Non-elasticity hollow core big-belly yarn and preparation method thereof

A yarn and hollow core technology is applied in the field of non-elastic hollow-core potbellied yarn and its preparation, which can solve the problems of short length of yak wool fiber, great difficulty in pure spinning, coarse fineness, etc., and achieve uniform and stable pattern. , The appearance is gorgeous and elegant, and the style is diversified.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

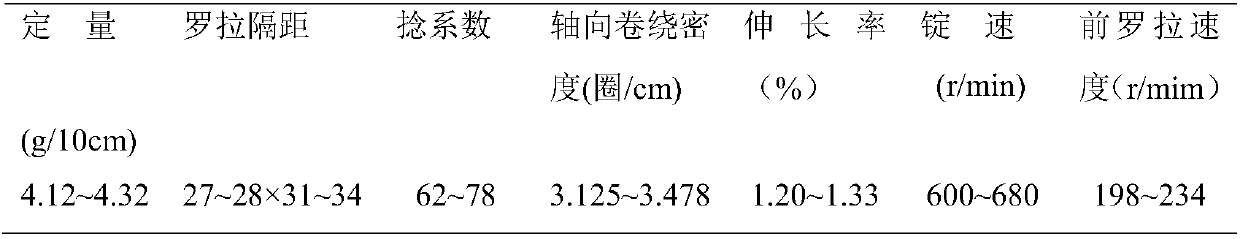

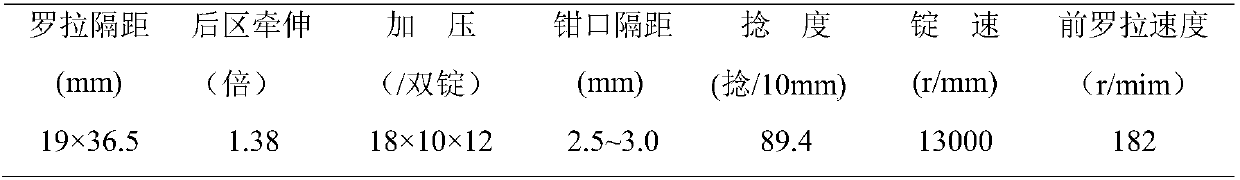

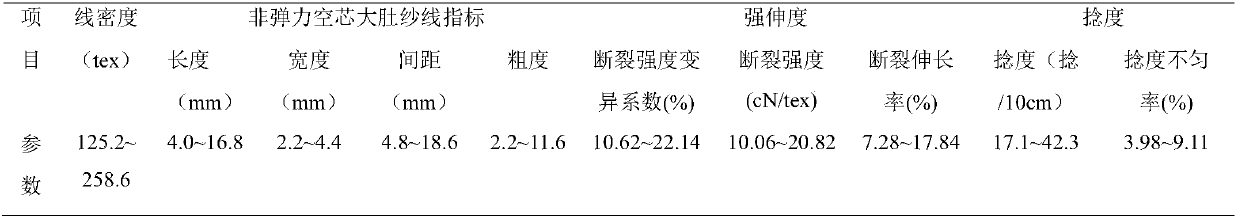

Embodiment 1

[0084] Using PTT fiber filament, silk fiber, coconut charcoal fiber, water-soluble vinylon filament, coffee fiber, seashell fiber, bark fiber, nettle fiber and yak down fiber as the main multi-component raw materials, after blending processing And a kind of non-elastic hollow core yarn obtained after the processing of compound spinning technology is an example. It is a novel fancy yarn, mainly including core yarn, fixed yarn and decorative yarn, fancy yarn The fixed yarn in the thread product is a non-elastic binding yarn blended with PTT fiber filament, silk hemp fiber and coconut carbon fiber, wherein it is made of the following raw materials in weight ratio: the filament in the blended yarn The weight content of hemp fiber accounts for 30%, and the weight content of coconut charcoal fiber accounts for 70%. Made, wherein, it is made by the raw material of following weight ratio, and the weight content of structure bark fiber accounts for 50% in described blended yarn, and th...

Embodiment 2

[0086] Using PTT fiber filament, silk fiber, coconut charcoal fiber, water-soluble vinylon filament, coffee fiber, seashell fiber, bark fiber, nettle fiber and yak down fiber as the main multi-component raw materials, after blending processing And a kind of non-elastic hollow core yarn obtained after the processing of compound spinning technology is an example. It is a novel fancy yarn, mainly including core yarn, fixed yarn and decorative yarn, fancy yarn The fixed yarn in the thread product is a non-elastic binding yarn blended with PTT fiber filament, silk hemp fiber and coconut carbon fiber, wherein it is made of the following raw materials in weight ratio: the filament in the blended yarn The weight content of hemp fiber accounts for 50%, and the weight content of coconut charcoal fiber accounts for 50%. Made, wherein, it is made by the raw material of following weight ratio, and the weight content of structure bark fiber accounts for 30% in described blended yarn, and th...

Embodiment 3

[0088] Using PTT fiber filament, silk fiber, coconut charcoal fiber, water-soluble vinylon filament, coffee fiber, seashell fiber, bark fiber, nettle fiber and yak down fiber as the main multi-component raw materials, after blending processing And a kind of non-elastic hollow core yarn obtained after the processing of compound spinning technology is an example. It is a novel fancy yarn, mainly including core yarn, fixed yarn and decorative yarn, fancy yarn The fixed yarn in the thread product is a non-elastic binding yarn blended with PTT fiber filament, silk hemp fiber and coconut carbon fiber, wherein it is made of the following raw materials in weight ratio: the filament in the blended yarn The weight content of hemp fiber accounts for 40%, and the weight content of coconut charcoal fiber accounts for 60%. Made, wherein, it is made by the raw material of following weight ratio, and the weight content of structure bark fiber accounts for 40% in described blended yarn, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com