Camshaft segment with camshaft bearing

A technology of camshafts and segments, applied in the direction of shafts and bearings, elements with teeth, bearings, etc., can solve problems such as high weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

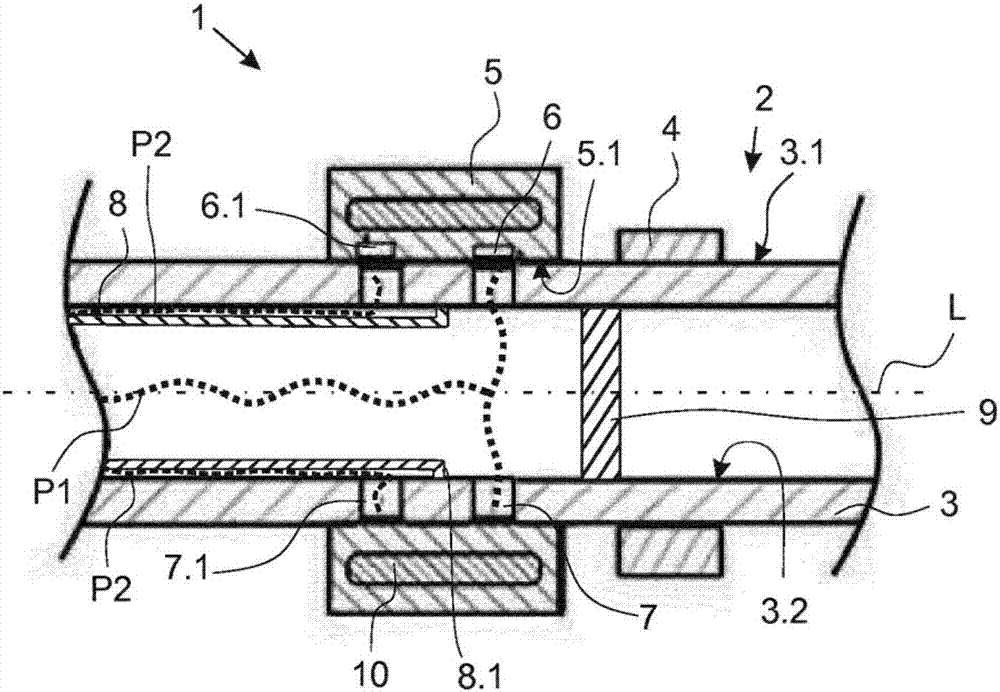

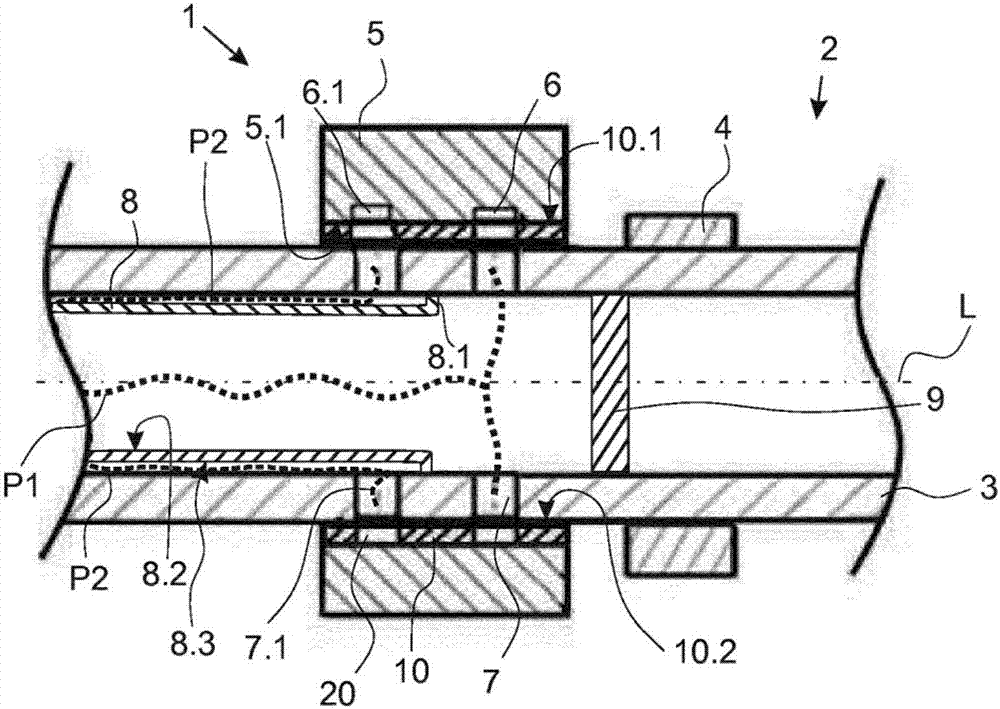

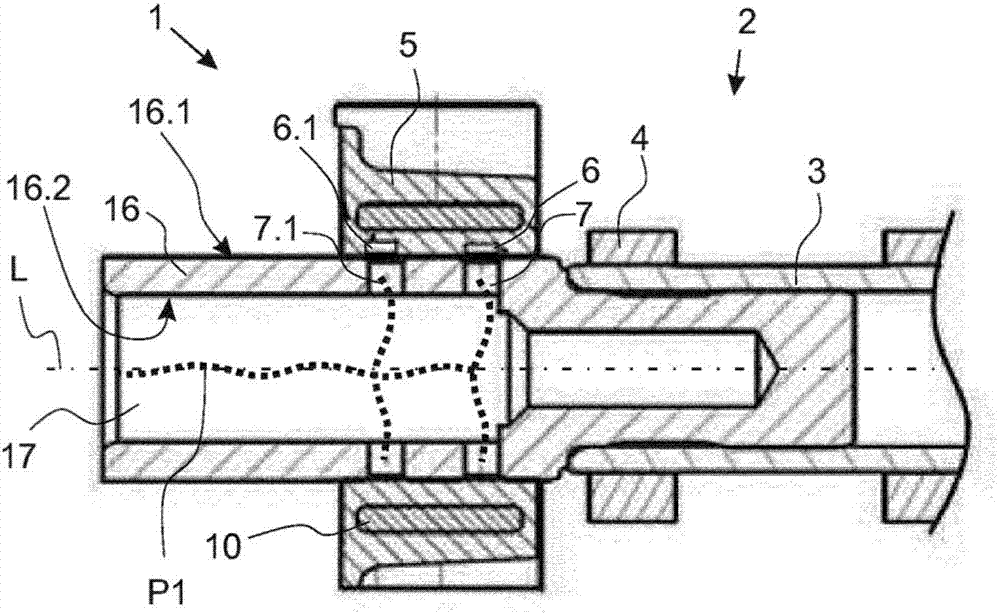

[0023] figure 1 A cross-sectional view of a detail of an embodiment, in particular a first embodiment, of a camshaft segment 1 according to the invention is schematically shown. The camshaft section 1 has in particular a camshaft 2 with a shaft element 3 and a cam element 4 fixedly connected to the shaft element 3 for rotation with the shaft element 3 . The shaft element 3 is advantageously a hollow shaft or has at least one cavity extending at least partially in the axial direction of the shaft element 3 , that is to say along the longitudinal axis L of the shaft element 3 . The camshaft bearing 5 serves to mount the camshaft 2 , in particular the shaft element 3 of the camshaft 2 . The camshaft bearing 5 is advantageously a constituent part of the camshaft section 1 and has a reduction element 10 which is completely enclosed by the material of the camshaft bearing 5 and which according to the finished camshaft bearing 5 at least partially surrounds the shaft in the circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com