Fireproofing panel and preparation method thereof

A technology of sheet materials and raw materials, applied in the field of fireproof sheets and their preparation, can solve the problems of poor fireproof performance and low manufacturing cost of fireproof sheets, and achieve the effects of enhanced flame retardant performance, low cost, and simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

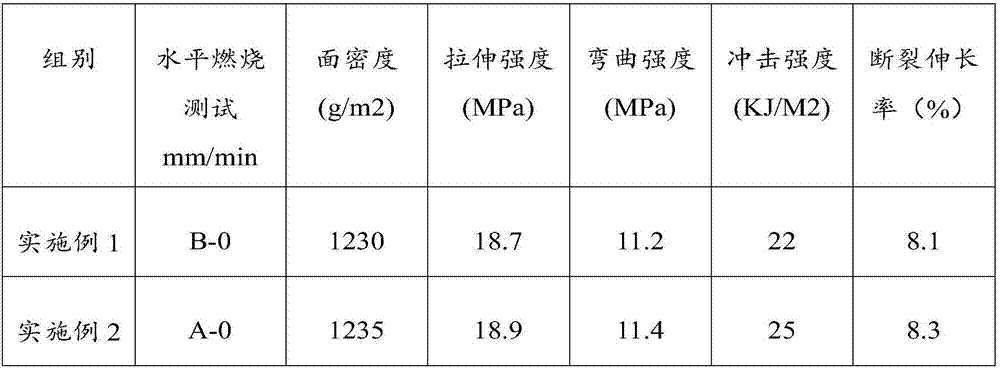

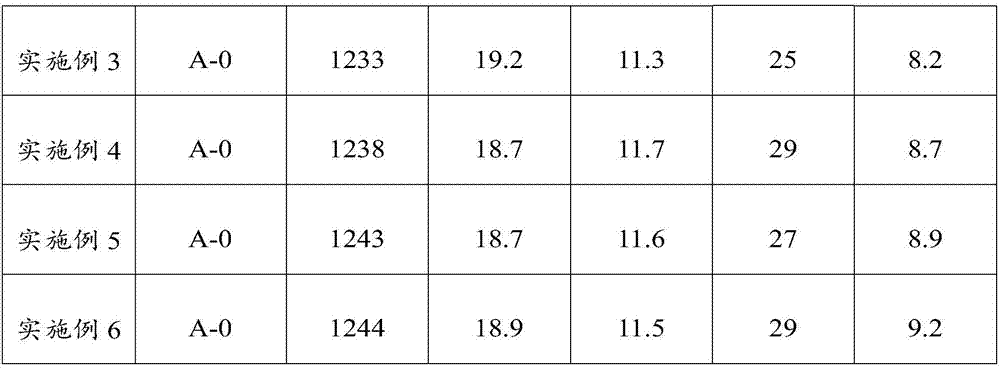

Examples

preparation example Construction

[0026] The embodiment of the present invention also provides a method for preparing a fireproof board, which includes the following steps: uniformly mixing metamorphic marble powder, reinforcing fiber, flame retardant, Portland cement and dispersant and pulverizing to obtain a mixed powder; mixing The powder is pressure-molded in a fixed mold.

[0027] The raw materials in the fireproof board of the present invention are added and mixed according to their respective proportions, crushed and then pressurized and formed in a fixed mold, and the hydraulic pressure is approximately 40-70 MPa. During the mixing process, a mechanical stirring device can be used to make the mixing more uniform.

[0028] Preferably, after molding, it can also be dried at a constant temperature to speed up the drying rate, and then cooled naturally after drying.

[0029] Specifically, the preparation process of the mixed powder includes: grinding metamorphic marble powder, reinforcing fiber and Portla...

Embodiment 1

[0032] This embodiment provides a kind of fire-proof board, and it is made of various raw materials, and counts by weight parts, and various raw materials include 25 parts of metamorphic marble powders, 6 parts of glass fibers, 3 parts of self-sulfidyl urea, 20 parts of silicic acid salt cement and 3 parts calcium stearate.

[0033] This embodiment also provides a method for preparing a fireproof board, which includes the following steps:

[0034] Mix 25 parts of metamorphic marble powder, 6 parts of glass fiber, 3 parts of self-mimidyl urea, 20 parts of Portland cement and 3 parts of calcium stearate and pulverize to obtain a mixed powder; mix the mixed powder with water to obtain The solution with a mass fraction of 50% is poured into a fixed mold for press molding, and the pressure of the hydraulic press is 50 MPa.

Embodiment 2

[0036] This embodiment provides a fireproof board, which is made of various raw materials. In parts by weight, the various raw materials include 40 parts of metamorphic marble powder, 15 parts of carbon fiber, 10 parts of zinc borate, 30 parts of Portland cement and 10 parts polyethylene glycol.

[0037] This embodiment also provides a method for preparing a fireproof board, which includes the following steps:

[0038] First, 40 parts of metamorphic marble powder, 15 parts of carbon fiber and 30 parts of Portland cement were ground to 1000 mesh to obtain a first mixed powder.

[0039] Secondly, the first mixed powder was stirred and mixed with 10 parts of zinc borate and 10 parts of polyethylene glycol at a temperature of 50° C. to obtain a mixed powder.

[0040] Finally, mix the mixed powder with water to obtain a solution with a mass fraction of 50%, and pour it into a fixed mold for press molding, and the pressure of the hydraulic press is 50 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com