An evaporative cooling air-conditioning system using industrial waste heat to provide electrical energy

An evaporative cooling air-conditioning and industrial waste heat technology, which is applied in air-conditioning systems, machines using waste heat, energy-saving heating/cooling, etc., can solve the problems of heat loss, accelerated power loss of air-conditioning equipment, and low utilization of hot water. Full recycling, reduced operating load, accelerated cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

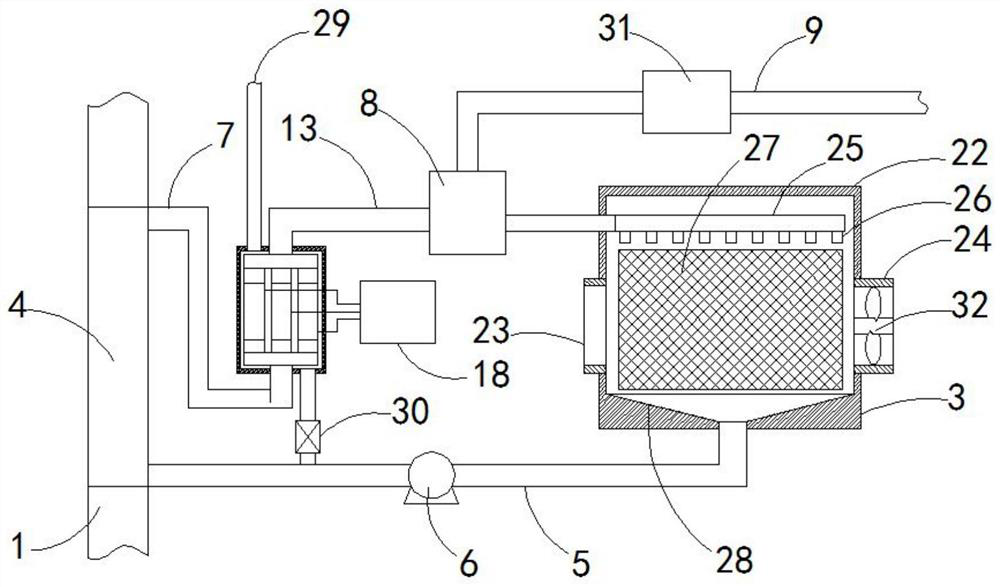

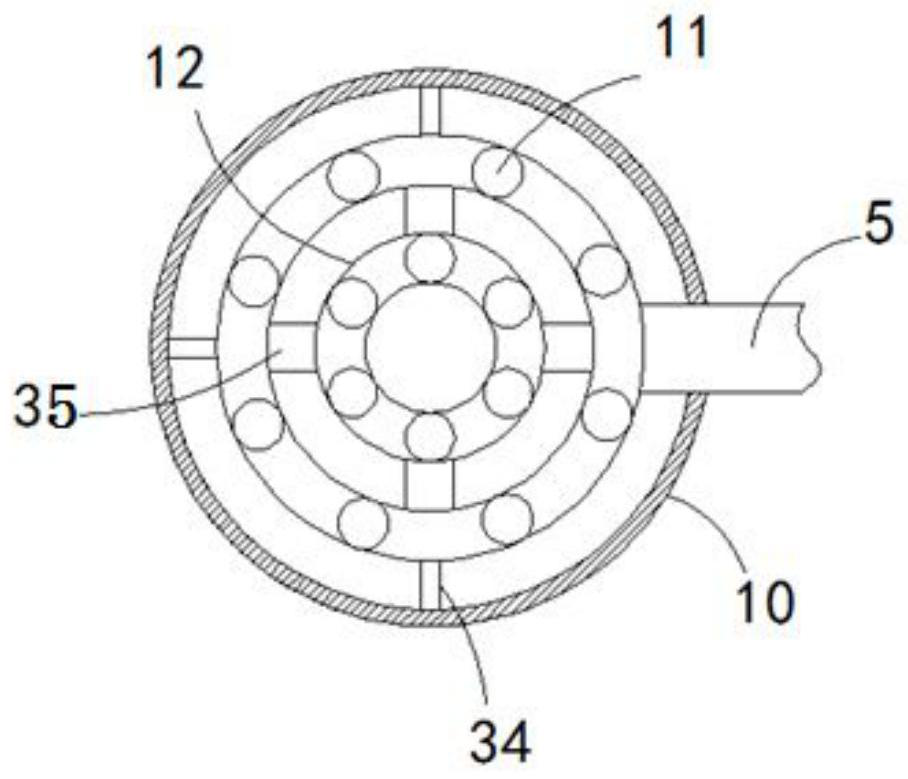

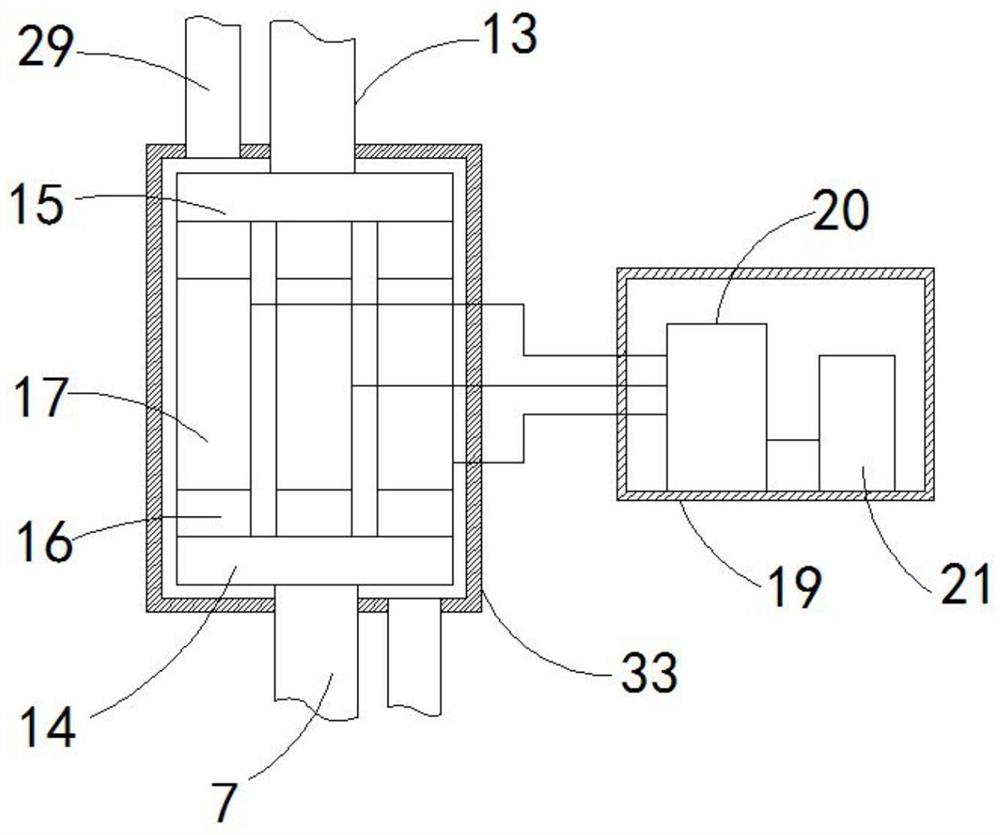

[0021] Such as Figure 1-3 As shown, an evaporative cooling air-conditioning system that utilizes industrial waste heat to provide electric energy includes a smoke exhaust pipe 1, a thermoelectric exchange device 2, and an evaporative cooling air-conditioning device 3. The smoke exhaust pipe 1 is connected with a heat exchange pipe 4, and the heat exchange pipe 4 One end is connected to the evaporative cooling air conditioner 3 through the water inlet pipe 5, and the circulation pump 6 is connected to the water inlet pipe 5, and the other end of the heat exchange pipe 4 is connected to the input end of the thermoelectric exchange device 2 through the water outlet pipe 7, and the thermoelectric exchange device 2 The output end is connected to the heat source input end of the absorption refrigerating machine 8 through the drain pipe 13, and the hot water output end of the thermoelectric exchange device 2 is connected to the hot water supply pipe 9. It is worth mentioning that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com