Pearl shell factory-like recirculating aquaculture system and method

A technology of recirculating aquaculture and aquaculture system, which is applied in the field of industrialized recirculating aquaculture system of pearl oysters. The effect of simple and effective control, maintaining normal growth and survival requirements, and stabilizing bait supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

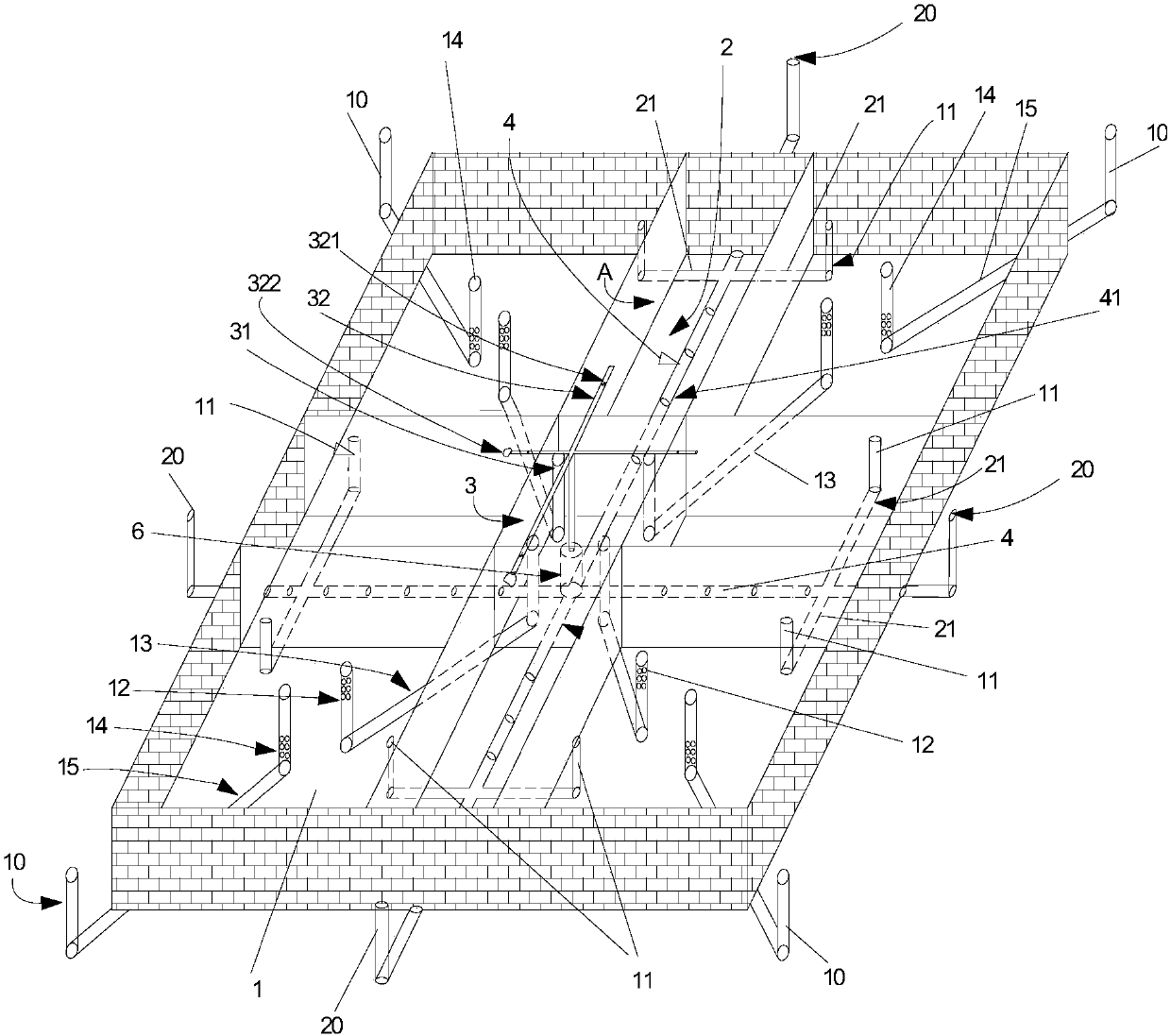

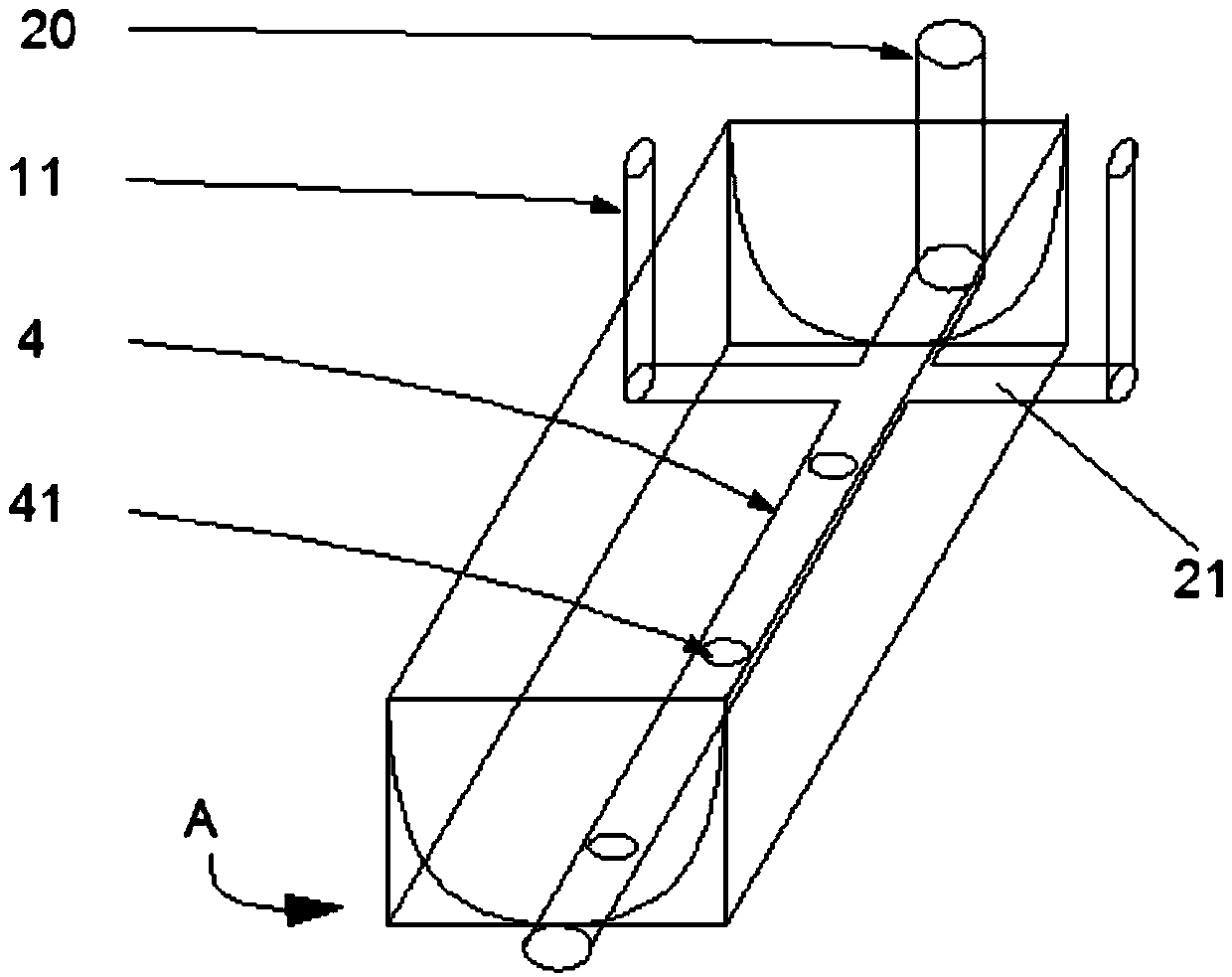

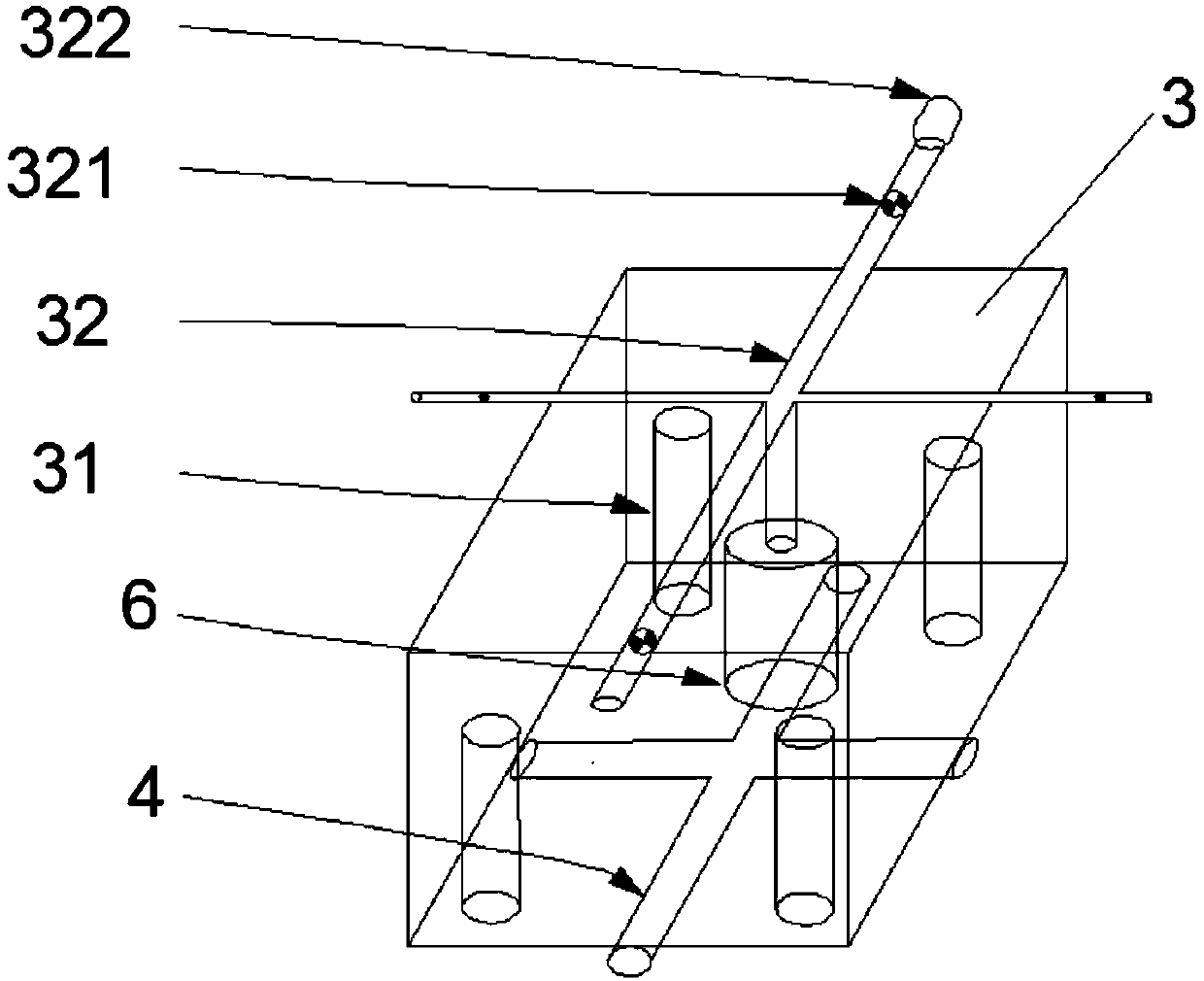

[0040] like figure 1As shown in -3, the pearl oyster industrialized recirculating aquaculture system of the present invention includes a bait cultivation pond 1, a shellfish cultivation pond 2 and a return tank 3. Their layout is as follows: In a large breeding pond, 9 independent small pools are separated by a "well"-shaped partition wall, with 1 small pool in the middle as the return tank 3, and 4 small pools at the corners It is the bait cultivation pond 1, and the remaining 4 small ponds are then used as the shellfish cultivation pond 2. The bait and the pearl oyster are cultivated in separate pools, and the environment control is simple and effective. Each of the four bait cultivation ponds 1 can carry out bait cultivation independently, and a plurality of bait cultivation ponds 1 can provide bait for shellfish cultivation ponds in rotation, which is conducive to ensuring sufficient and stable bait supply. The layout of the pools in the culture system of the present inv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap