Oil burning and drying integrated machine for steam and hot water dual-purpose boiler

An integrated machine and boiler technology, applied in dryers, steam boilers, steam boiler accessories, etc., can solve problems such as limitations, slow heat transfer, and inability to dry, so as to improve the quality of baking materials, reduce heat loss, The effect of reducing waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

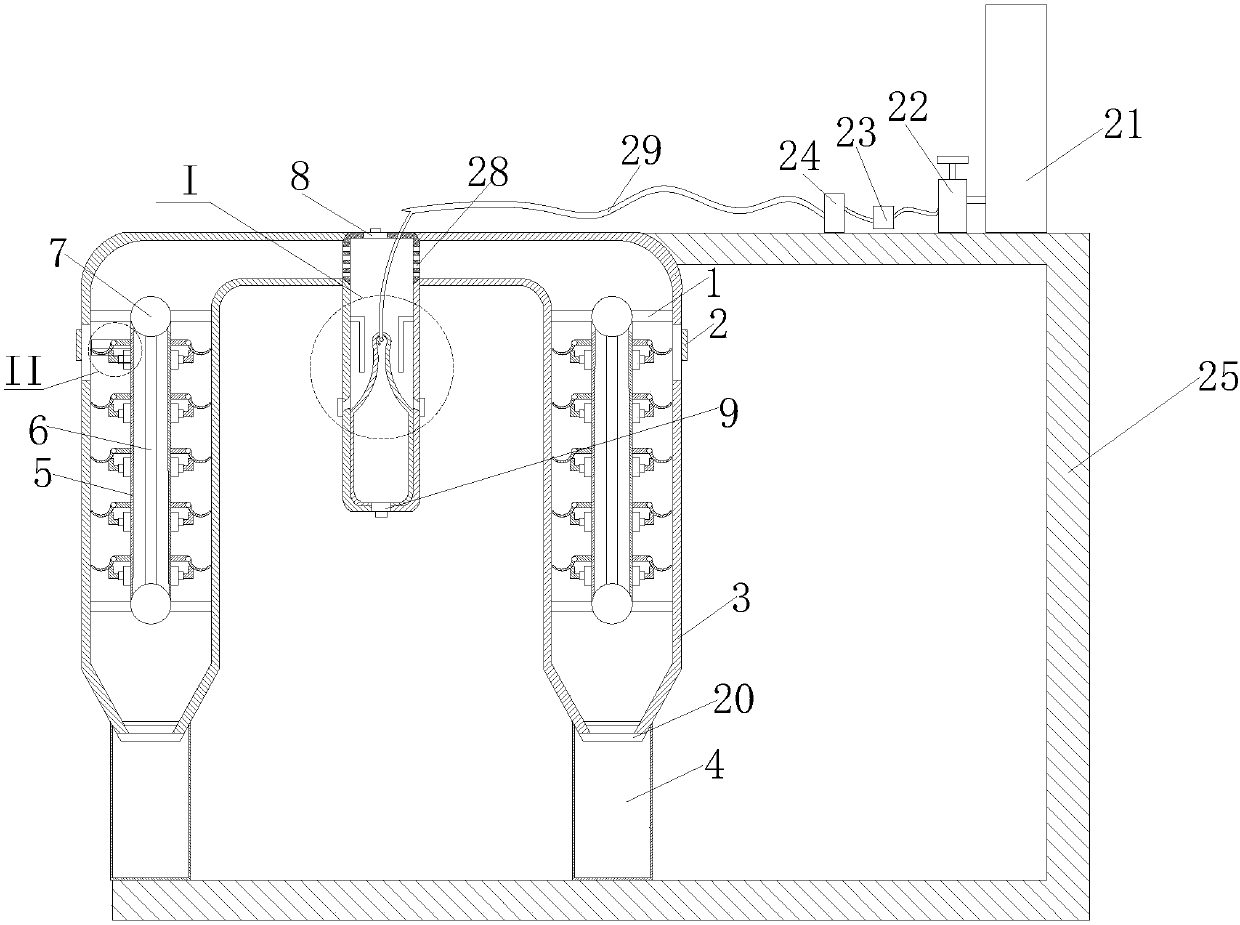

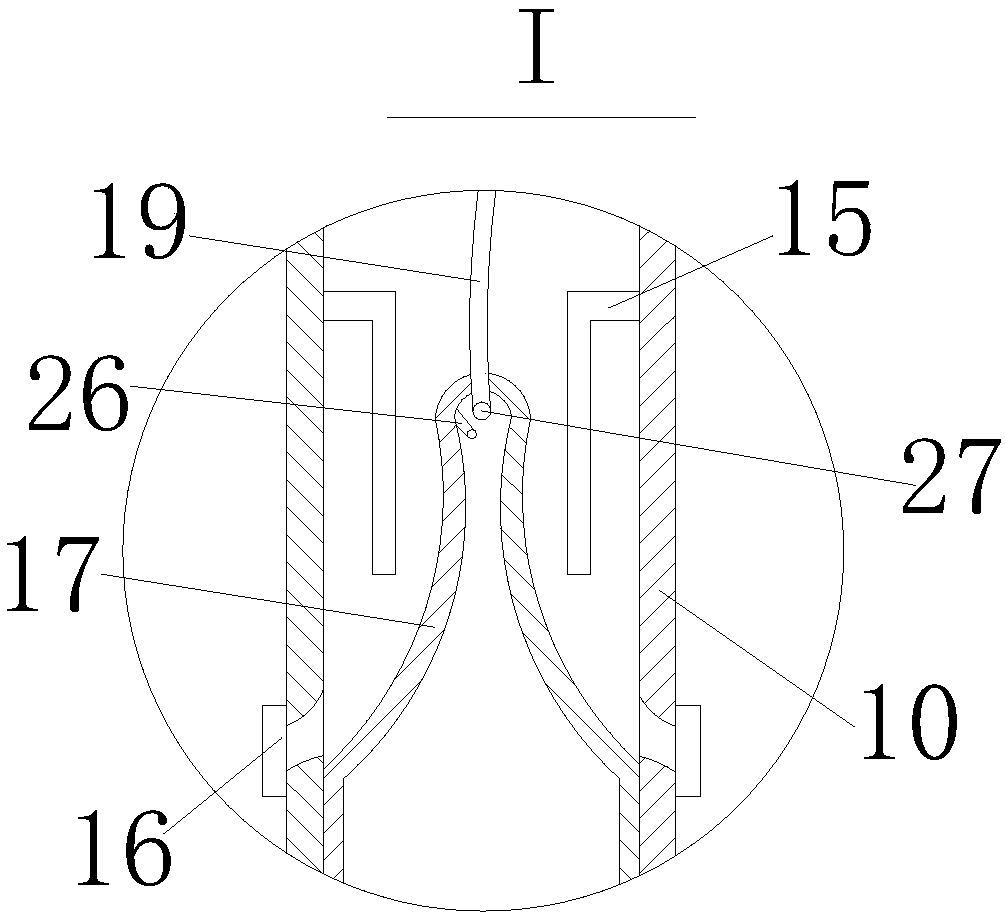

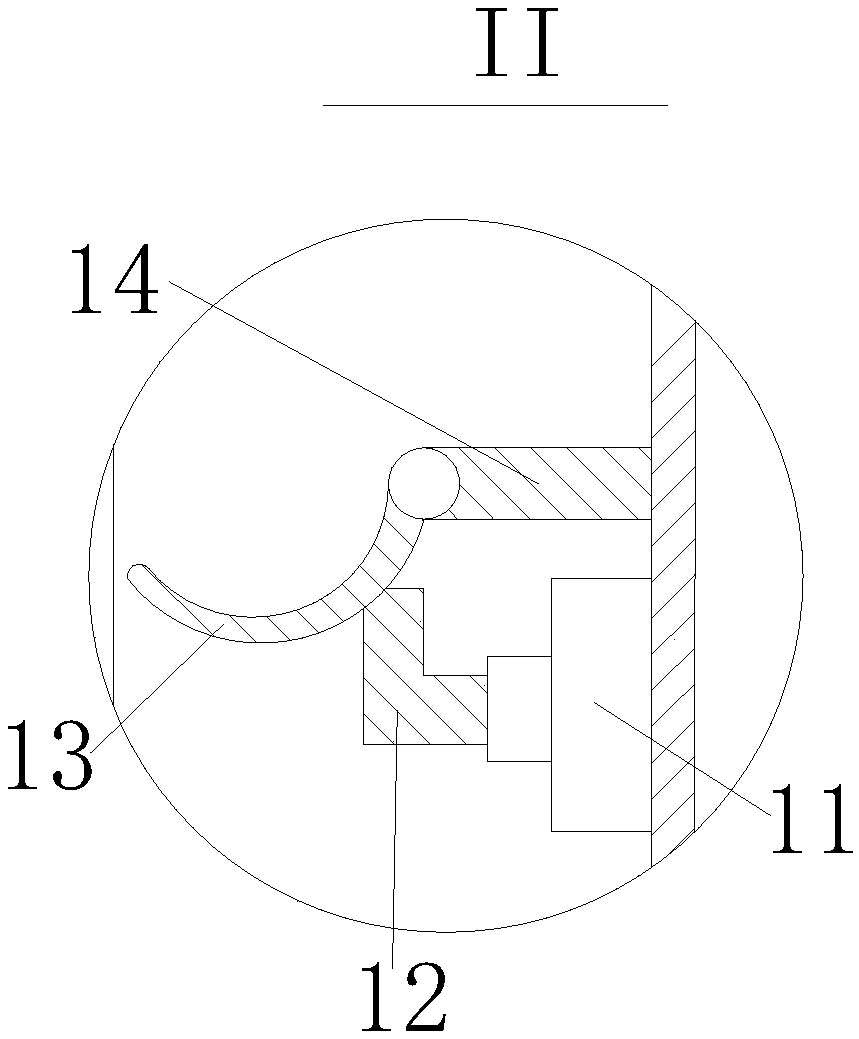

[0018] In order to make it easy to understand the technical means, creative features, achieved goals and effects of the present invention, the present invention is further described below.

[0019] like Figure 1 to Figure 4 As shown, an all-in-one fuel oil drying machine for a steam-water dual-purpose boiler includes a boiler 10, a support frame 25 supporting the boiler 10, and a fuel oil cylinder 17 built in the boiler 10. The boiler 10 has a built-in fuel oil device, and the Both ends of the fuel oil device are provided with drying devices, the drying device is provided with a rotating device, and the end of the drying device away from the fuel device is provided with a charging box for storing the dried baking material 4.

[0020] The fuel oil device is arranged on the support frame 25, and plays the role of heating oil; the rotation device is arranged on both sides of the boiler 10, mainly for drying the baking material: the rotation device is arranged on the side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com