Wind turbine generator bearing fault diagnosis method for multi-channel deep convolutional neural network

A deep convolution and neural network technology, applied in biological neural network models, mechanical bearing testing, neural architecture, etc., can solve problems such as low signal-to-noise ratio, poor diagnostic performance of fault samples, and difficulty in application, achieving good versatility and scalability, realize automatic feature learning, and avoid the effect of feature engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation will be described in detail below in conjunction with the accompanying drawings.

[0025] A deep convolutional neural network-based fault diagnosis method for wind turbine bearings. The method includes diagnostic signal collection, diagnostic model establishment, model training and evaluation, and model application.

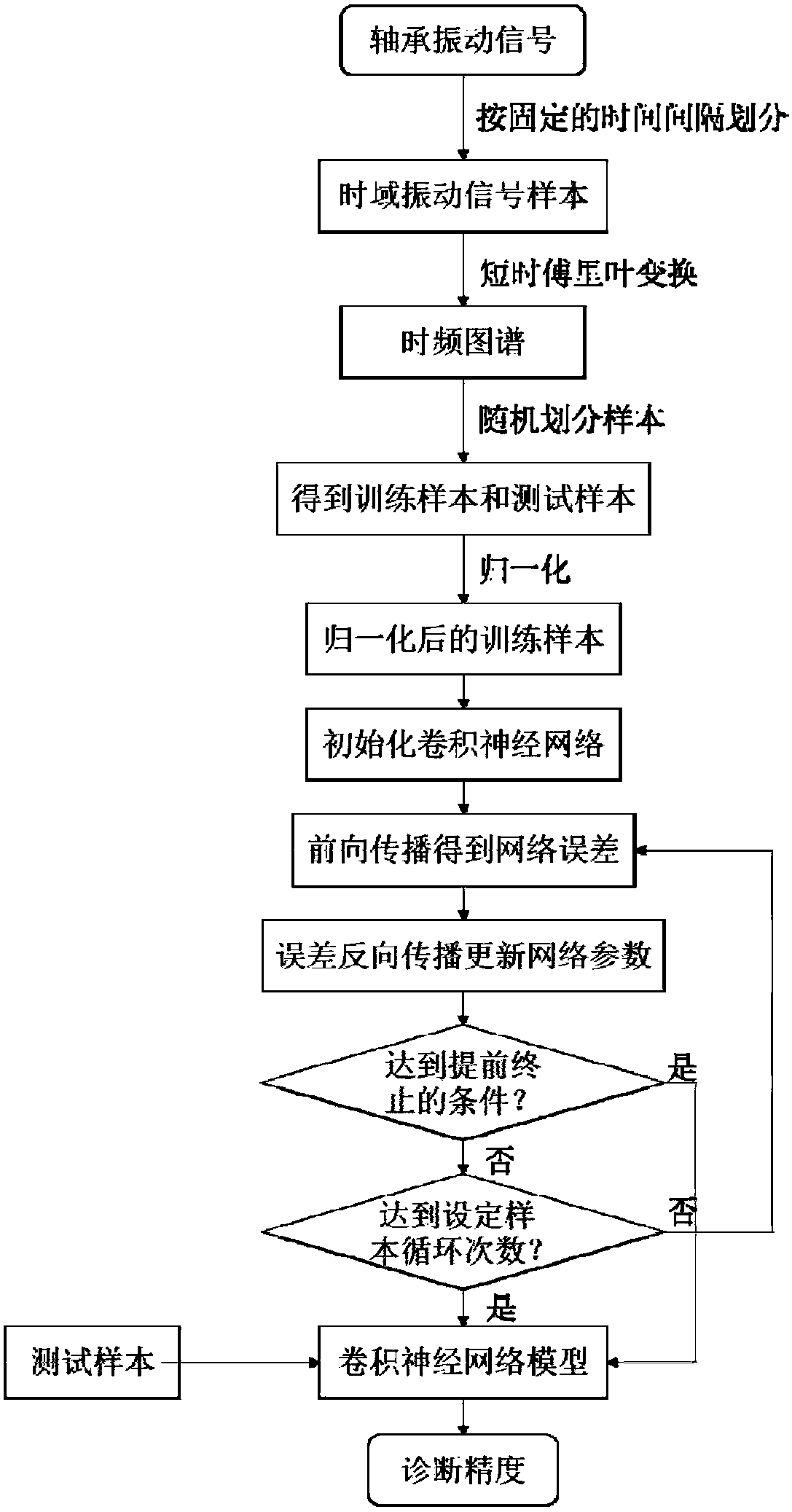

[0026] A wind turbine bearing fault diagnosis method based on deep convolutional neural network, such as figure 1 shown, including the following steps:

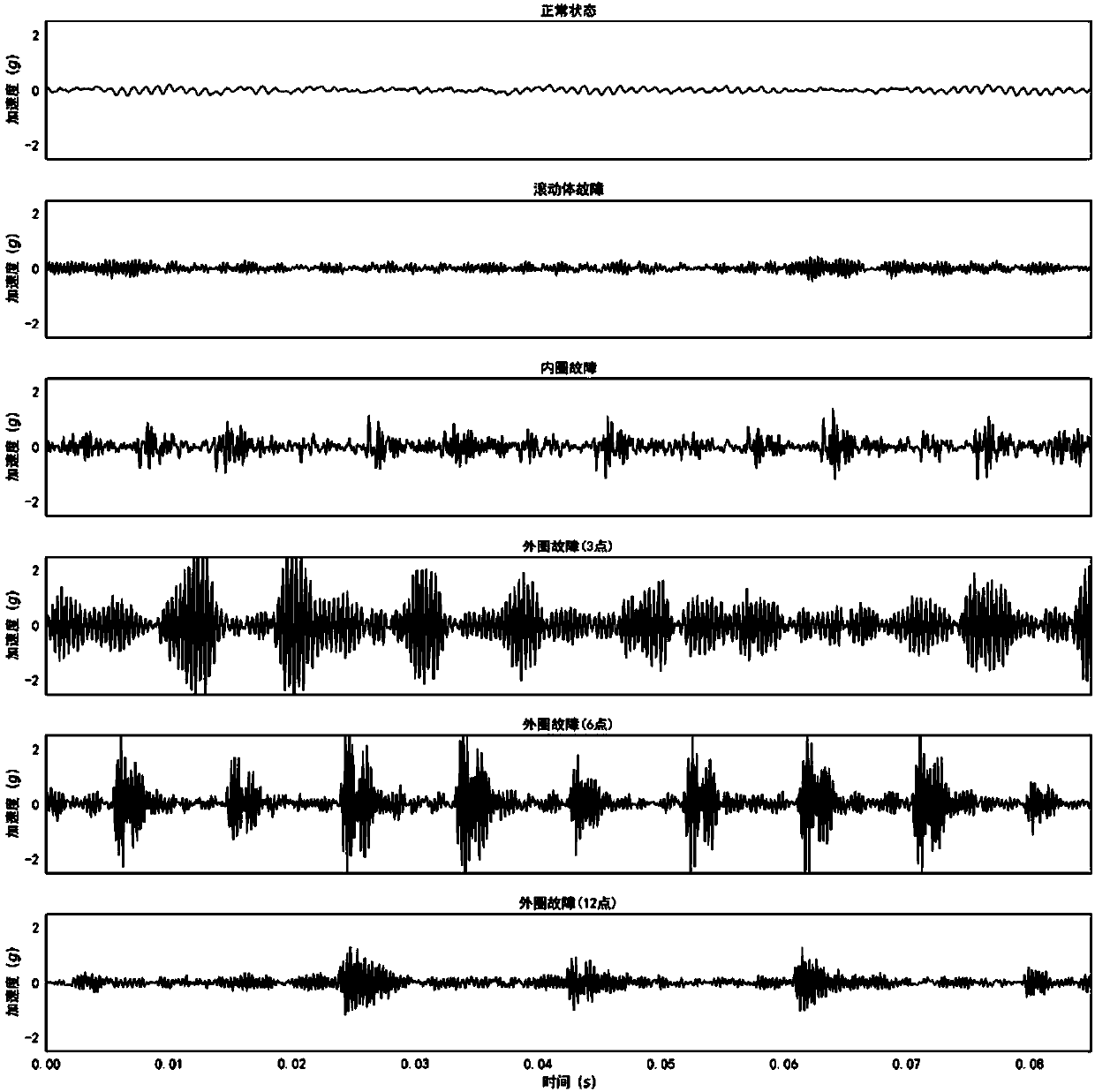

[0027] Step 1: Use the vibration acceleration sensor to simultaneously collect the high-frequency vibration acceleration signals of the driving end and the non-driving end of the test bearing in various states.

[0028] Step 2: Apply time-frequency analysis technology to the collected vibration signal to obtain the corresponding time-frequency spectrum.

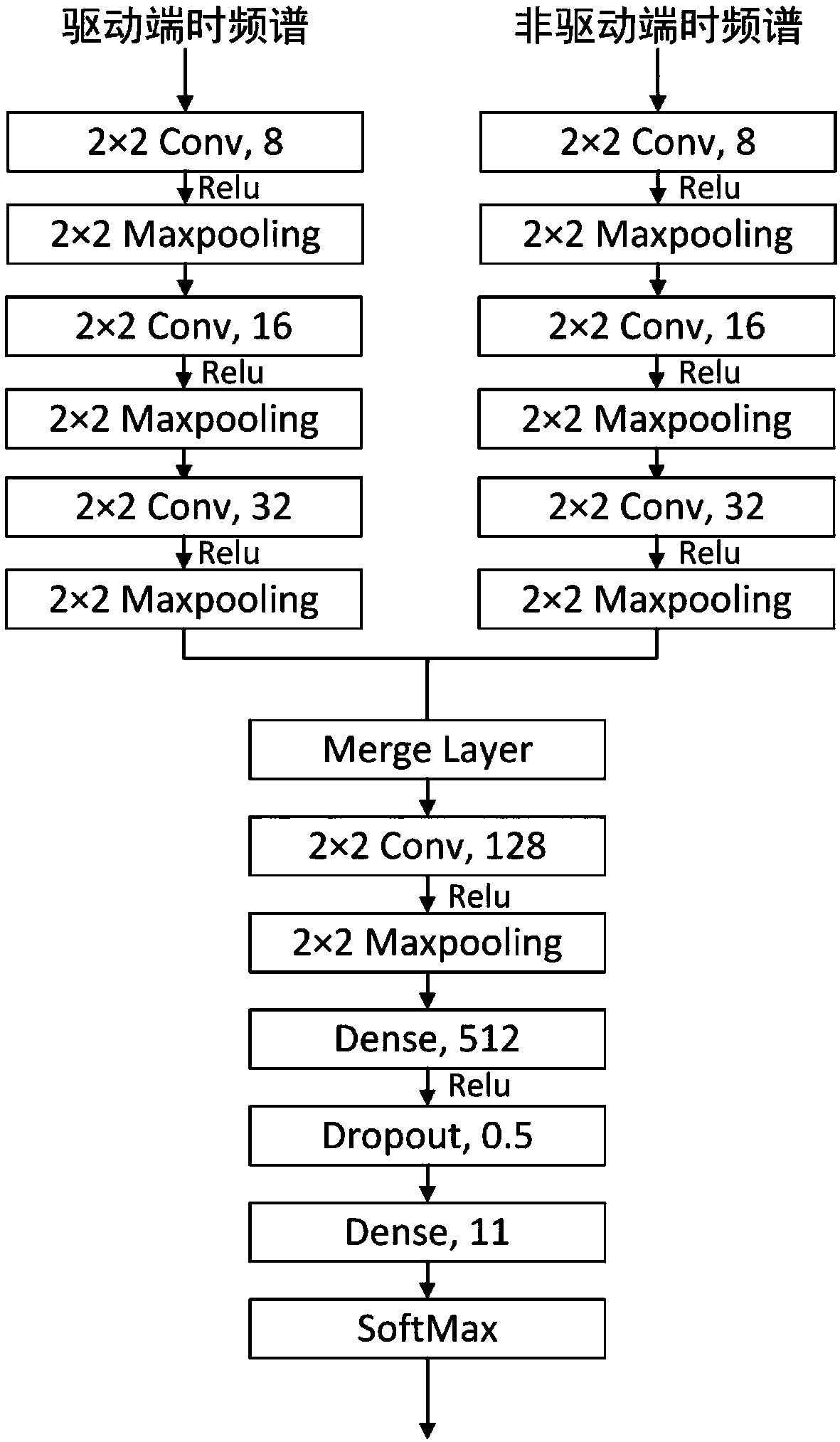

[0029] Step 3: Establish a deep convolutional neural network diagnostic model, and use the time-frequency spectrum and bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com