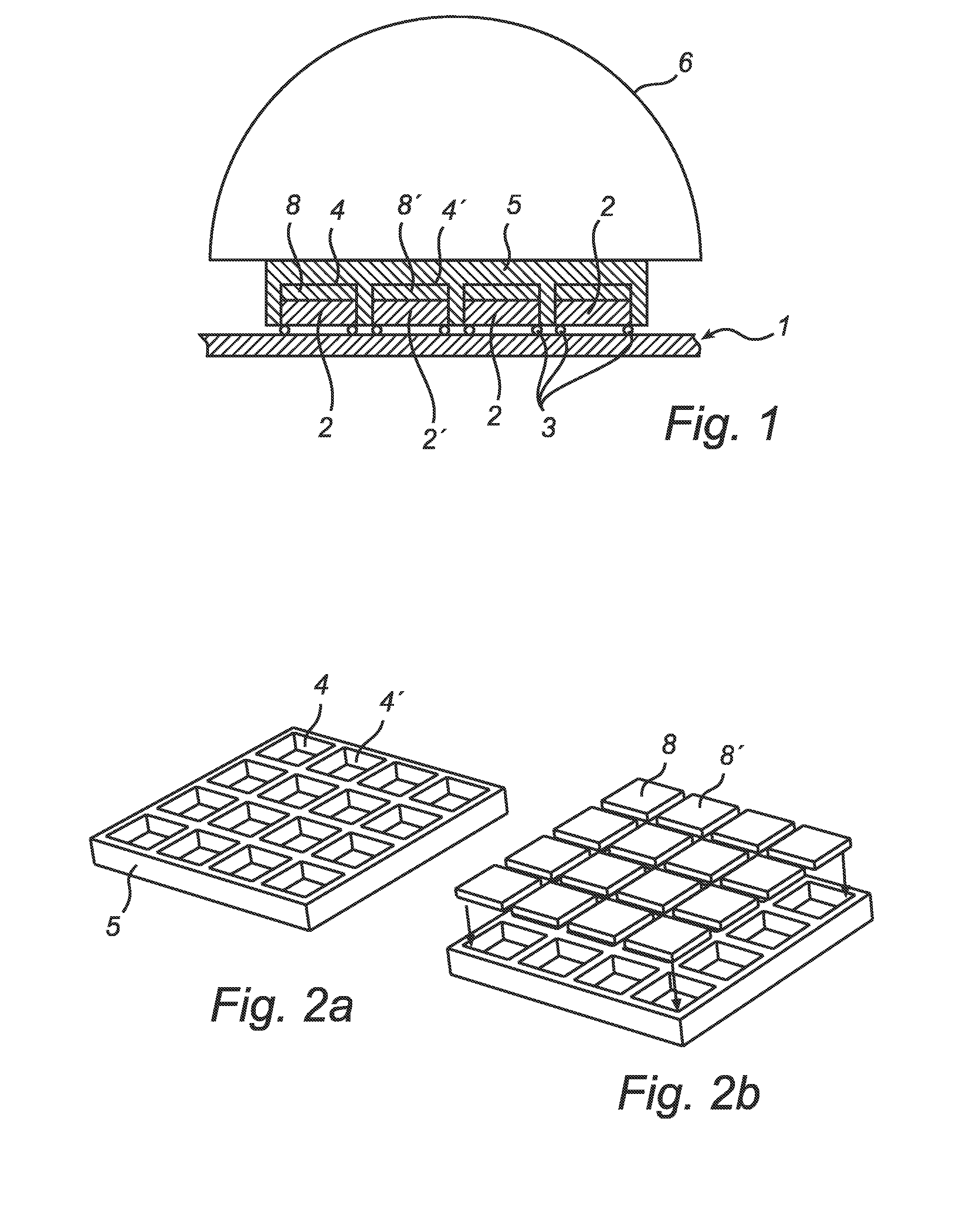

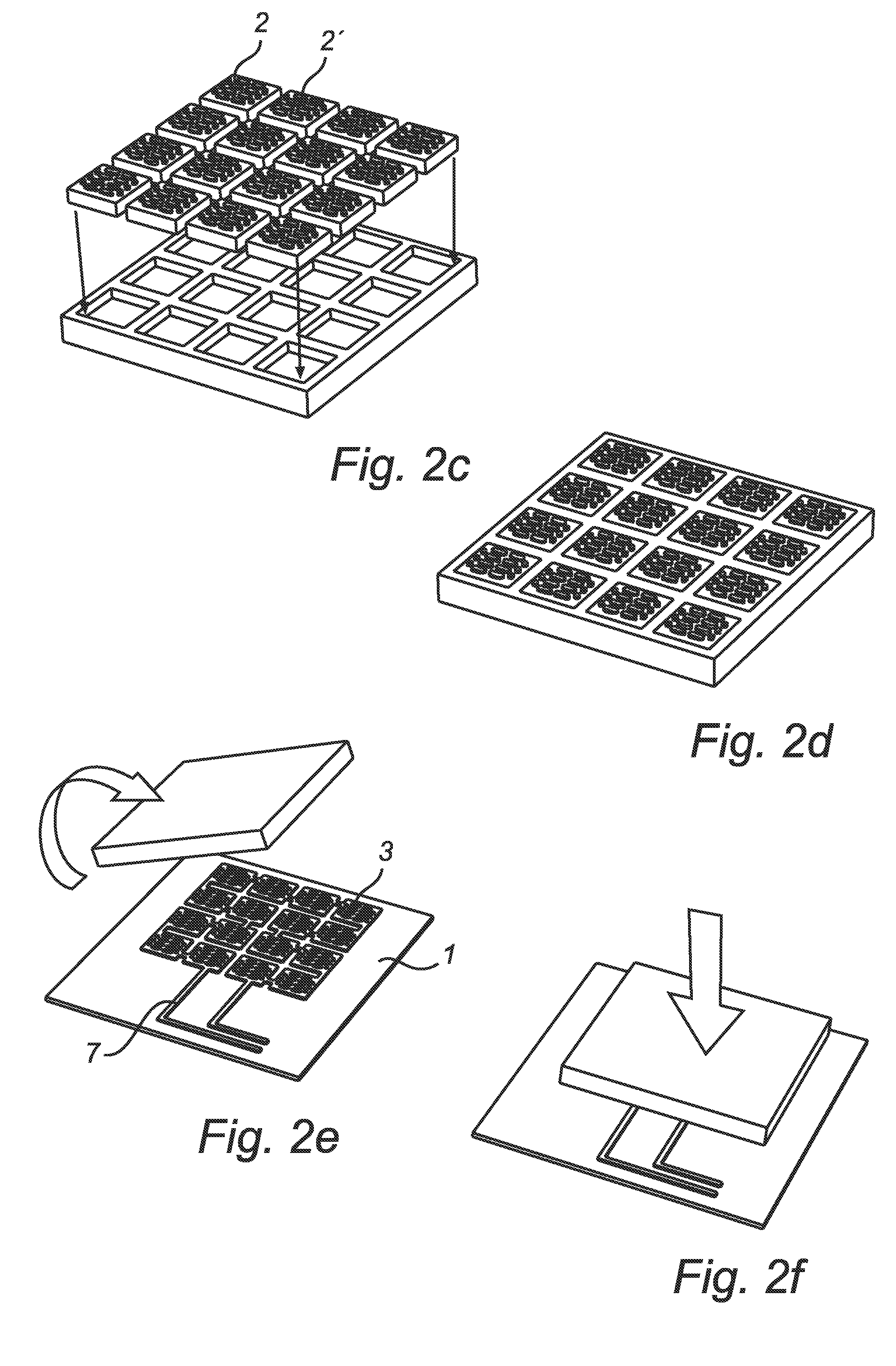

[0025]One exemplary embodiment of the present invention, as shown in FIG. 1, comprises a sub-mount 1 provided with a circuitry. An array of light-emitting diodes (LEDs) 2, 2′ is arranged on the circuitry, and each LED of the array is separately connected to the circuitry by metal bumps 3 at pre-determined positions.

[0026]Each LED 2, 2′ is arranged in a separate recess 4, 4′ in a housing 5 of a translucent glass material, and the location and the orientation of each LED 2, 2′ is determined by the walls of the corresponding recess 4, 4′.

[0027]Each LED comprises the active layers arranged on a crystalline substrate, through which light is emitted when the LEDs are active. The substrate is physically bonded to the housing in order to optically connect the LED with the housing.

[0028]Furthermore, a transparent hemisphere 6 is arranged on the housing 5 to spread the light emitted by the device. A preferred method for the manufacture of a light source of the present invention is outlined in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com