Environment-protective cleaning brush for embossing roller

A technology for printing rollers and cleaning brushes, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of unsatisfactory safety and reliability of digital printing presses, high maintenance costs, and low data transmission efficiency, so as to improve fault diagnosis. efficiency, improve safety and reliability, and improve the effect of data transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

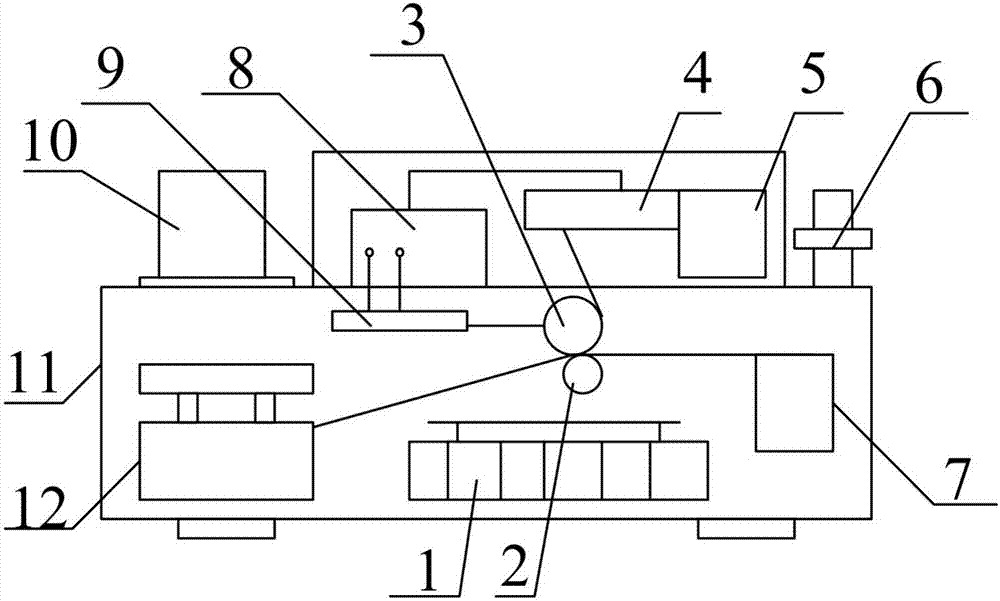

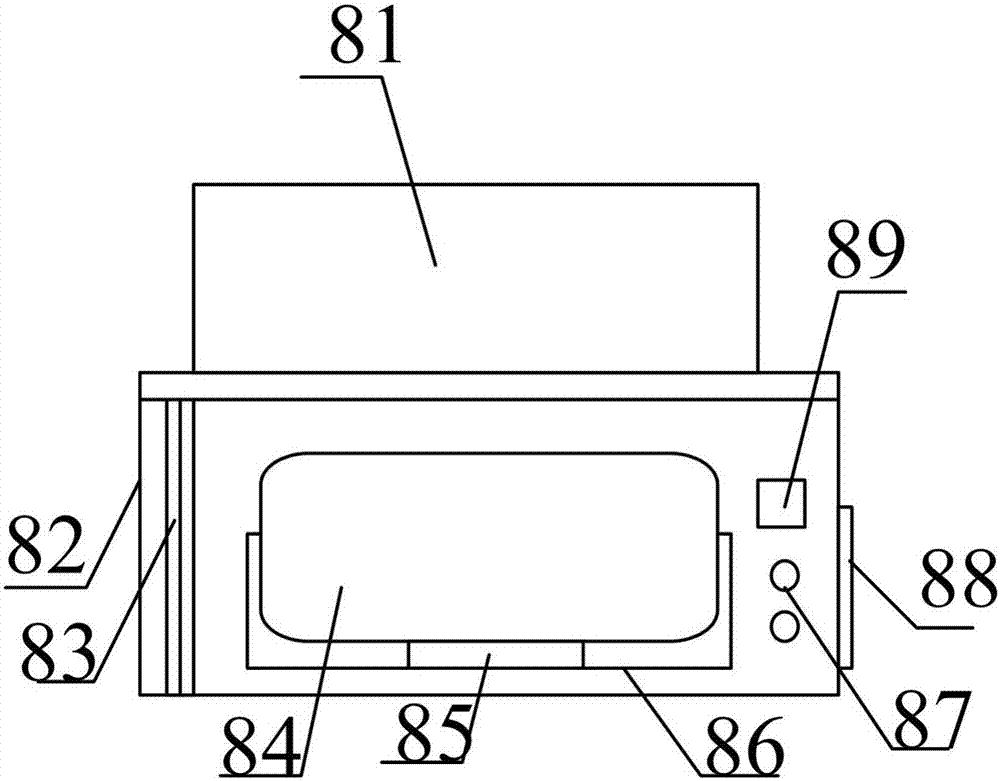

[0023] as attached figure 1 To attach figure 2 shown

[0024] The invention provides an environment-friendly printing roller cleaning brush, which includes a color printing device 1, an embossing cylinder 2, a rubber cylinder 3, a laser imager 4, a numerical control device 5, a signal transceiver 6, a printing paper conveyor 7, and a fault diagnosis device 8. Ink valve 9, control panel 10, machine body 11 and binding processor 12, the color printing device 1 is installed directly above the impression cylinder 2; the rubber cylinder 3 is installed on the upper side of the impression cylinder 2 The laser imager 4 is connected to the numerical control device 5; the signal transceiver 6 is connected to the fault diagnosis device 8 through a wire; the printing paper conveyor 7 is connected to the impression cylinder 2; the ink valve 9 is connected directly below the fault diagnosis device 8; the control panel 10 is installed on the upper part of the body 11; the binding processo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com