Automatic horizontal correcting device for platform

An automatic correction and level correction technology, which is applied in the fields of electrical components, printed circuit manufacturing, printed circuits, etc., can solve the problems of insurmountable platform bearing capacity, poor operation efficiency, platform level deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

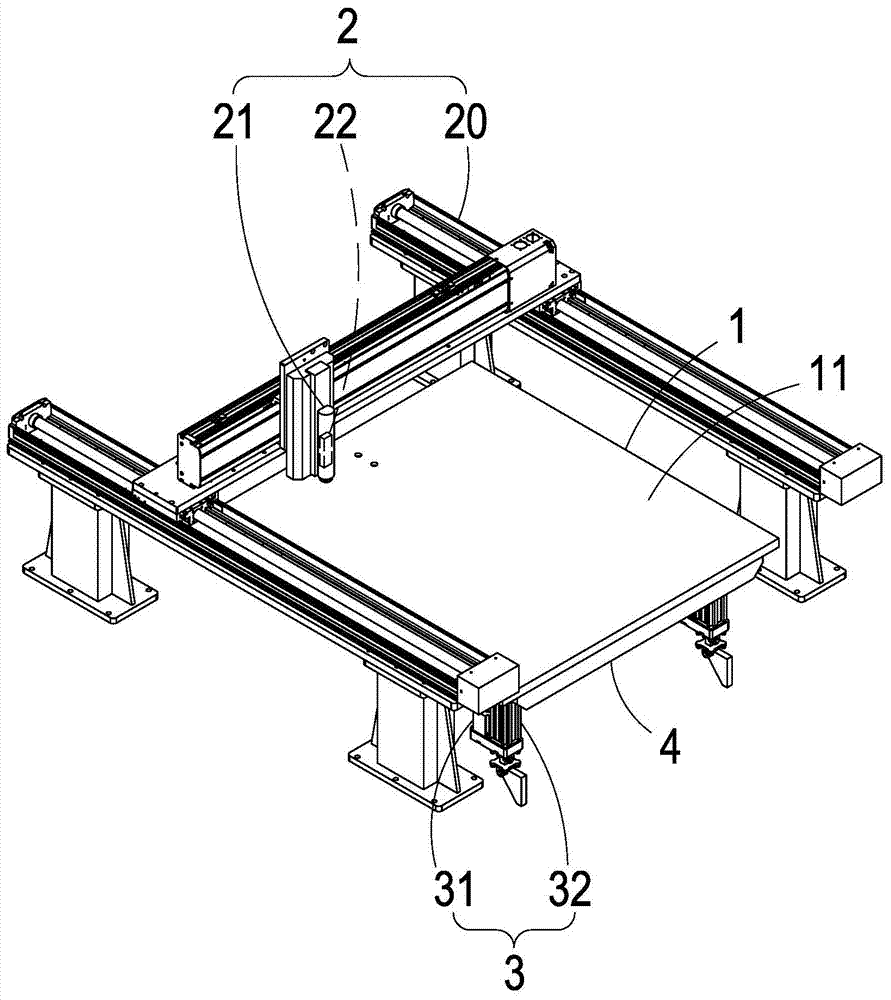

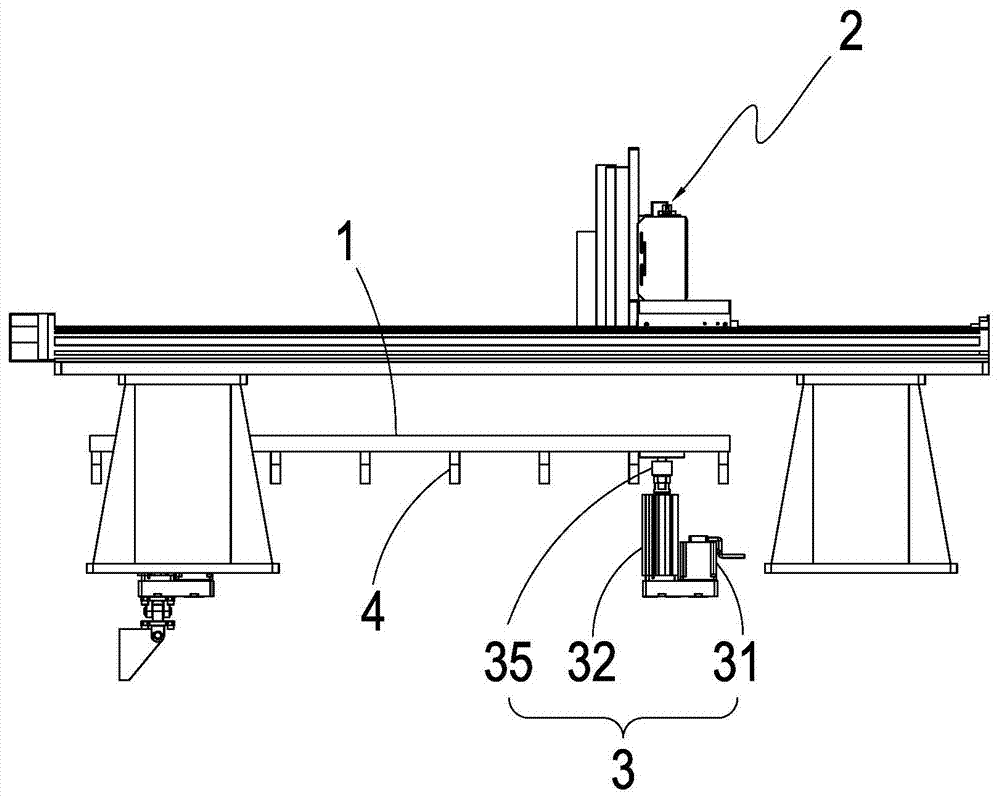

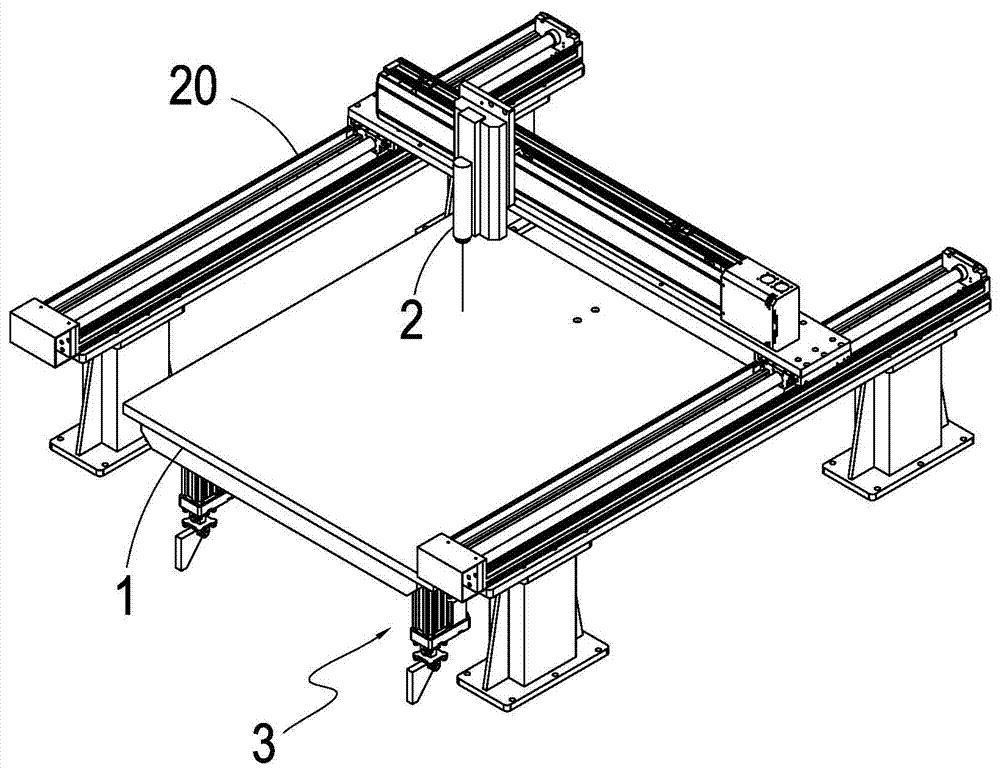

[0046] see figure 1 and figure 2 Shown, be the three-dimensional perspective view and the side view of preferred embodiment of the present invention, can clearly find out that the present invention comprises from the figure:

[0047] A carrying platform 1, the carrying platform 1 is one of a dispensing machine platform, a printing machine platform or a screen printing machine platform;

[0048] a bearing surface 11 arranged on the surface of the bearing platform 1;

[0049] At least one horizontal detection device 2 arranged on one side of the carrying platform 1, the horizontal detection device 2 includes a moving mechanism 20 providing displacement in three-axis directions, a laser generator 21 arranged on the moving mechanism 20, The laser generator 21 uses the laser signal to measure the level value, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com