Patents

Literature

50results about How to "Utilization area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

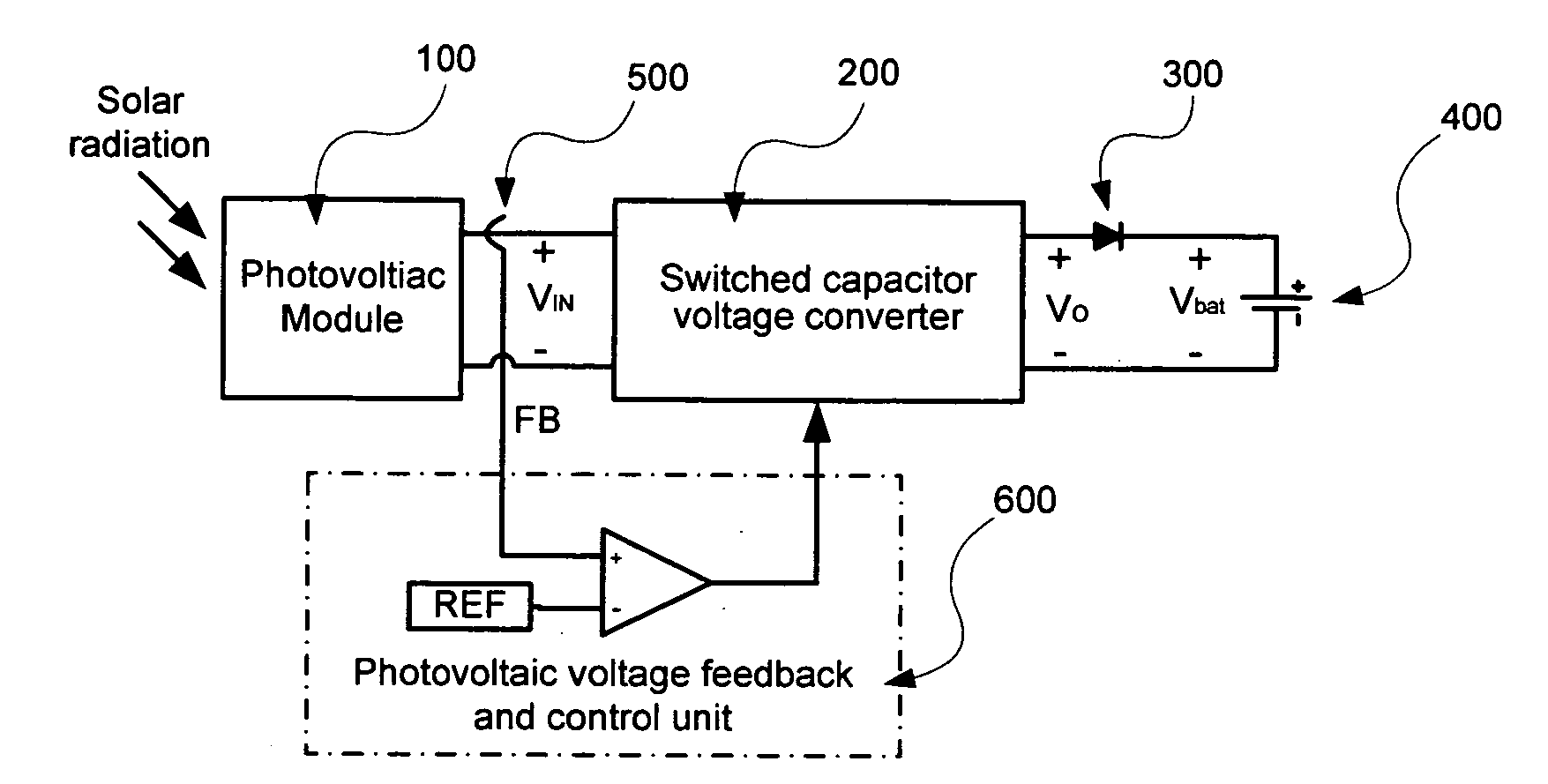

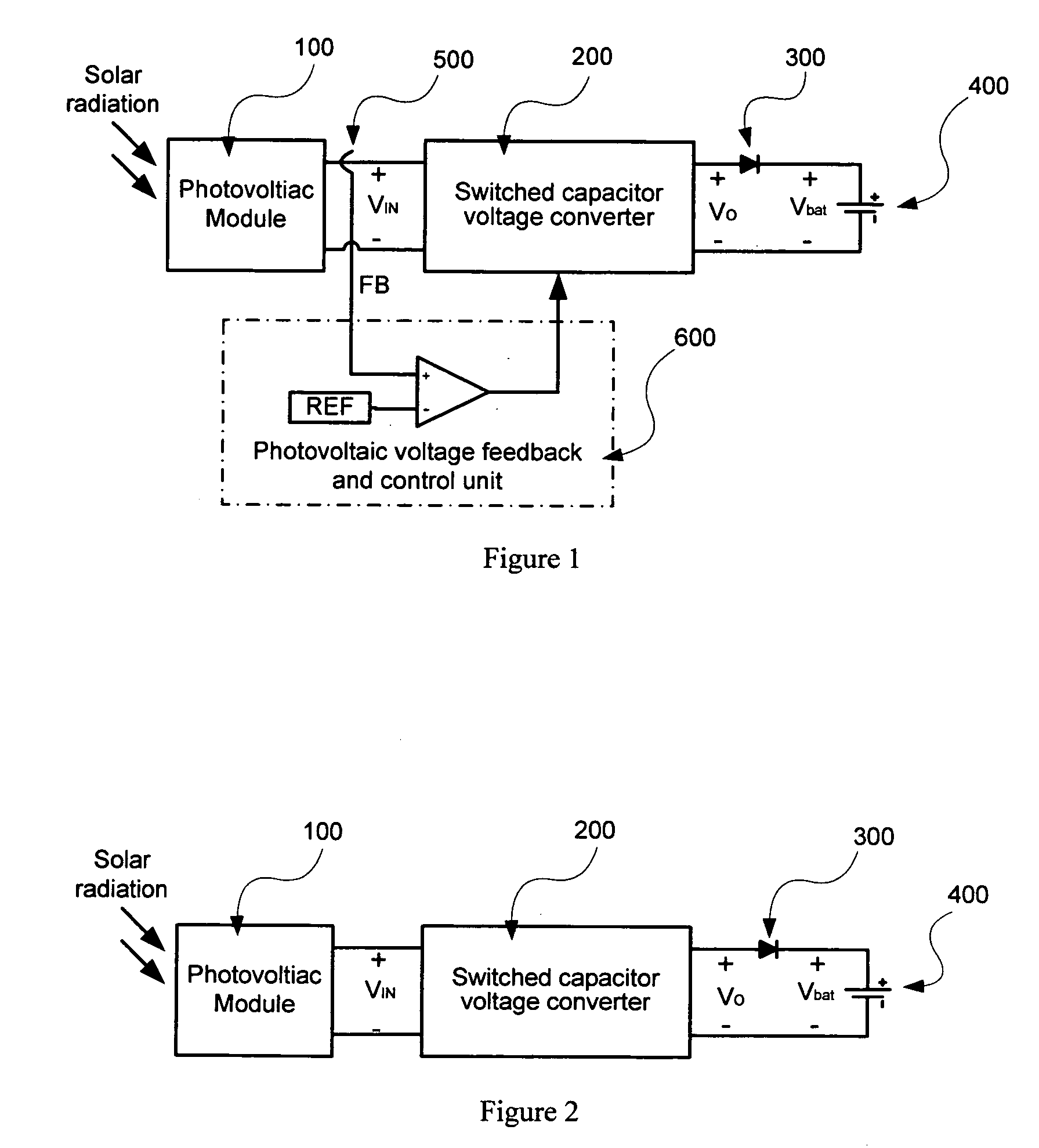

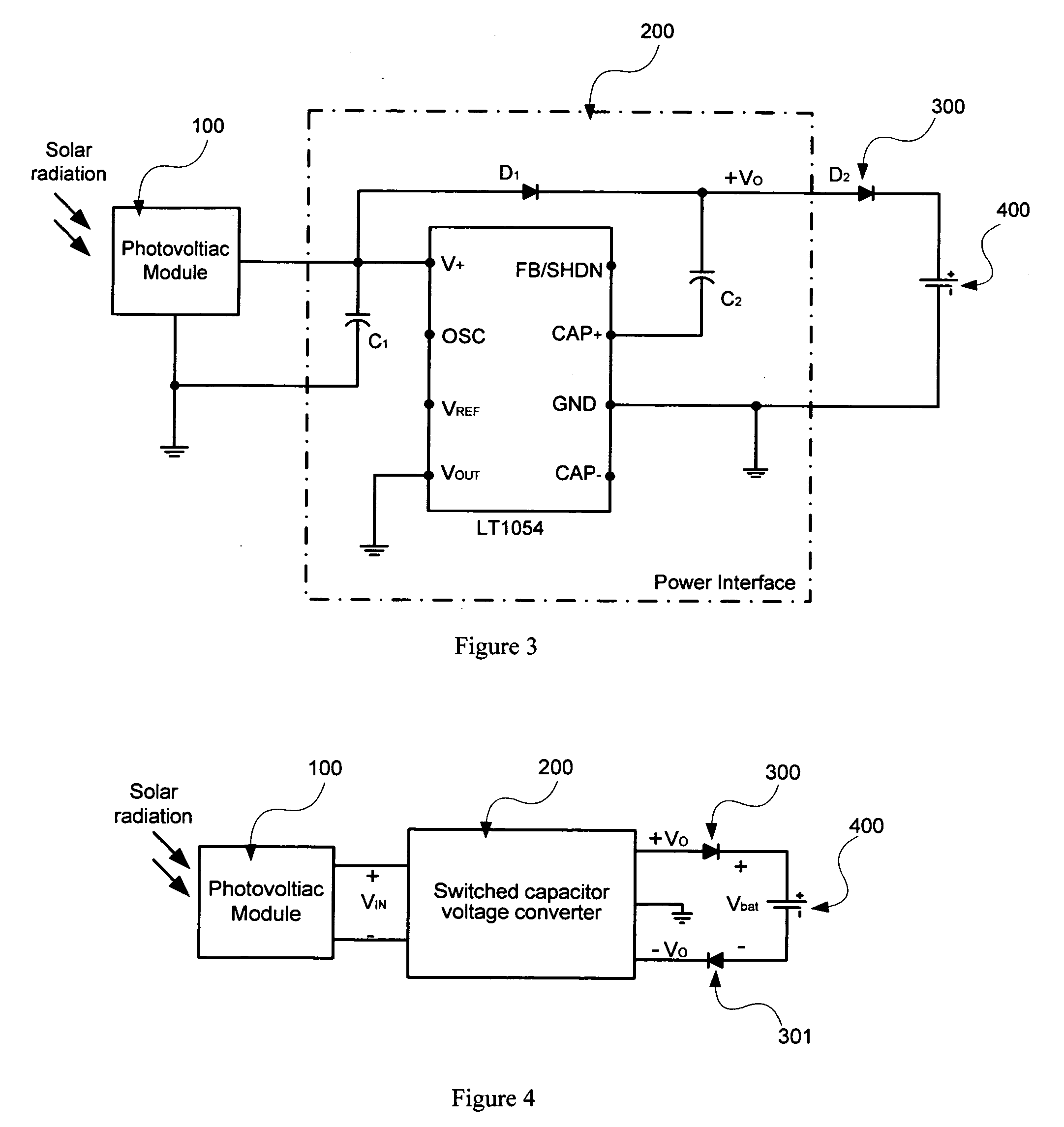

Solar powered battery charger using switch capacitor voltage converters

InactiveUS20090079385A1Low costEliminate battery drainageBatteries circuit arrangementsApparatus without intermediate ac conversionVoltage converterLow voltage

The invention provides a charging device that uses switched capacitor voltage converters to charge a battery using solar power. The charger uses boosting topology to efficiently use solar module photovoltaic power. The boosting topology enables a lower voltage to be used resulting in reduced cutting and soldering of photovoltaic cells. The battery charger has overcharge protection and uses inductor-less circuitry.

Owner:MSR INNOVATIONS

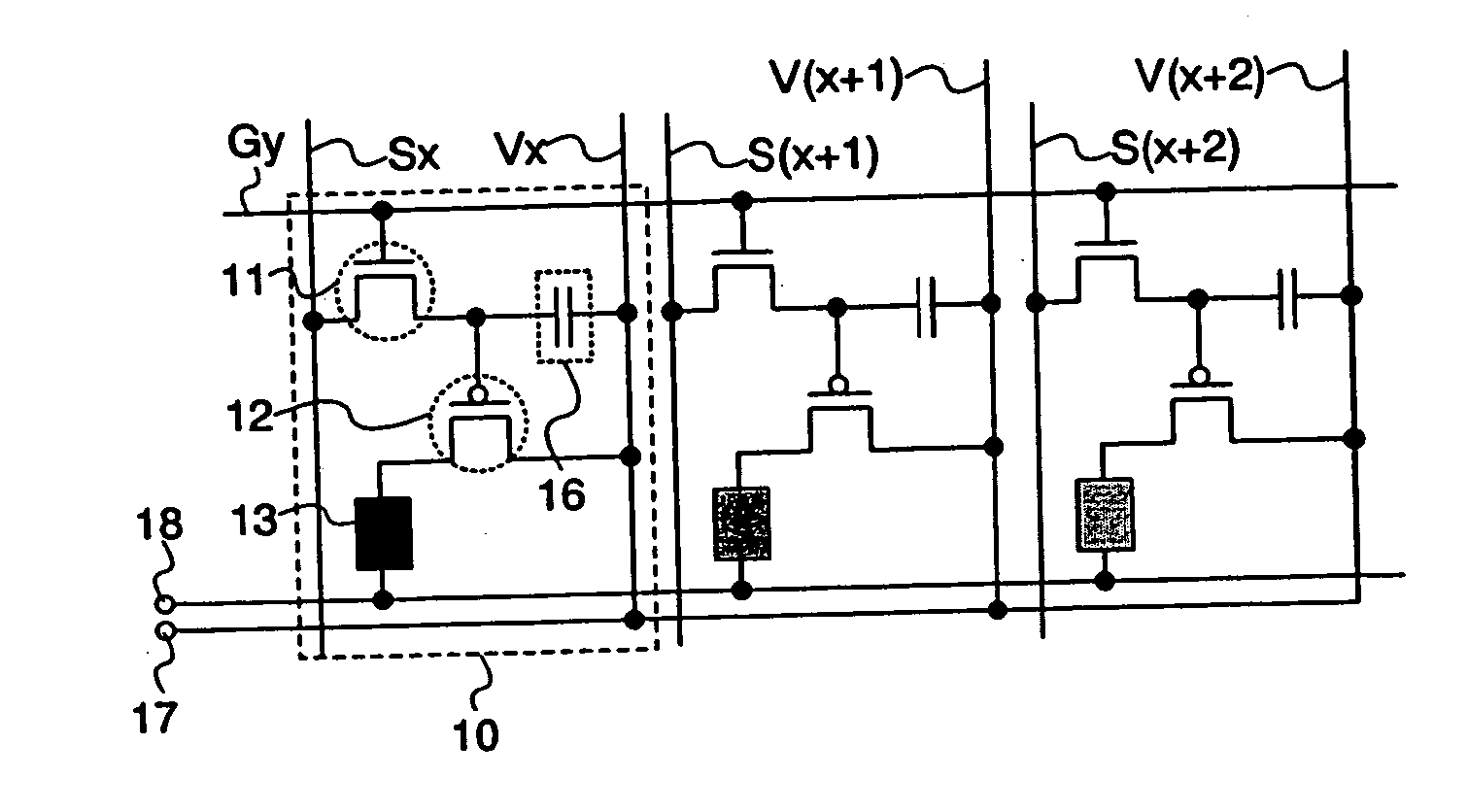

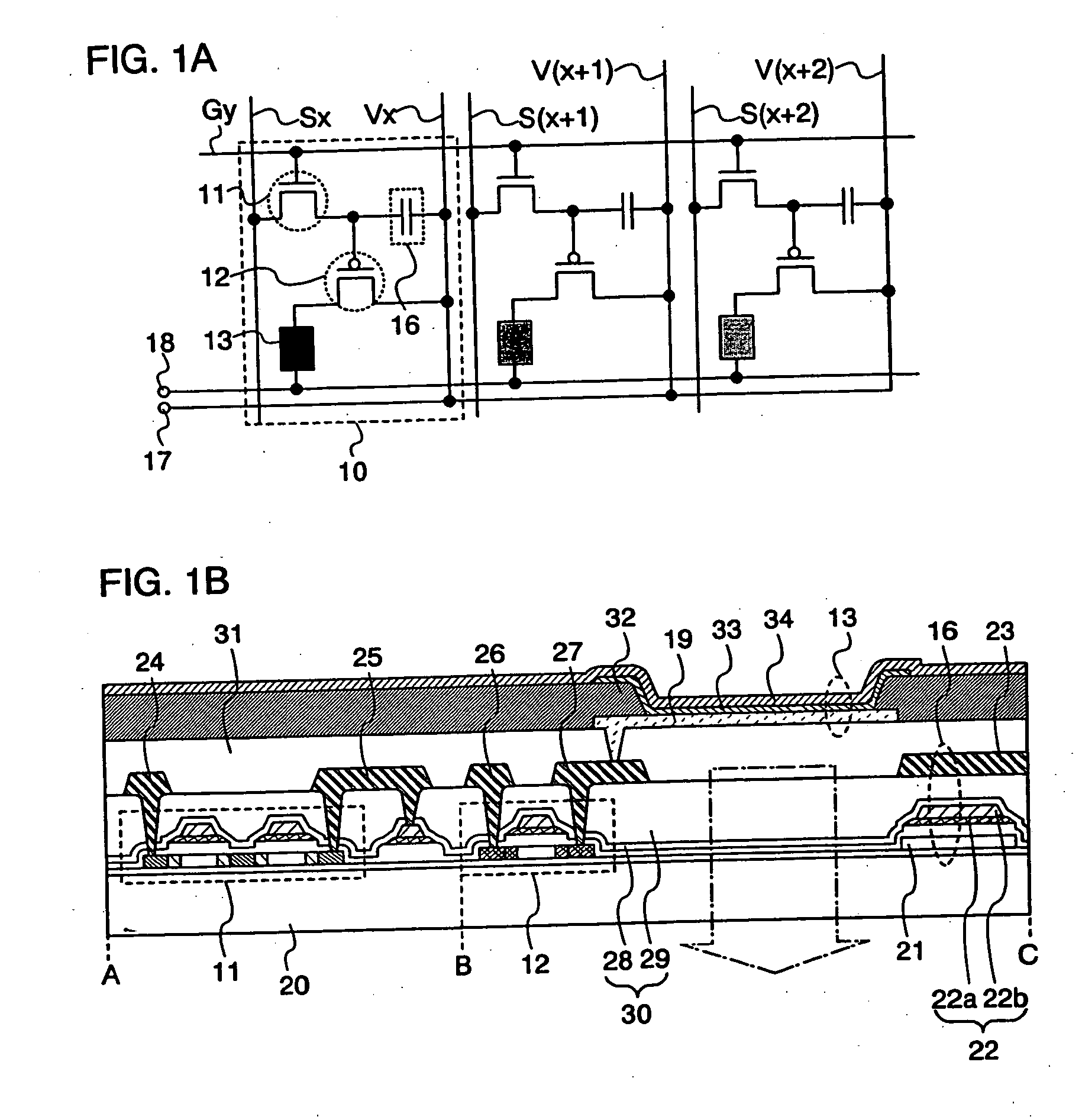

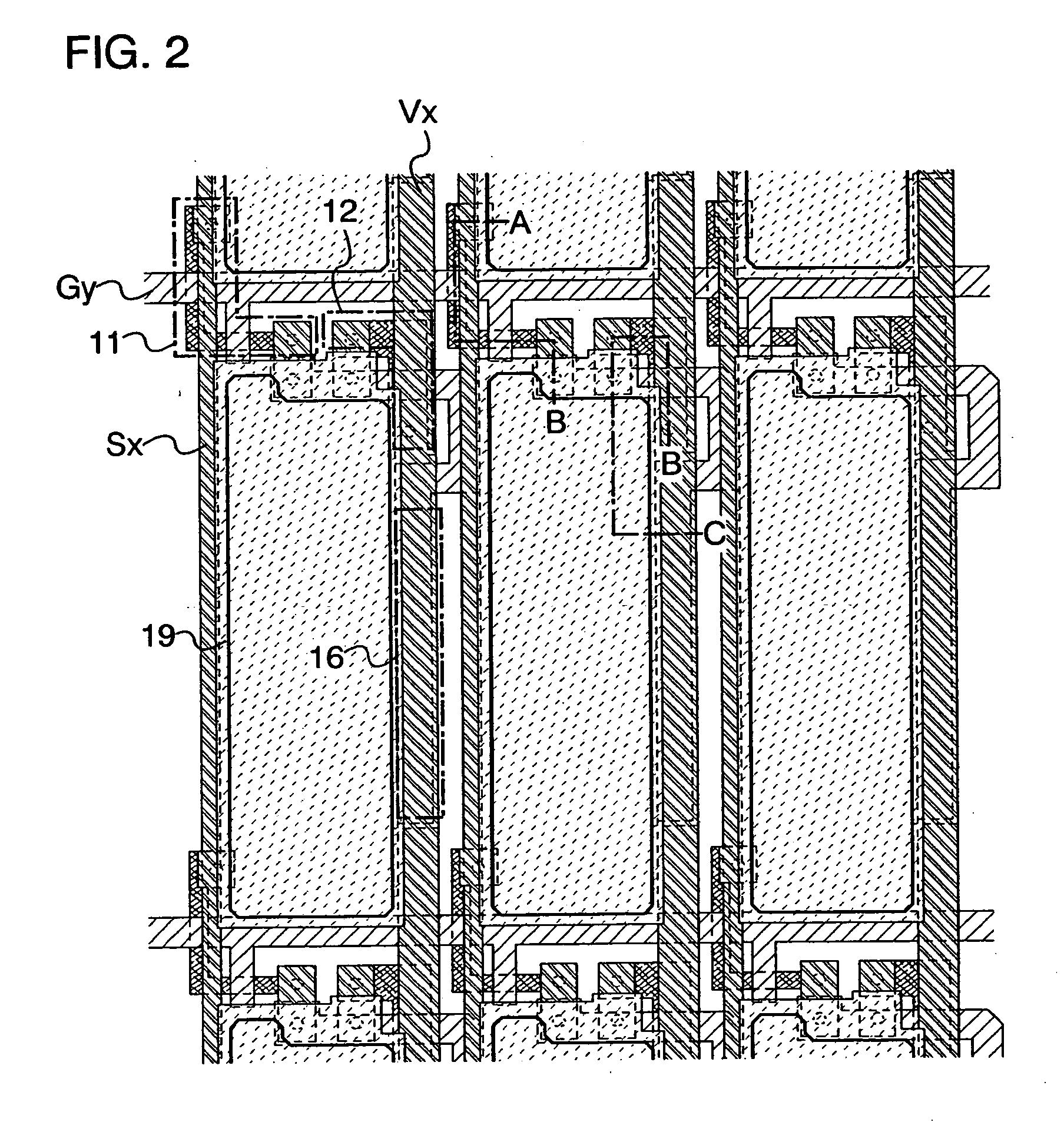

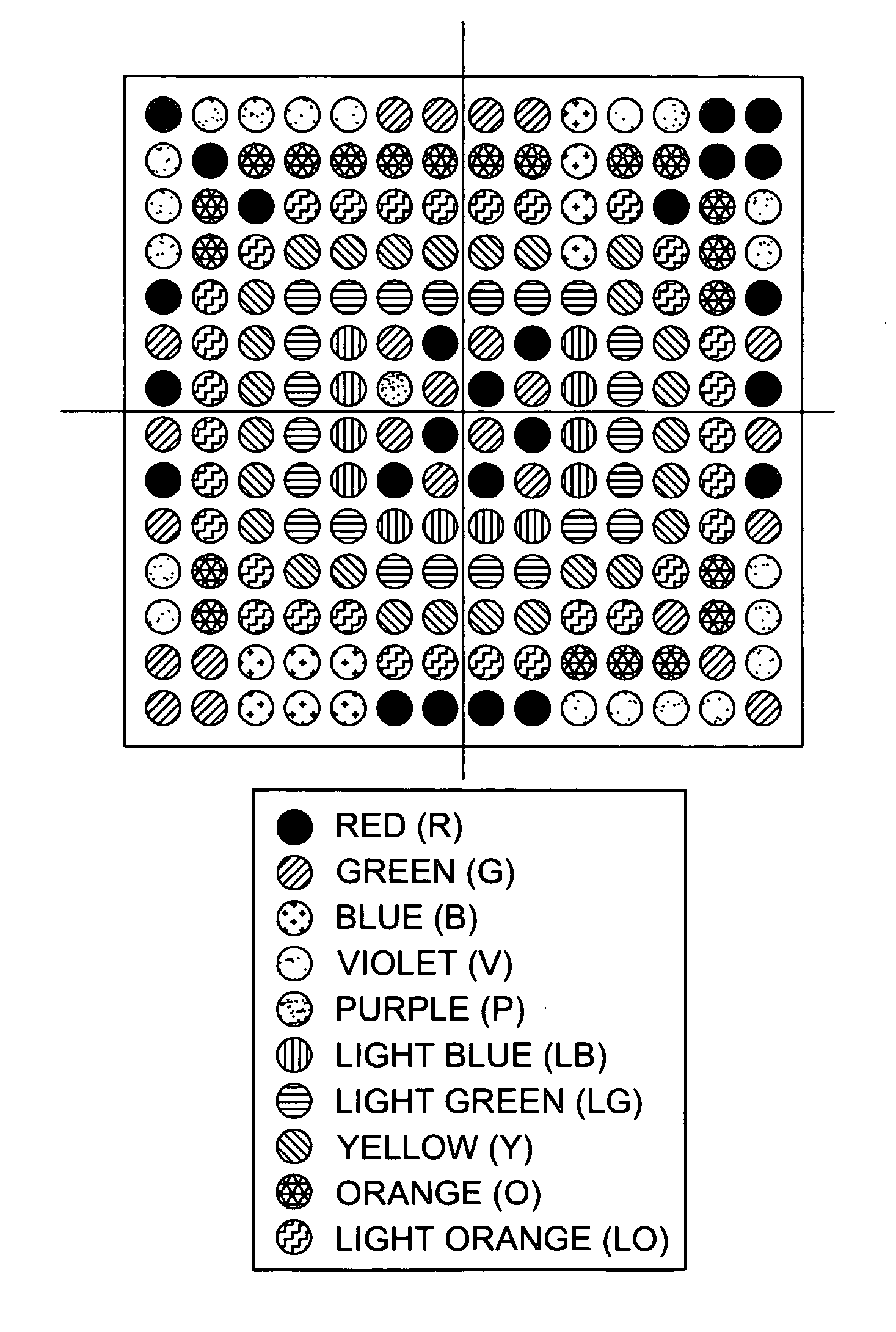

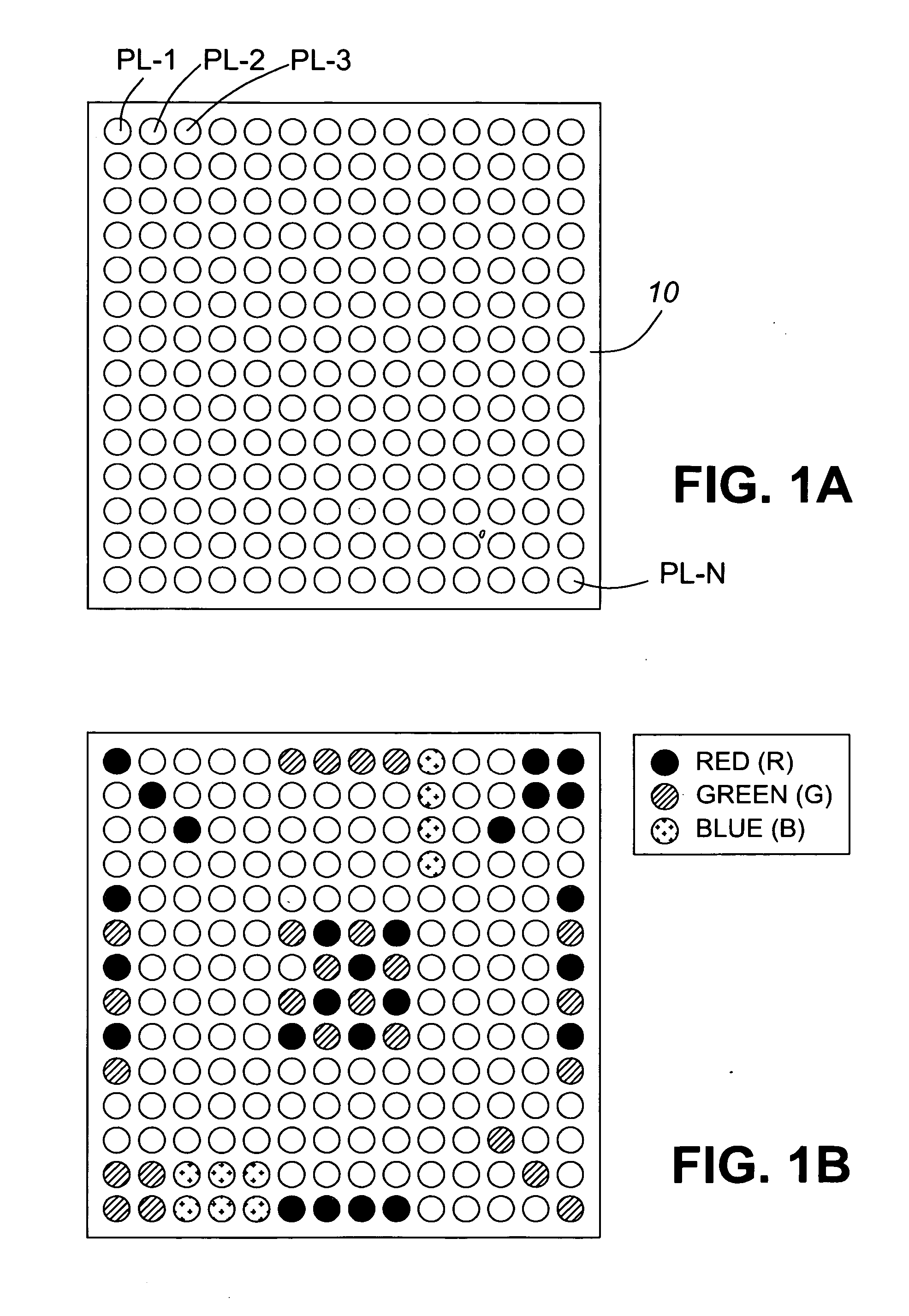

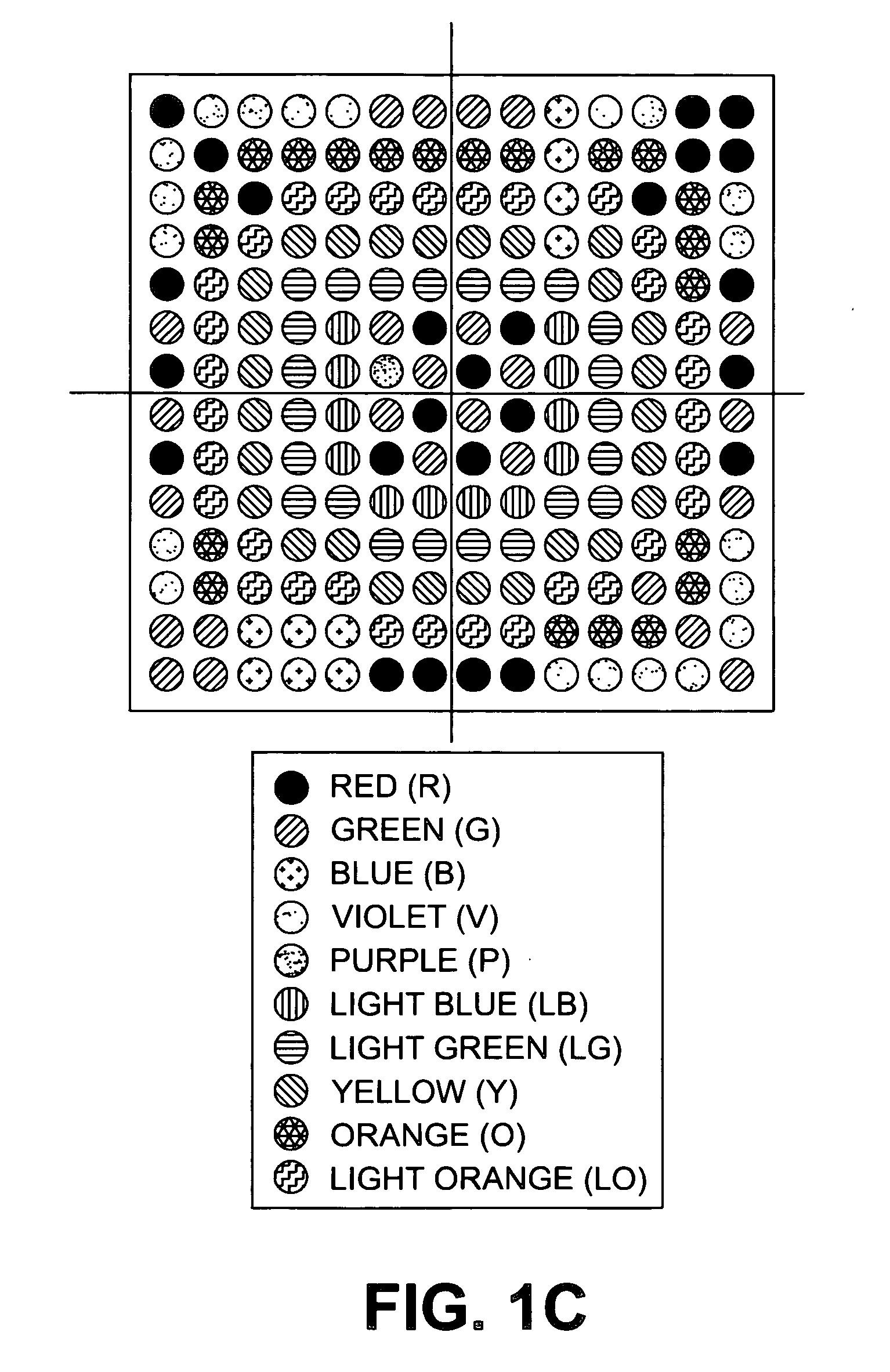

Display device and electronic appliance

InactiveUS20050205880A1Reduce power consumptionReduce the driving voltageStatic indicating devicesElectroluminescent light sourcesDisplay deviceEngineering

A low power consumption display device and an electronic appliances are provided. The display device of the invention comprises a pixel region including a plurality of pixels, a source driver, a first gate driver, and a second gate driver. Each of the plurality of pixels includes a light emitting element, a first transistor for controlling a video signal input to the pixel, a second transistor for controlling emission / non-emission of the light emitting element.

Owner:SEMICON ENERGY LAB CO LTD

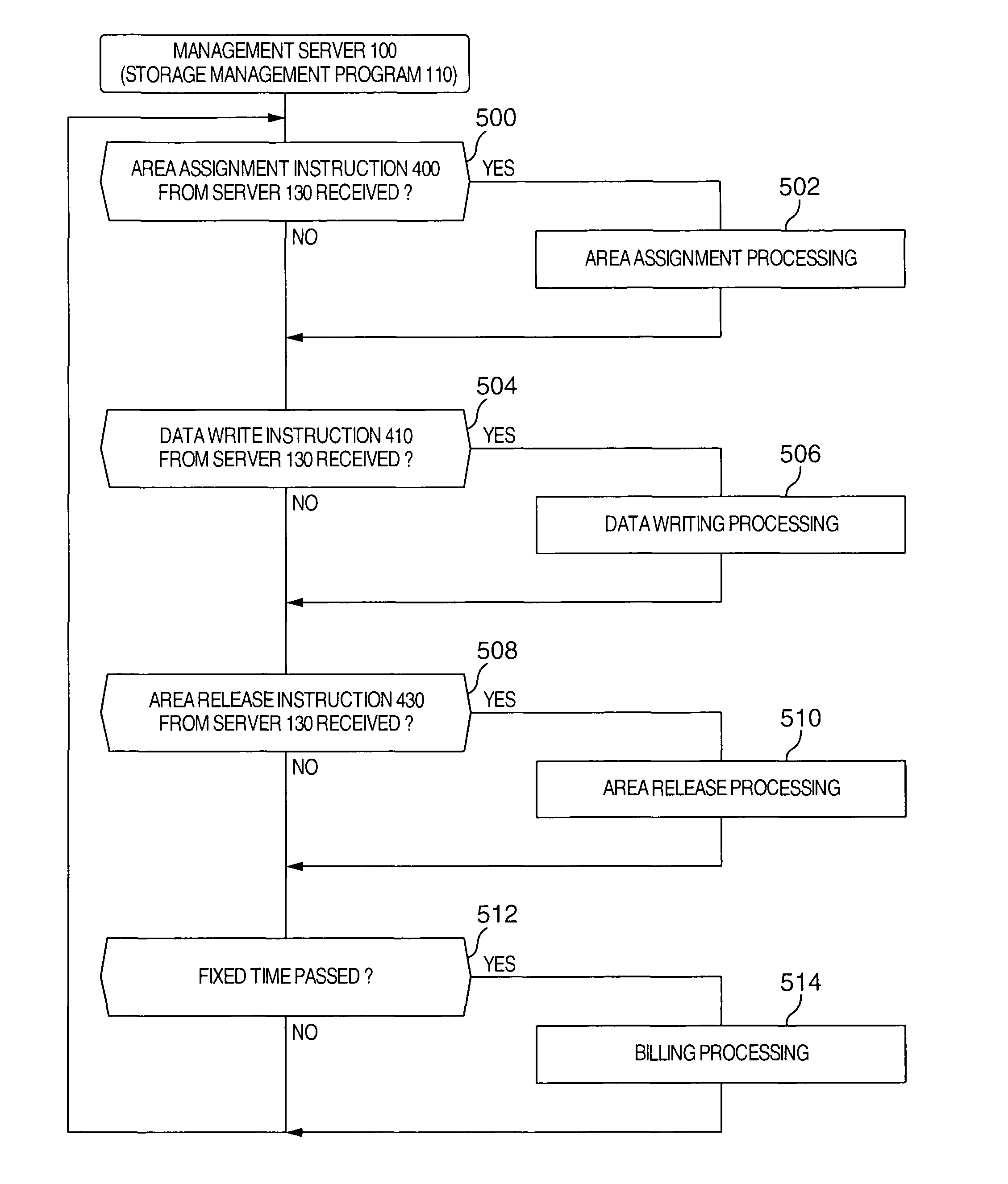

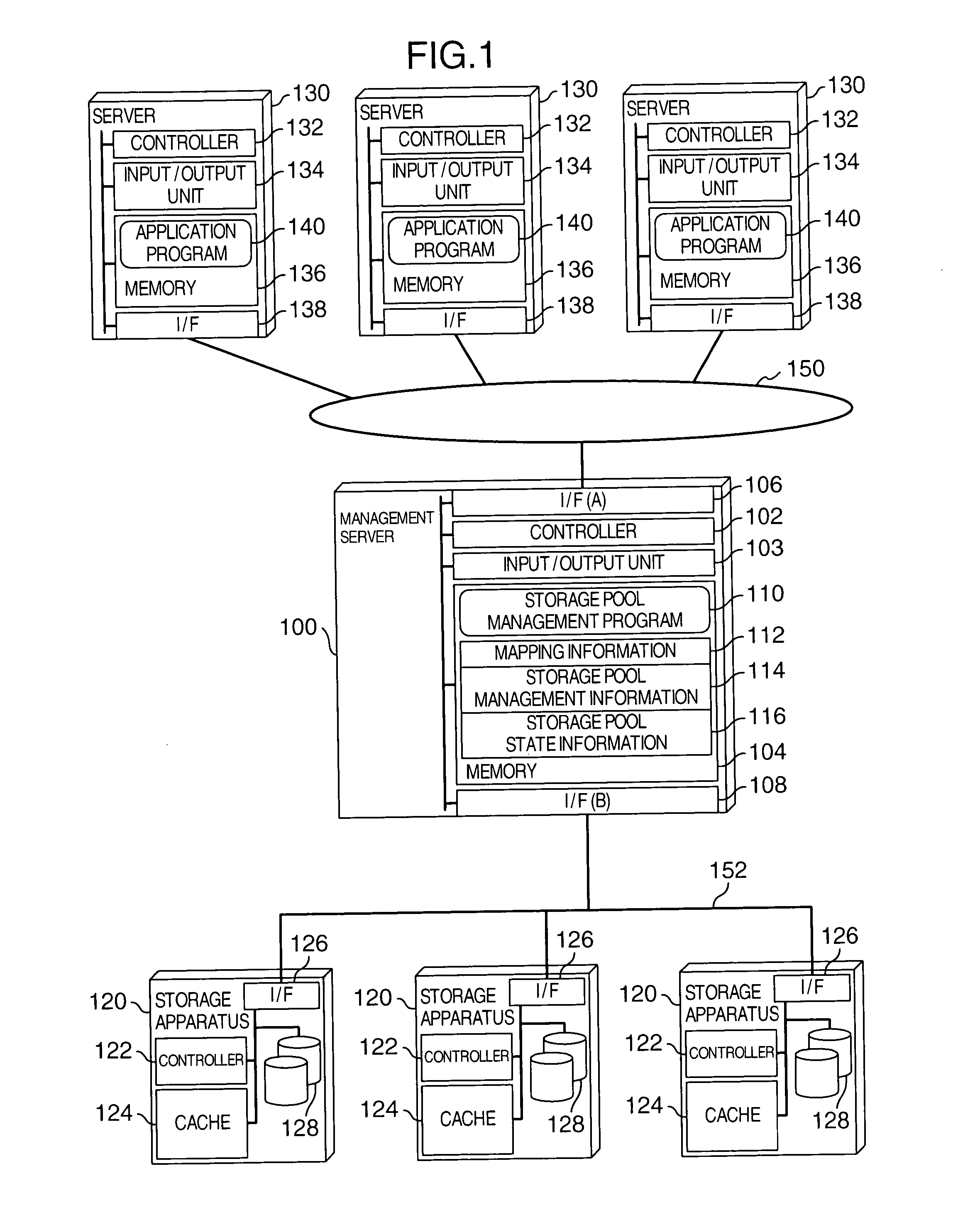

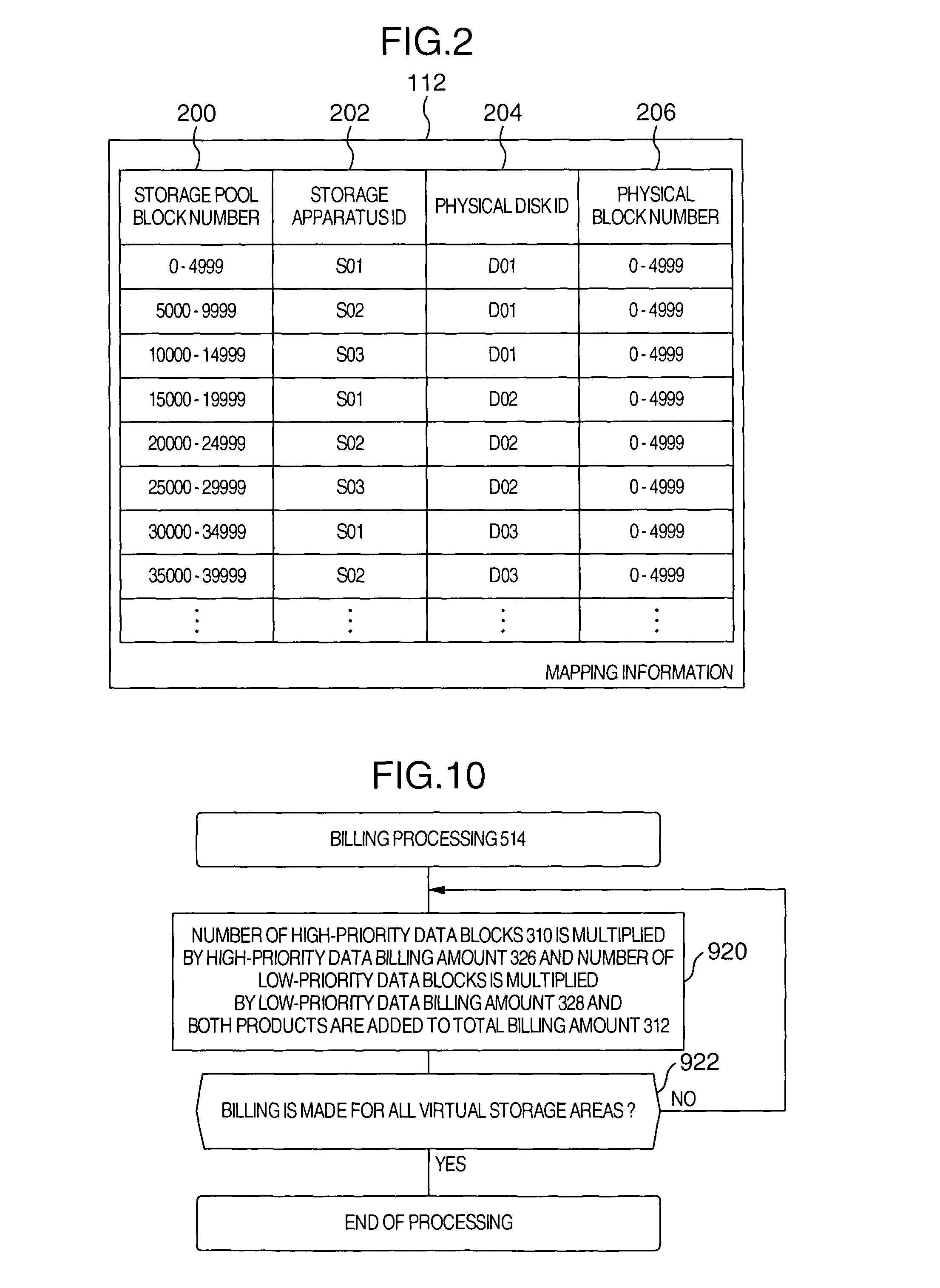

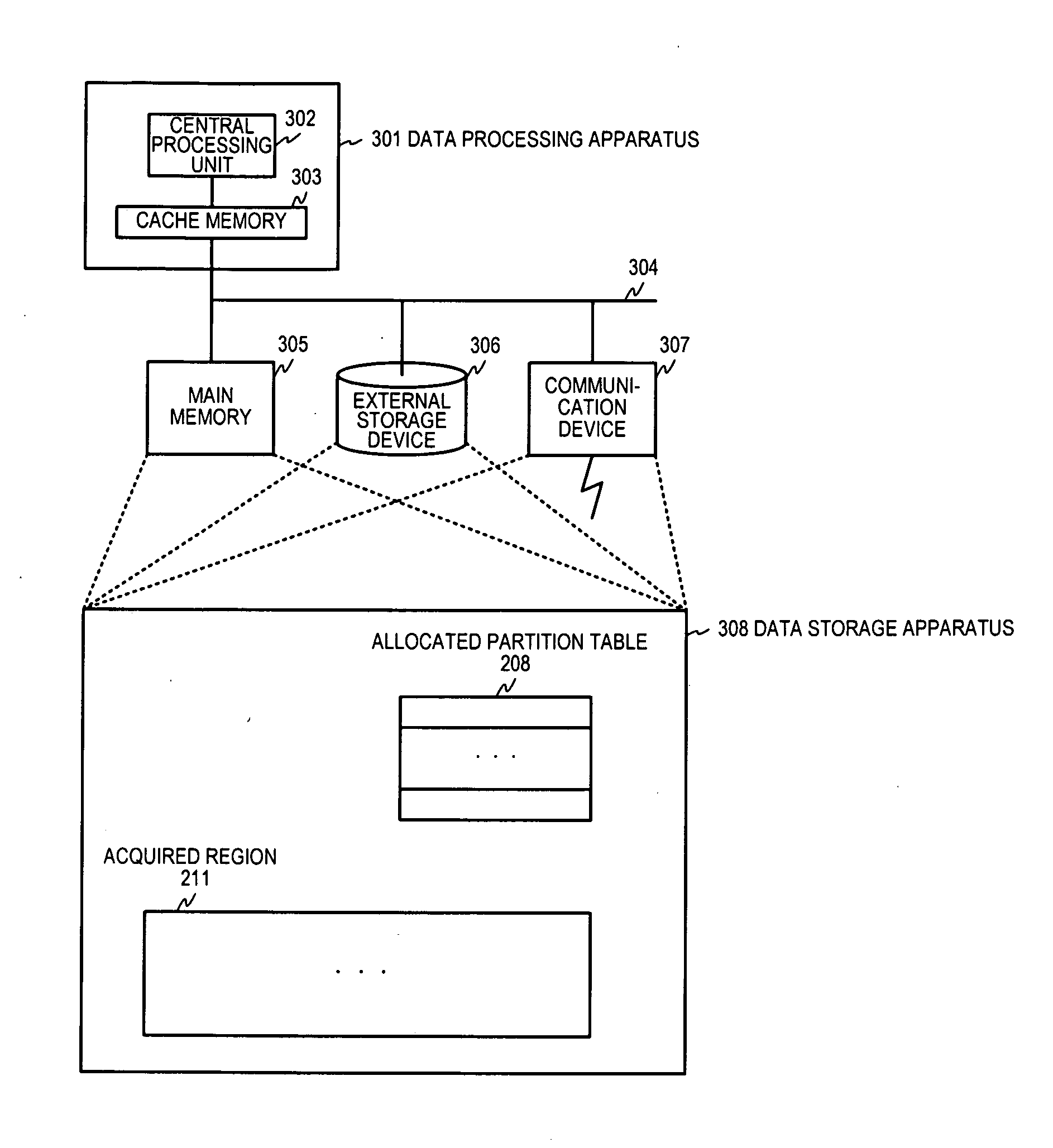

Management server for assigning storage areas to server, storage apparatus system and program

InactiveUS20050021562A1Effectively utilizedUtilization areaInput/output to record carriersDigital data processing detailsOperating systemProcfs

Even when an assignment request of storage areas exceeding unassigned areas is issued from a server, storage areas can be assigned to the server, so that storage areas in a storage pool can be utilized effectively. A management server connected to a plurality of servers and storage apparatuses to manage physical storage areas of the storage apparatuses used by the plurality of servers as virtual areas (storage pool) is responsive to an area assignment instruction of storage areas exceeding unassigned areas received from a server to release at least part of assignment areas of other servers to be assigned to the server which issued the area assignment instruction.

Owner:HITACHI LTD

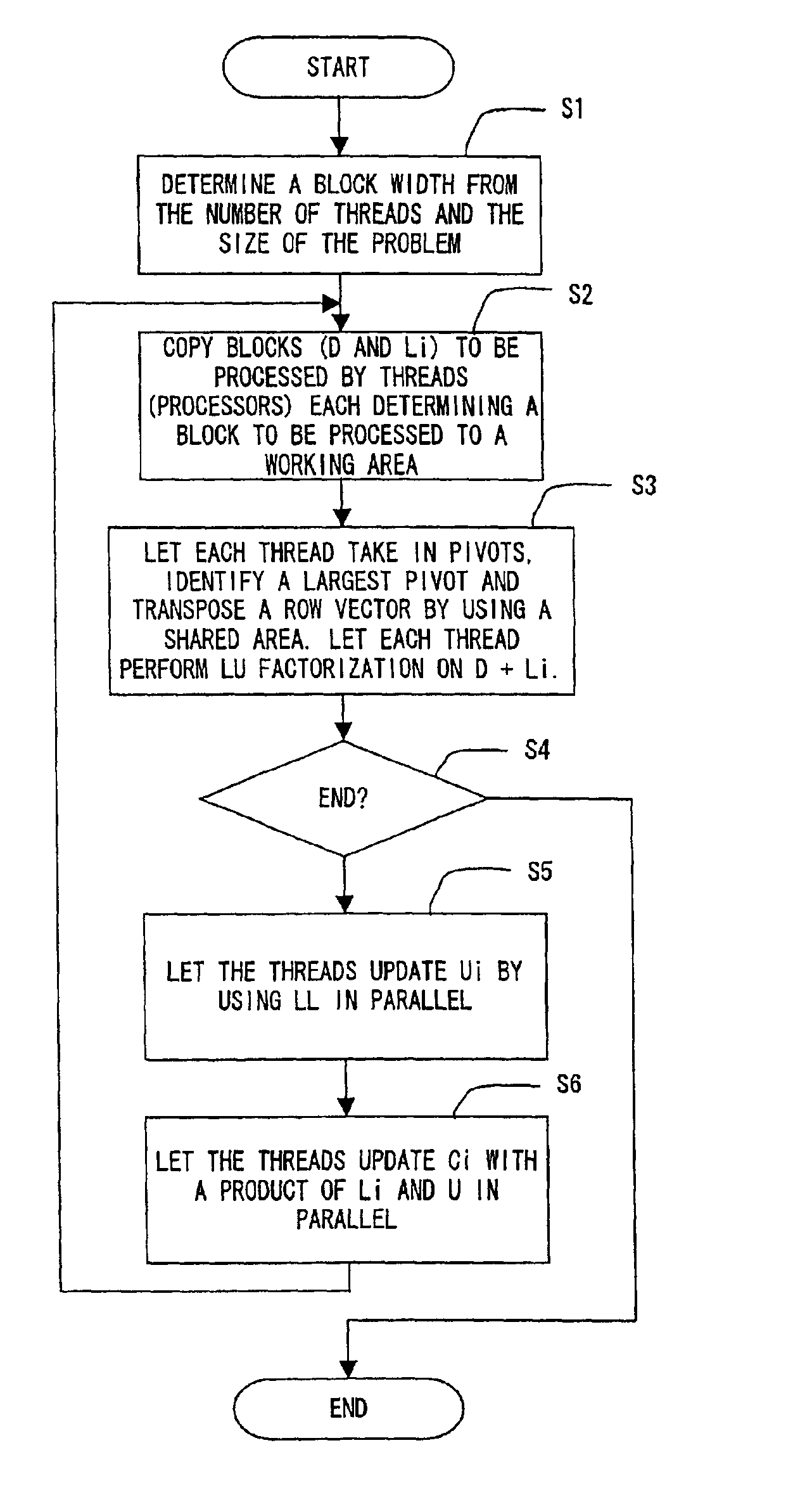

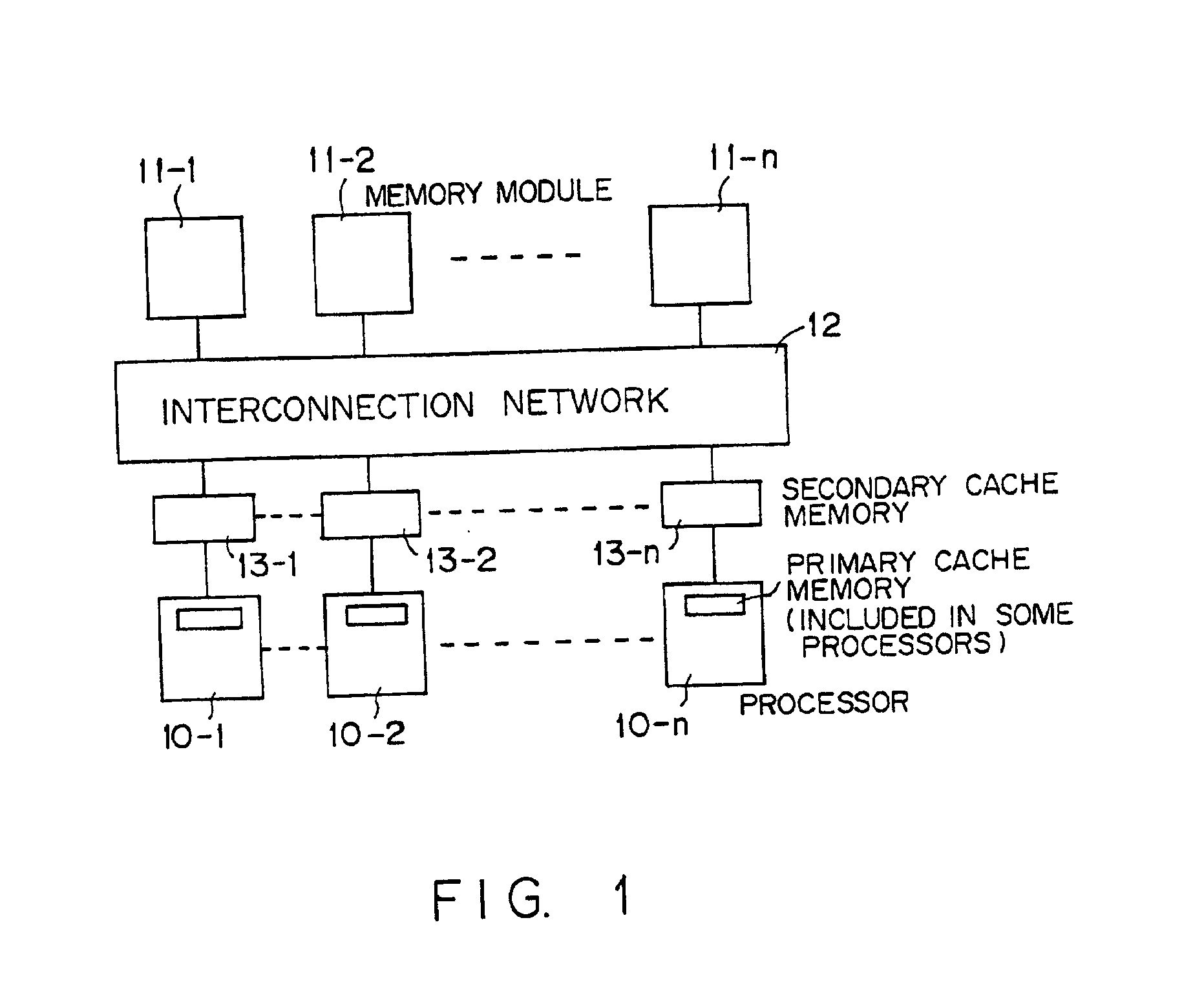

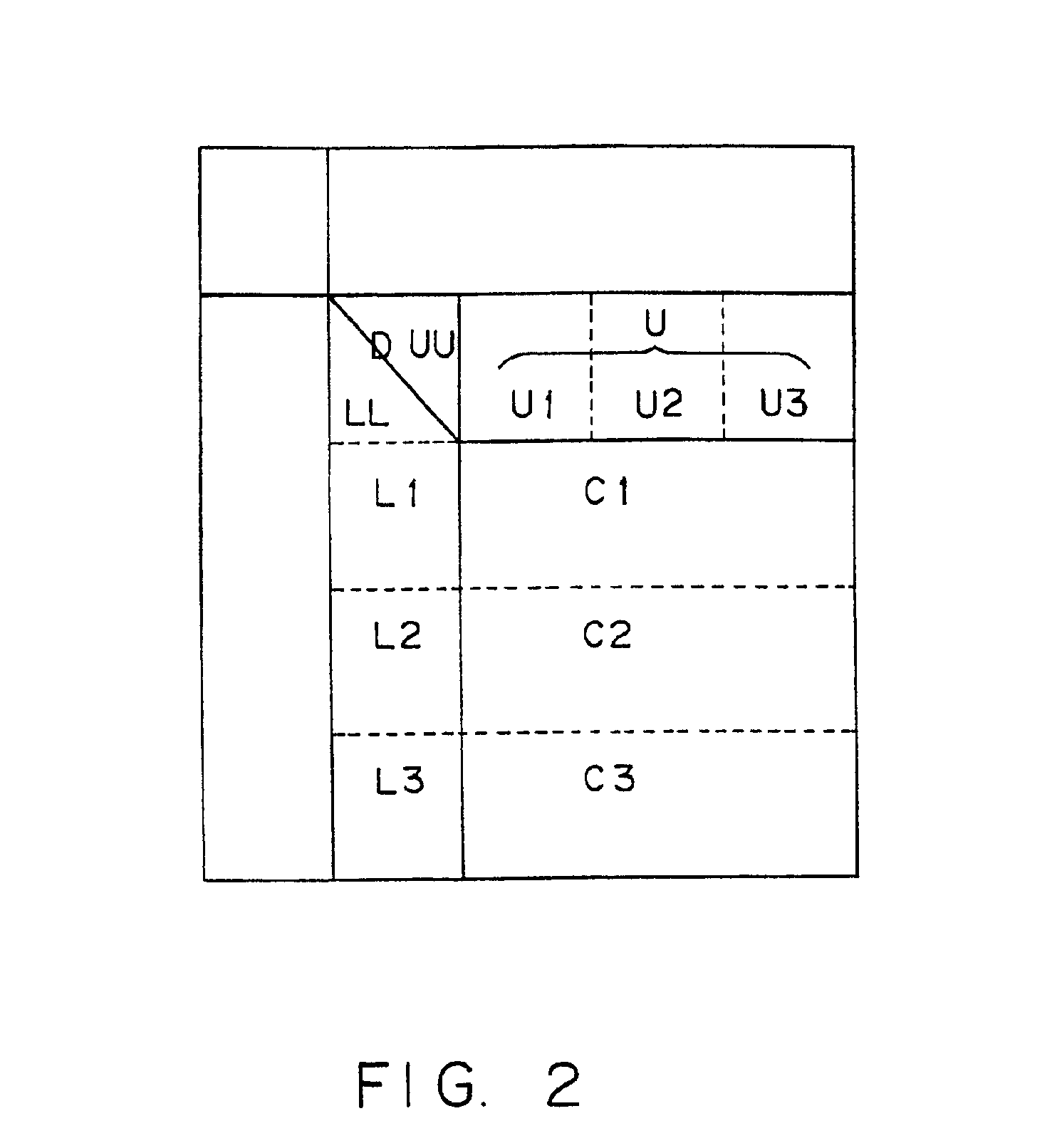

Matrix processing method of shared-memory scalar parallel-processing computer and recording medium

InactiveUS6907513B2Improve efficiencyUtilization areaGeneral purpose stored program computerConcurrent instruction executionLU decompositionDiagonal

In accordance with a parallel matrix processing method adopted in a shared-memory scalar computer, a matrix to be subjected to LU factorization is divided into a block D of the diagonal portion and blocks beneath the D diagonal block such as L1, L2 and L3. Then, D+L1, D+L2 and D+L3 are assigned to 3 processors respectively for processing them in parallel. Next, a block U is updated by adopting an LU-factorization method and C1 to C3 are updated with L1 to L3 and U. By carrying out this processing on the inner side gradually decreasing in size as blocks, finally, a portion corresponding to the D diagonal block remains to be processed. By applying the LU factorization to this D portion, the LU factorization for the entire matrix can be completed.

Owner:FUJITSU LTD

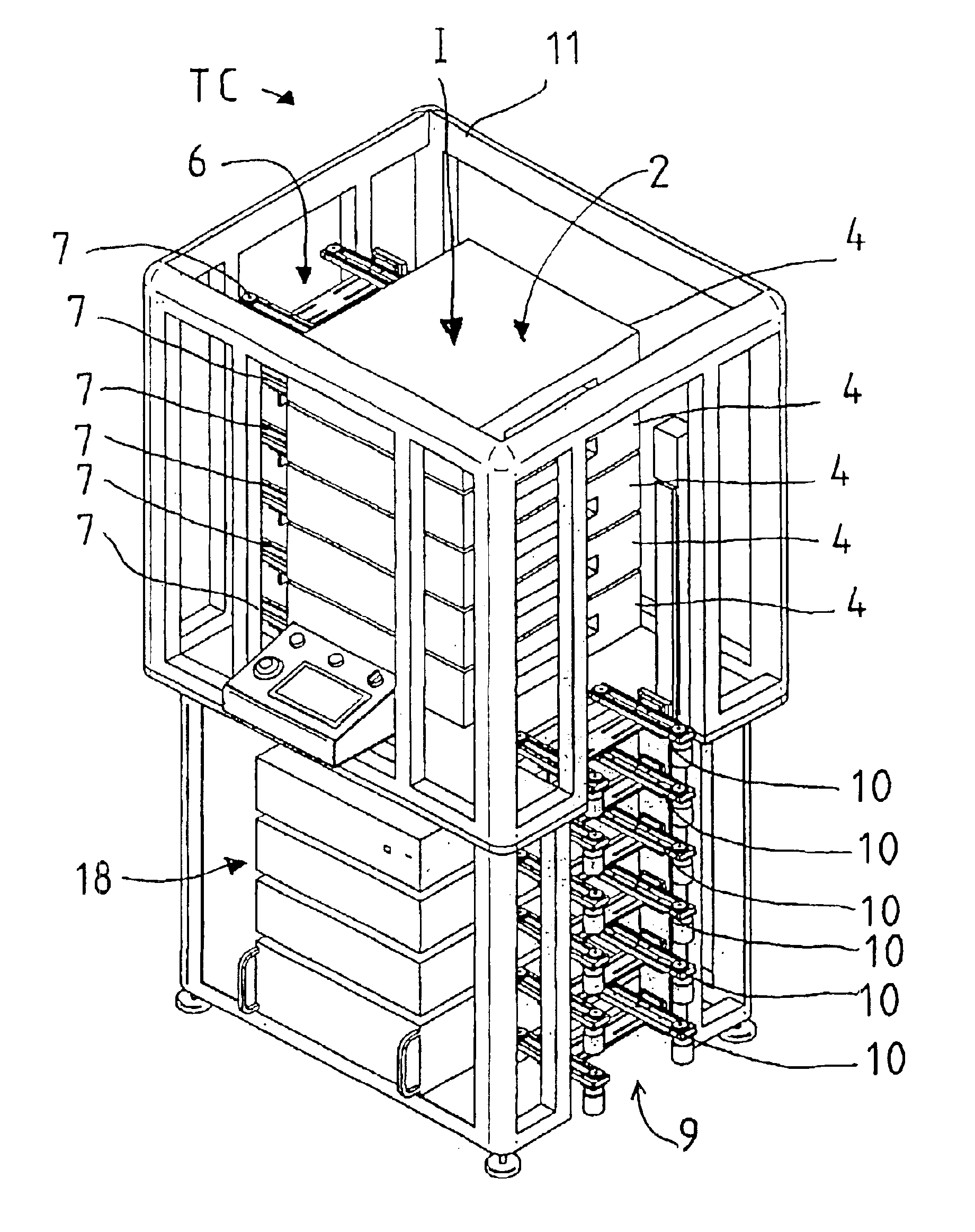

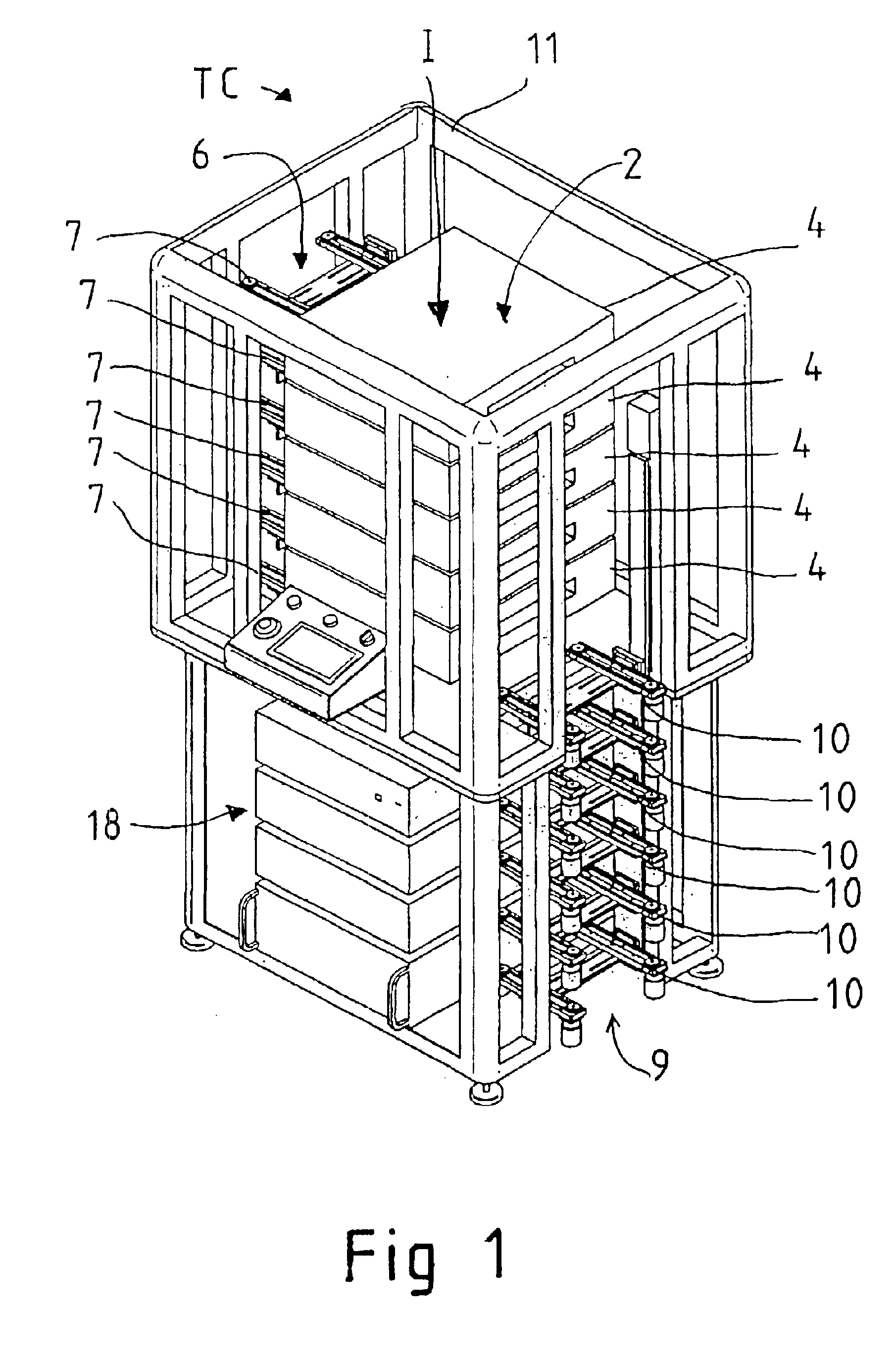

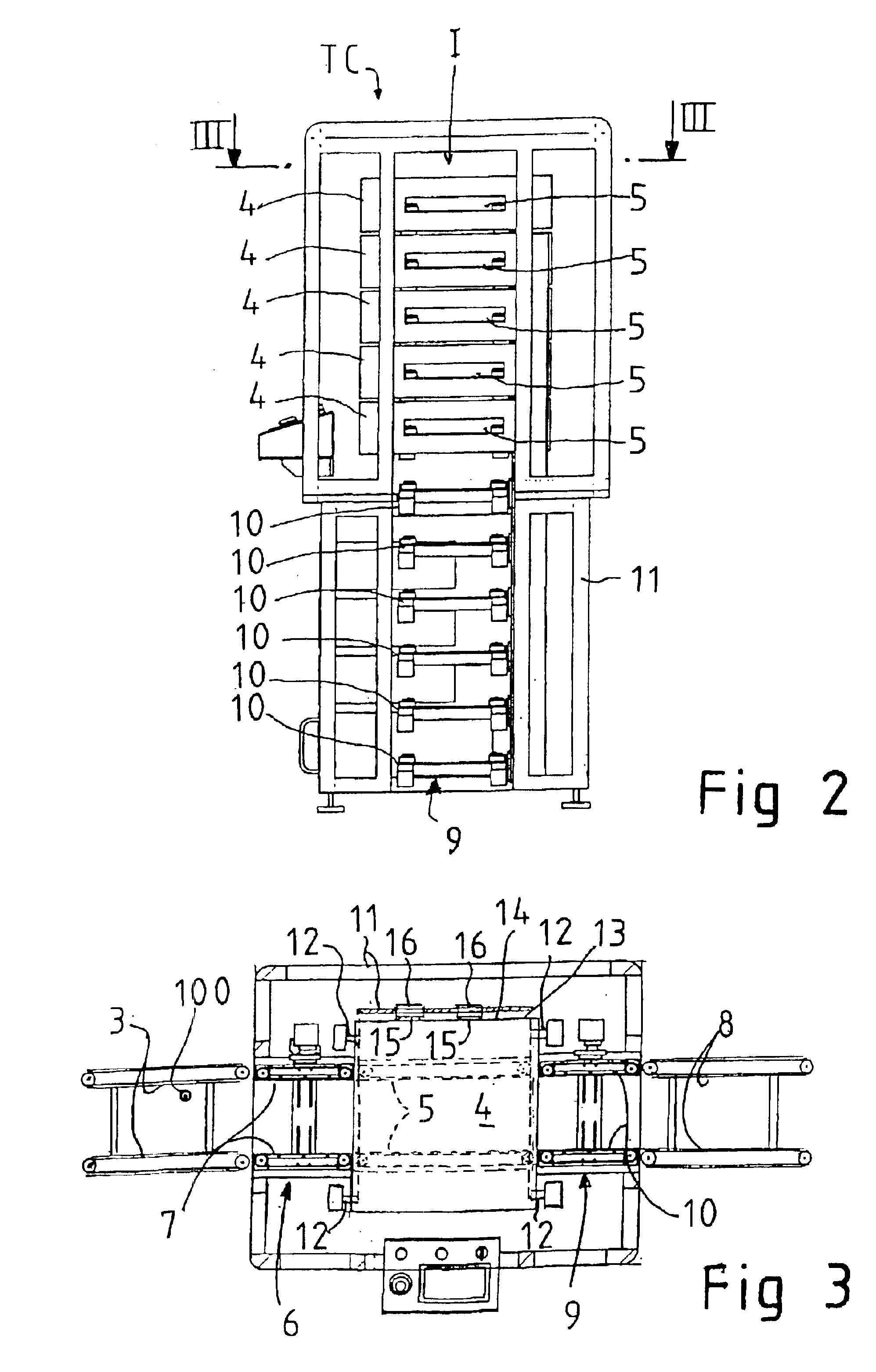

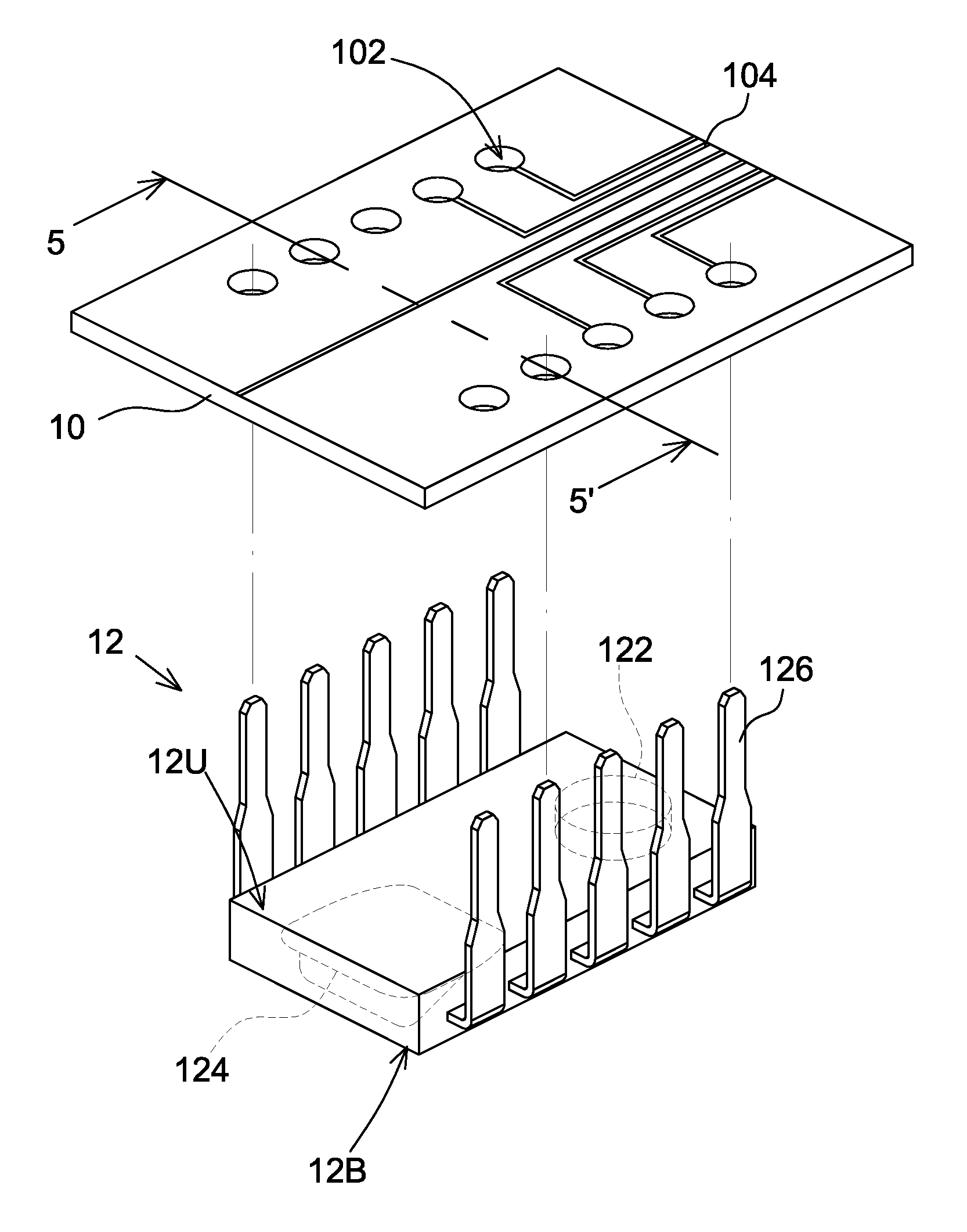

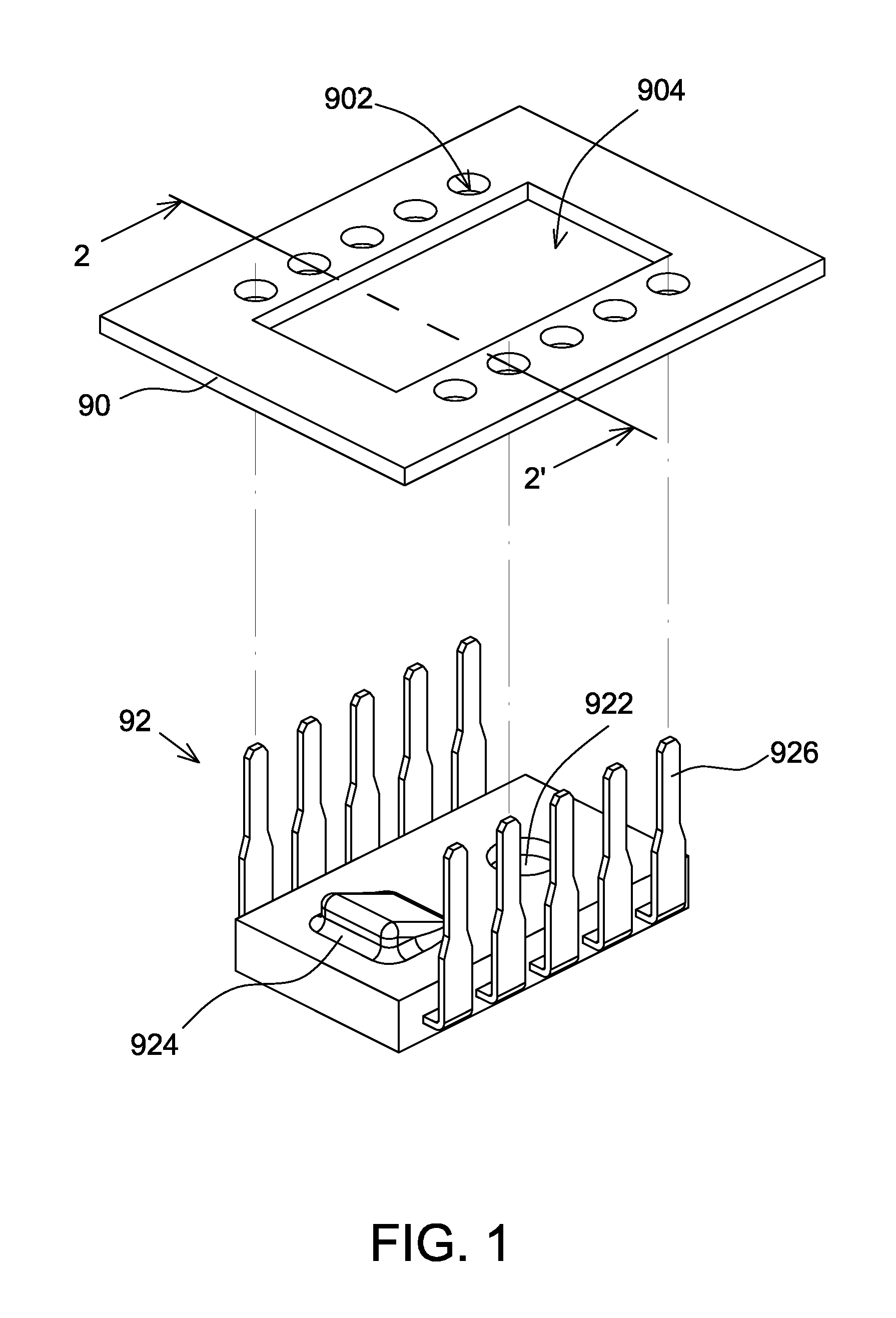

Testing system in a circuit board manufacturing line for a automatic testing of circuit boards

InactiveUS6876192B2Utilization areaCoupling device connectionsPrinted circuit testingEngineeringAutomatic testing

A testing system for automatic testing of circuit boards (1) in a circuit board manufacturing line. The testing system comprises a set (I) of test modules (4) comprising a testing apparatus. Each test module comprises a horizontal module conveyor (5) for conveying a circuit board (1) into and out of the test module. The test modules are arranged in a superposed relation with respect to each other. The set (I) contains test modules differing from each other so that the testing operations performed by these test modules are different from each other. A feed device (6) has been fitted to receive circuit boards from the first line conveyor (3) and to feed them into the test modules (4).

Owner:CENCORP INC

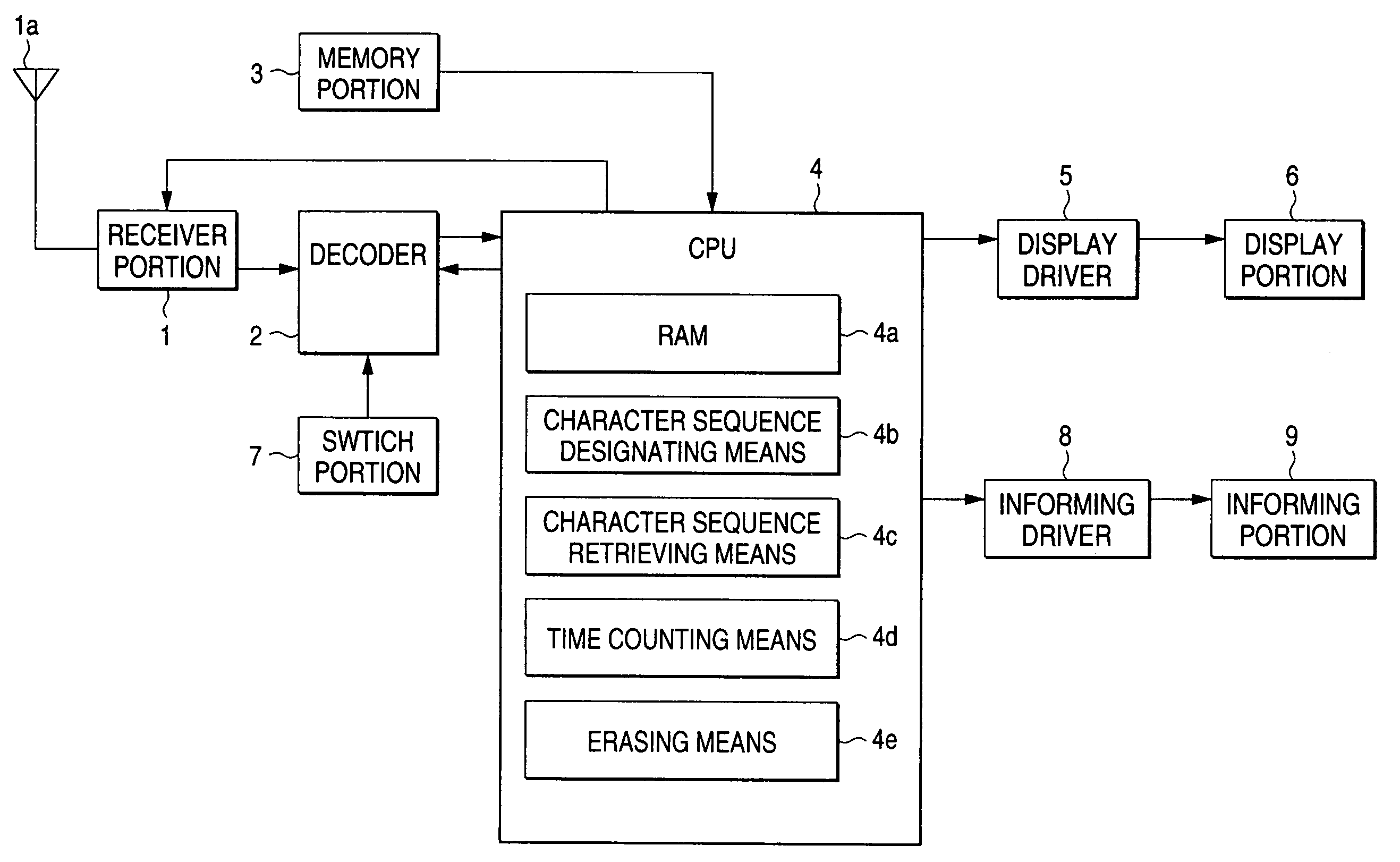

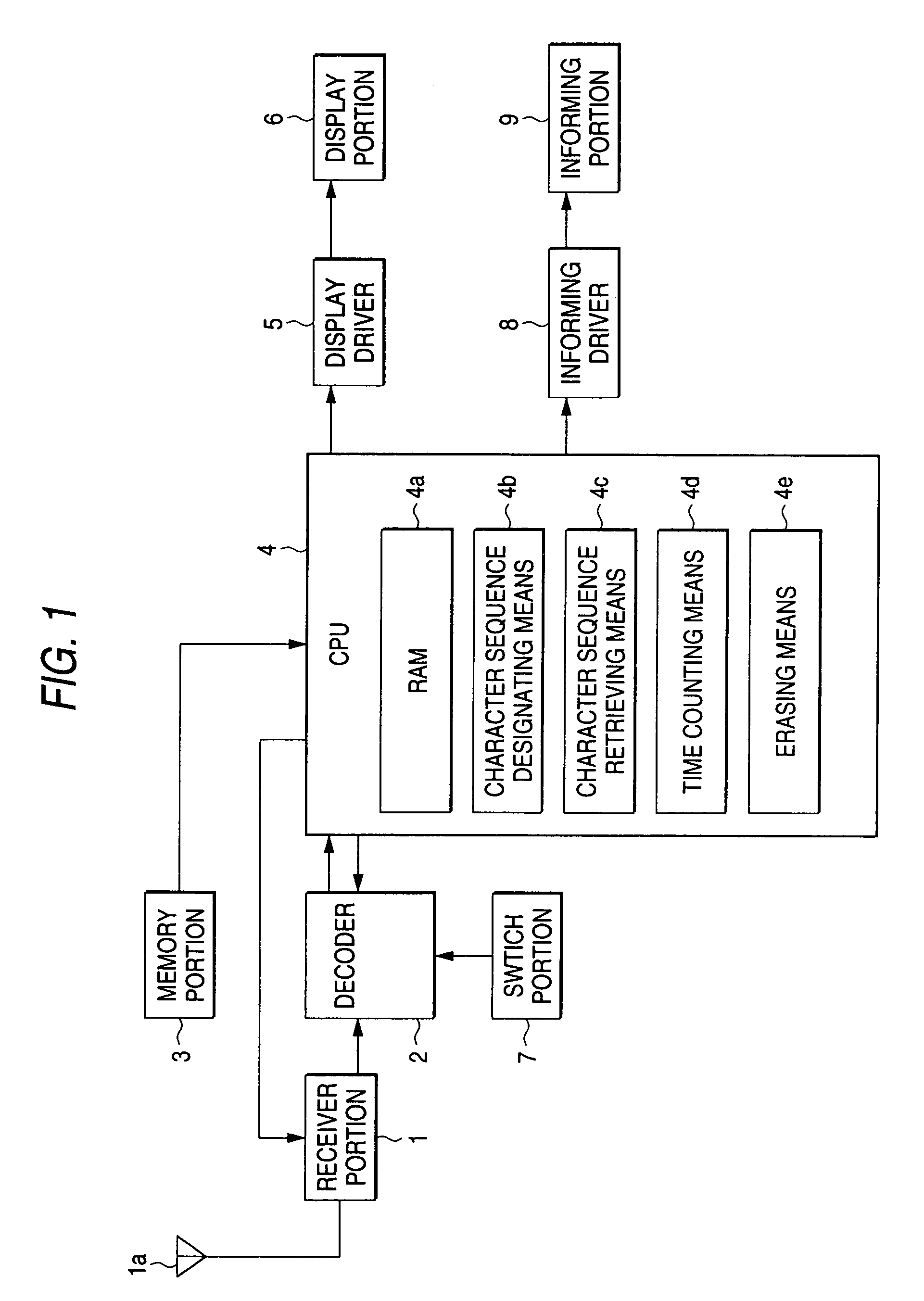

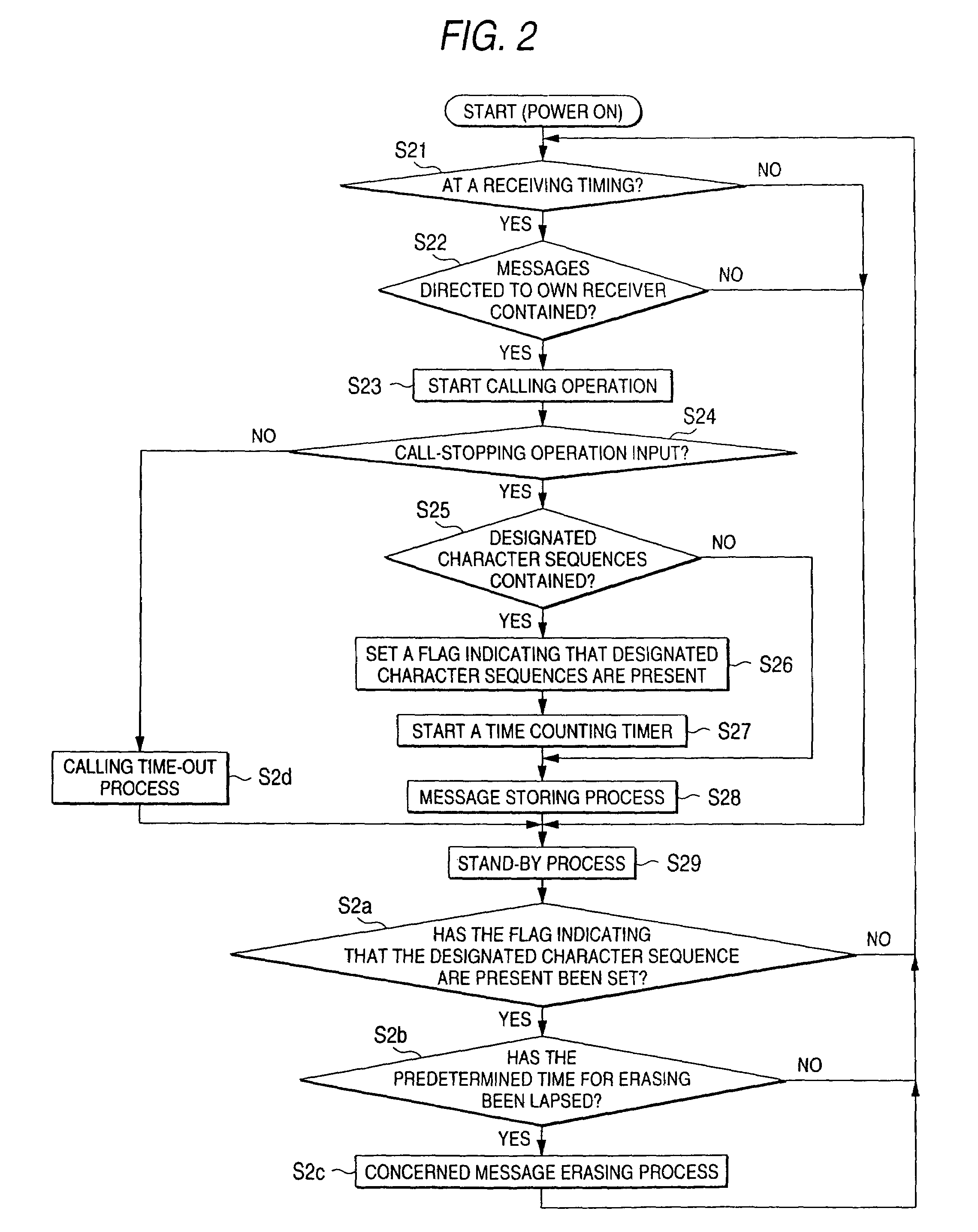

Radio paging receiver and message erasing method

InactiveUS7079006B1Utilization areaElectric signal transmission systemsMultiple keys/algorithms usageTelecommunicationsPaging

Message data are picked up by using a decoder 2 from received signals received by a receiver portion 1 of a radio paging receiver, and stored in a RAM 4a of a CPU 4. An informing portion 9 informs a user of the message. The user designates any character sequences in the message stored in the RAM 4a by a character sequence designating unit 4b. A character sequence retrieving unit 4c retrieves whether or not designated character sequences are contained in stored messages. When the messages containing the designated character sequences are detected, a time counting unit 4d monitors whether or not a predetermined time has been lapsed after storage of concerned messages. An erasing unit 4e erases unnecessary messages stored in the RAM 4a from the RAM 4a after the predetermined time has been lapsed. Accordingly, the messages which are transmitted periodically and repeatedly to the radio paging receiver can be erased collectively and automatically and thus complicatedness in erasing the messages can be eliminated and also operability can be enhanced.

Owner:PANASONIC CORP

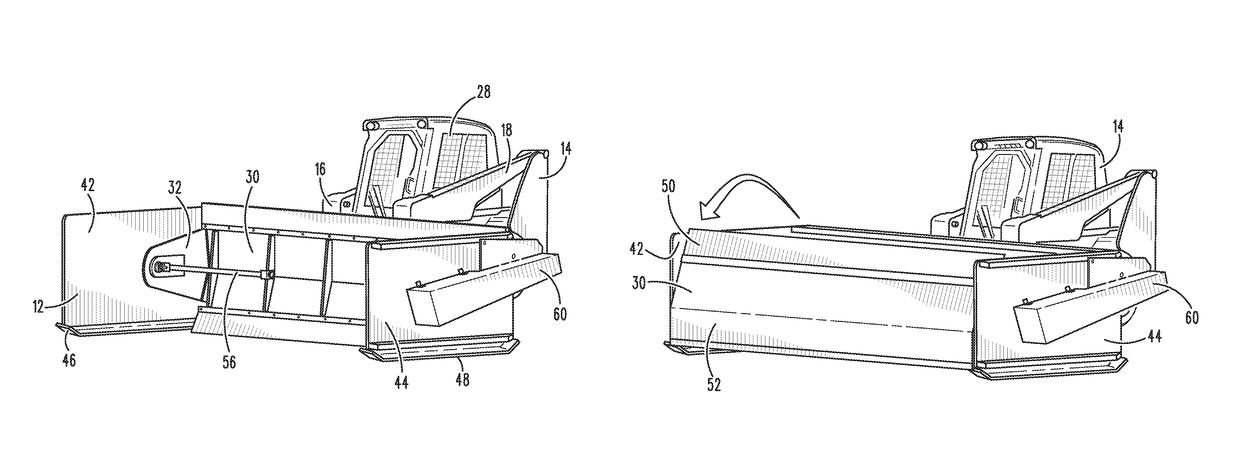

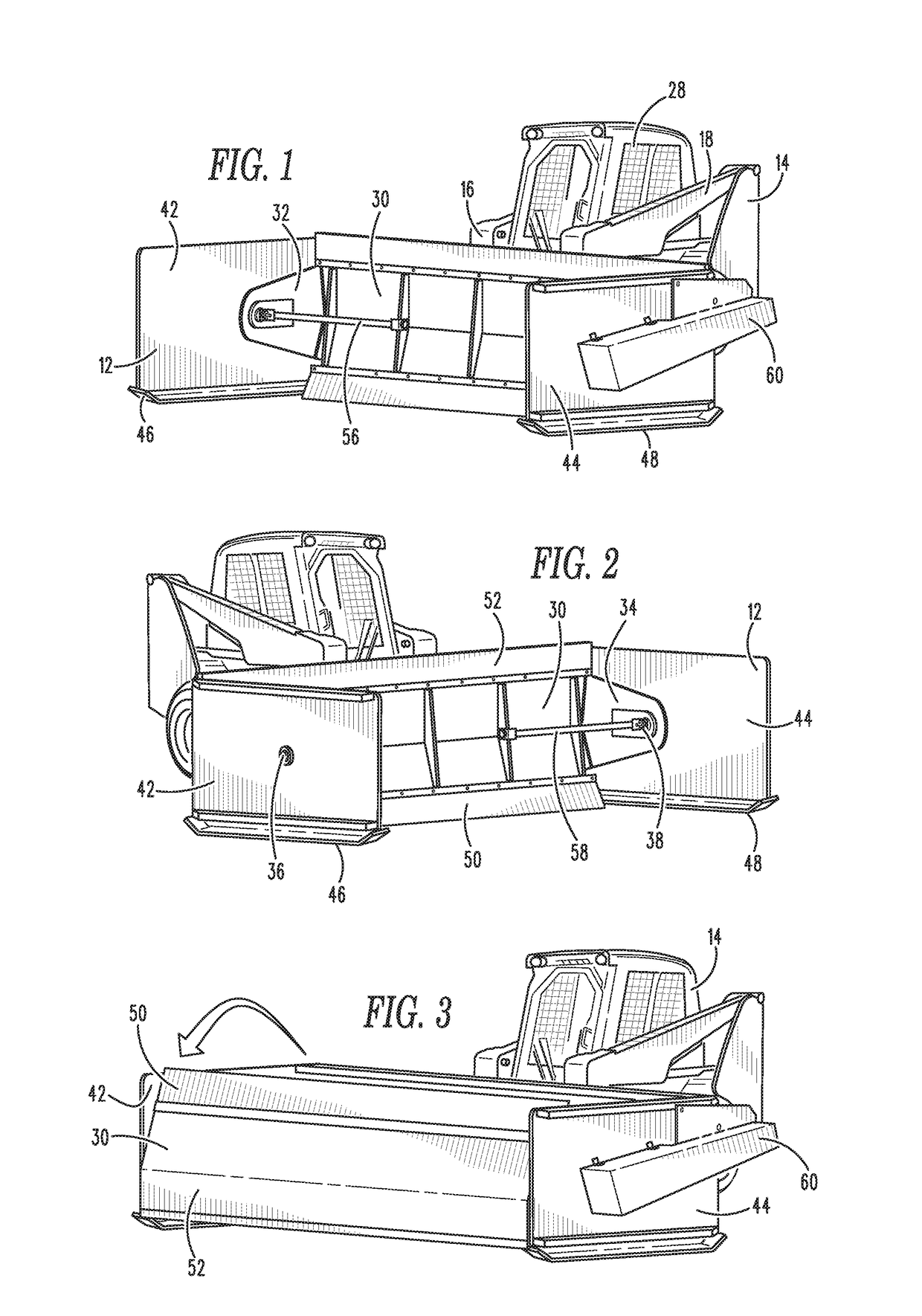

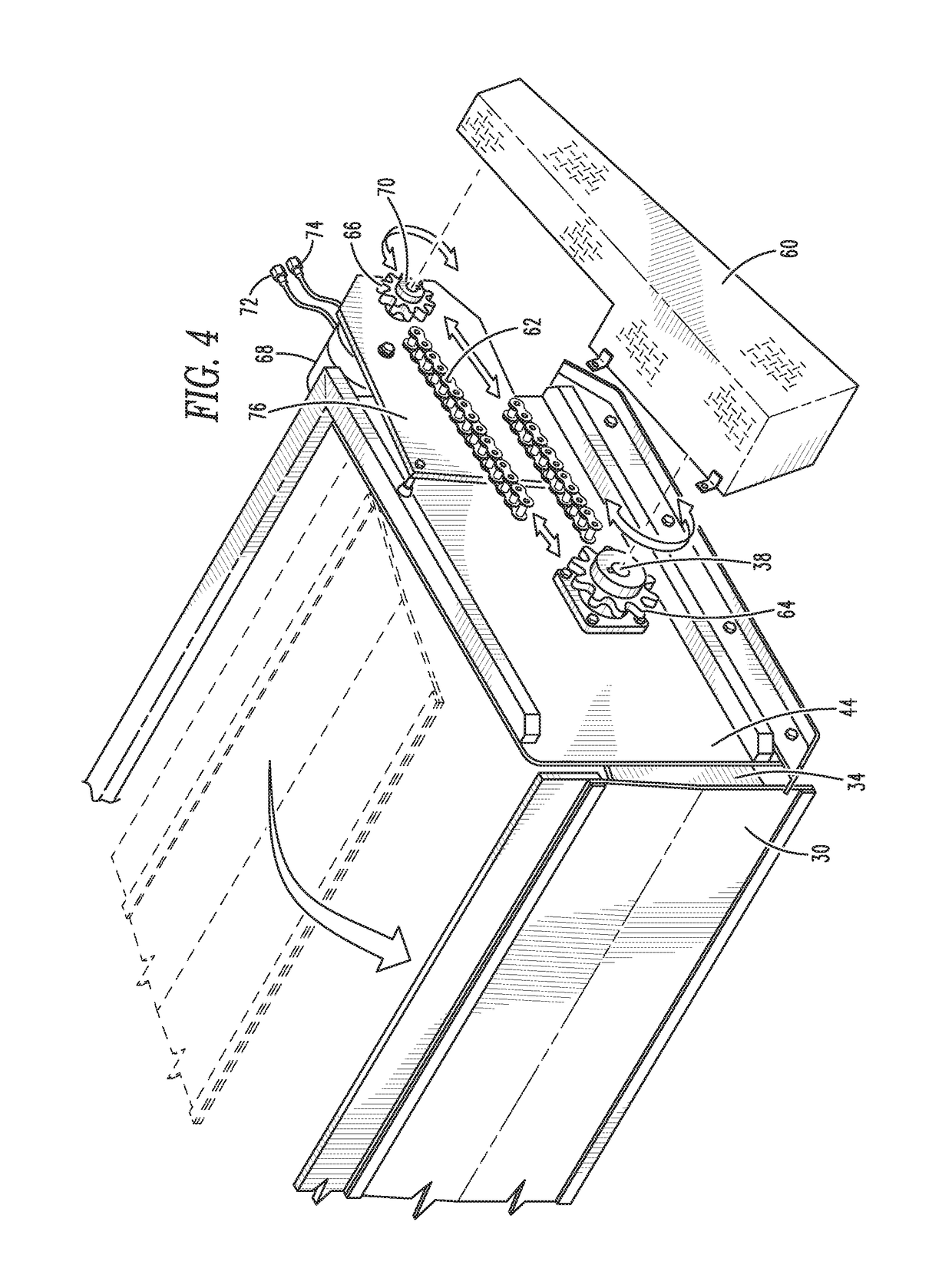

Rotatable snowplow blade apparatus, systems and methods of using the same

A snow pusher, also known as a box plow has a blade that is configured to be disposed in a first position for pushing snow forwardly, as is typical of snow pushers, and is further configured to be disposed in a second position for pulling snow rearwardly. The blade of the snow pusher may be contained within a snow plow box that may be reversible, allowing the blade to be disposed at a rear of the box for pushing the snow forwardly and at a front of the box for pulling snow rearwardly.

Owner:STONE KEVIN

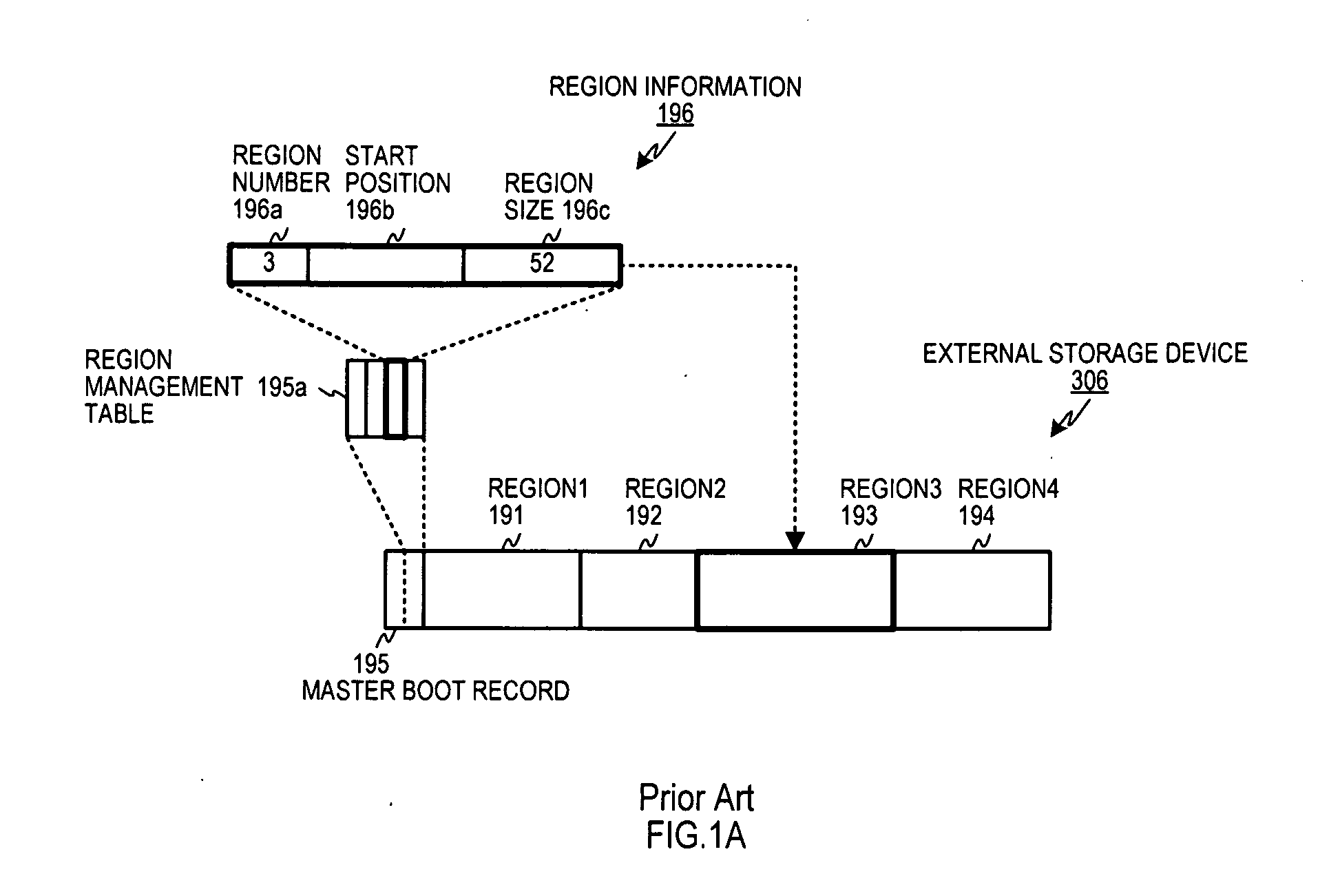

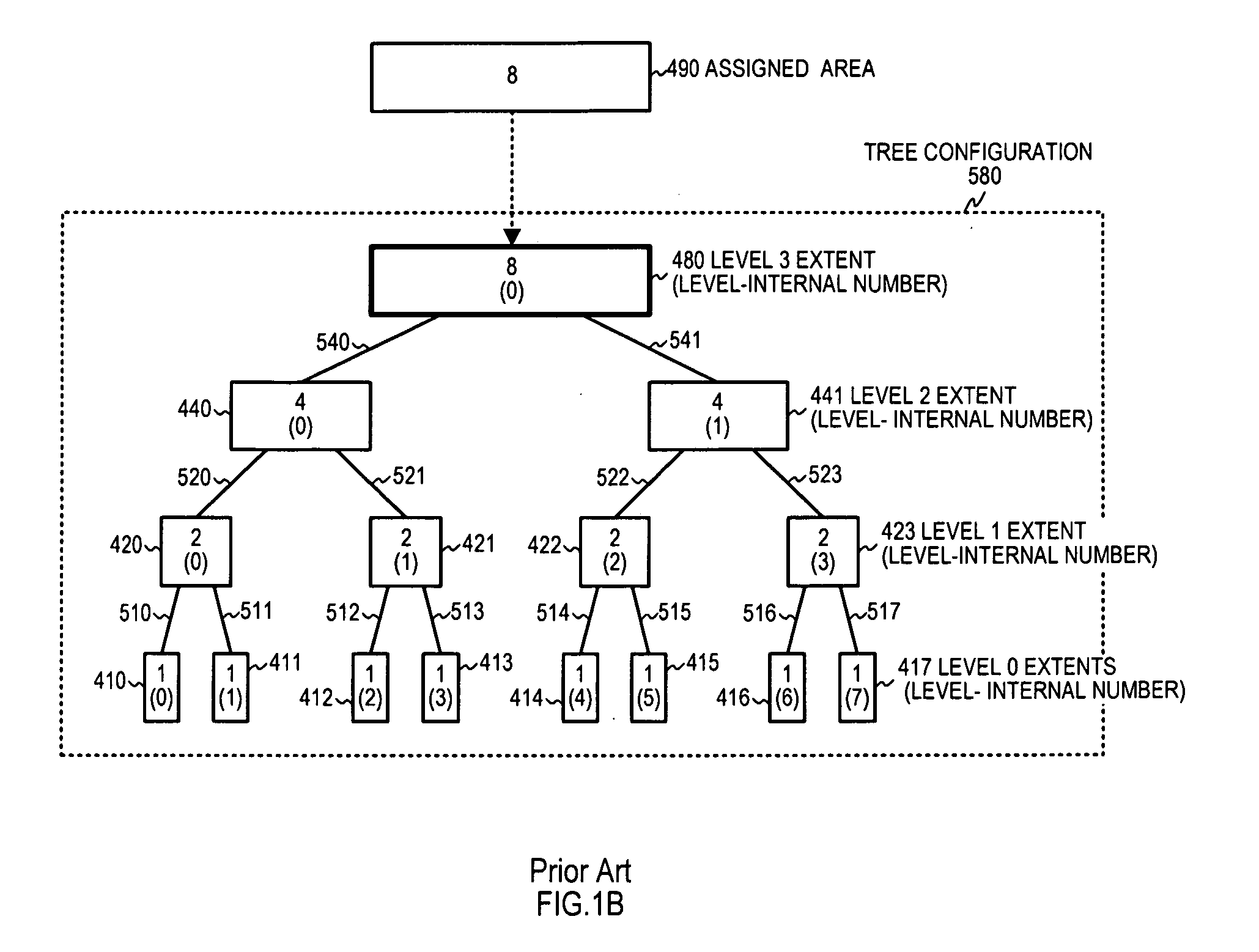

Storage region management method, storage region allocation method and program

ActiveUS20110145538A1Efficient managementUtilization of storage areaMemory adressing/allocation/relocationInput/output processes for data processingOperating systemAllocation method

A storage area management method for a data storage apparatus partitions an acquired storage area into storage areas with differing power-of-2 sizes and manages each of them. Also, a storage area allocation method receives an allocation request for a storage area that includes a requested allocation size, and acquires an available storage area whose size is the smallest power-of-2 size encompassing the requested allocation size, and obtains a binary expression of the requested allocation size, and in response to the received allocation request, allocates a contiguous storage area comprised of storage areas each of whose size is a power of 2 of a value of a bit position wherein a 1 is set in the binary expression.

Owner:YOSHIOKA MAKOTO

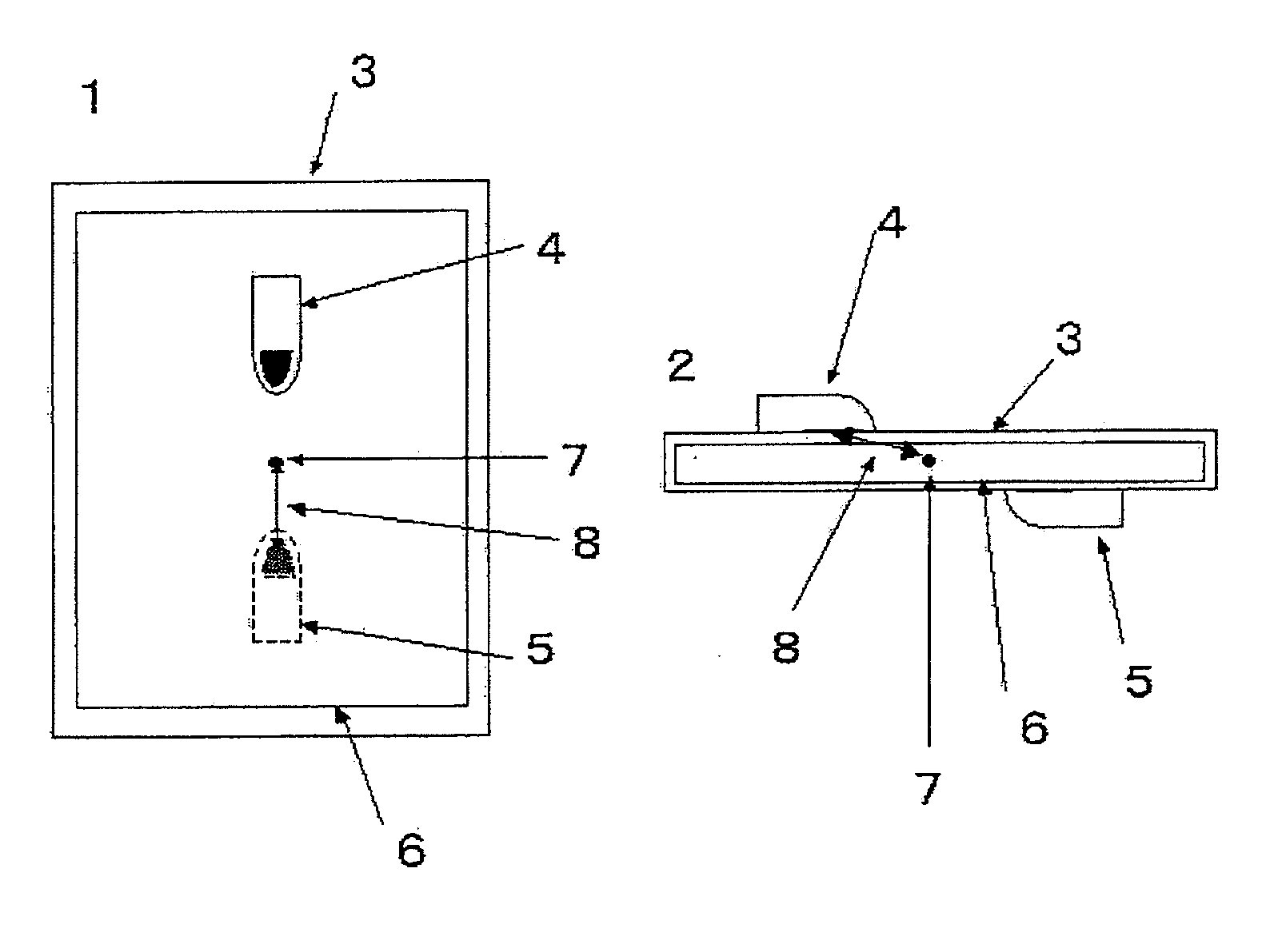

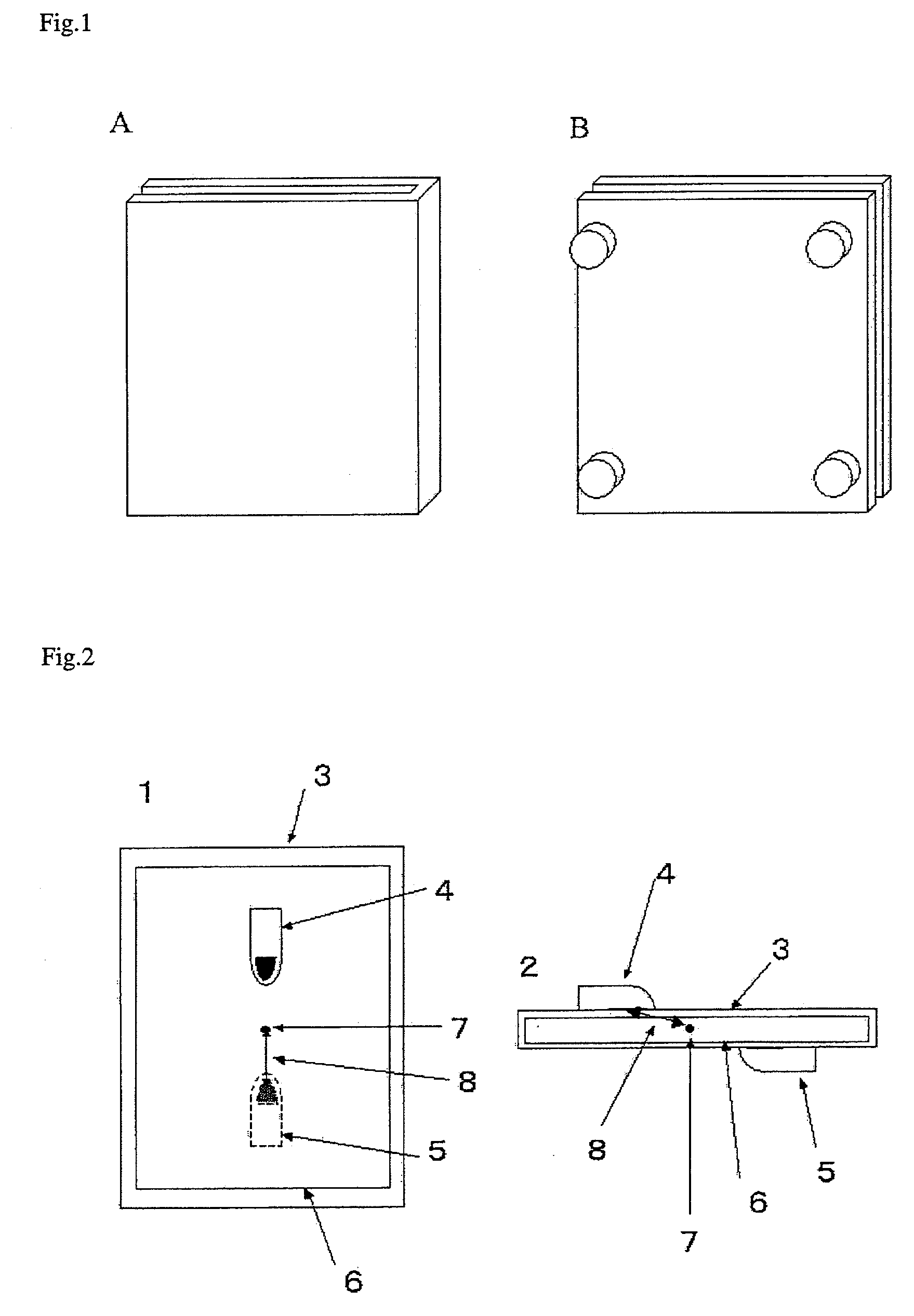

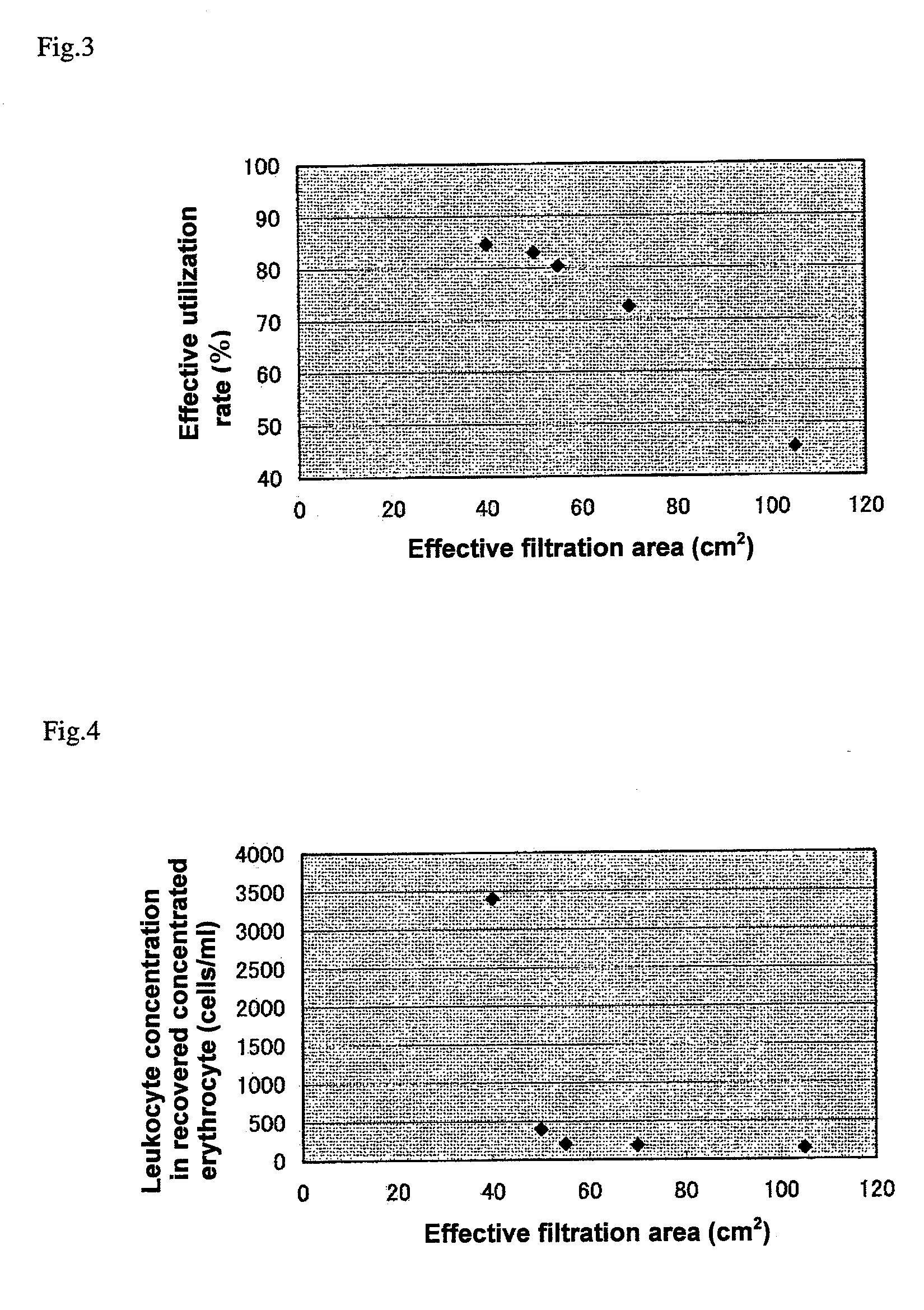

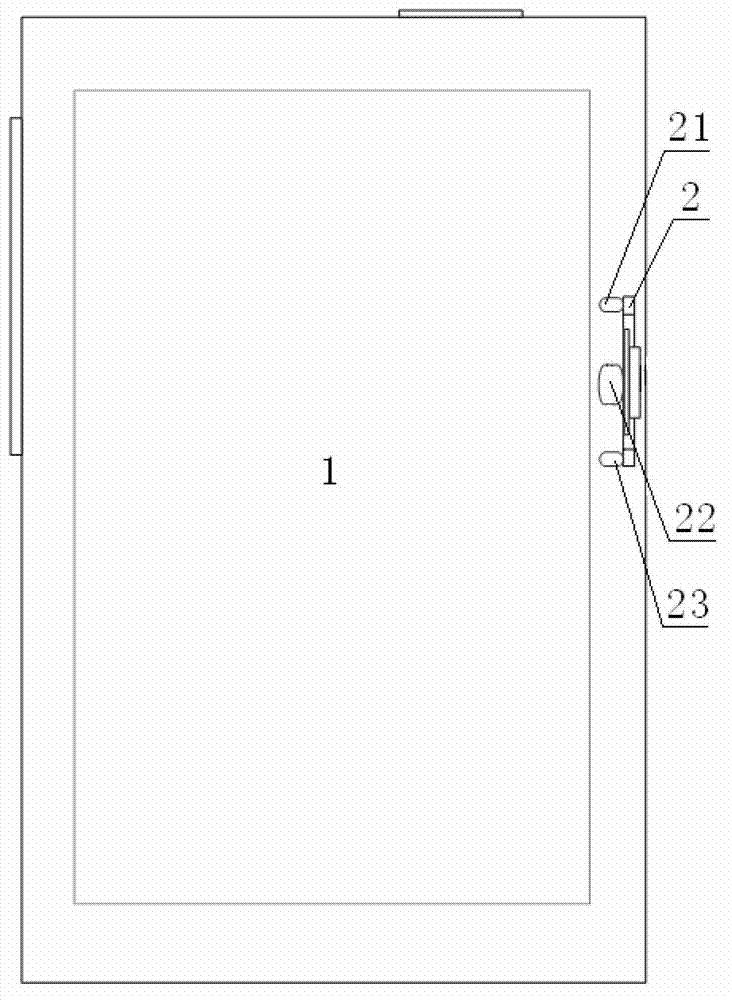

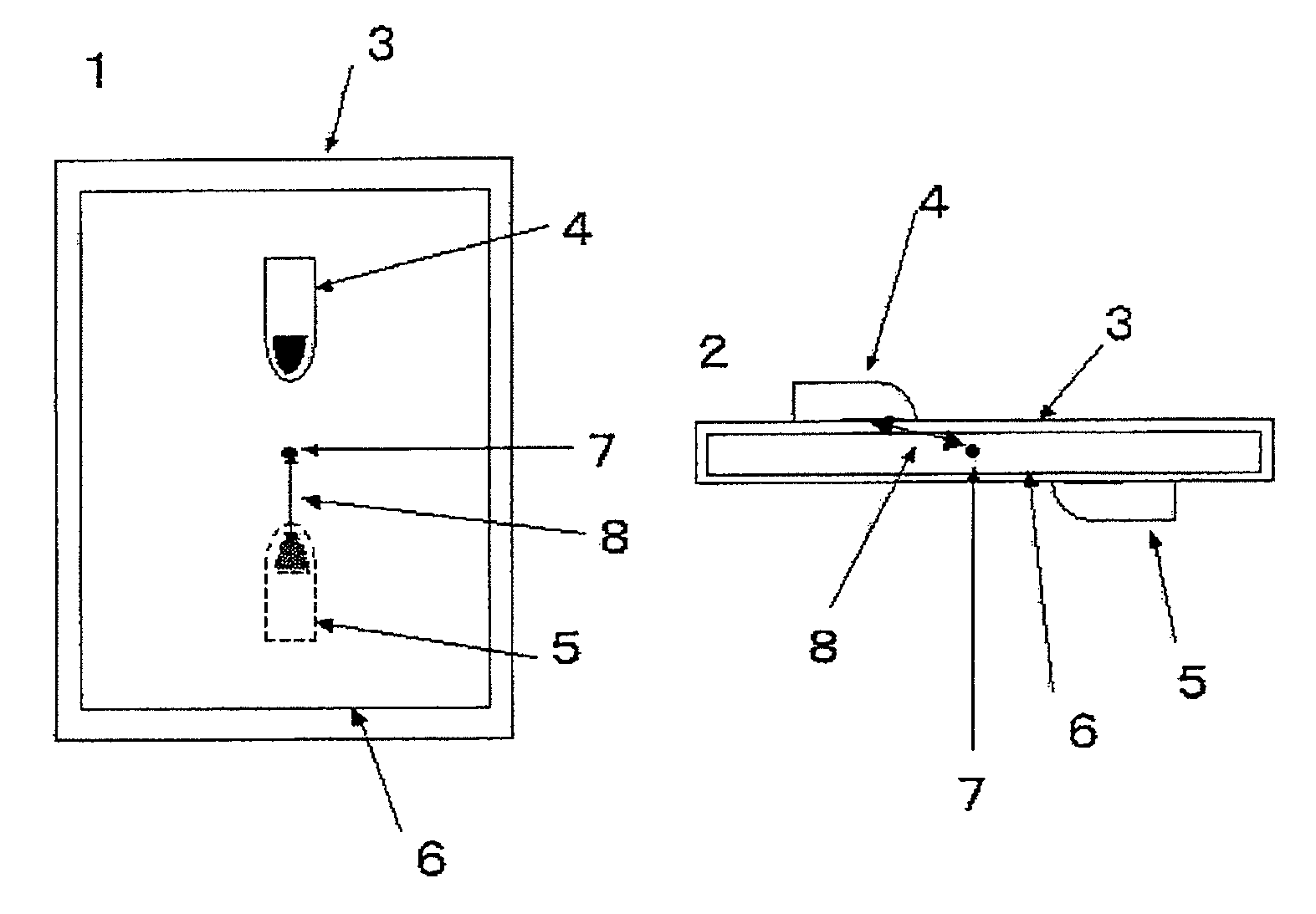

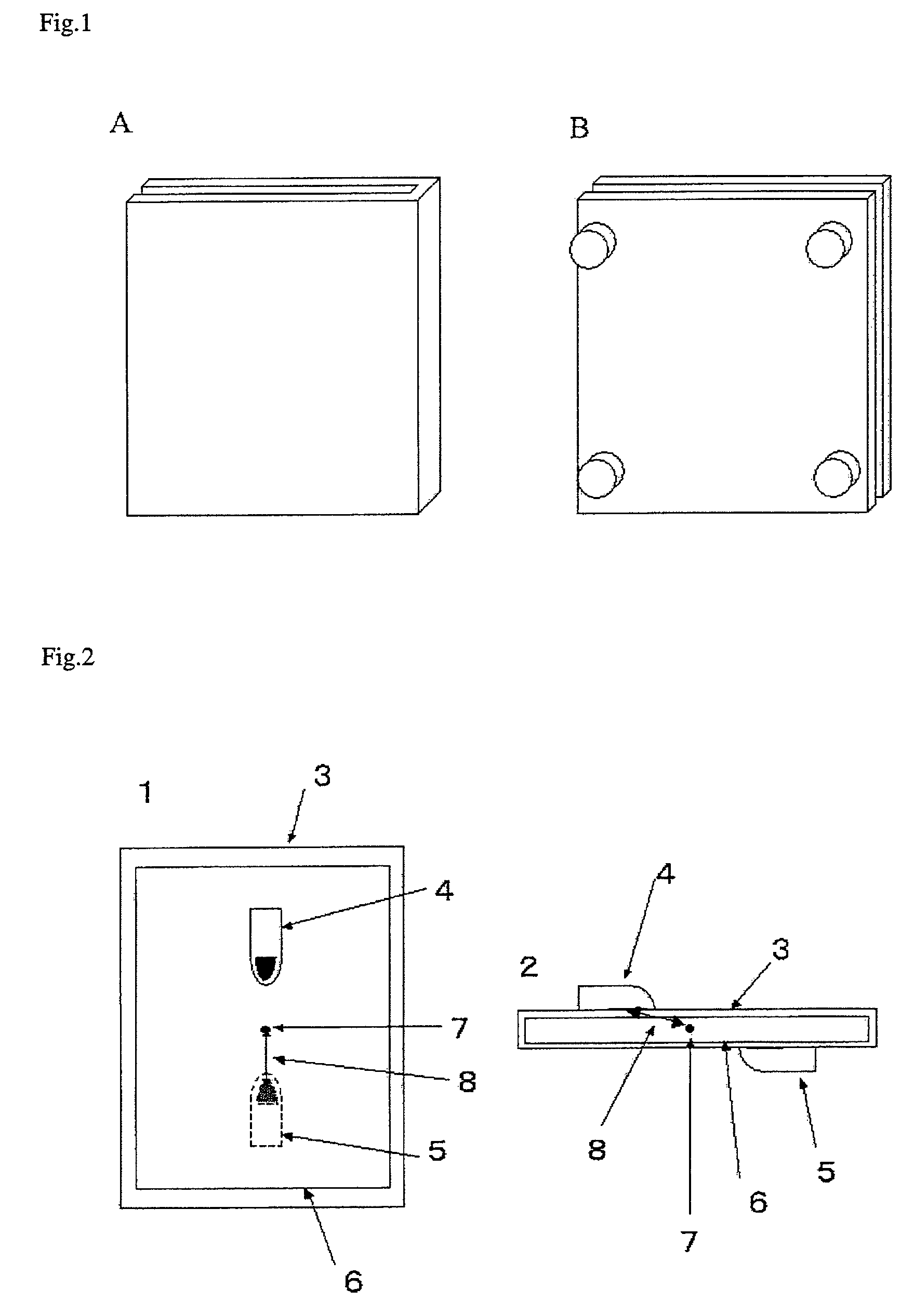

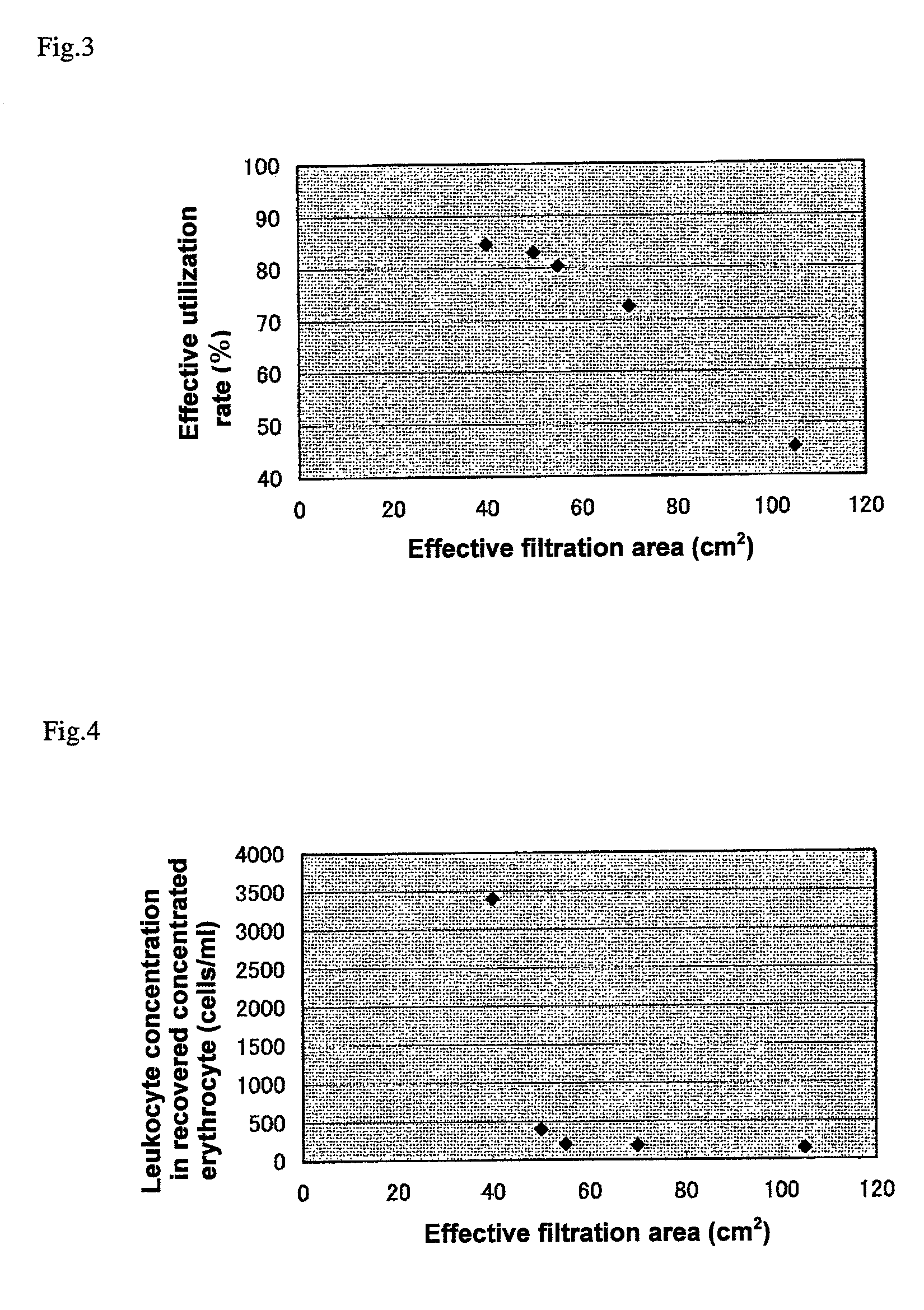

Method for filtering blood or blood components using leukocyte-removing filter and filter device

ActiveUS20070199897A1Good removal effectUtilization areaMembranesSemi-permeable membranesBlood componentWhite blood cell

An object of the present invention is to provide a method and device for filtering blood or blood components which simultaneously attains 1) efficiently increasing leukocyte removal capability and 2) effectively utilizing the filtration area by preventing nonuniform flow, when blood is filtered by being fed to a leukocyte-removing filter comprising flexible containers by being pressurized using a pump or the like. The method comprises providing a leukocyte-removing filter having a thickness of 9.0 mm to 9.4 mm, an air permeability pressure drop of 300 Pa to 700 Pa, and effective filtration area of 50 cm2 to 70 cm2 which comprises a flat and flexible container having an inlet port and an outlet port and a sheet-like leukocyte-removing-filter material with a thickness of 8.2 mm to 8.6 mm disposed to divide the container into an inlet-port side chamber and an outlet-port side chamber, providing a pair of volume restriction boards disposed outside of the inlet port side external surface and the outlet port side external surface of the flexible container, having the distance between the volume restriction boards at the portion where the volume restriction boards facing each other sandwich the leukocyte-removing filter being in a range from [thickness of leukocyte-removing filter+0.5 mm] to [thickness of leukocyte-removing filter+2.5 mm], and filtering blood or blood components through the leukocyte-removing filter under a pressure of 30 kPa to 50 kPa while restraining expansion of the flexible container occurring during filtration by means of the volume restriction boards.

Owner:ASAHI KASEI MEDICAL CO LTD

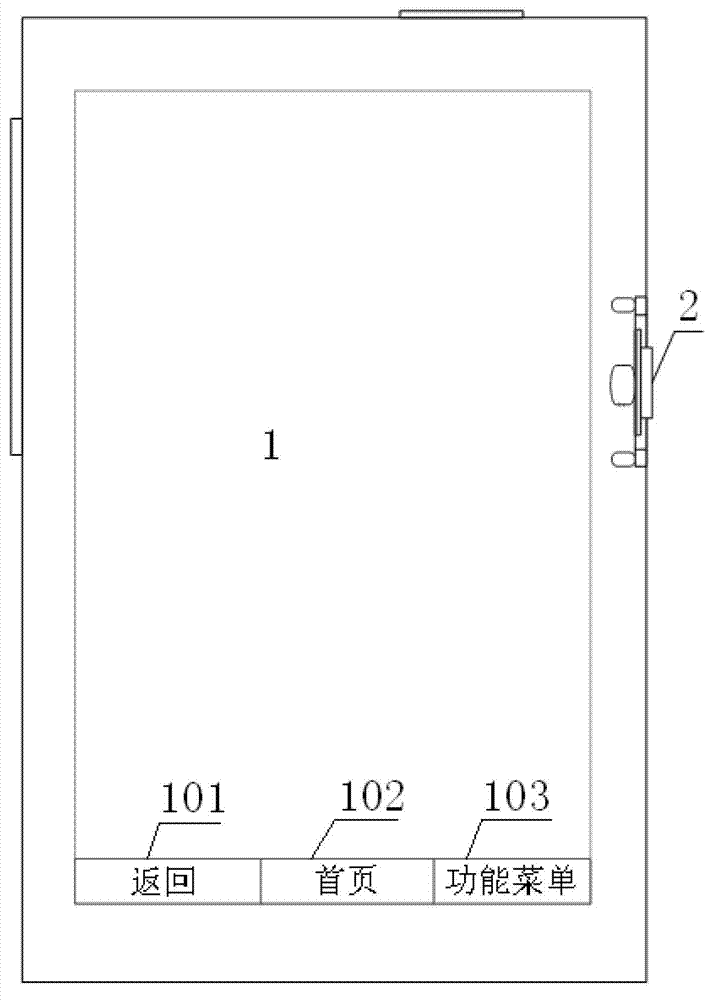

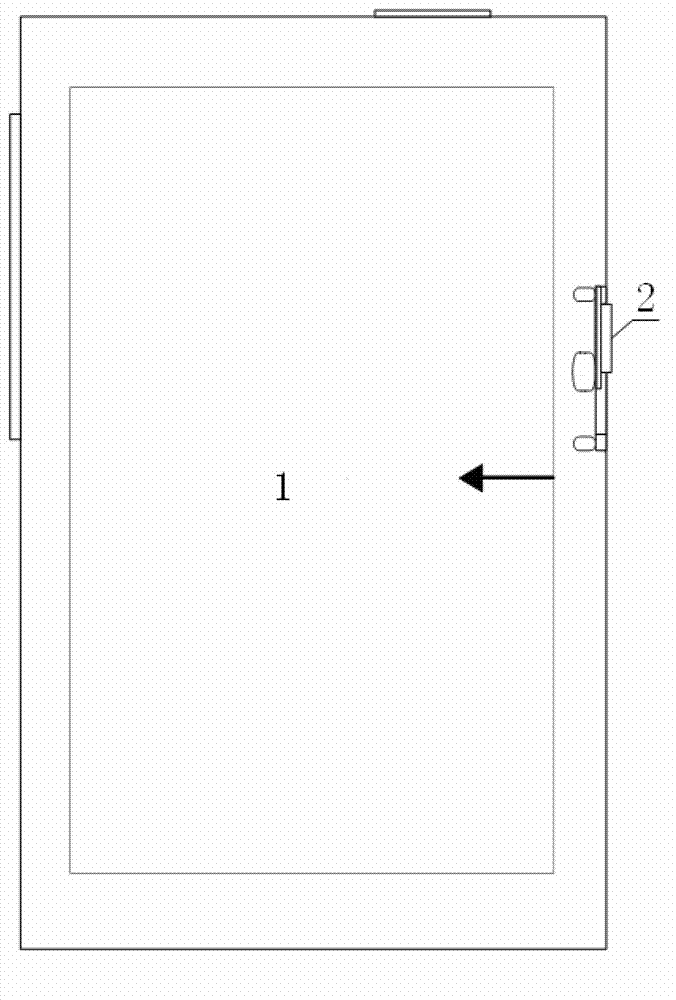

Method for switching touch mode by mobile terminal

ActiveCN103179238AUtilization areaTelephone set constructionsInput/output processes for data processingElectricityKey pressing

The invention discloses a method for switching a touch mode by a mobile terminal. A three-section type toggle switch is arranged at the side edge of the mobile terminal and is electrically connected with a CPU (Central Processing Unit) chip, the three-section type toggle switch is provided with a first gear, a second gear and a third gear, when the three-section type toggle switch is switched in the first gear, a touch screen is in a first display mode; when the three-section type toggle switch is switched into the second gear, the touch screen is in a second display mode; and when the three-section type toggle switch is switched into the third gear, the touch screen is in a third display mode. According to the method, a touch button originally occupying a region at the bottom of a display screen is removed, and is transformed to the side edge of the mobile terminal, and thus all touch operations are completed in a display region of the display screen, and the area of a front panel of a mobile phone is utilized as wide as possible.

Owner:杭州吉吉知识产权运营有限公司

Method for filtering blood or blood components using leukocyte-removing filter and filter device

ActiveUS7655146B2Good removal effectUtilization areaSemi-permeable membranesMembranesBlood componentWhite blood cell

The method comprises providing a leukocyte-removing filter having a thickness of 9.0 mm to 9.4 mm, an air permeability pressure drop of 300 Pa to 700 Pa, and effective filtration area of 50 cm2 to 70 cm2 which comprises a flat and flexible container having an inlet port and an outlet port and a sheet-like leukocyte-removing-filter material with a thickness of 8.2 mm to 8.6 mm disposed to divide the container into an inlet-port side chamber and an outlet-port side chamber, providing a pair of volume restriction boards disposed outside of the inlet port side external surface and the outlet port side external surface of the flexible container, having the distance between the volume restriction boards at the portion where the volume restriction boards facing each other sandwich the leukocyte-removing filter being in a range from [thickness of leukocyte-removing filter+0.5 mm] to [thickness of leukocyte-removing filter+2.5 mm], and filtering blood or blood components through the leukocyte-removing filter under a pressure of 30 kPa to 50 kPa while restraining expansion of the flexible container occurring during filtration by means of the volume restriction boards.

Owner:ASAHI KASEI MEDICAL CO LTD

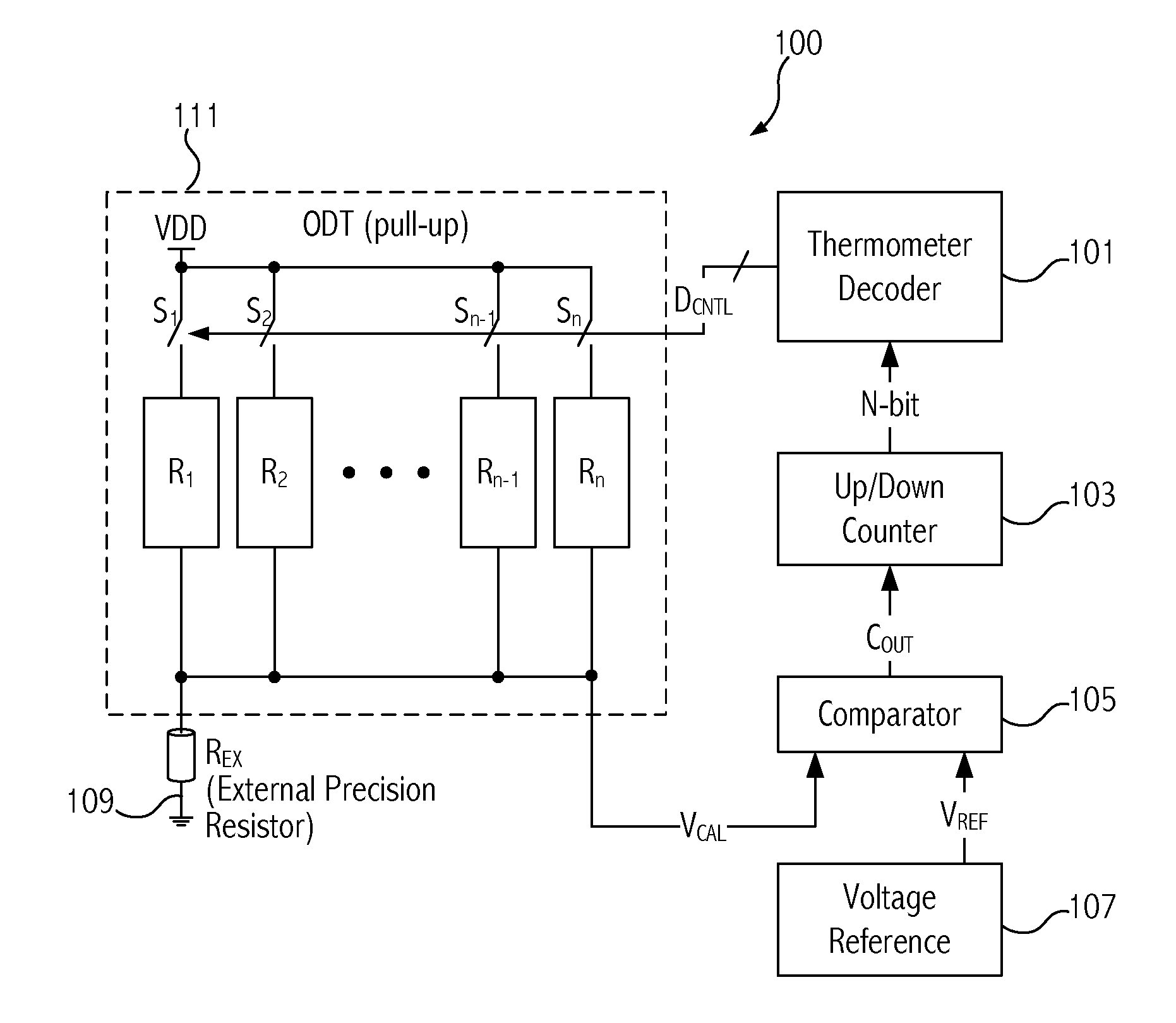

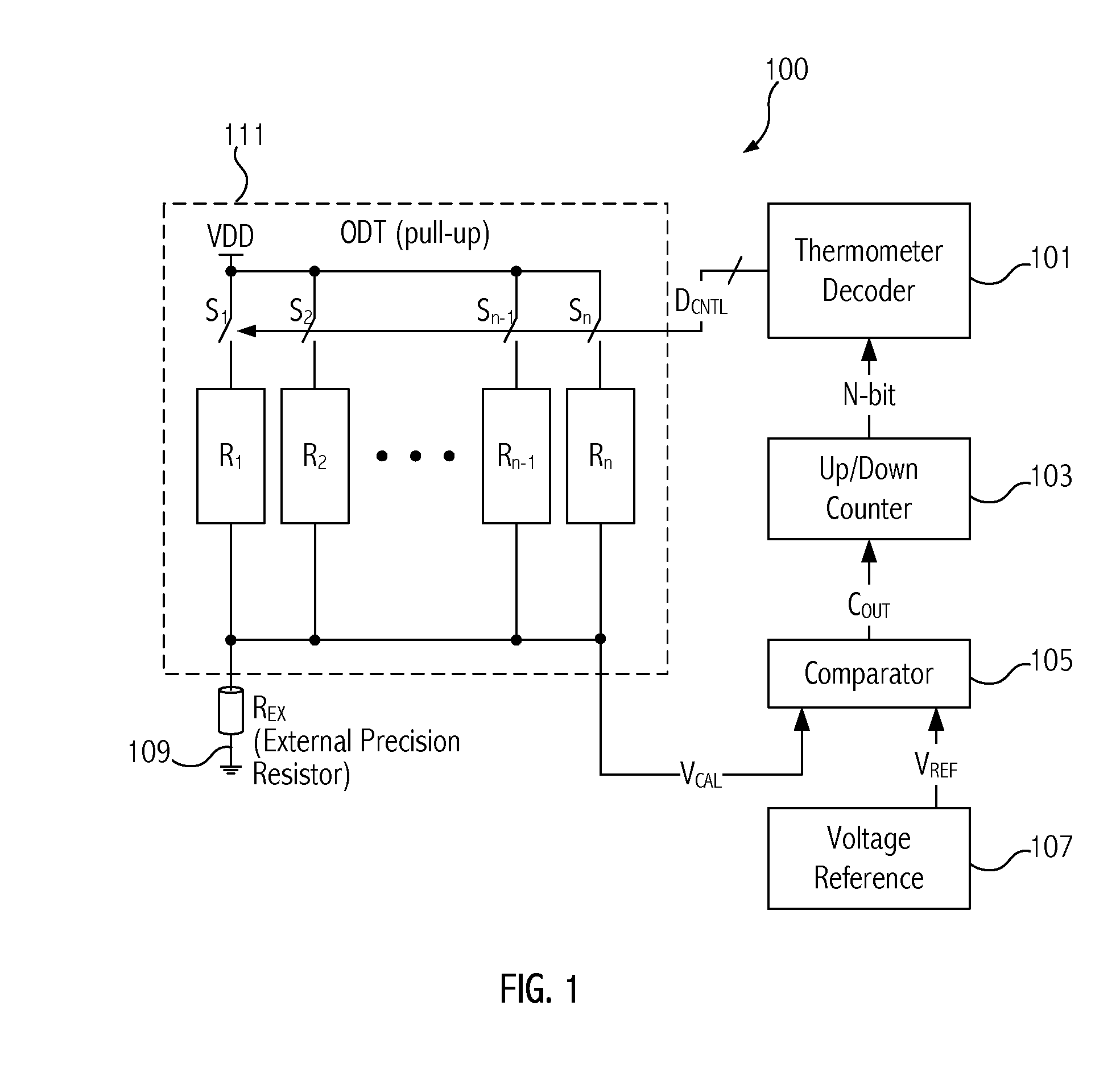

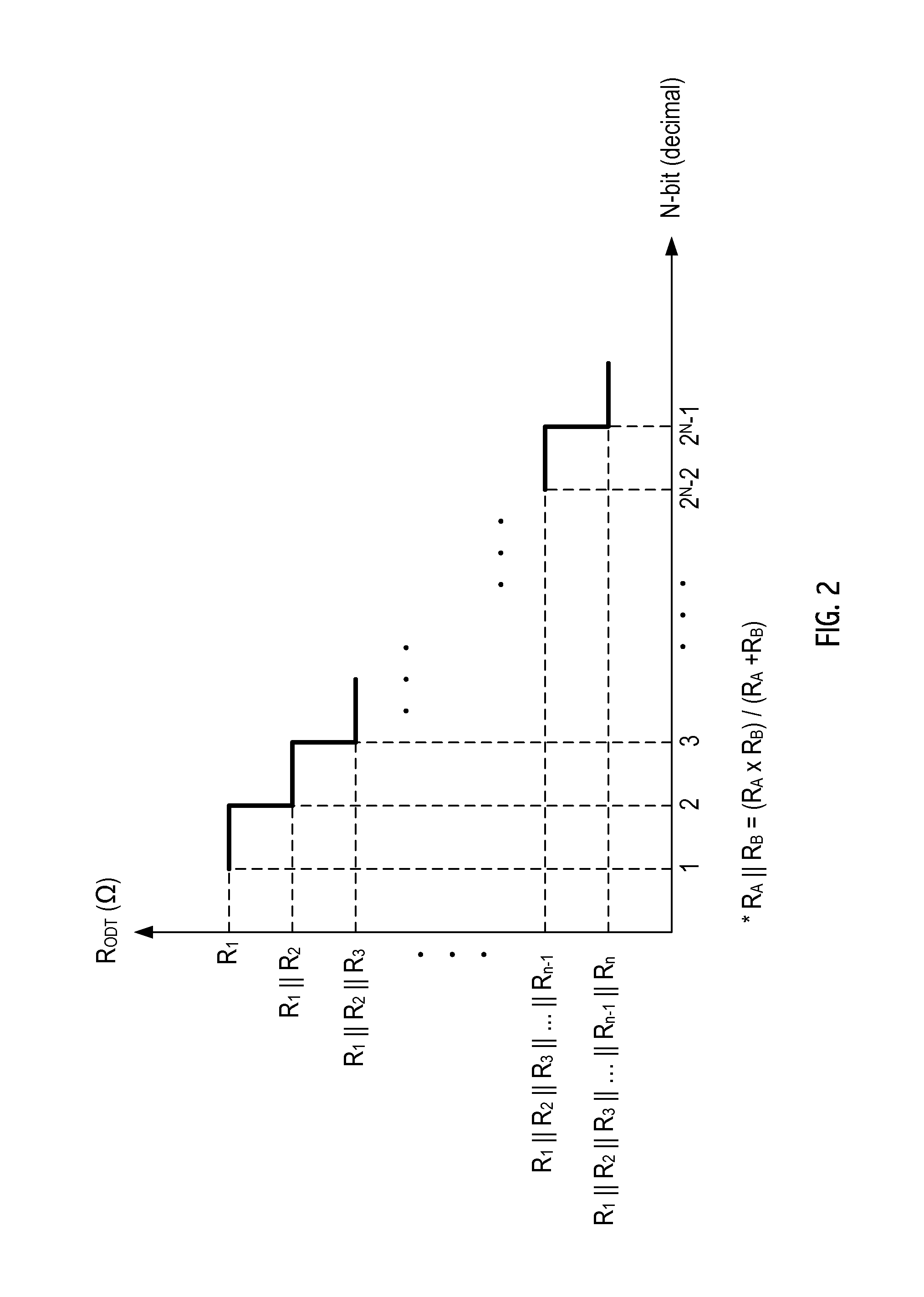

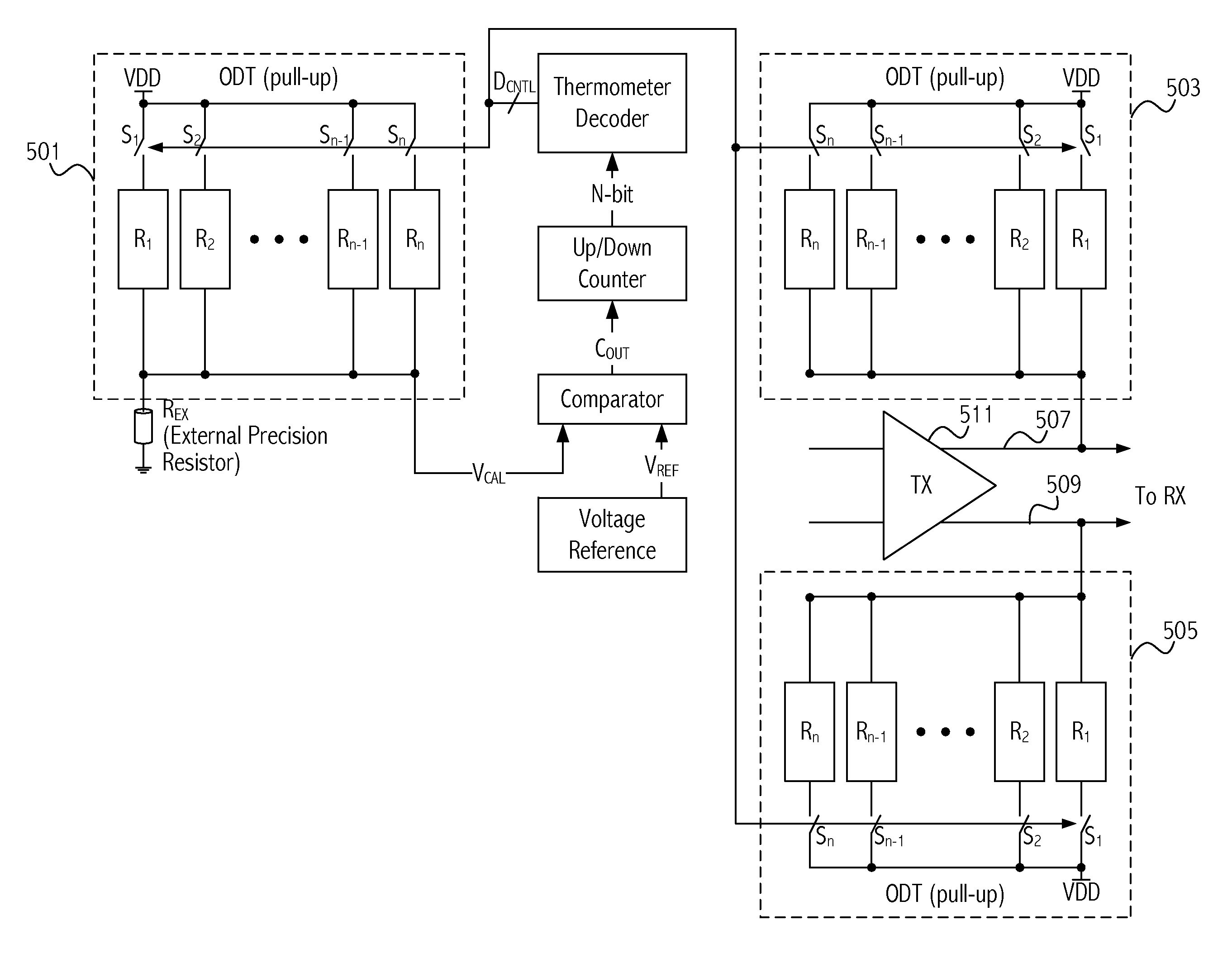

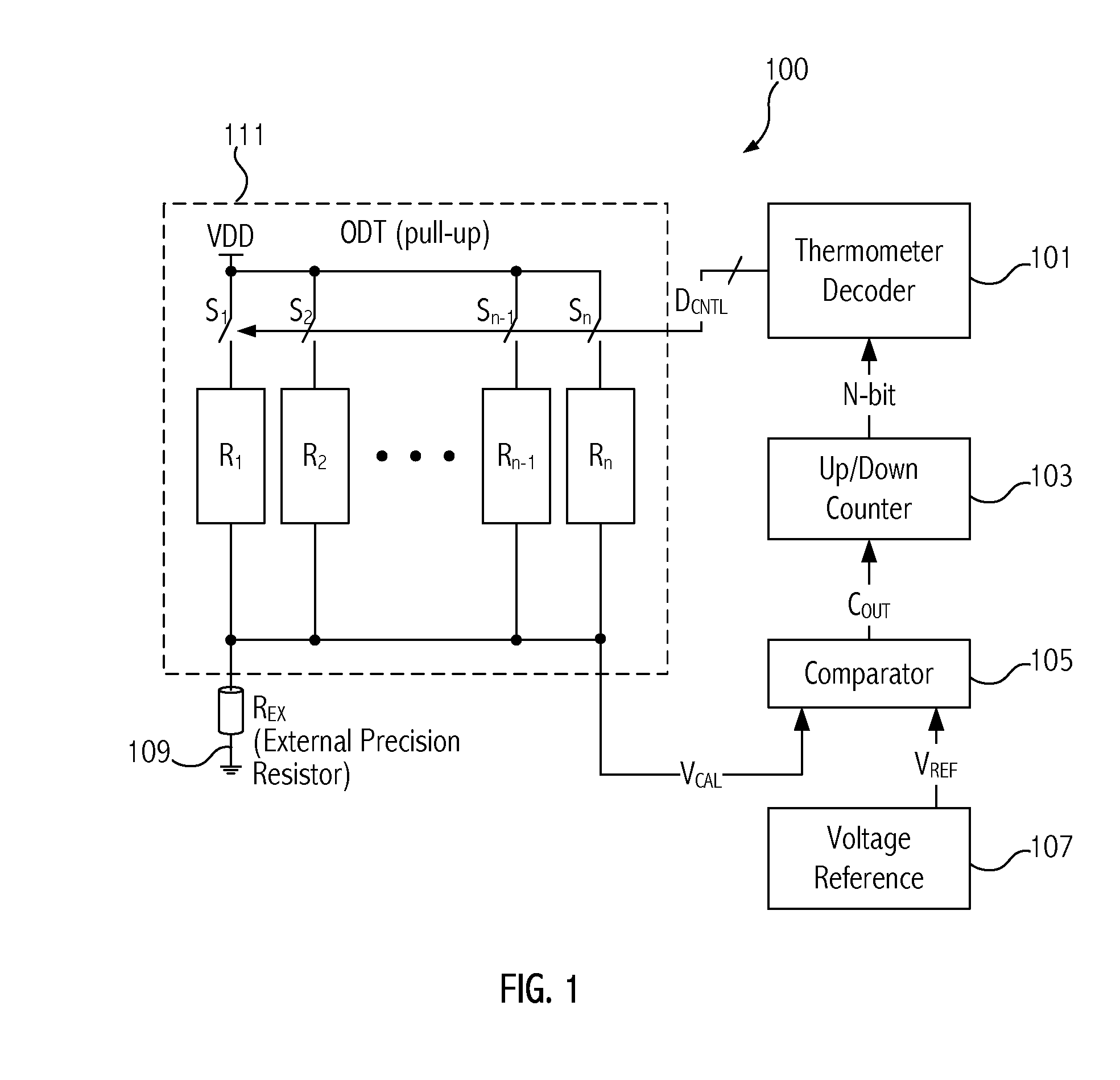

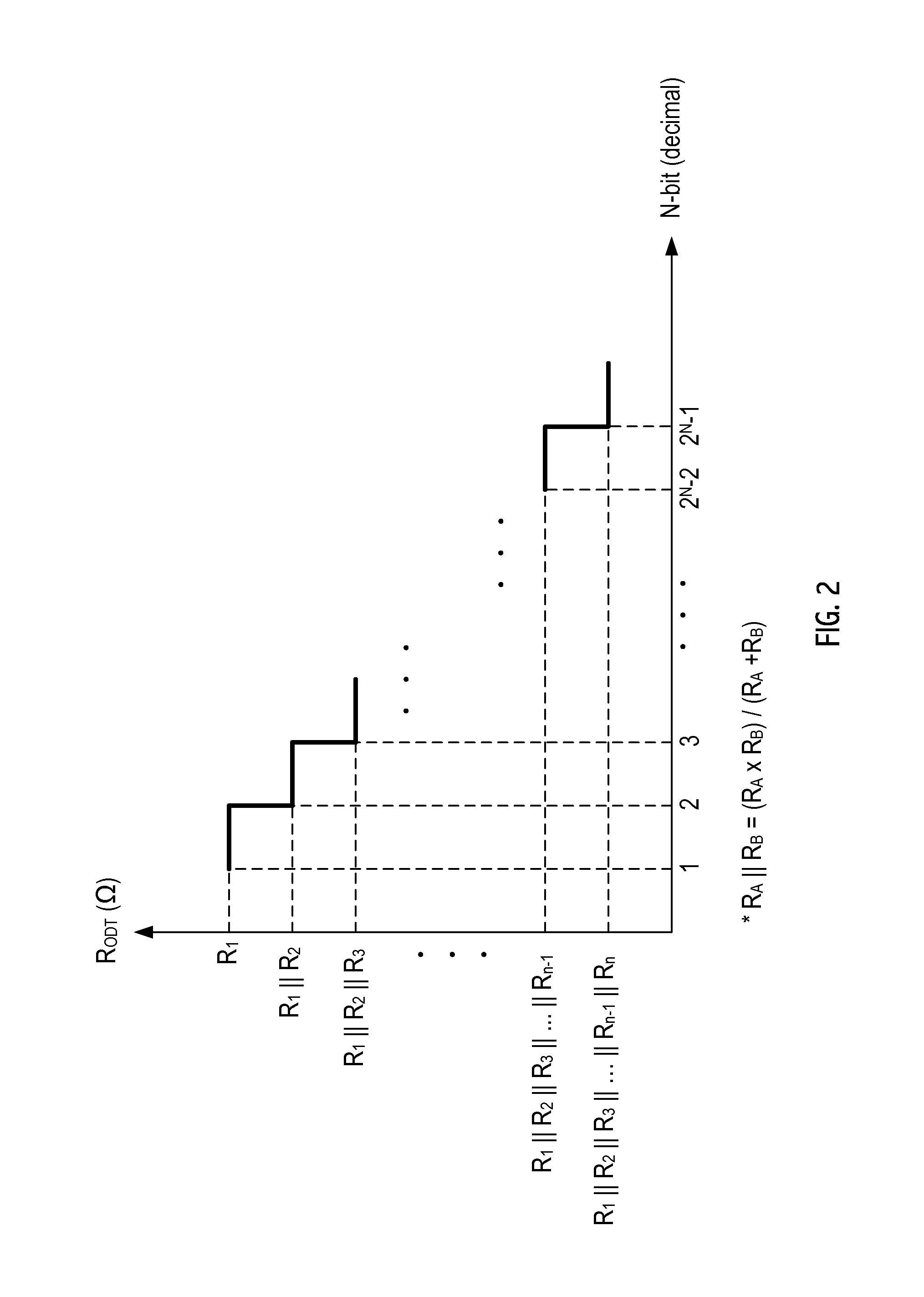

Real time averaged impedance calibration for on-die termination

ActiveUS20120256654A1High accuracySmall area utilizedLogic circuit coupling arrangementsReliability increasing modificationsTime averageOn-die termination

Owner:ATI TECH INC

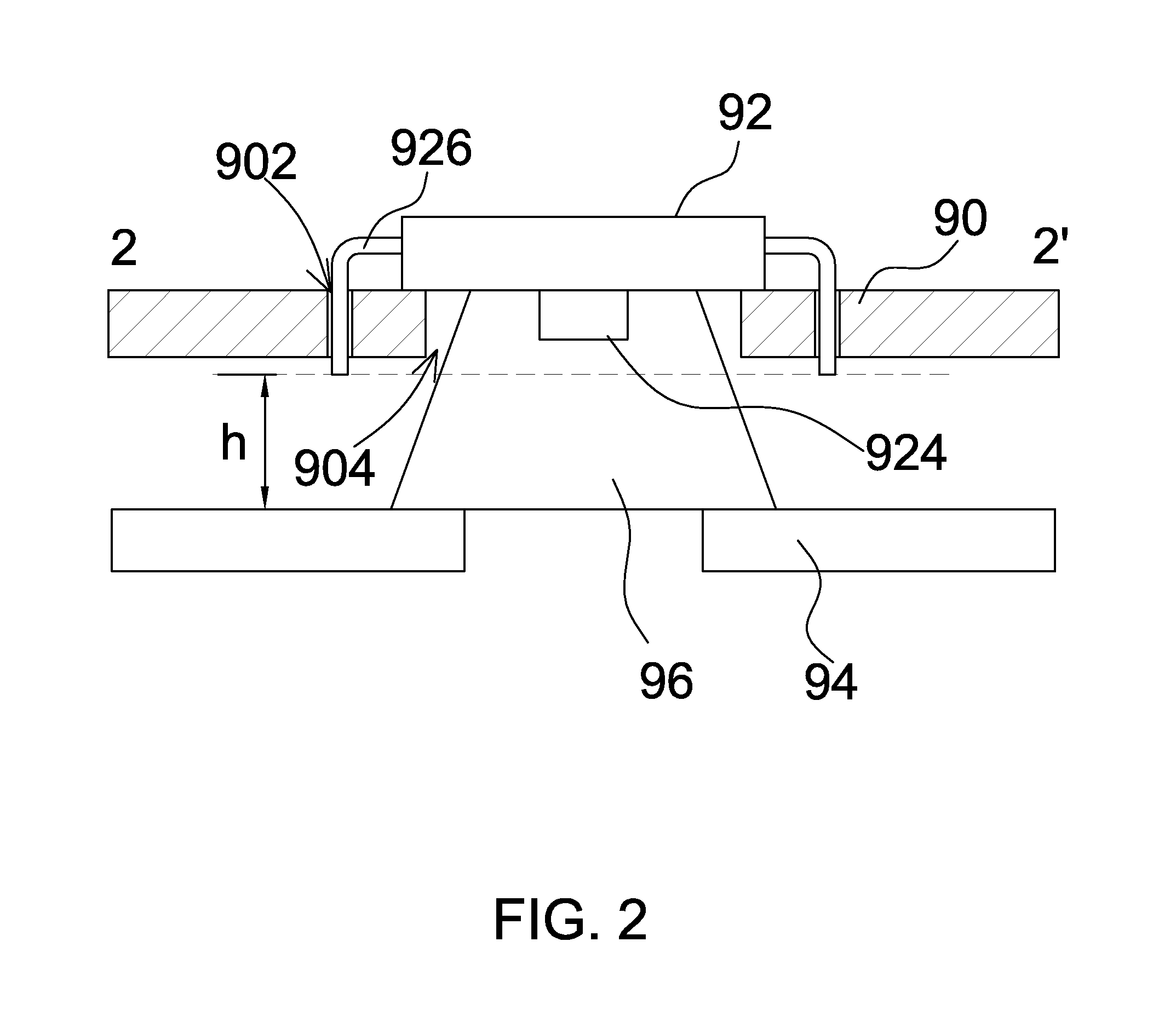

Area array routing masks for improved escape of devices on PCB

InactiveUS20070057362A1OptimizationReduce the numberSemiconductor/solid-state device detailsPrinted circuit aspectsDesign phaseEngineering

A method for optimizing area array device pin utilization and reducing the number of layers on a multilayered PCB comprising: preparing a package of BGA pin-out maps which anticipate the effect of existing fixed pins and derives the resulting optimum pin location assignment. Each pin-out map includes an indication of the best routing for circuits from a given component to be mounted to a PCB. Applying the package of pin-out maps during an area array pin assignment phase, thereby making an area array package capable of supporting the optimum routing configuration proposed by the pin-out maps. Applying the package of pin-out maps during a PCB design phase so that the optimum circuit routing to each pin is achieved, thereby completing the strategy layed out by the proposed pin-out maps, resulting in a lower number of PCB layers.

Owner:ALCATEL LUCENT SAS

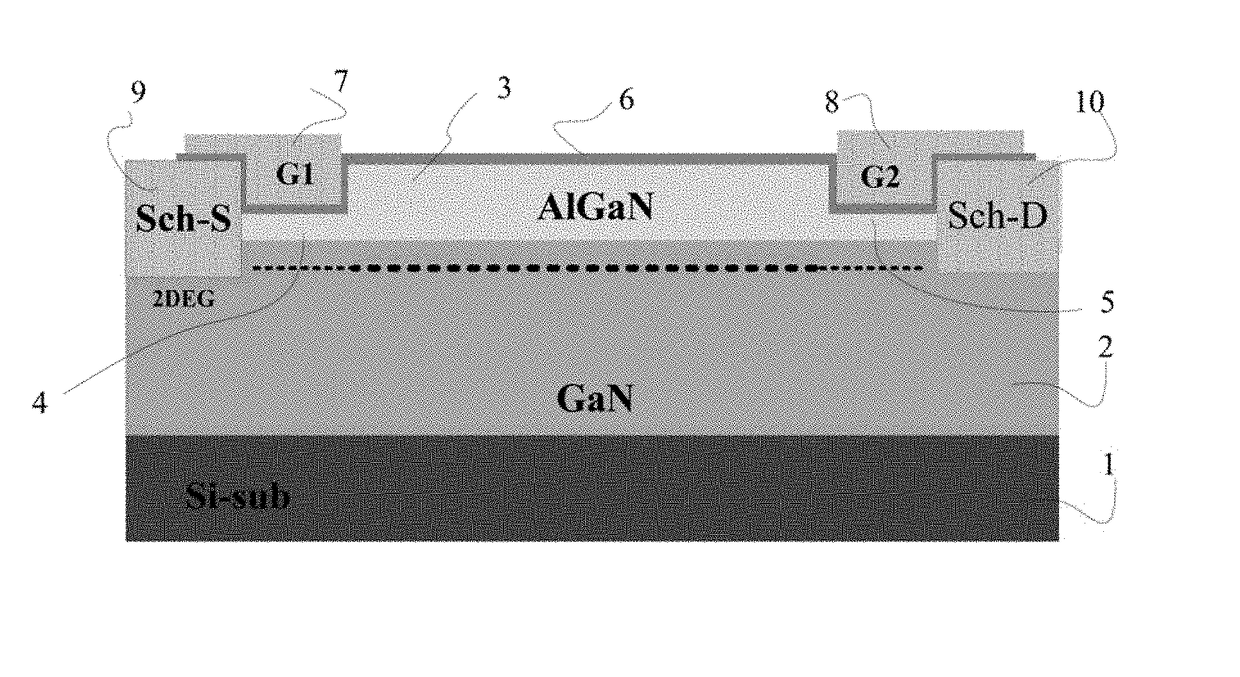

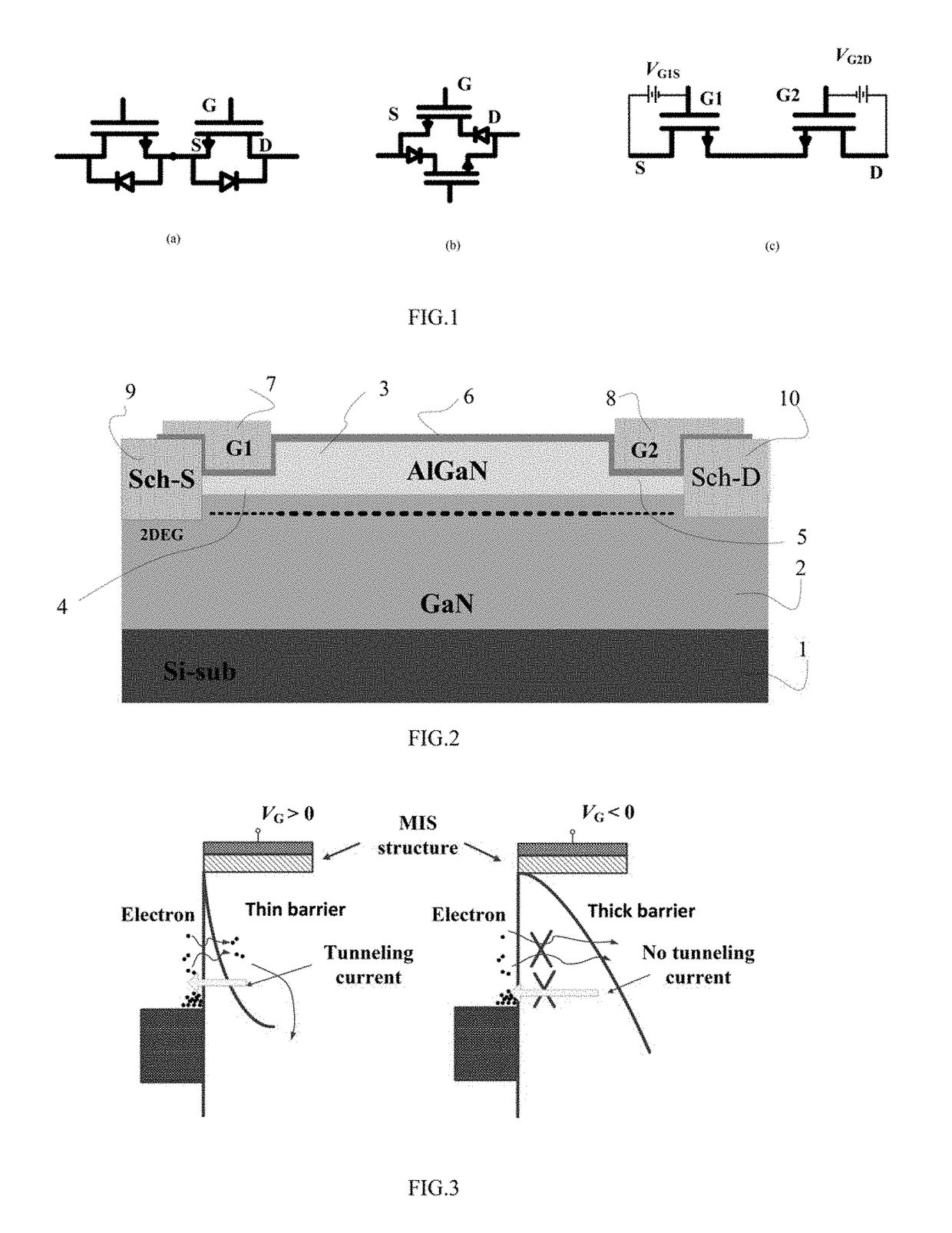

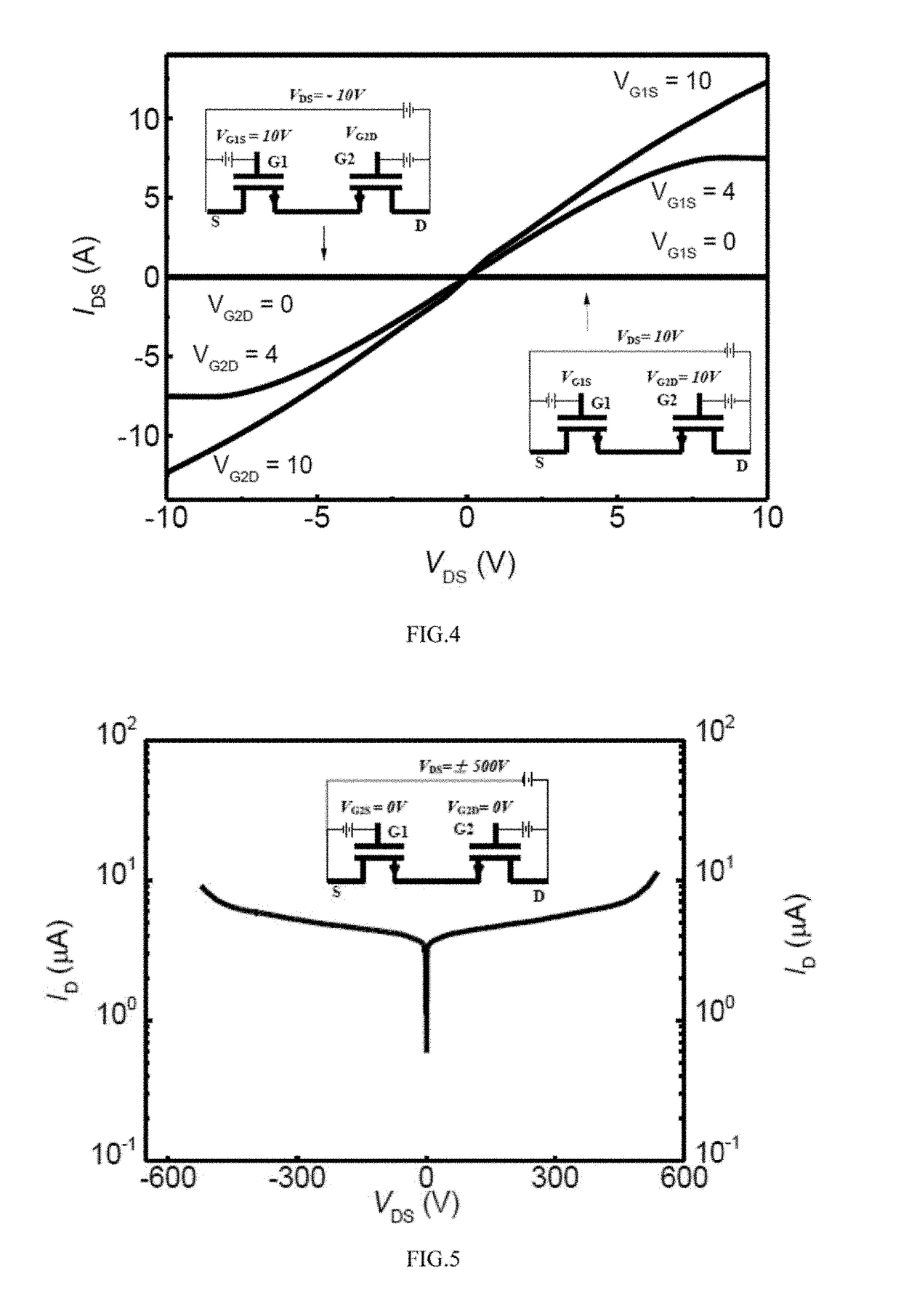

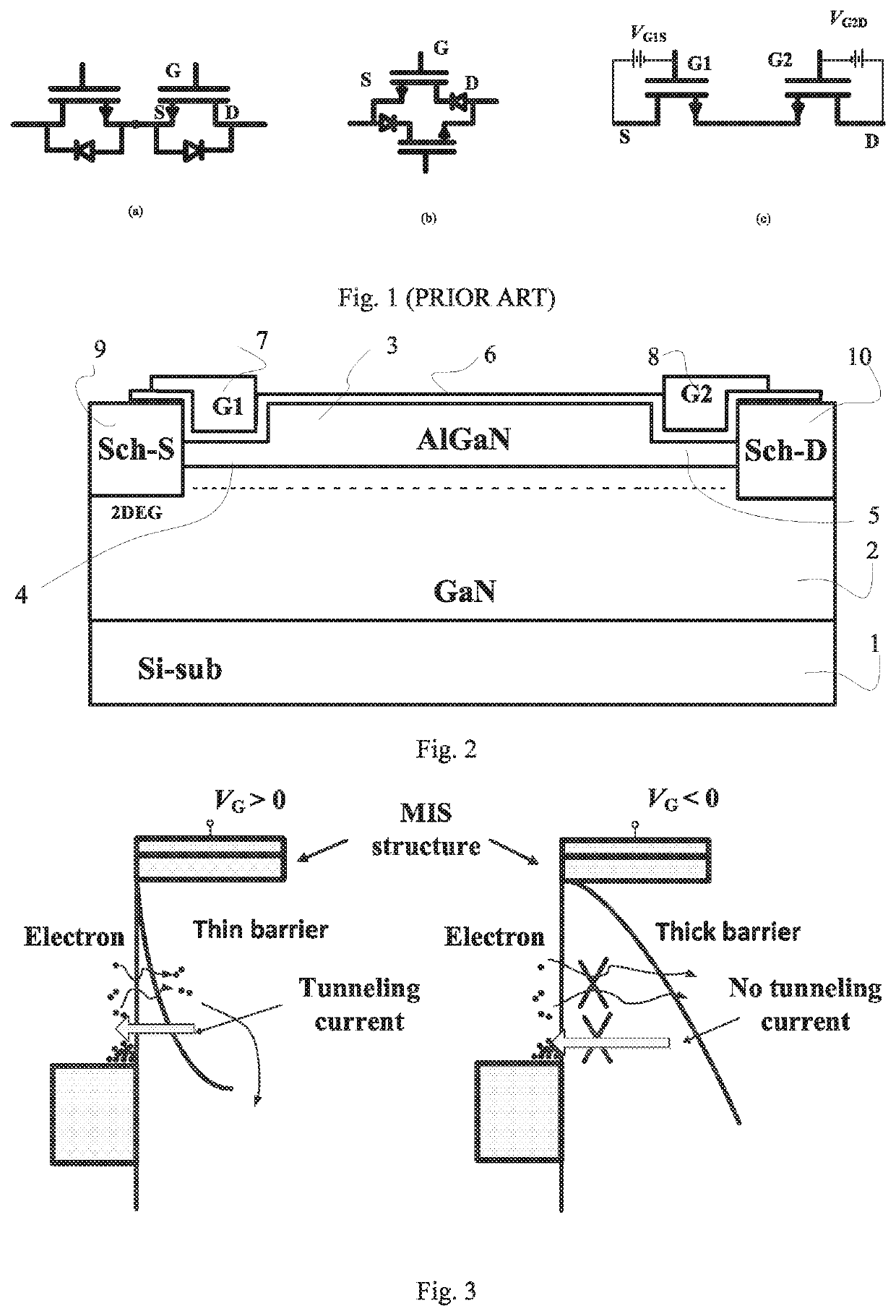

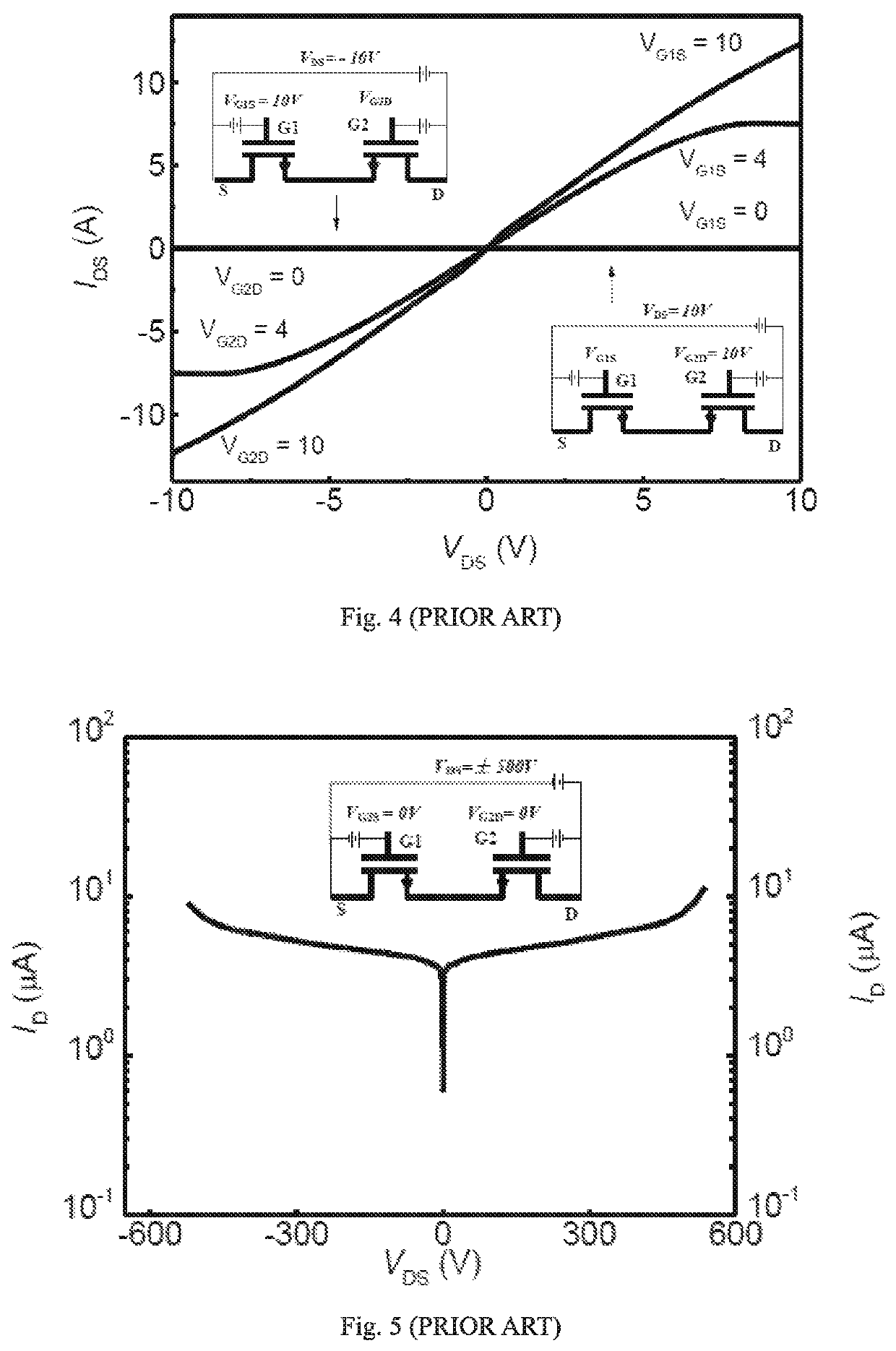

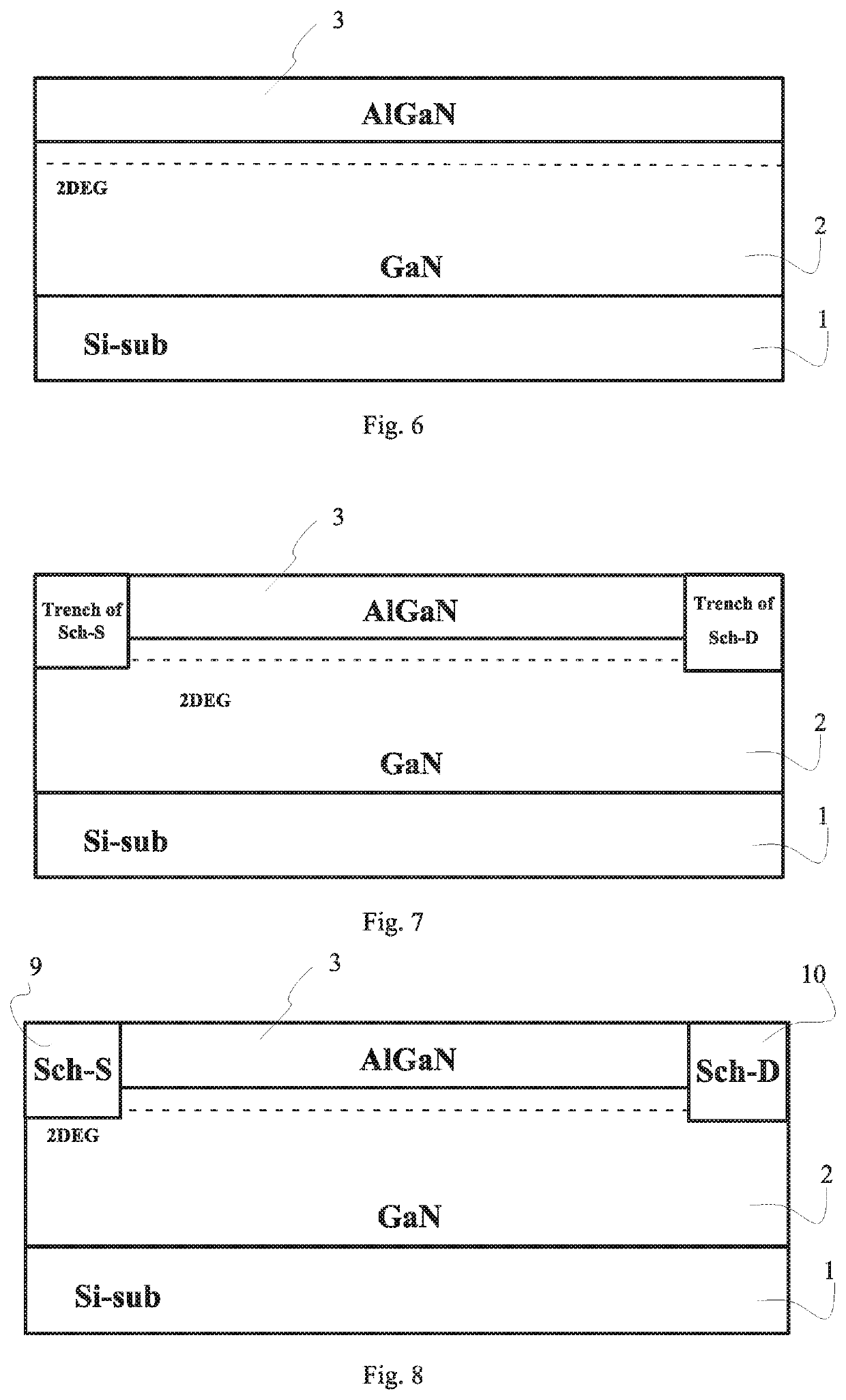

GaN-BASED BIDIRECTIONAL SWITCH DEVICE

The present invention relates to the field of semiconductor switches, and relates more particularly to a GaN-based bidirectional switch device. The present invention provides a gate-controlled tunneling bidirectional switch device without Ohmic-contact, which avoids a series of negative effects (such as current collapse, incompatibility with traditional CMOS process) caused by the high temperature ohm annealing process. Each insulated gate structure near schottky-contact controls the band structure of the schottky-contact to change the working state of the device, realizing the bidirectional switch's ability of bidirectional conducting and blocking. Due to the only presence of schottky in this invention, no heavy elements such as gold is needed, and this device is compatible with traditional CMOS technology.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Electronic device with high electrostatic protection

ActiveUS20150276472A1Increase discharge distanceImprove electrostatic protection abilityBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansElectricityOptoelectronics

An electronic device including a substrate and an optoelectronic device package is provided. The optoelectronic device package includes a light source, an image sensor and a plurality of connecting pins. The light source is configured to emit light toward a direction of a bottom surface of the optoelectronic device package. The image sensor is configured to receive reflected light from the direction of the bottom surface. The connecting pins are bended toward an opposite direction of the direction of the bottom surface and electrically connected to the substrate thereby increasing a discharge path of the electrostatic discharge.

Owner:PIXART IMAGING INC

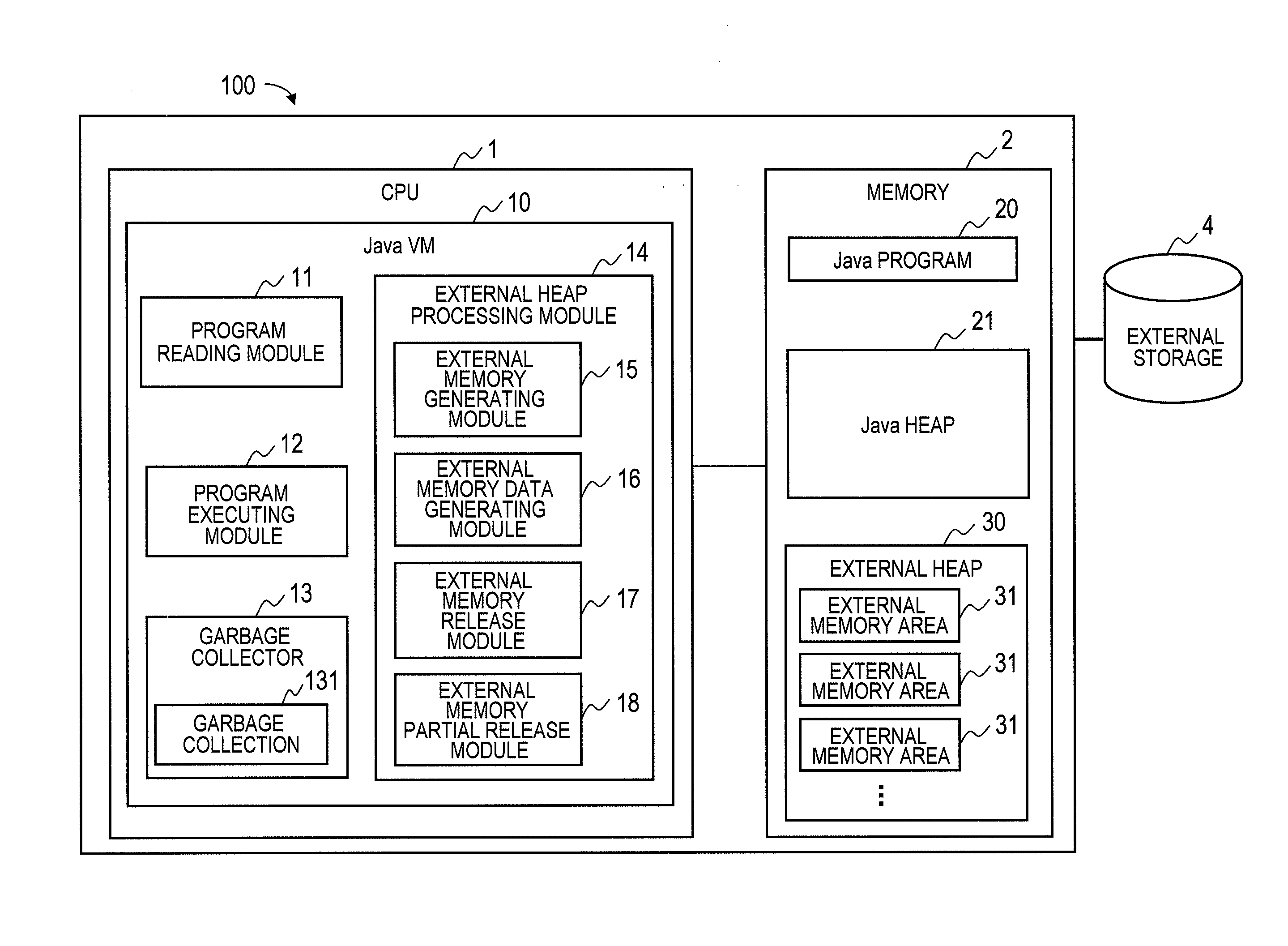

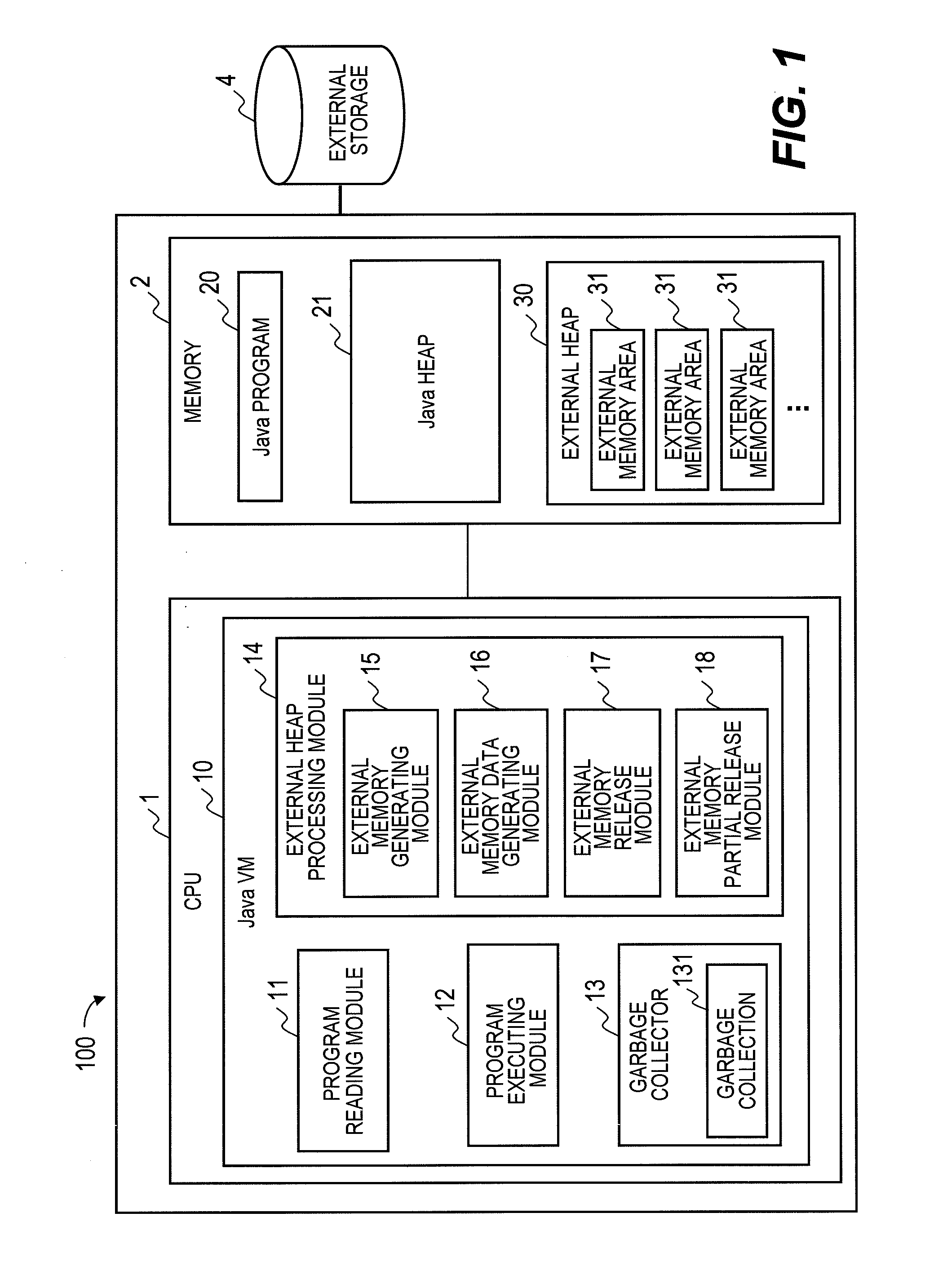

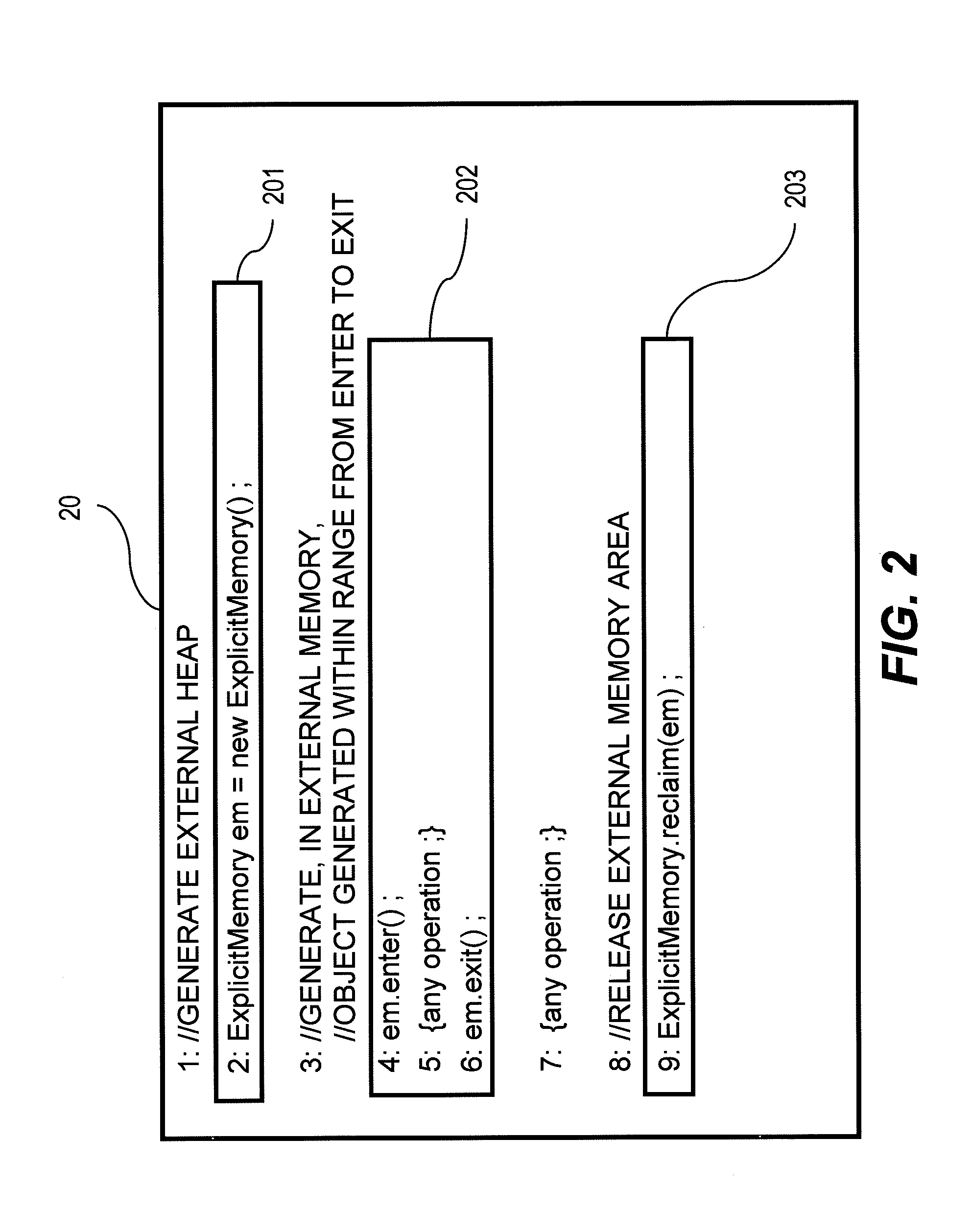

Memory management method, computer system and computer readable medium

ActiveUS20120198184A1Utilization efficiency of areaImprove utilization efficiencyMemory architecture accessing/allocationDigital data information retrievalComputerized systemObject store

It is provided a memory management method for releasing an unnecessary area in a memory area used by a program stored in the memory and executed by the computing device. The memory management method including the step of: setting in the memory, a first memory area which is used to execute the program; setting in the memory, a second memory area which can be operated by the program; setting a utilized area in the second memory area based on an instruction from the program; storing objects including data in the utilized area of the second memory area based on an instruction from the program; determining whether the program uses the objects stored in the utilized area within the second memory area; and releasing, by the computing device, the utilized area occupied by an object that is not used by the program among the objects stored in the utilized area.

Owner:HITACHI LTD

Real time averaged impedance calibration for on-die termination

ActiveUS8384424B2High resolutionImproved terminationLogic circuit coupling arrangementsReliability increasing modificationsElectrical resistance and conductanceResistive load

Owner:ATI TECH INC

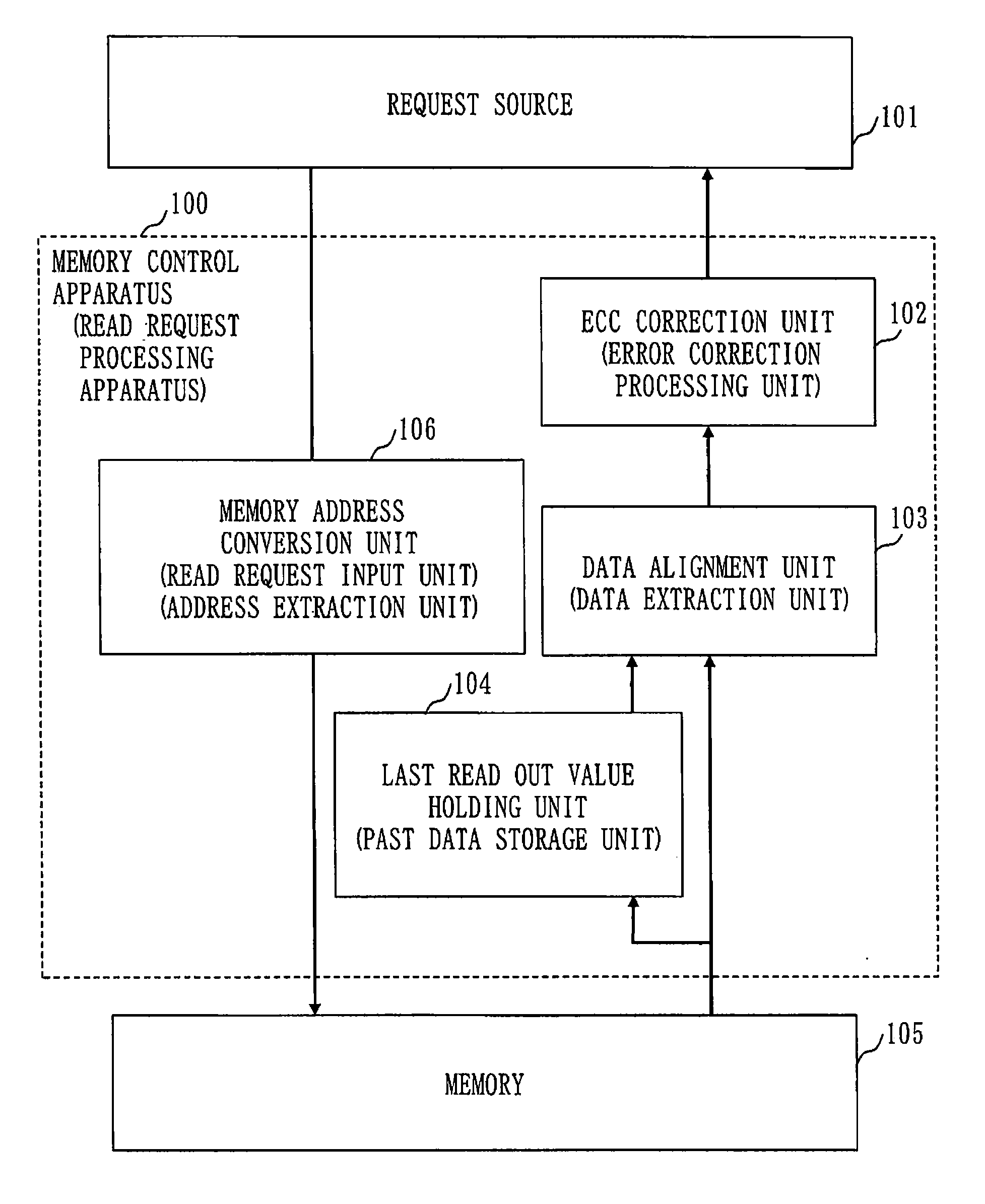

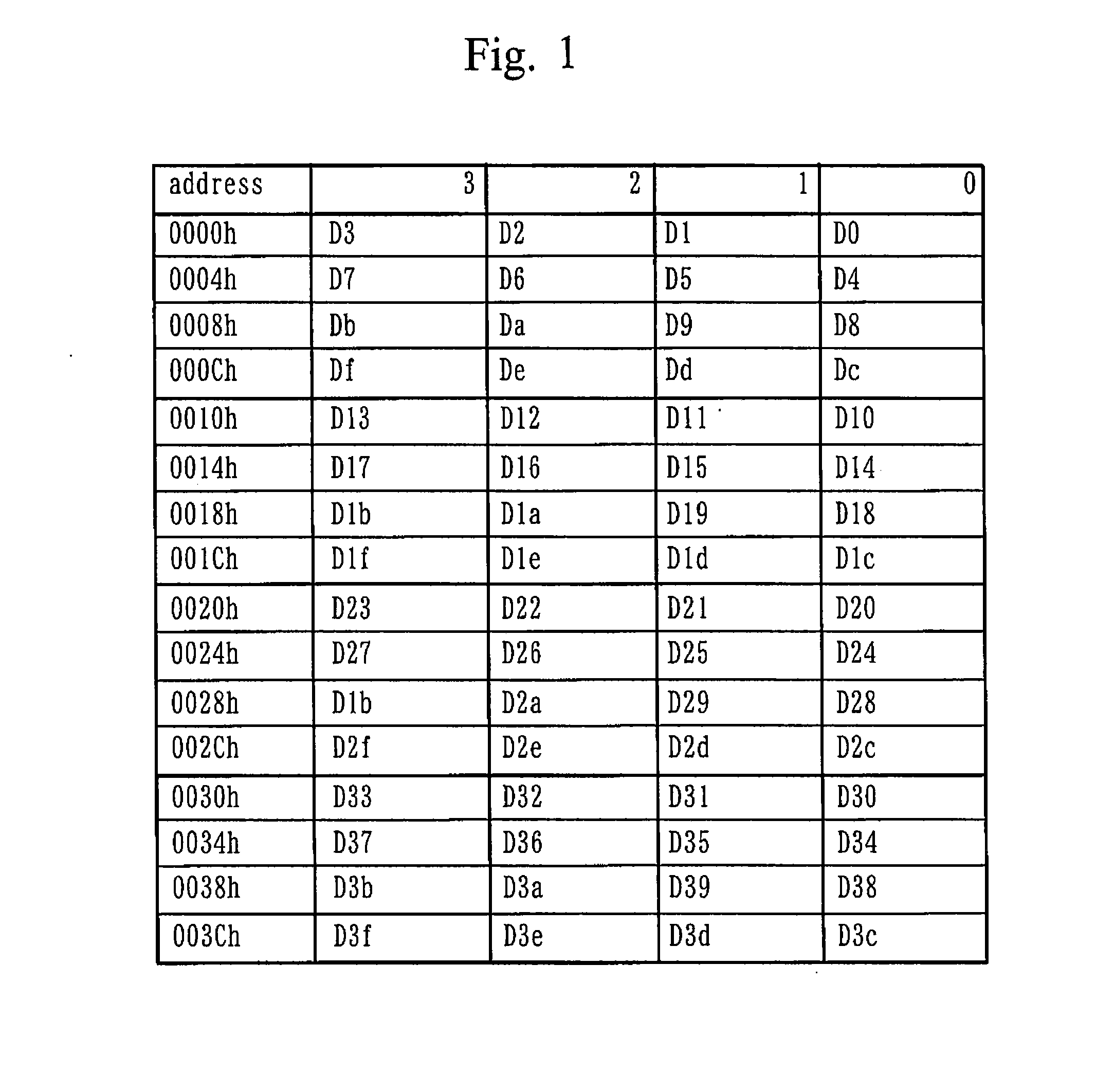

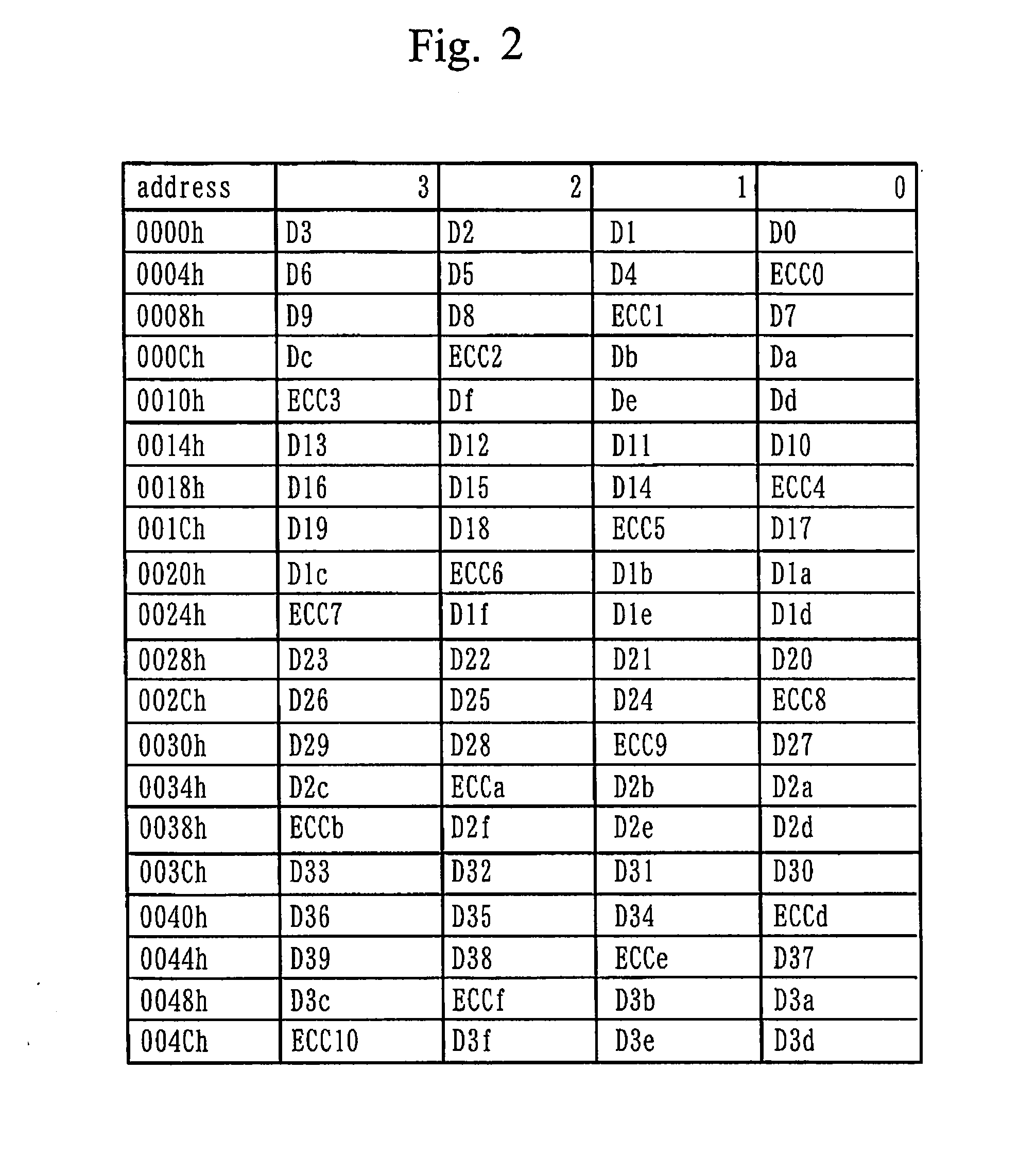

Read request processing apparatus

InactiveUS20150046773A1Avoid redundant reading out of dataUtilization areaInput/output to record carriersStatic storageMemory addressComputer hardware

A wrapping burst read determination unit determines whether or not a read request is a request of a wrapping read. If the read request is the request of the wrapping read, a memory address conversion unit extracts a plurality of addresses that includes an address in which payload data requested by the read request is stored, and designates a read out order of data from the plurality of addresses extracted. If the read request is the request of the wrapping read, a first data holding unit inputs first data read out from an address to which a forefront position in the read out order has been designated among the plurality of addresses, and stores the first data. If the read request is the request of the wrapping read, a data alignment unit, inputs trailing data read out from an address to which an end position in the read out order has been designated, and extracts payload data and an ECC which are correlated with each other from the first data and the trailing data.

Owner:MITSUBISHI ELECTRIC CORP

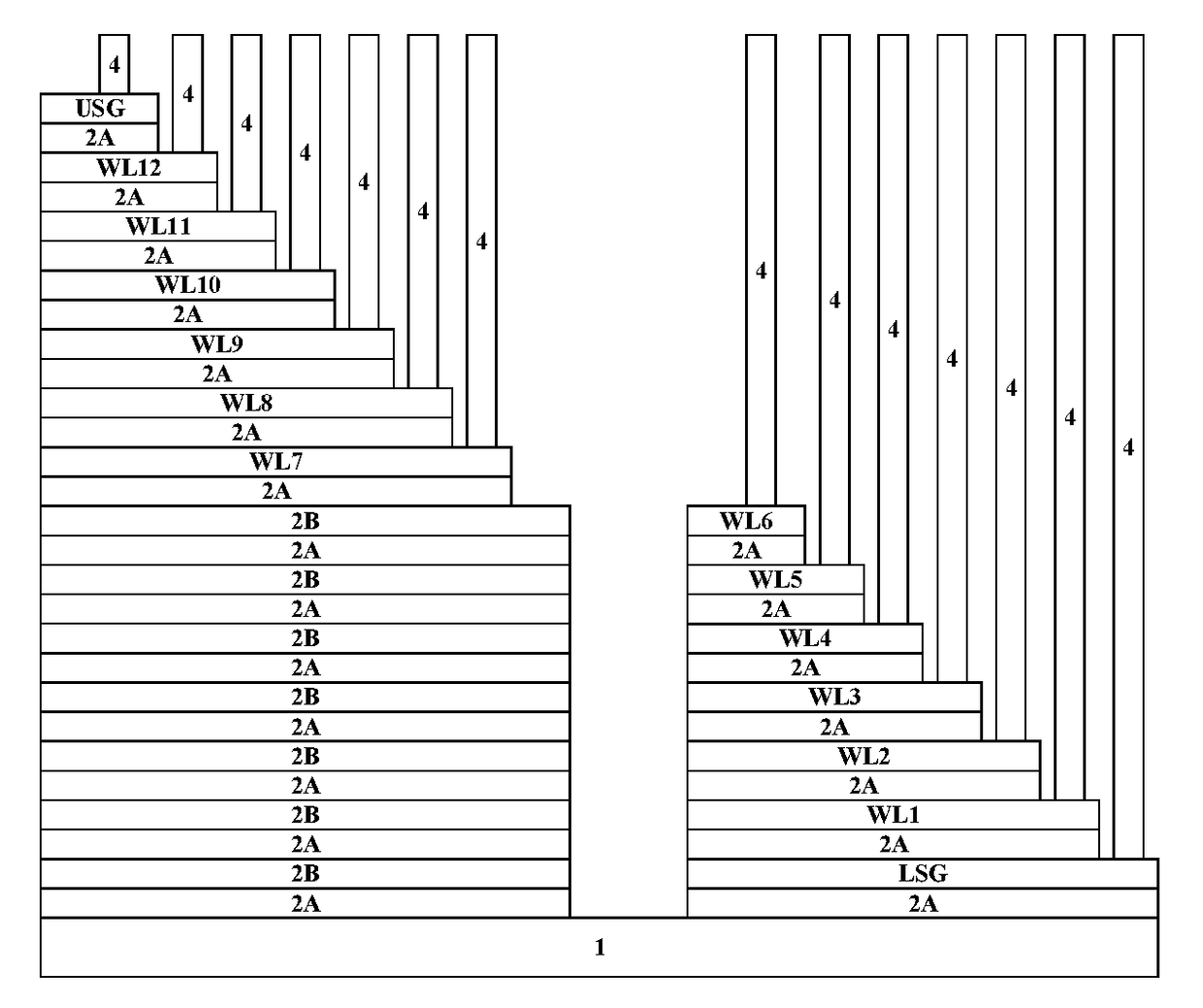

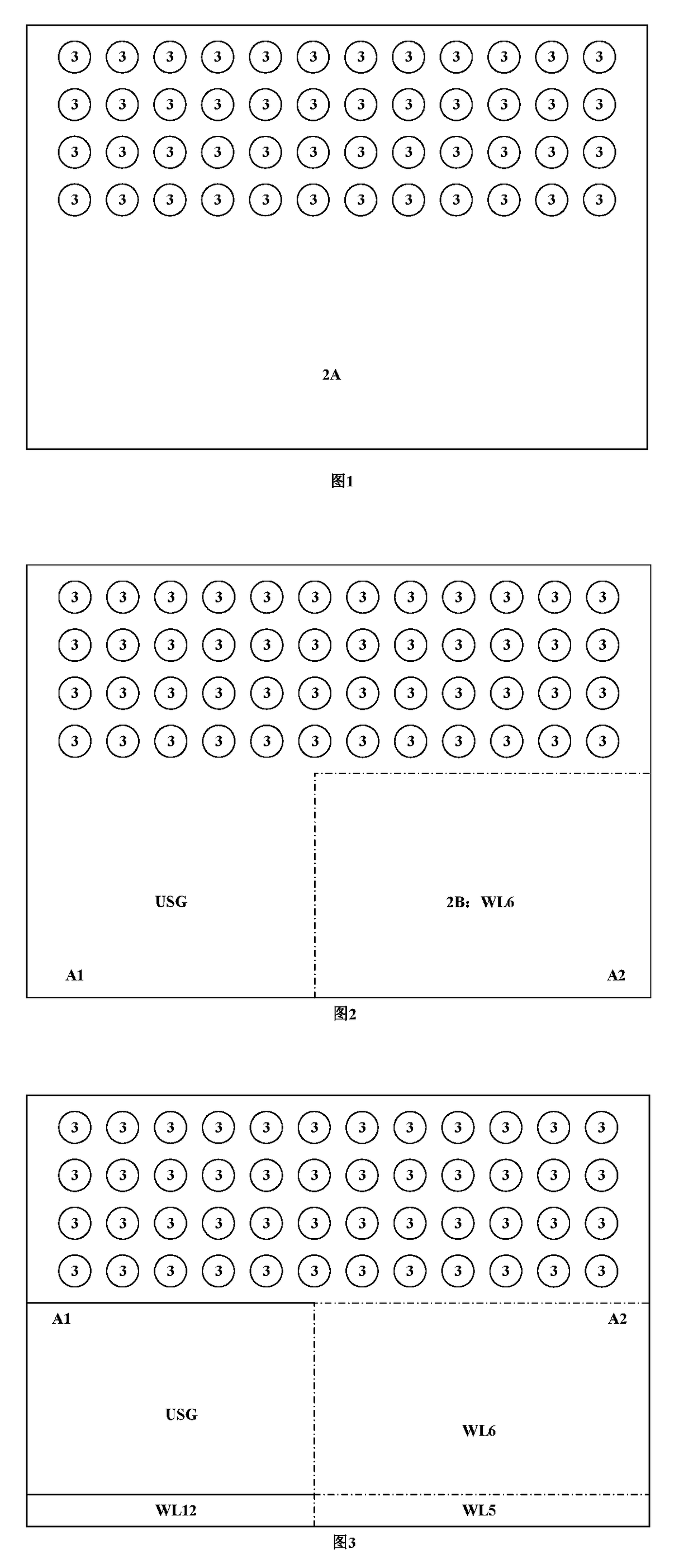

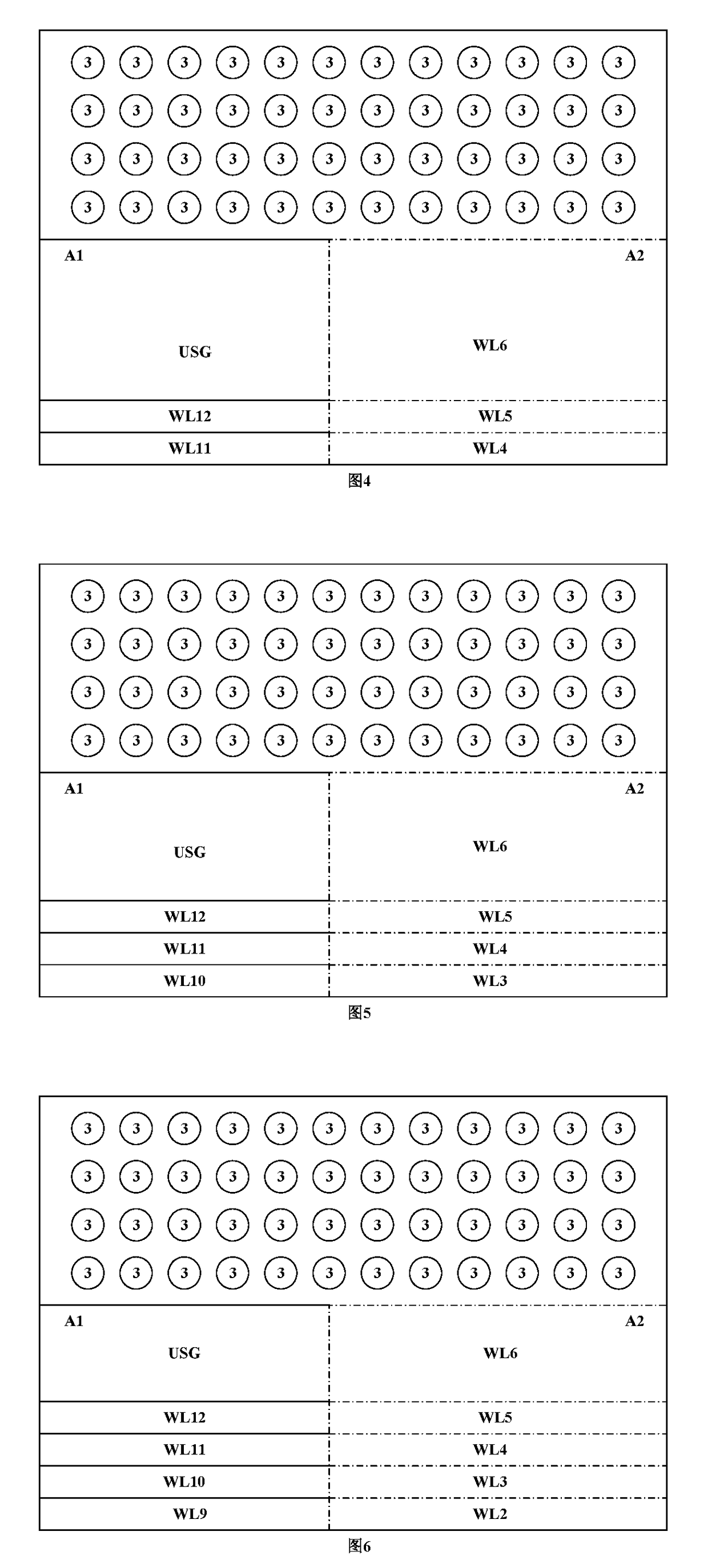

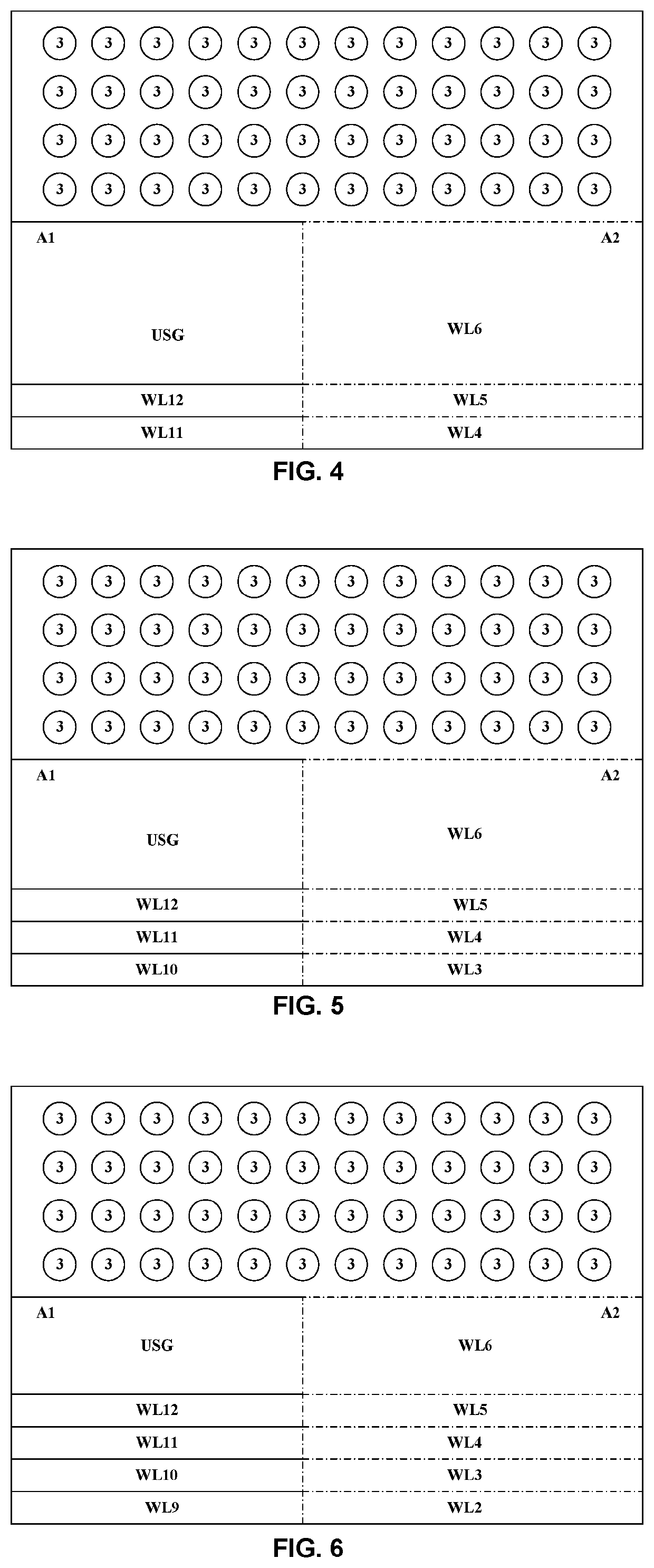

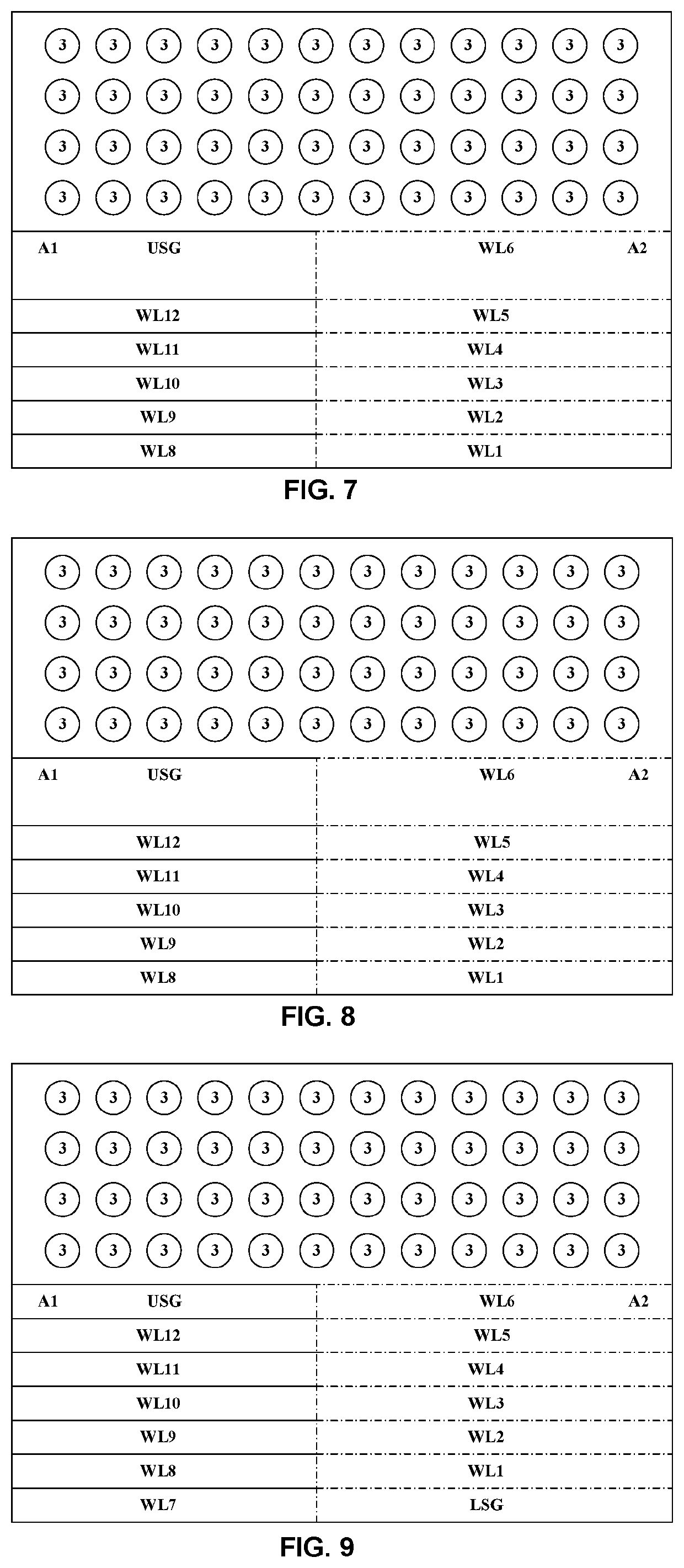

Method of manufacturing 3-d semiconductor device

ActiveUS20170170057A1Reduce numberImprove utilization of areaSemiconductor/solid-state device detailsSolid-state devicesResistPhotoresist

A method of manufacturing three-dimensional semiconductor device, comprising the steps of: a) forming a device unit on a substrate, the said device includes a plurality of stack structures composed of the first material layer and the second material layer stacked along a direction perpendicular to the substrate surface; b) forming a contact lead-out region around the said device unit, the contact lead-out region comprises a plurality of sub-partitions, each of the sub-partitions respectively exposes a different second material layer; c) forming a photoresist on said substrate, covering said plurality of sub-partitions, exposing a portion of said second material layer; d) using the photoresist as a mask, simultaneously etching the portion of the second material layer exposed by said plurality of sub-partitions, until another second material layer beneath said second material layer is exposed; e) slimming the size of the photoresist to expose a portion of said another second material layer; f) repeating said steps d and step e, until all of the second material layers are exposed; g) forming contact leads, connecting each of the plurality of the second material layers. In accordance with the method of the present invention, the total number of etching process steps is reduced dramatically and the area utilization is improved effectively by selectively etching each of the sub-partitions.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

GaN-based bidirectional switch device

ActiveUS10672896B2Utilization areaLower on-resistanceSemiconductor devicesOhmic contactElectronic band structure

The present invention relates to the field of semiconductor switches, and relates more particularly to a GaN-based bidirectional switch device. The present invention provides a gate-controlled tunneling bidirectional switch device without Ohmic-contact, which avoids a series of negative effects (such as current collapse, incompatibility with traditional CMOS process) caused by the high temperature ohm annealing process. Each insulated gate structure near schottky-contact controls the band structure of the schottky-contact to change the working state of the device, realizing the bidirectional switch's ability of bidirectional conducting and blocking. Due to the only presence of schottky in this invention, no heavy elements such as gold is needed, and this device is compatible with traditional CMOS technology.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

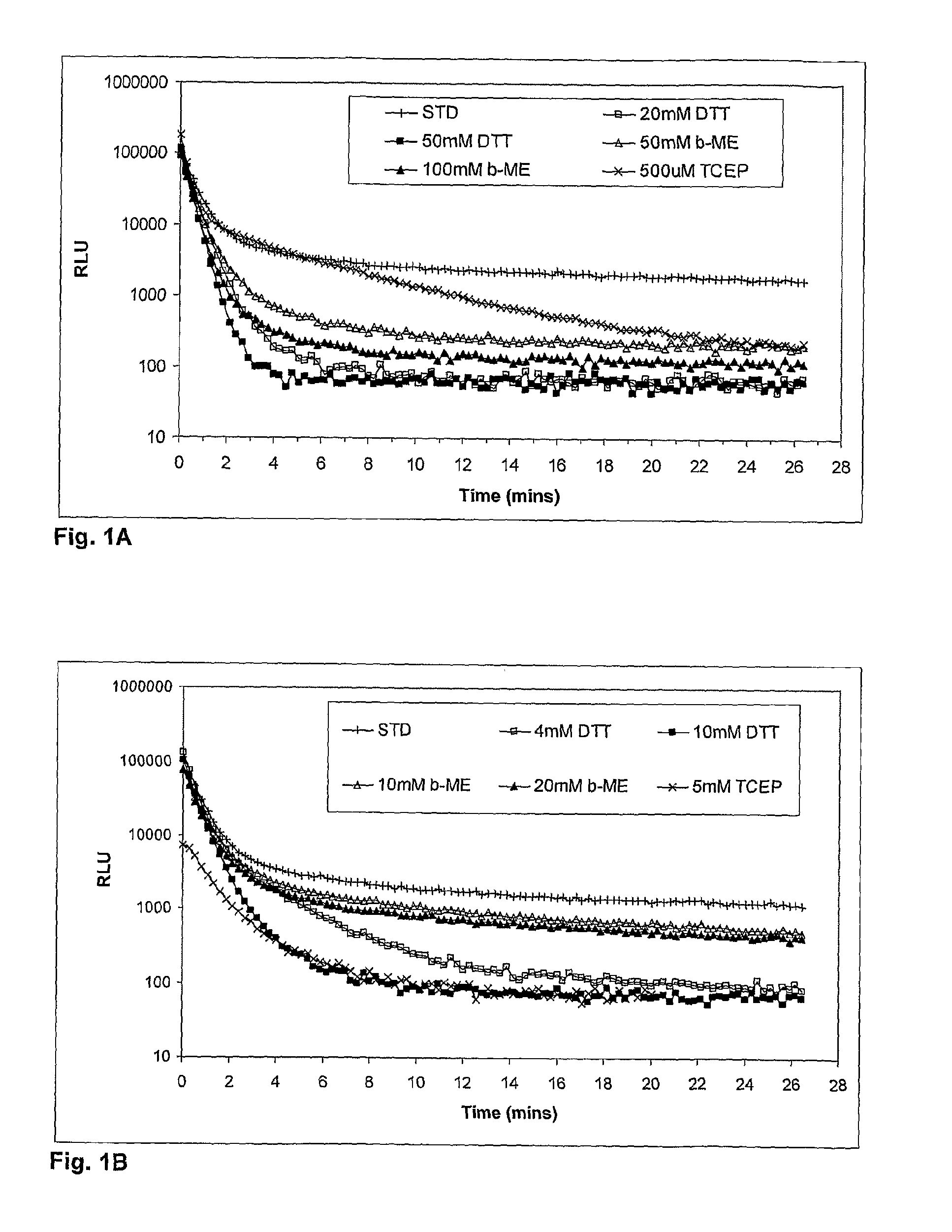

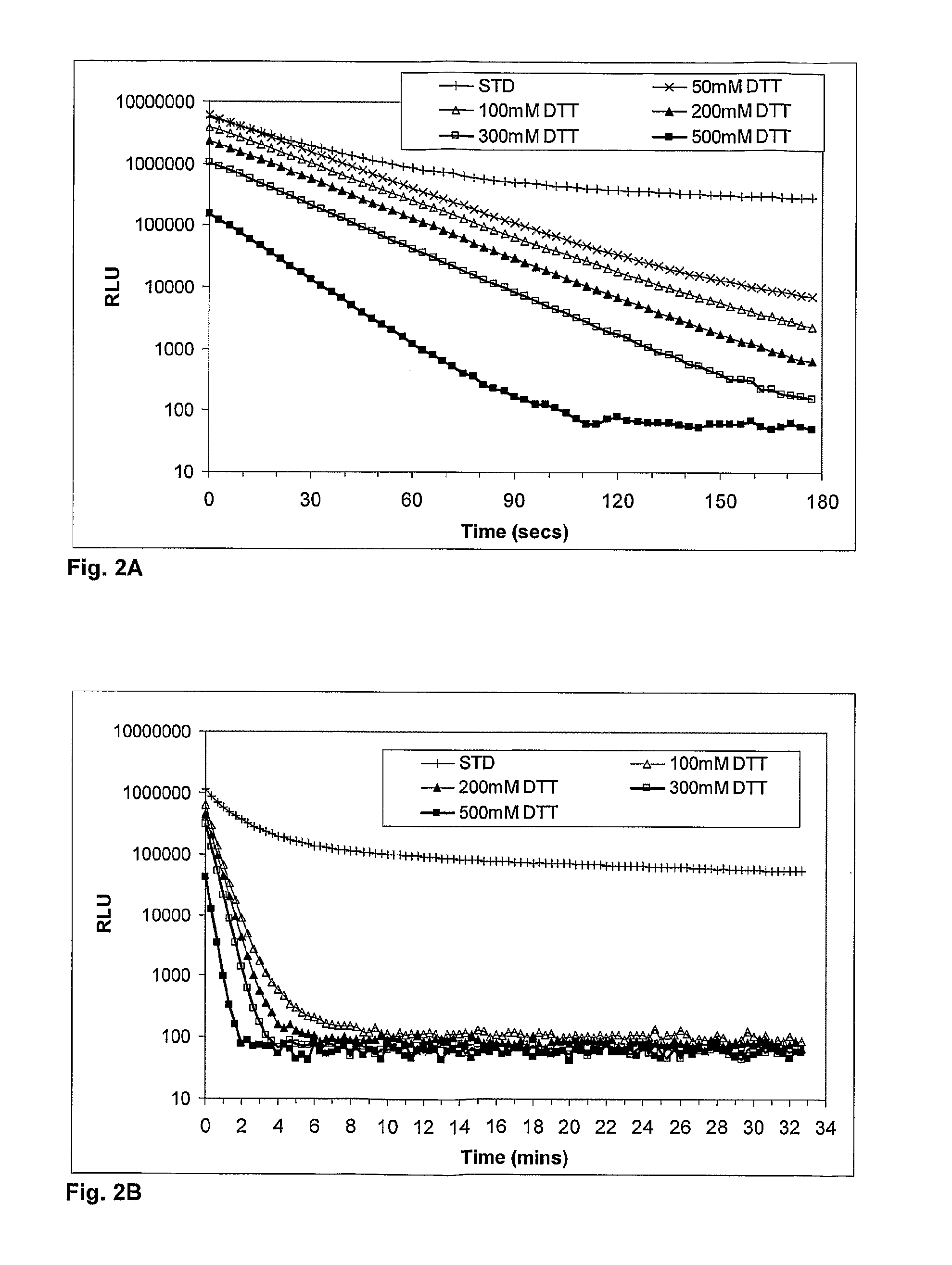

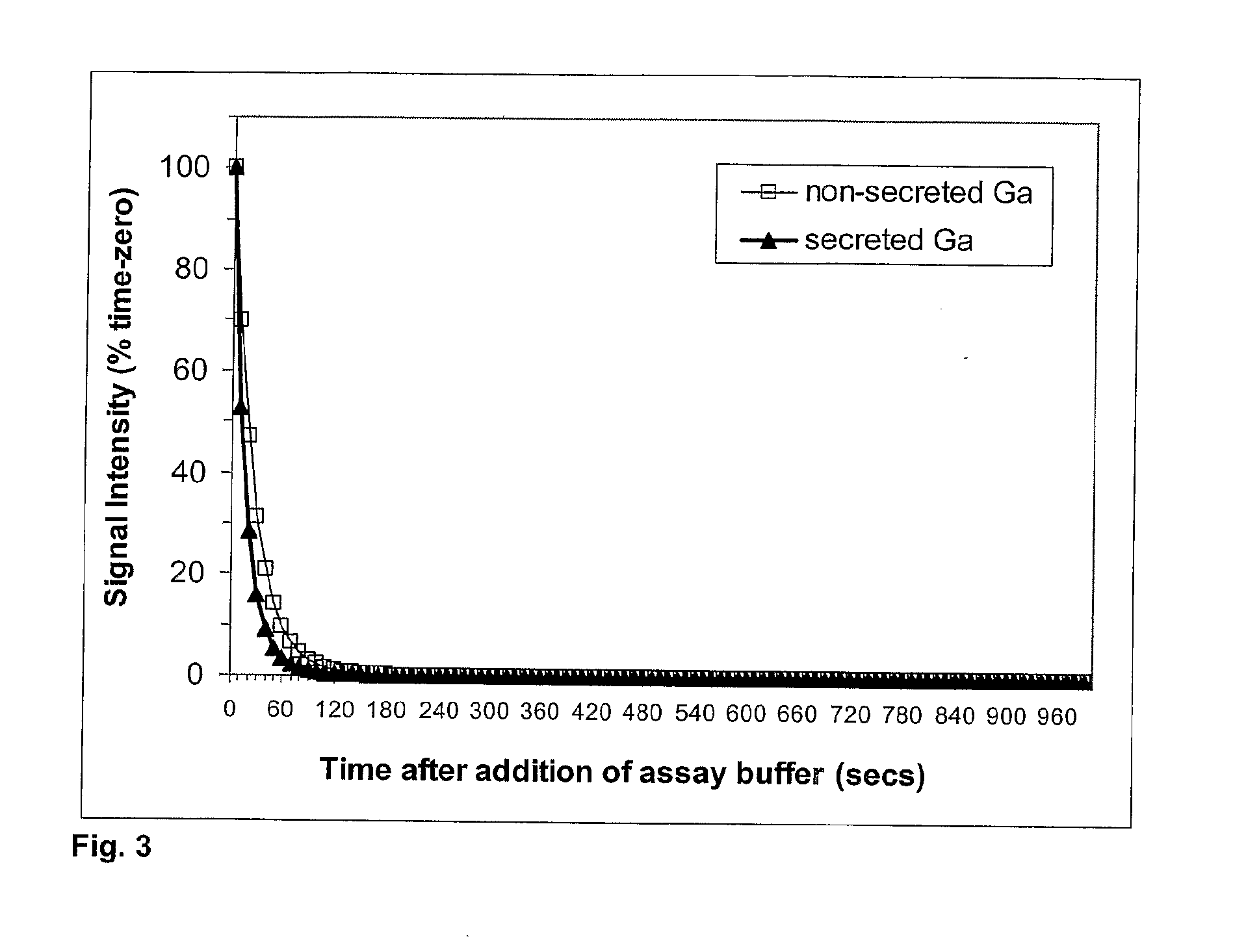

Bioluminescent assays utilising secreted luciferases

ActiveUS20100092967A1Shorten the overall cycleHigh sensitivityOrganic chemistryOrganic compound preparationLuciferasesBiology

Disclosed herein are methods for determining the amount or activity of one or more luciferases and methods for measuring the luminescent signal generated by one or more luciferases in a sample, the methods comprising incubating the sample with a reactive substrate(s) of the luciferase(s) to be analysed and a reducing agent to inactivate a first luciferase, wherein the first luciferase, in its native form, is a secreted luciferase.

Owner:PROMEGA

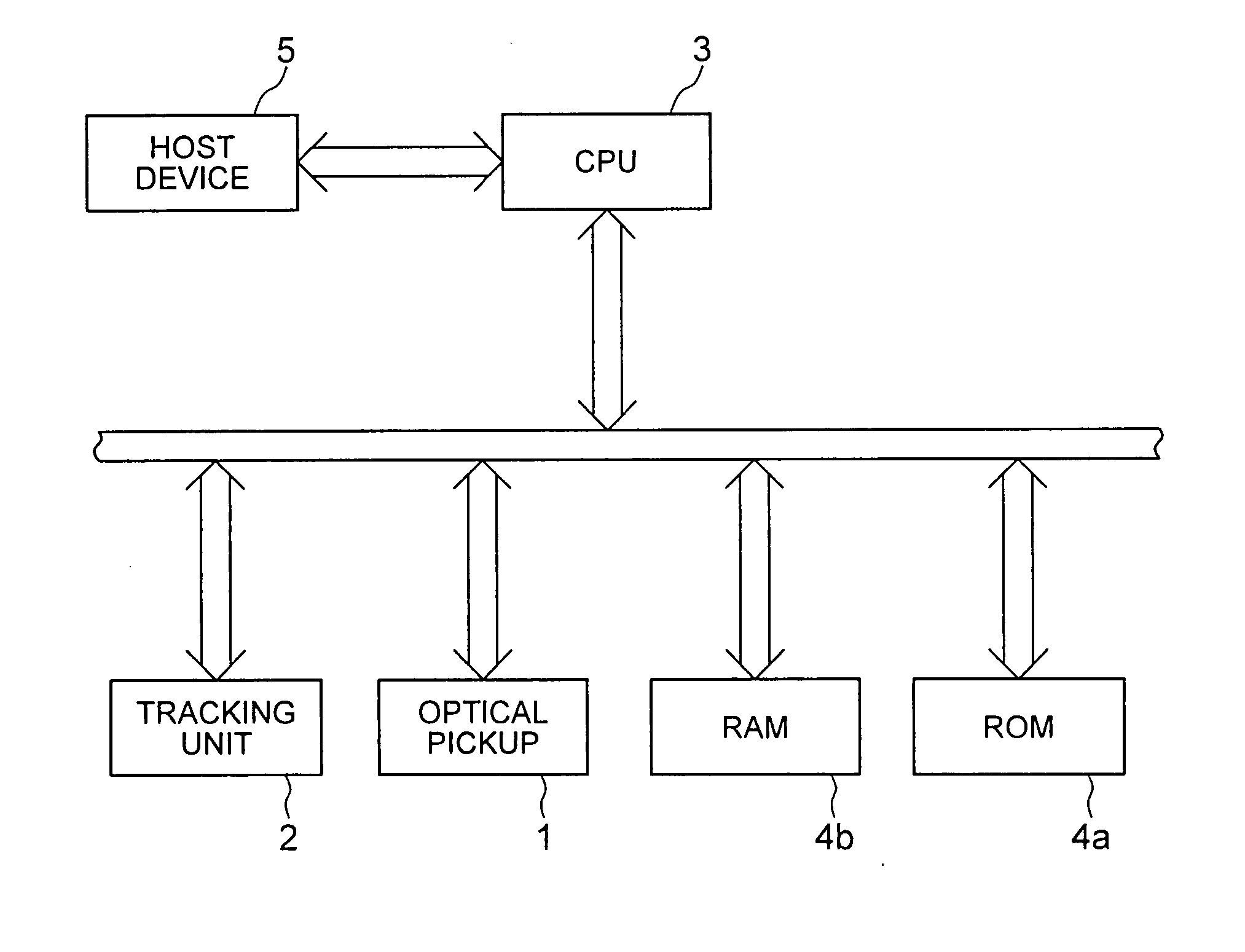

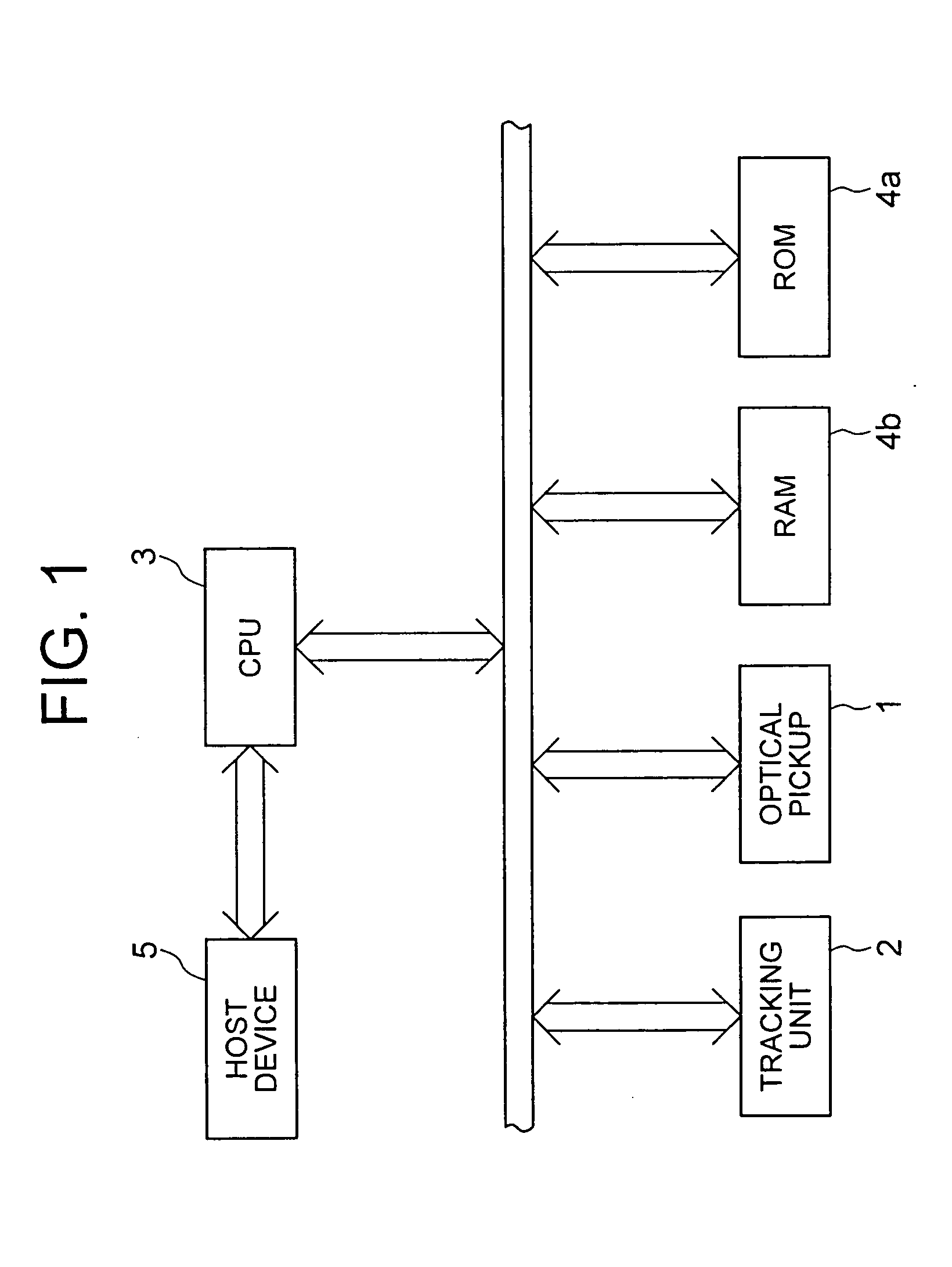

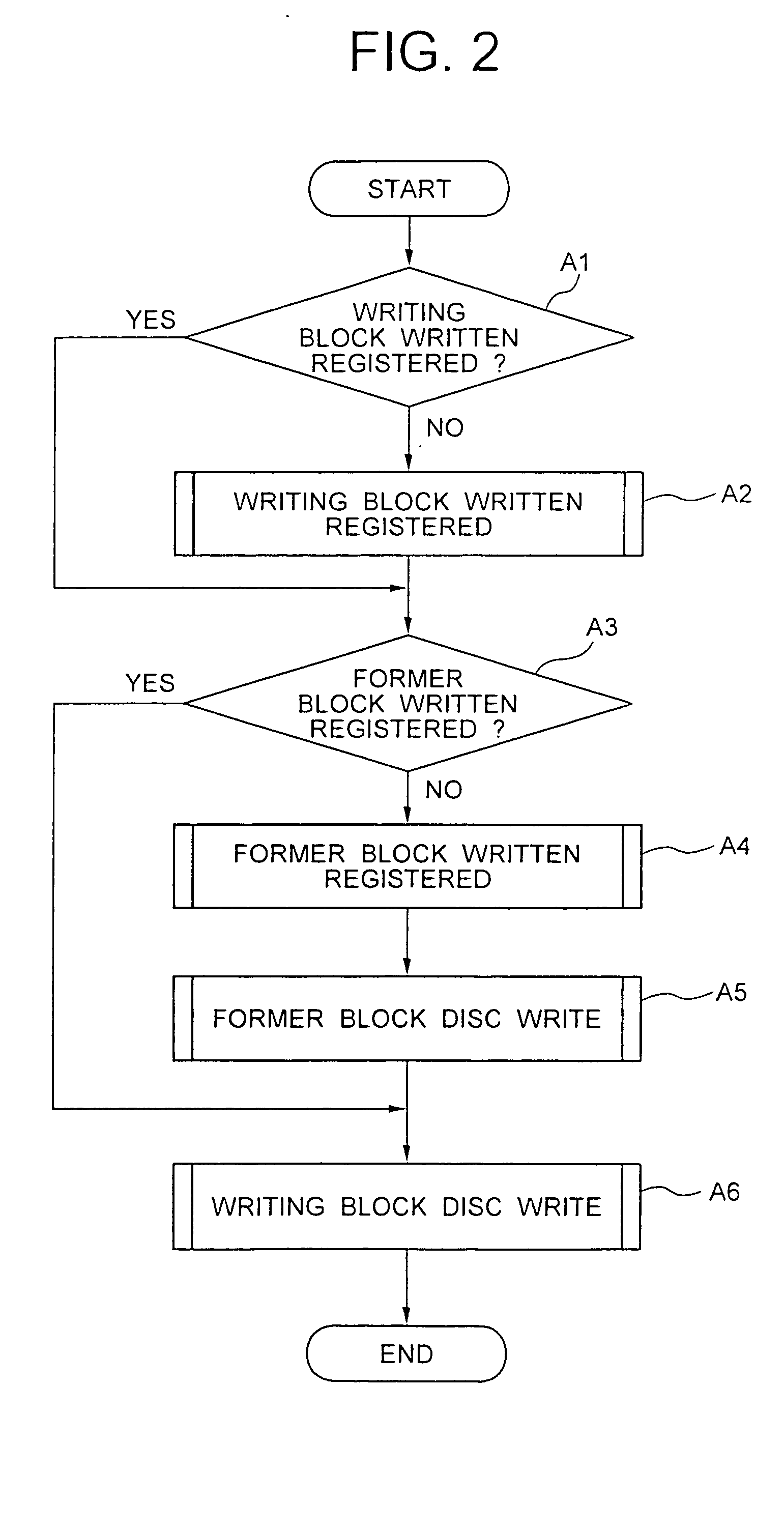

Method of writing into unwritten region of optical disc, optical disc writing device, optical disc, and program for writing data on optical disc

ActiveUS20040264232A1Utilization areaEfficient use ofRecord information storageDigital storageAddress mappingComputer engineering

To surely write data readably into a region of a designated address even if an unwritten region exists ahead of the designated address. A step of registering beforehand an address map attached to an unwritten region of the data writing area; a step of judging whether an address located ahead of the designated address for writing data is an unwritten region or a written region; and a step of writing data into the data writing area of the optical disc based on the judgment result, are included. In the writing step, if the address located ahead of the designated address is judged as a written region, data writing is performed starting from a region of the designated address, and if the address located ahead of the designated address is judged as an unwritten region, the data writing is performed to unwritten regions including the aforementioned unwritten region.

Owner:RAKUTEN GRP INC

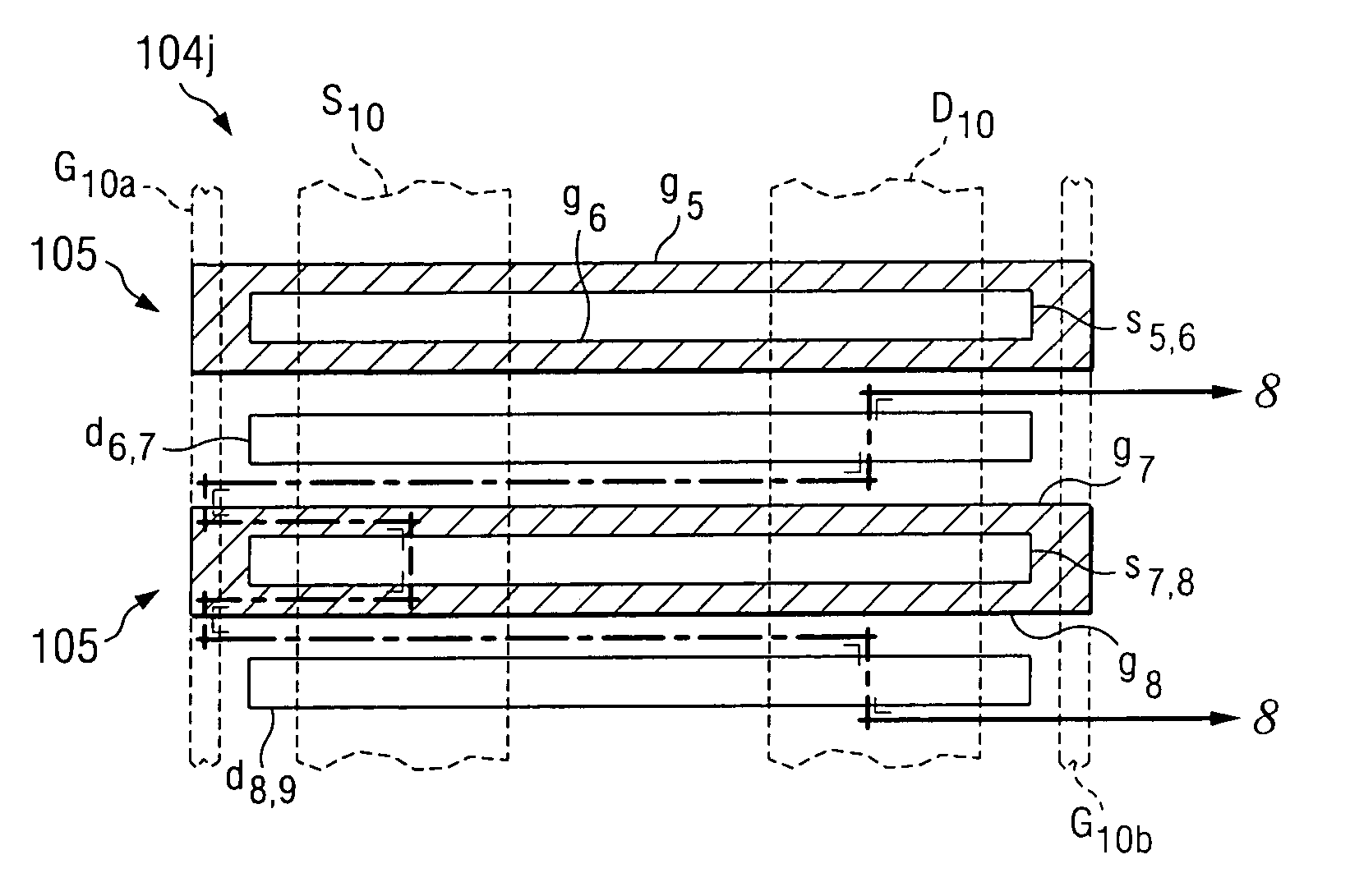

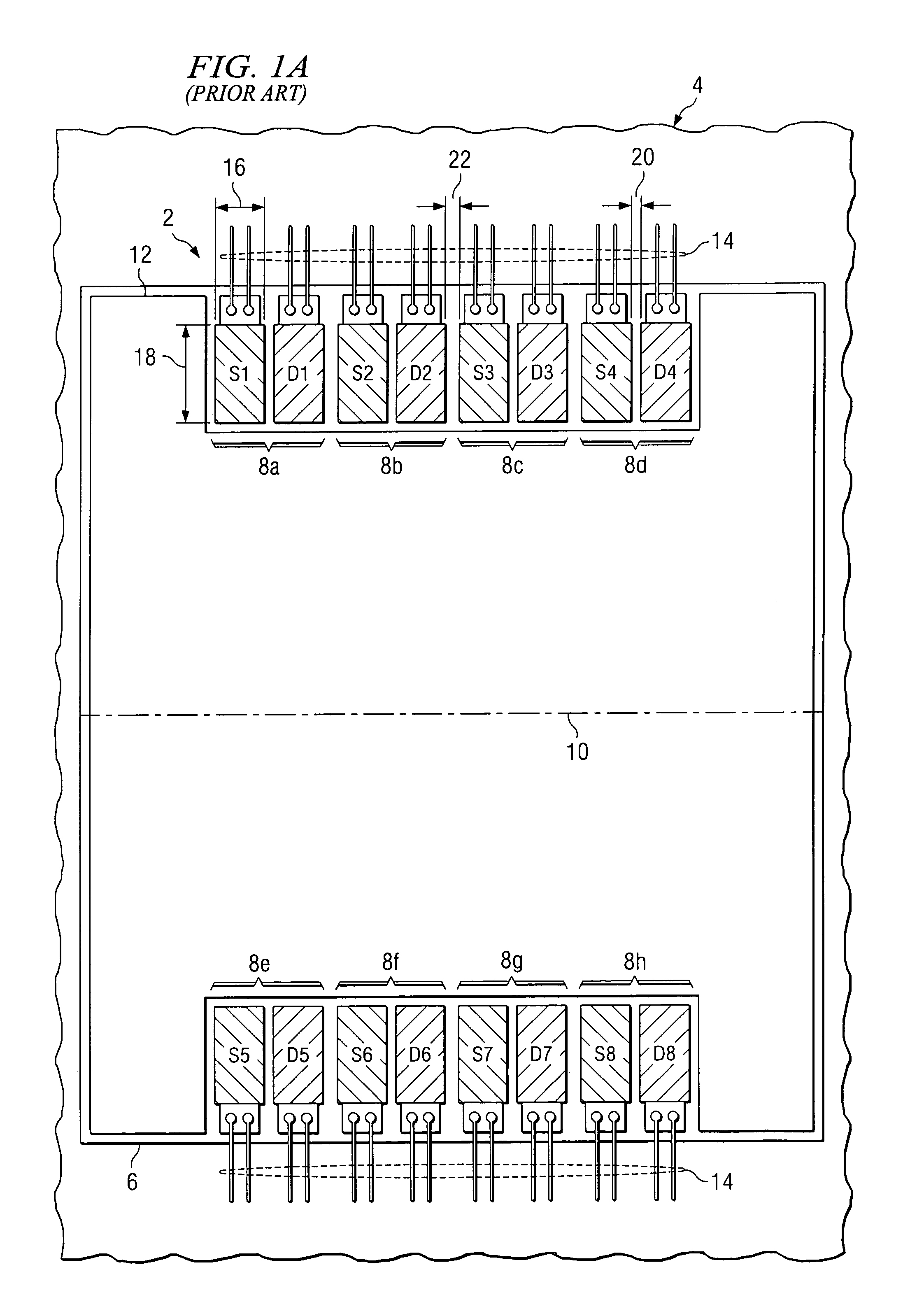

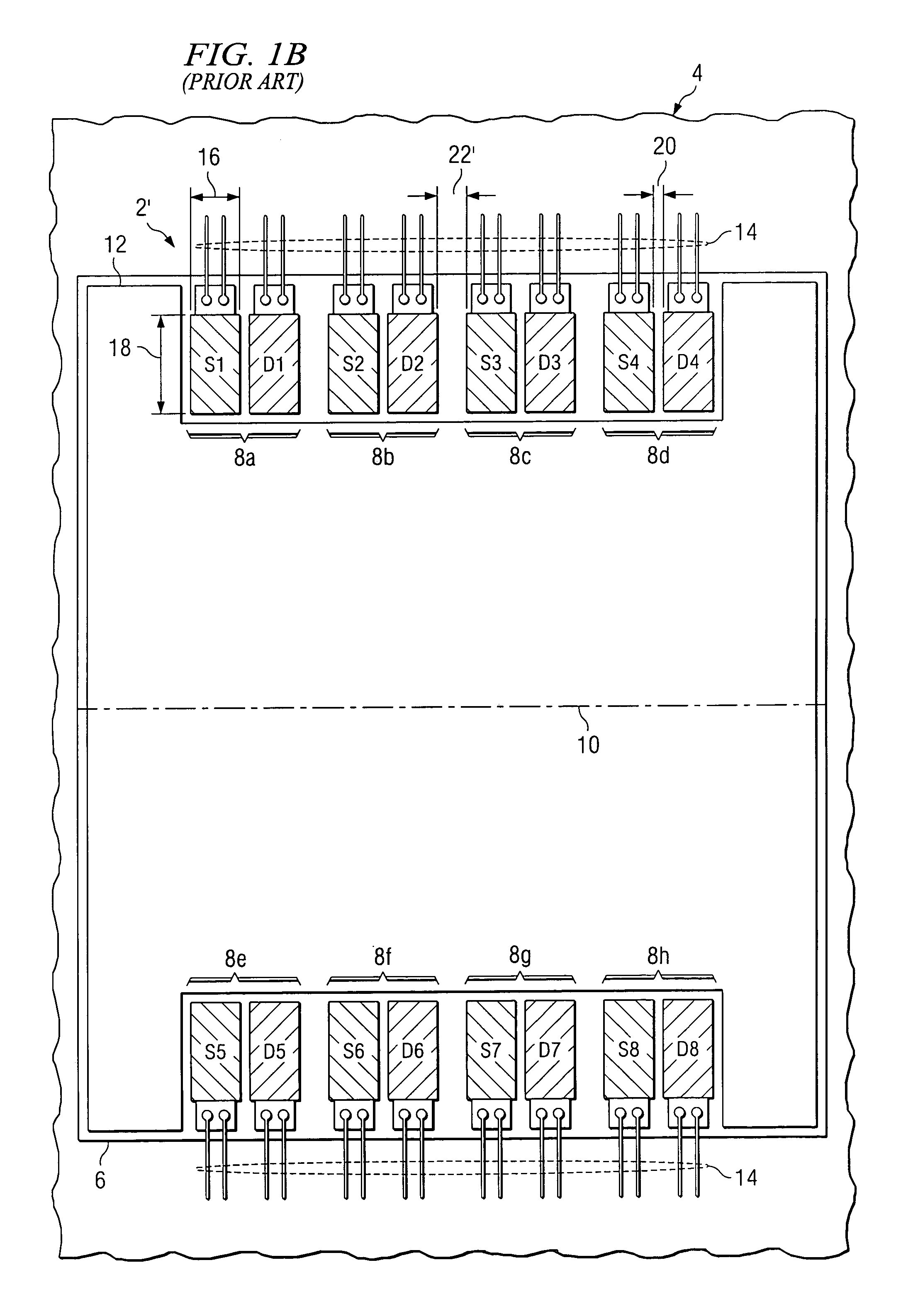

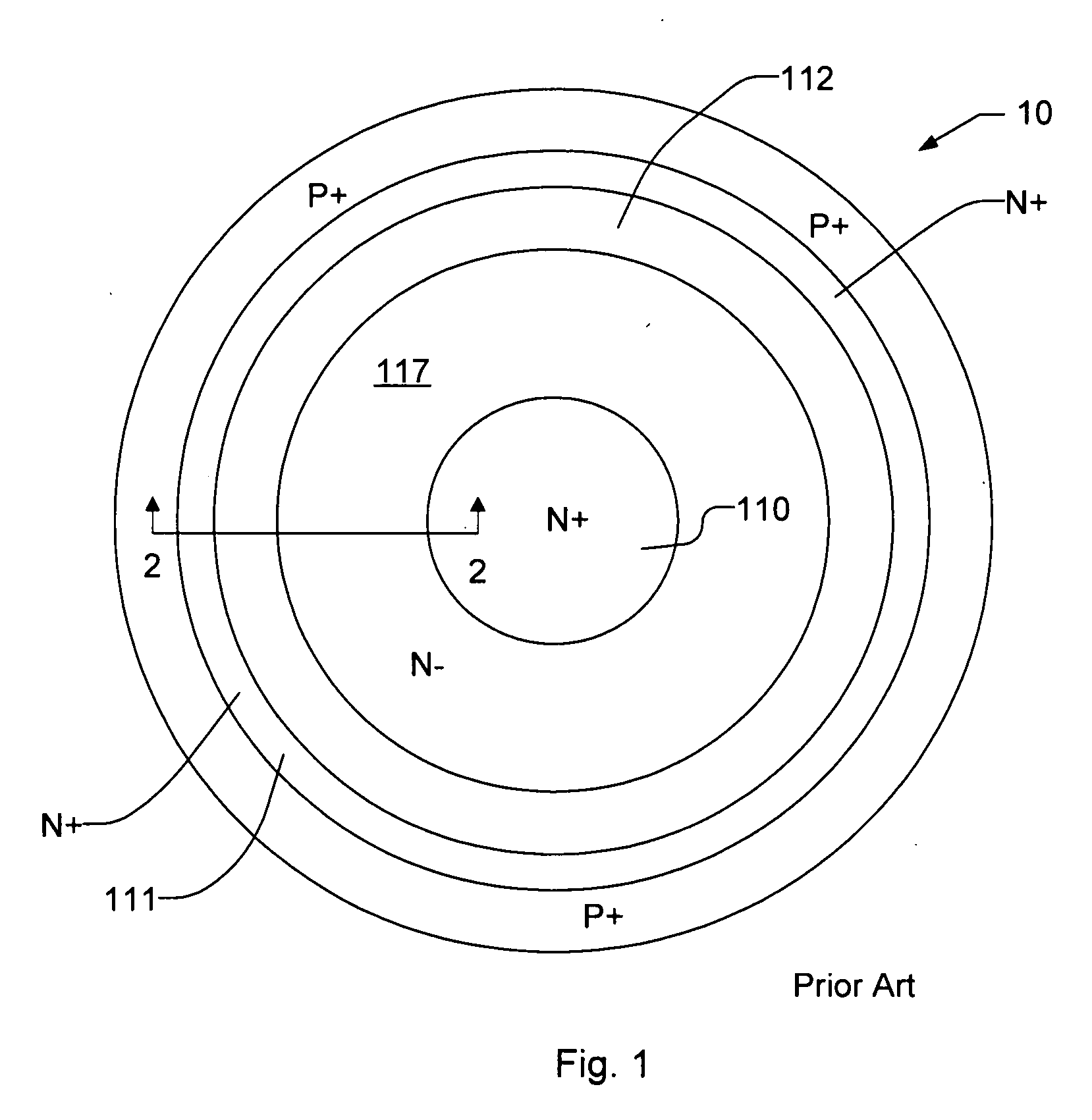

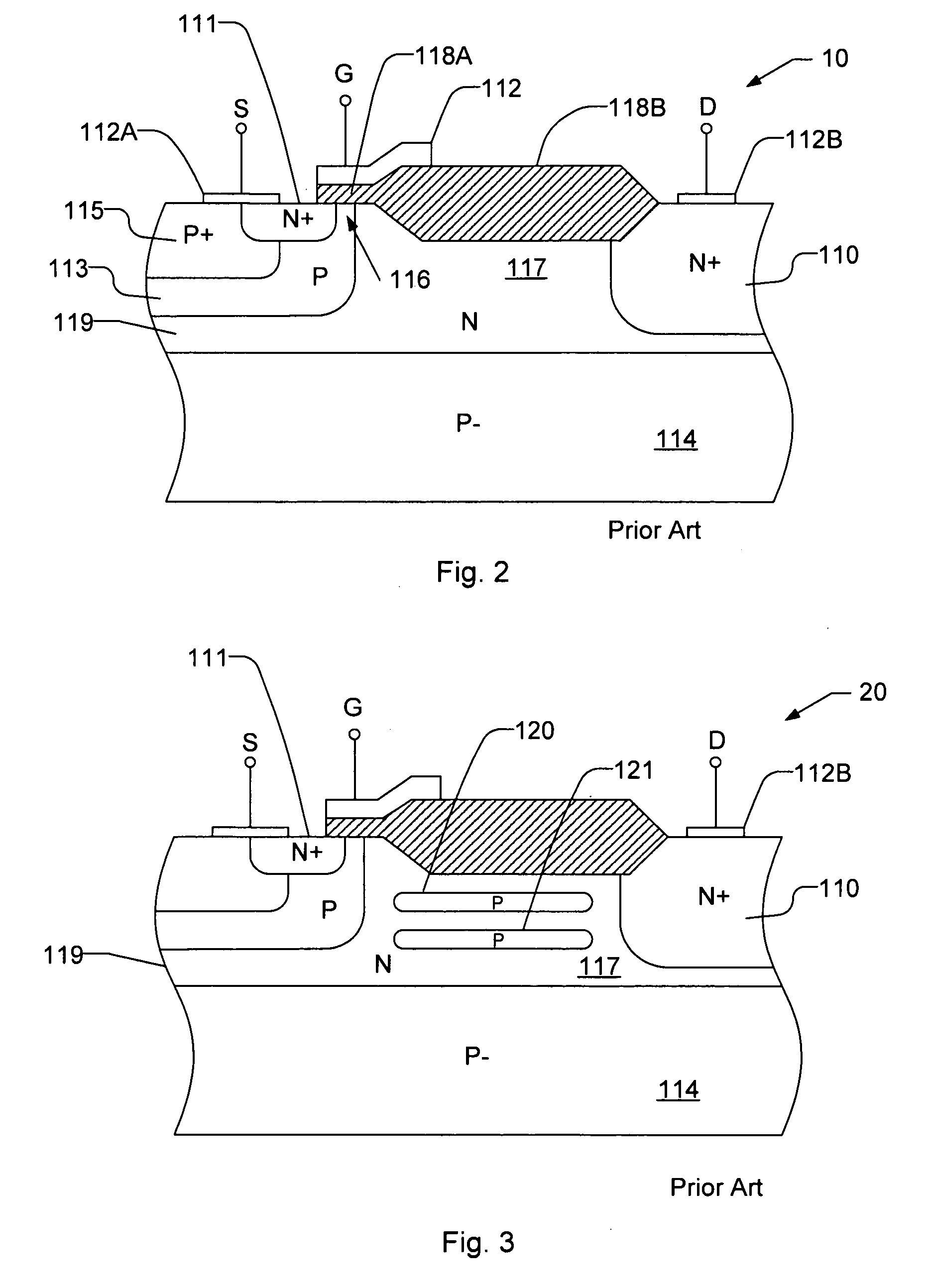

Distributed power MOSFET

InactiveUS7187034B2High Power Handling CapabilityImprove space utilizationTransistorSemiconductor/solid-state device detailsElectrical devicesEngineering

Segmented power transistors and fabrication methods are disclosed in which transistor segments are spaced from one another to facilitate thermal diffusion, and in which other electrical devices can be formed in the spaces between transistor segments.

Owner:TEXAS INSTR INC

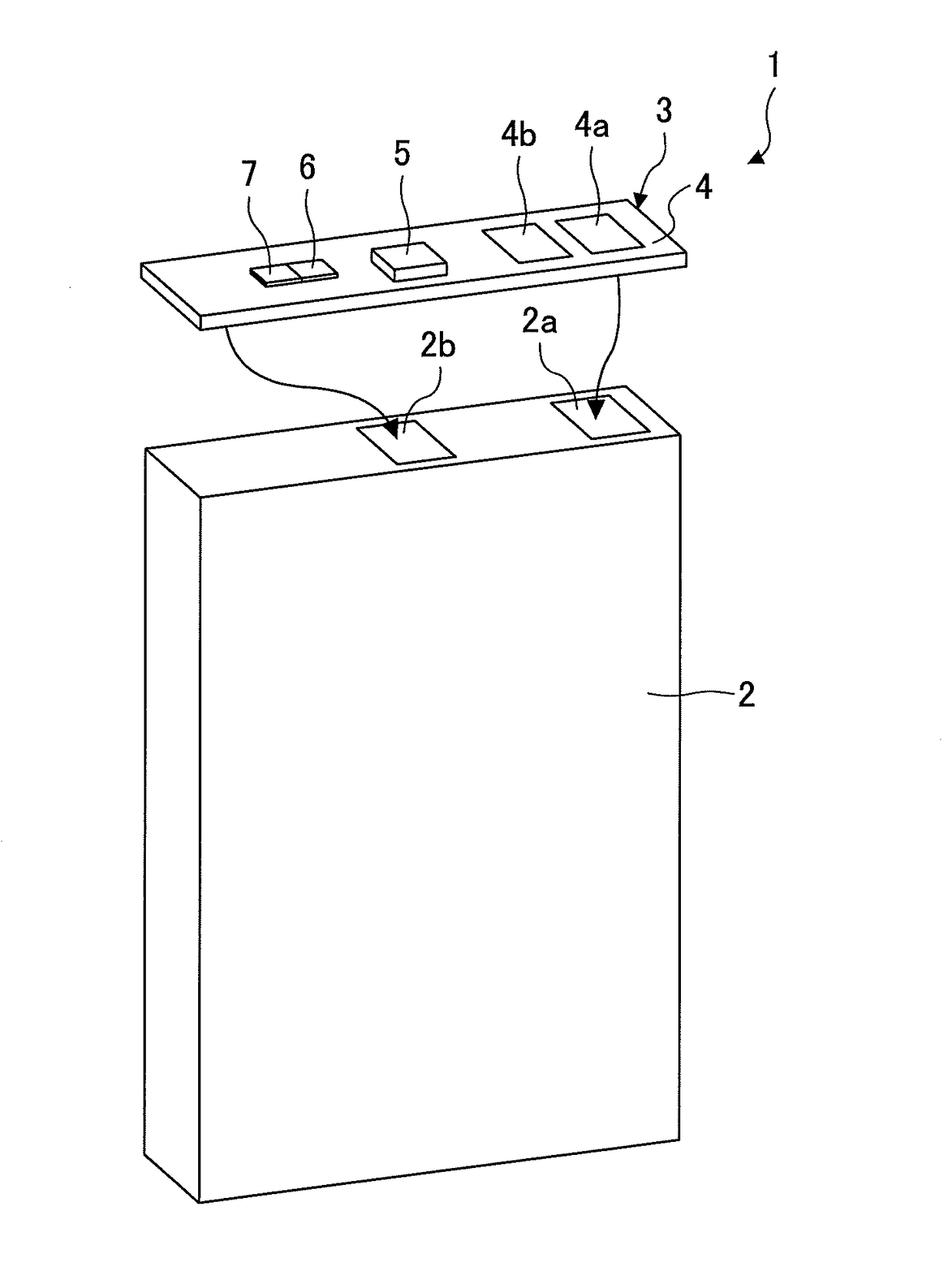

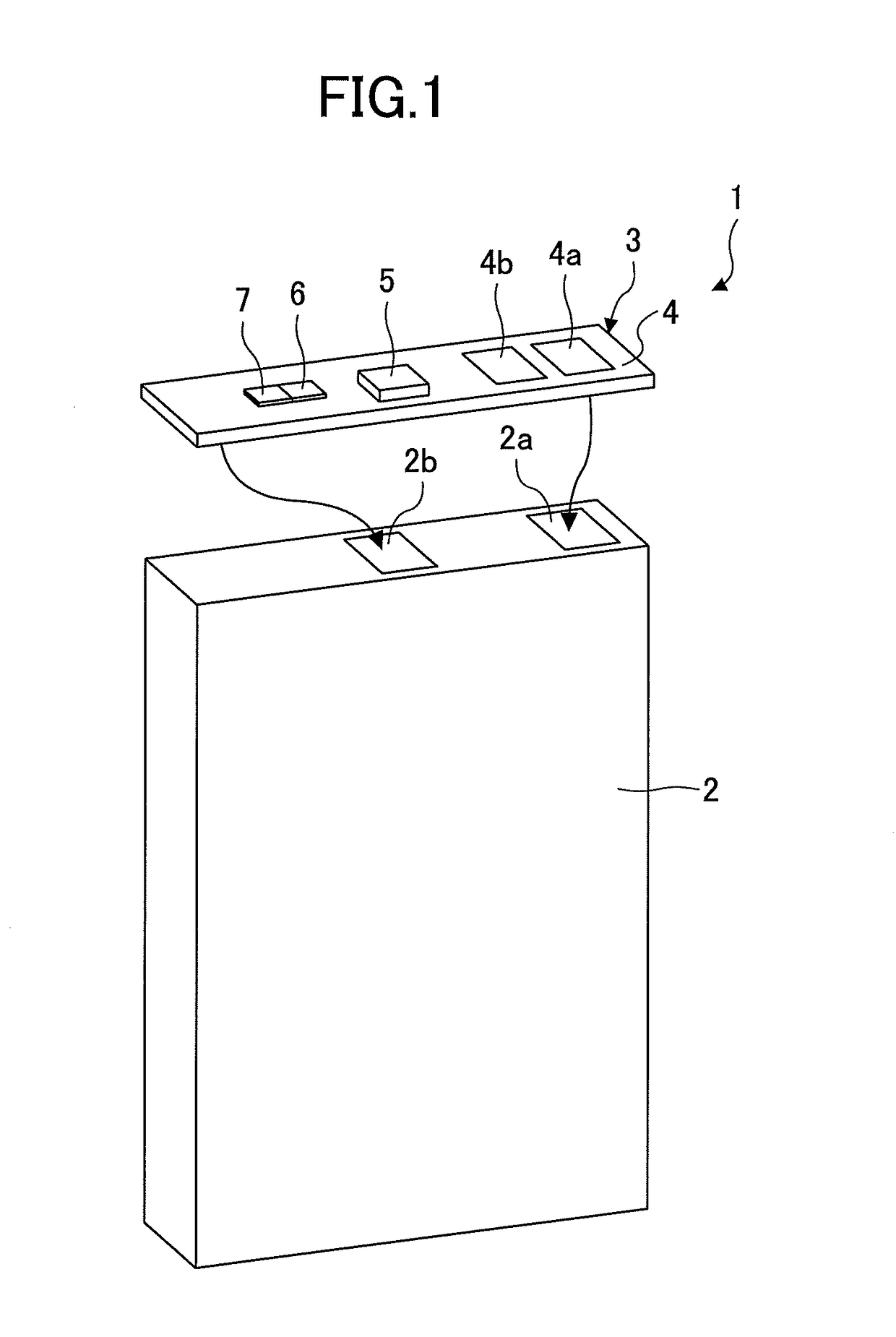

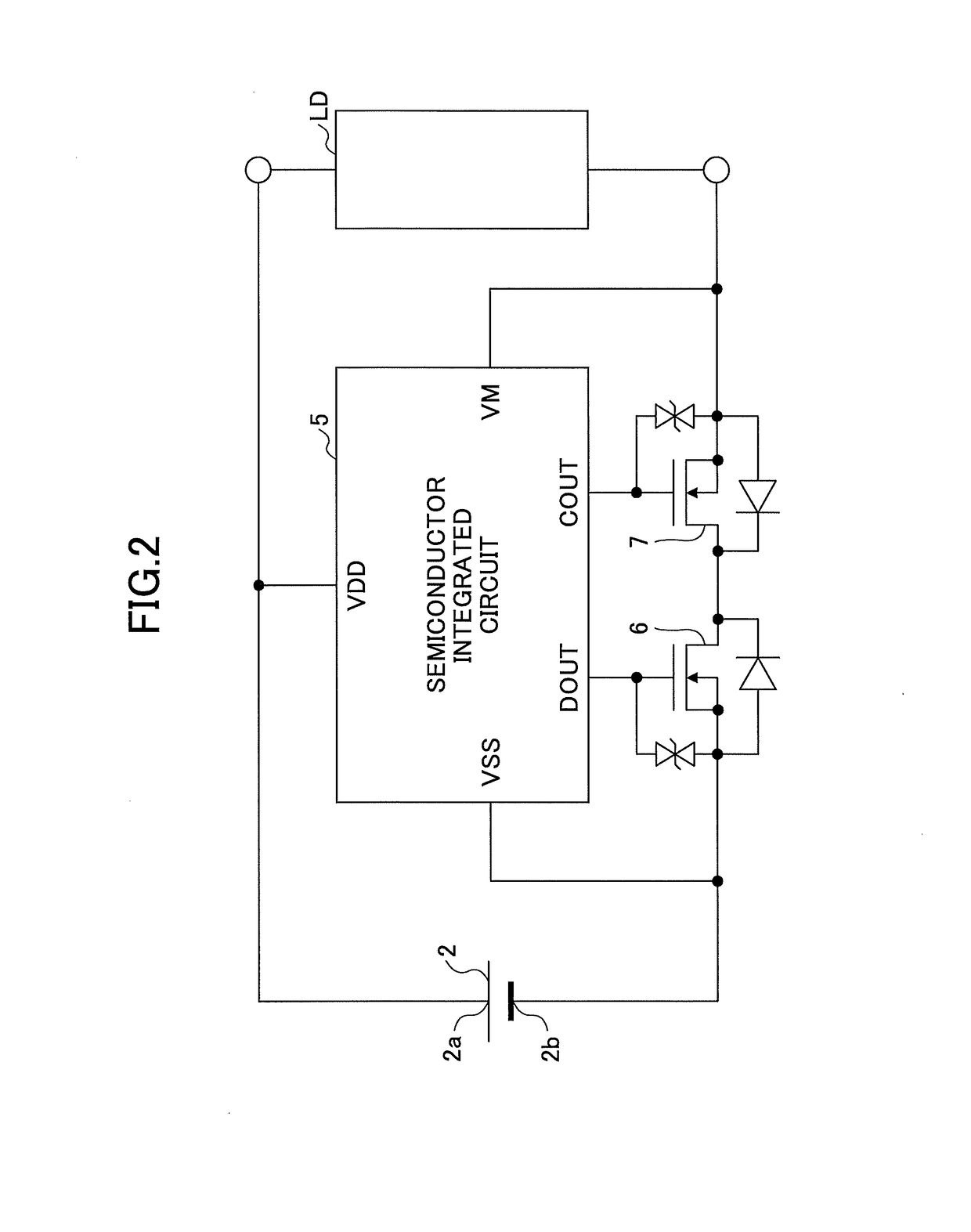

Semiconductor integrated circuit

ActiveUS20180090214A1Utilization of chip areaIncrease profitIndicating/monitoring circuitsRead-only memoriesEngineeringOperation mode

A semiconductor integrated circuit includes a first circuit, a second circuit, a memory circuit having a plurality of flip-flops, a storage unit, a signal generating unit to produce an operation mode setting signal, a control circuit configured to cause the memory circuit to operate such that the plurality of flip-flops holds a value for setting characteristics of the first circuit when the operation mode setting signal indicates a first operation mode, and configured to cause the memory circuit to operate as a counter to measure a time length used in the second circuit when the operation mode setting signal indicates a second operation mode, and a setting circuit configured to cause trimming data stored in the storage unit to set the characteristic of the first circuit when the operation mode setting signal indicates the second operation mode, the trimming data corresponding to the value held by the memory circuit.

Owner:MITSUMI ELECTRIC CO LTD

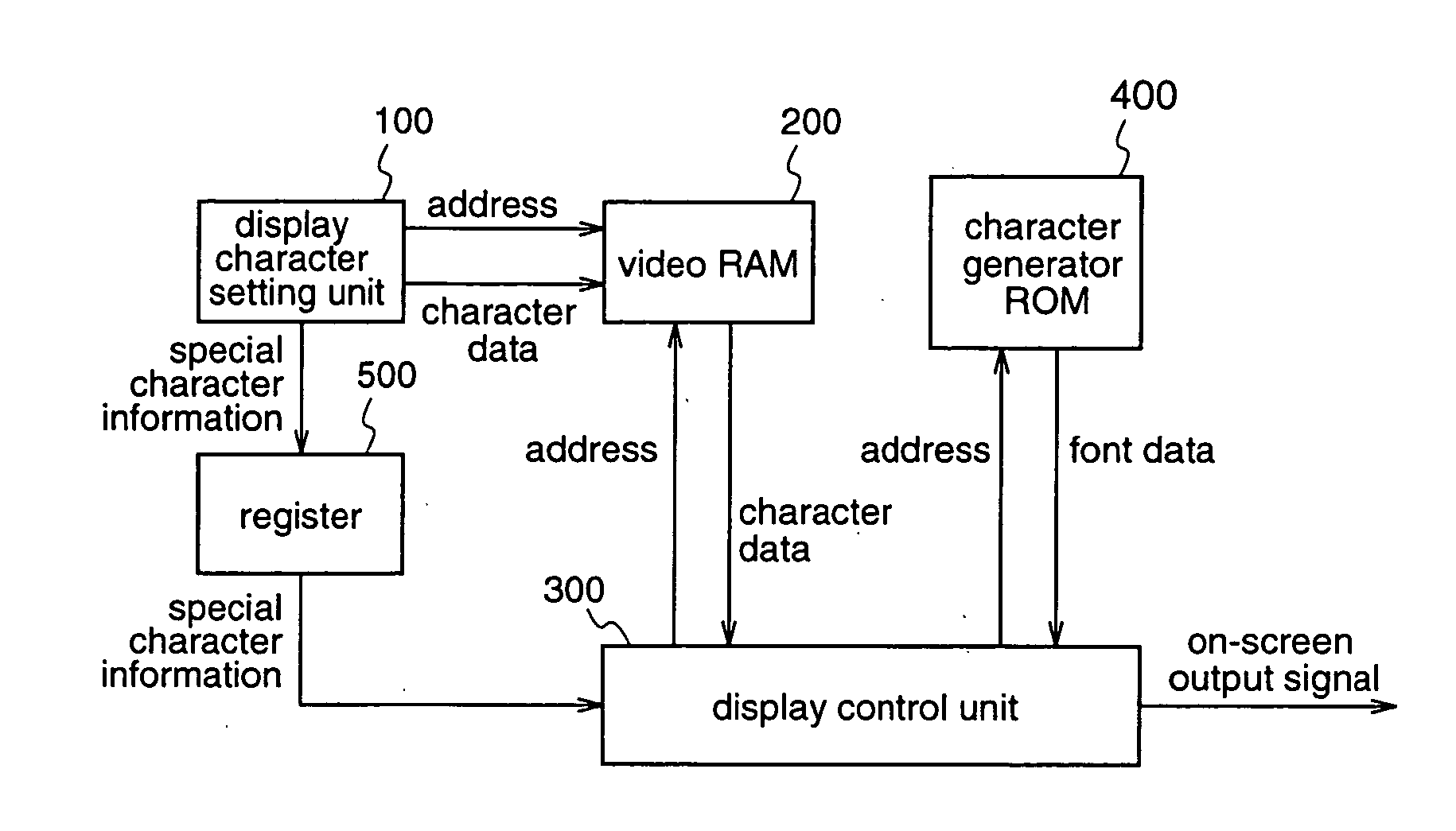

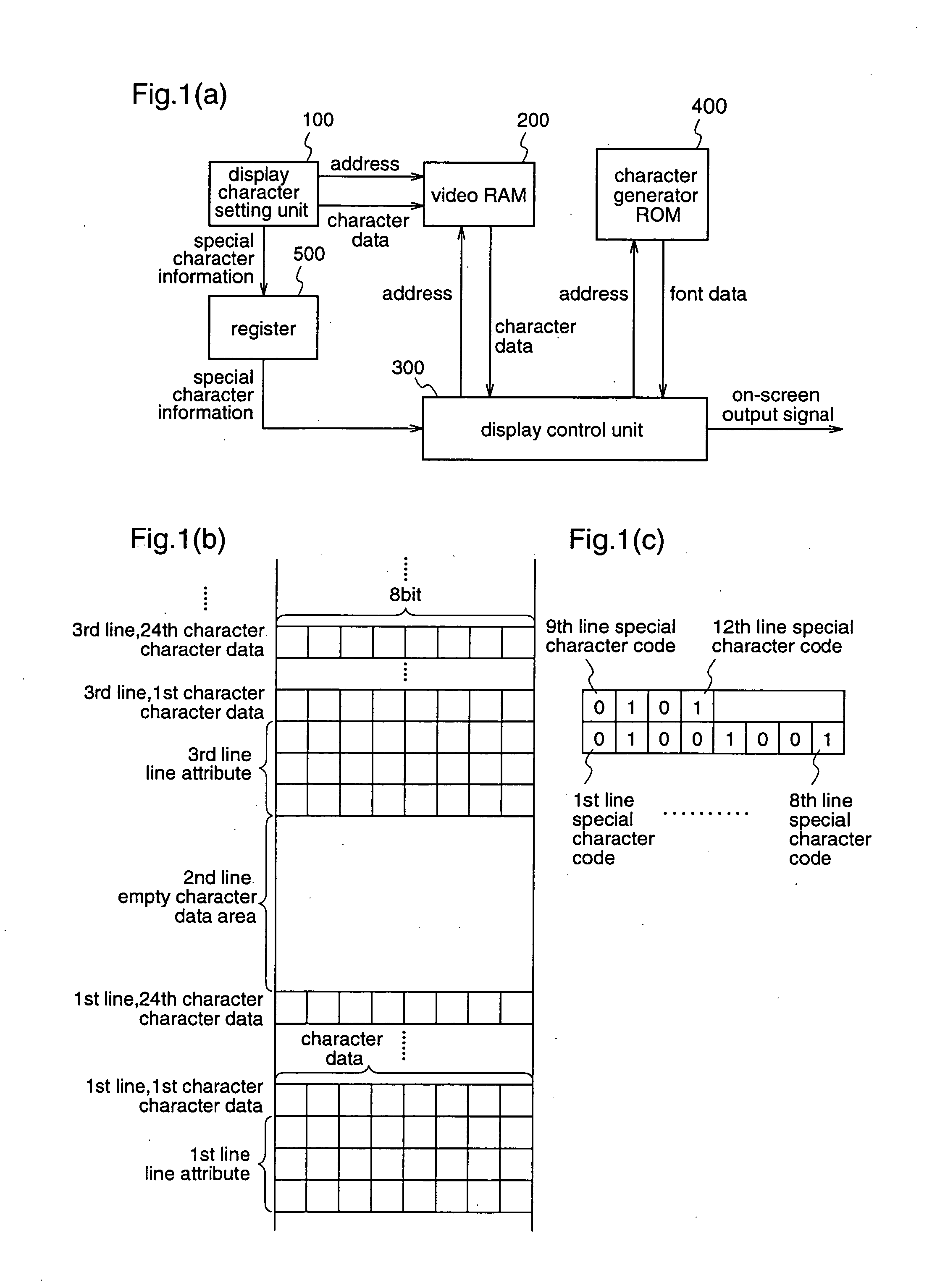

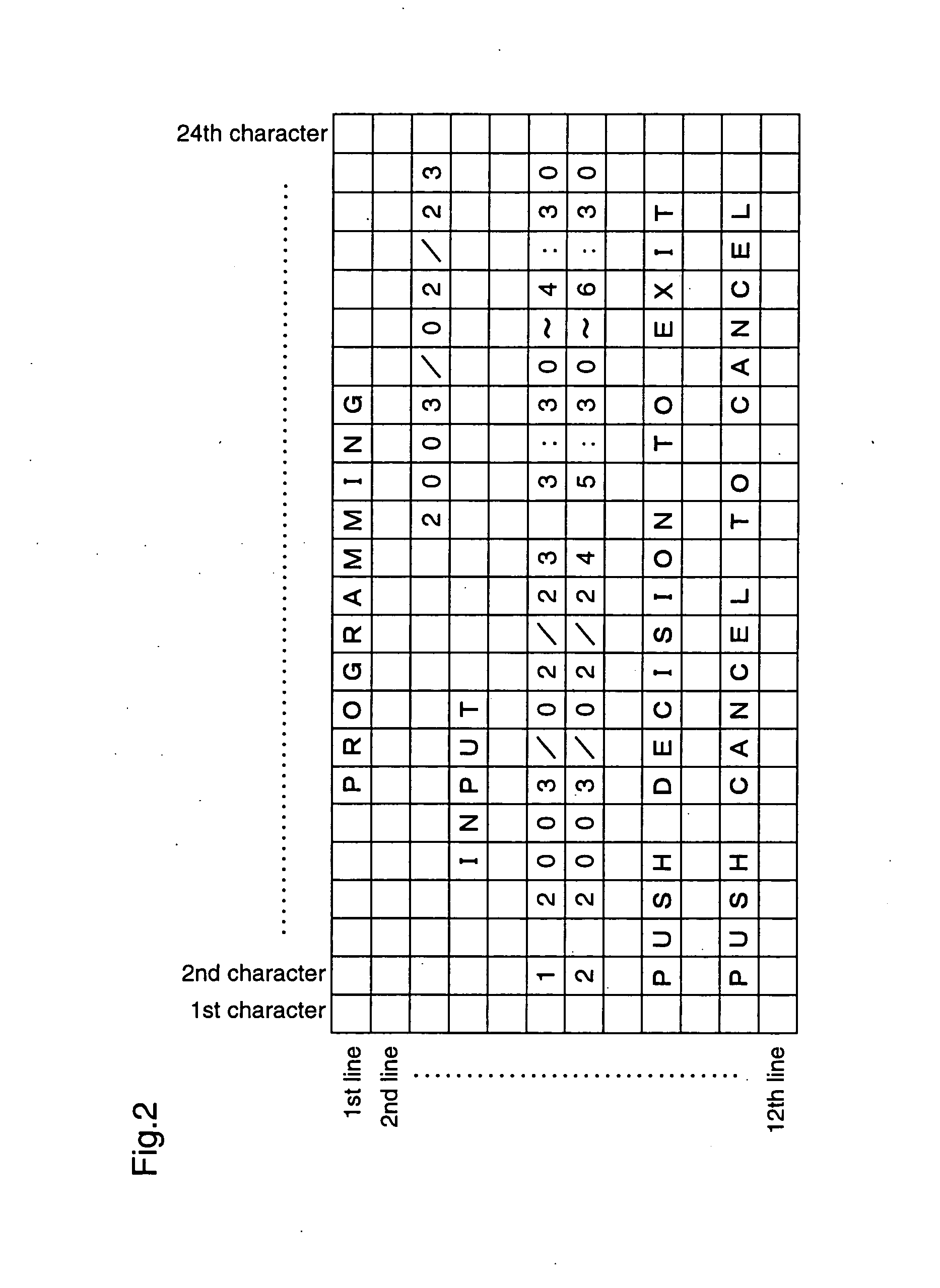

On-screen display device

InactiveUS20050030428A1Efficient use ofUtilization areaTelevision system detailsCathode-ray tube indicatorsOn-screen display

The present invention provides an on-screen display device that can effectively utilize a part of a video RAM area for characters which perform special character display. This on-screen display device includes a register that retains information for performing special character display of respective lines, such as through display or space display, and compares display information of the respective line between the register and a display line counter, to output information indicating whether the special character display is to be performed or not to the video RAM, thereby effectively utilizing a part for performing the special character display in the video RAM area.

Owner:PANASONIC CORP

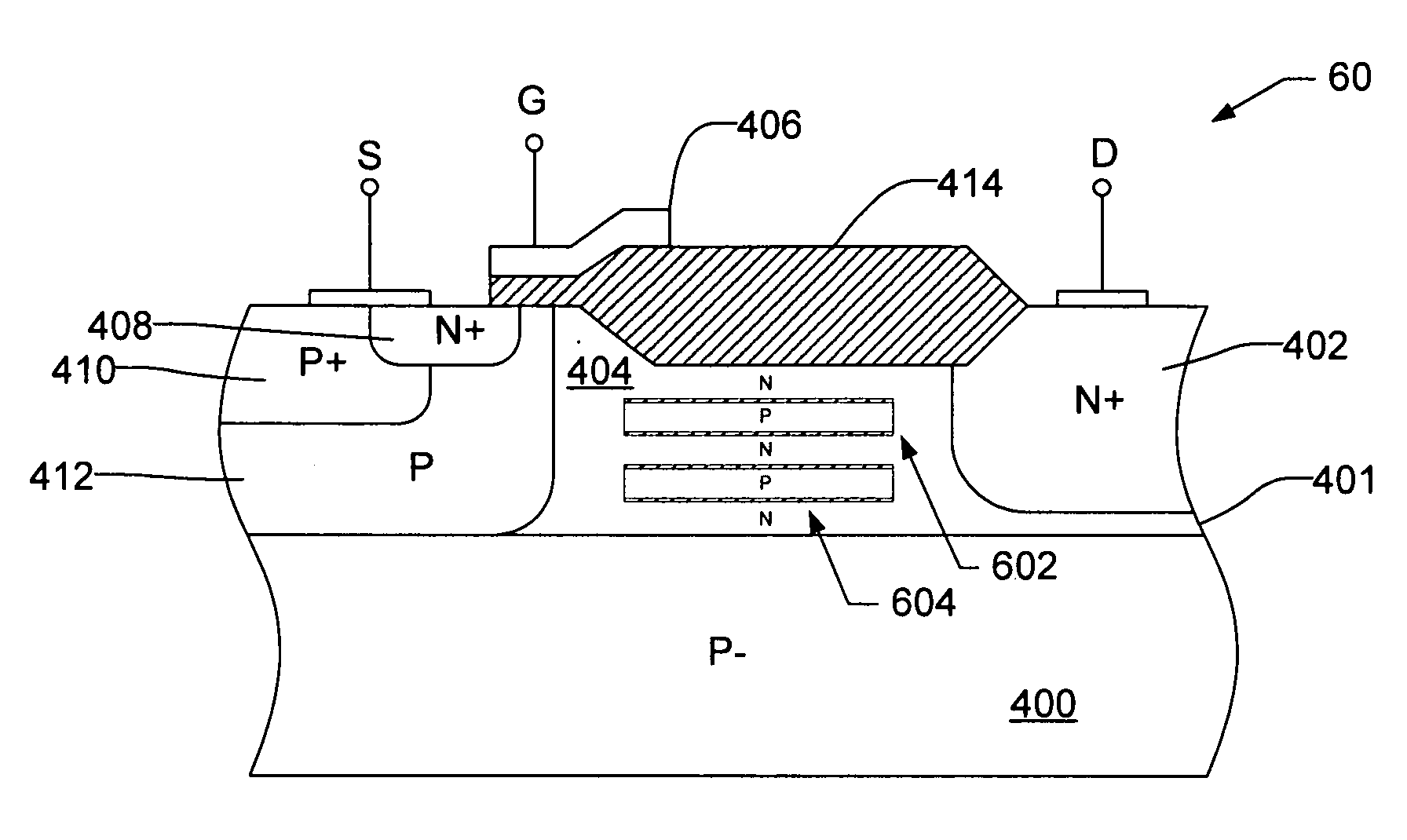

Method of fabricating high voltage semiconductor devices with JFET regions containing dielectrically isolated junctions

InactiveUS20100022059A1Easy to useIncrease concentrationSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsHigh pressure

A high-voltage field-effect device contains an extended drain or “drift” region having a plurality of JFET regions separated by portions of the drift region. Each of the JFET regions is filled with material of an opposite conductivity type to that of the drift region, and at least two sides of each JFET region is lined with an oxide layer. In one group of embodiments the JFET regions extend from the surface of an epitaxial layer to an interface between the epitaxial layer and an underlying substrate, and the walls of each JFET region are lined with an oxide layer. When the device is blocking a voltage in the off condition, the semiconductor material inside the JFET regions and in the drift region that separates the JFET regions is depleted. This improves the voltage-blocking ability of the device while conserving chip area. The oxide layer prevents dopant from the JFET regions from diffusing into the drift region and allowing the JFET regions to be accurately located in the drift region.

Owner:ALPHA & OMEGA SEMICON INC

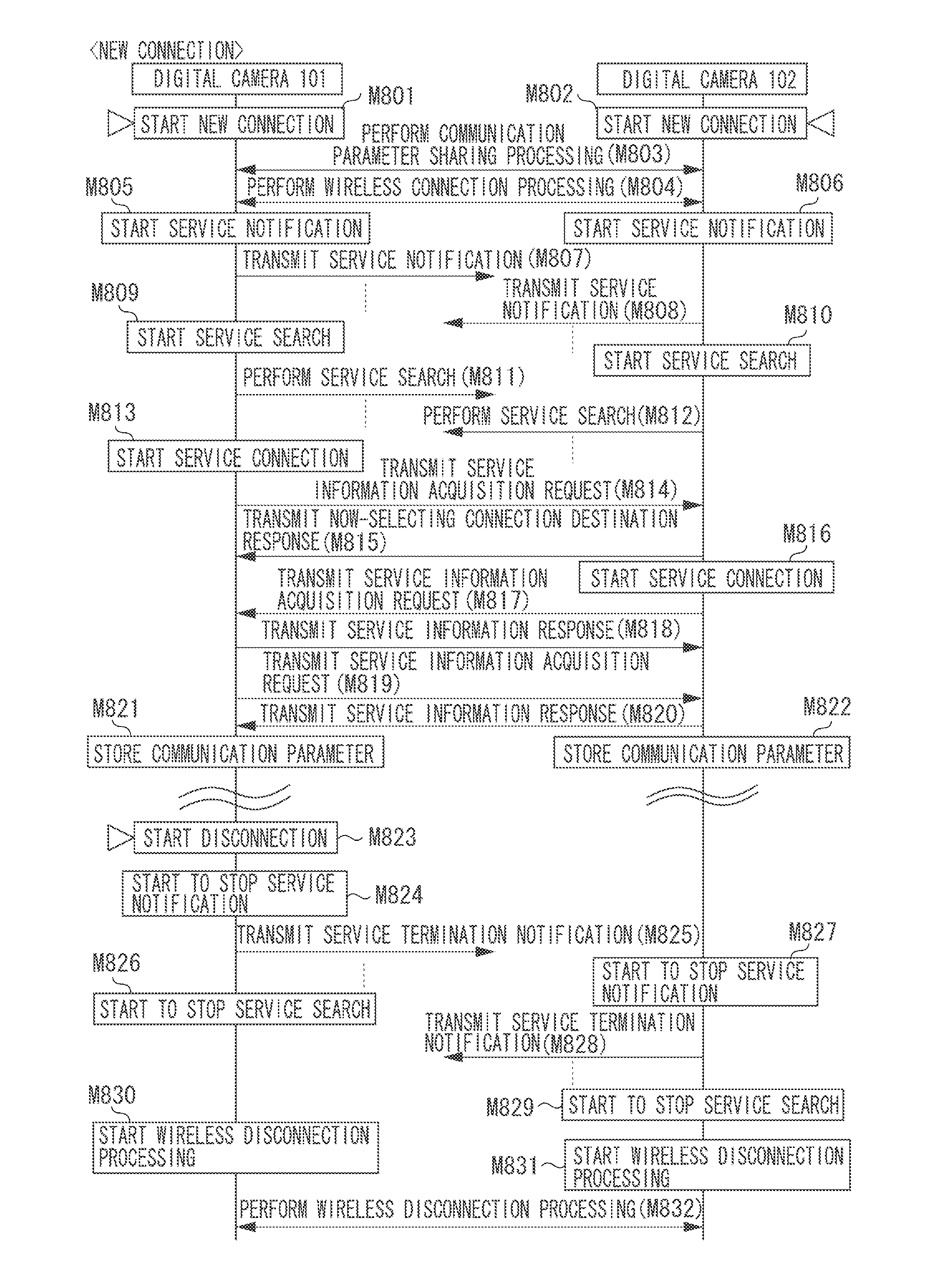

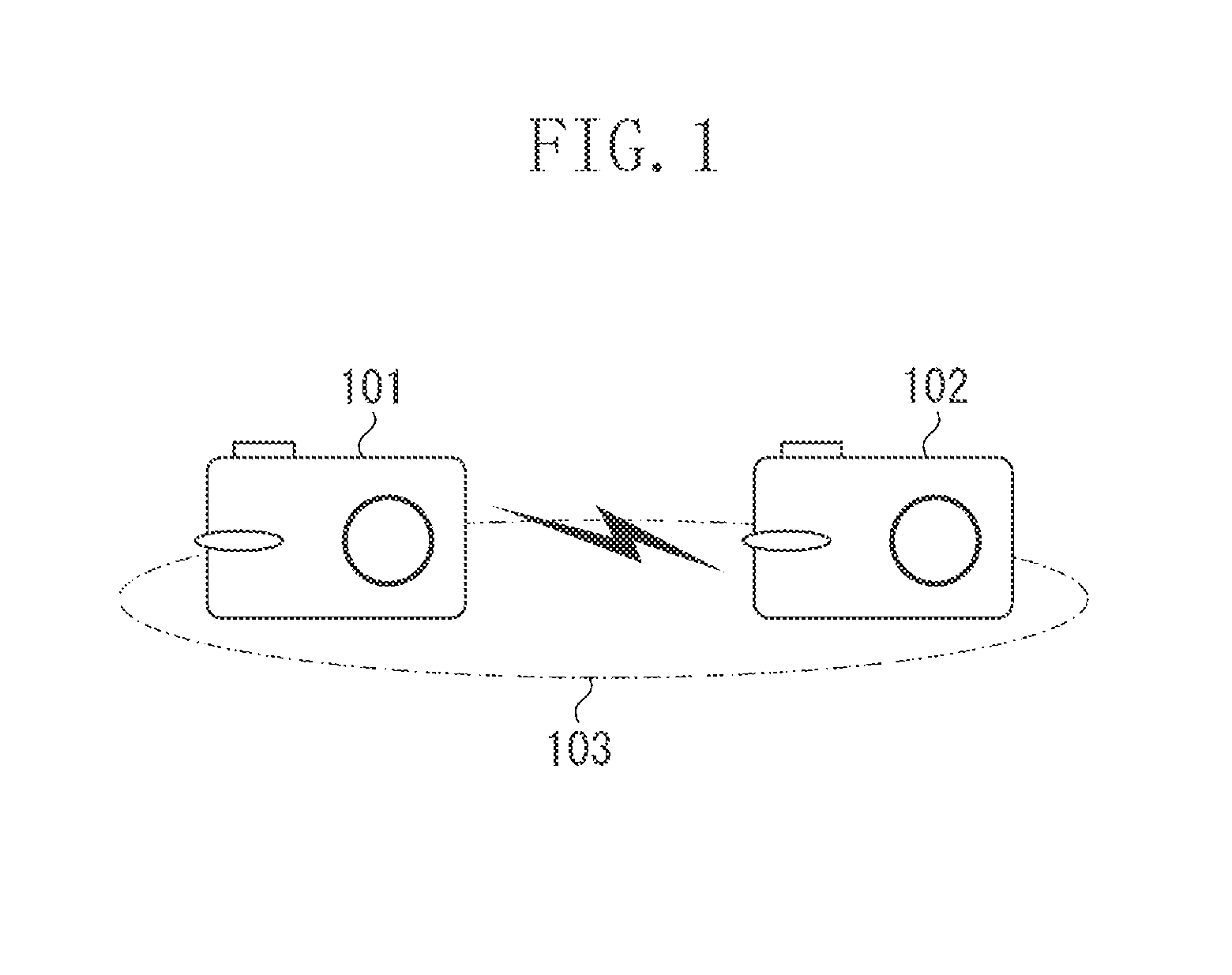

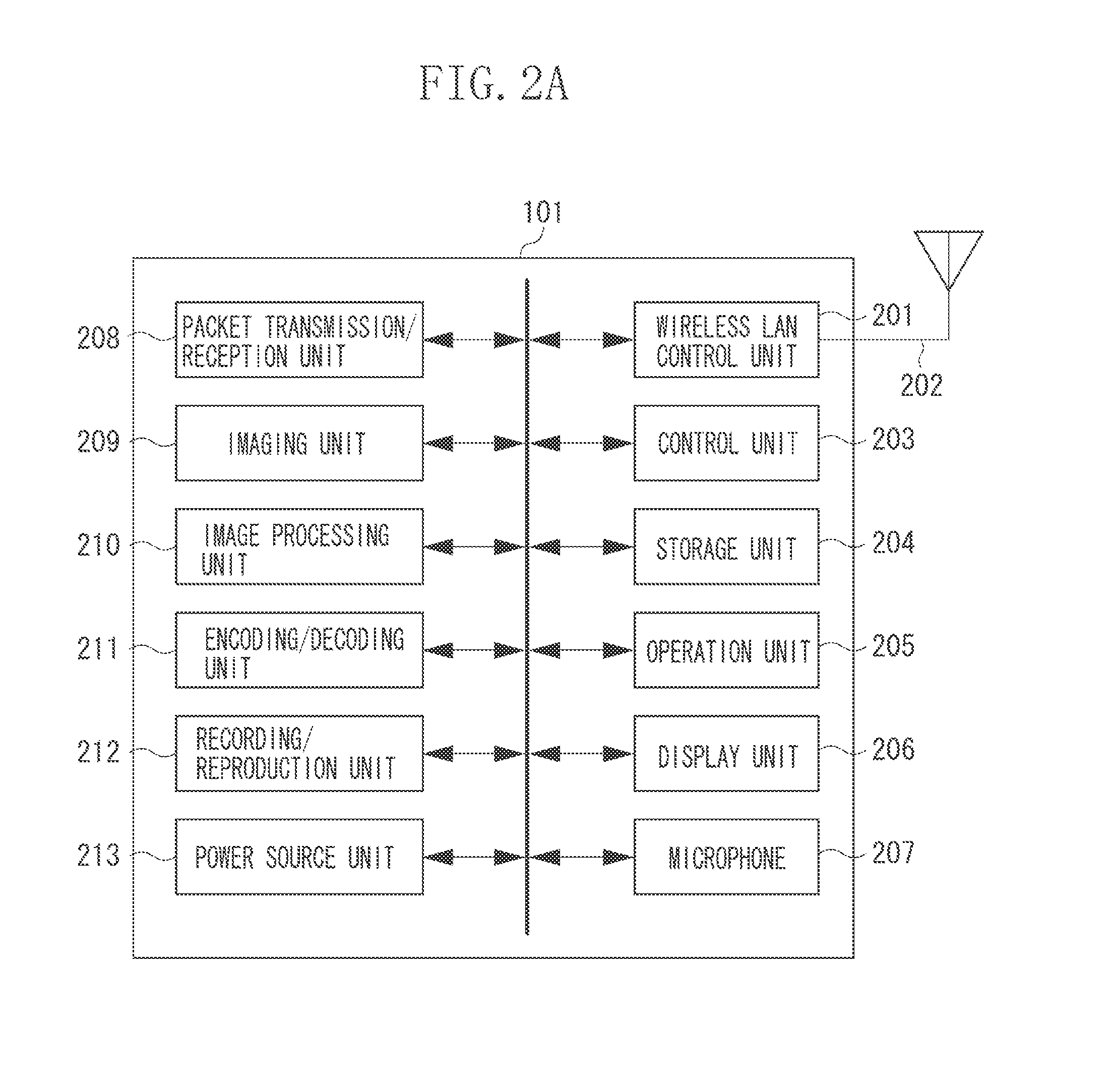

Communication apparatus, control method thereof, and storage medium

ActiveUS20130195090A1Efficient use ofUtilization areaConnection managementWireless commuication servicesComputer hardwareCommunication unit

A communication apparatus includes a sharing unit configured to share a communication parameter for wireless communication with another communication apparatus with the another communication apparatus, a connection unit configured to connect to the another communication apparatus using the communication parameter shared by the sharing unit, a communication unit configured to, after connection with the another apparatus by the connection unit, communicate with the another communication apparatus by utilizing a predetermined function, and a control unit configured to control the communication parameter shared by the sharing unit according to a result of communication by the communication unit utilizing the predetermined function.

Owner:CANON KK

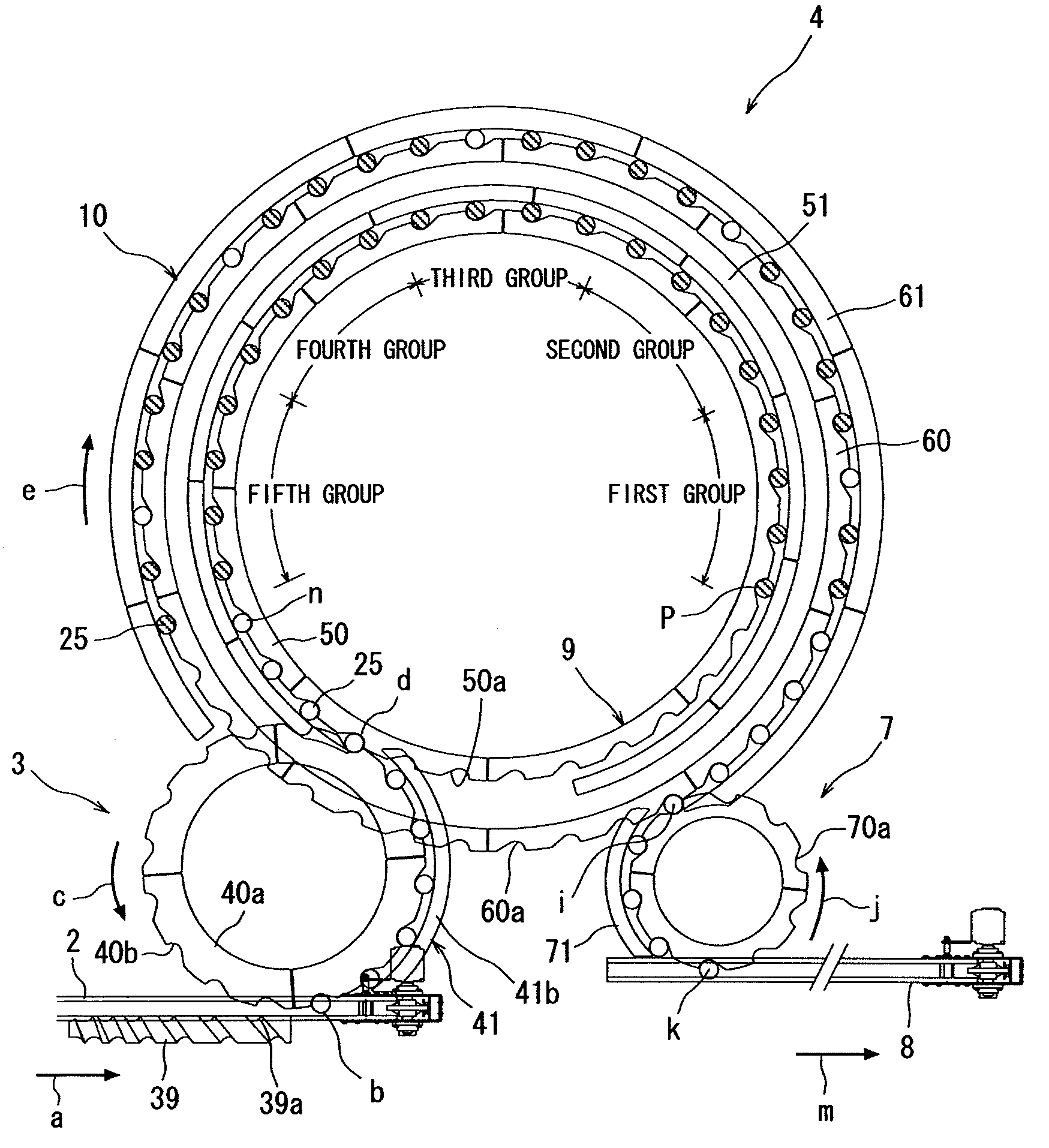

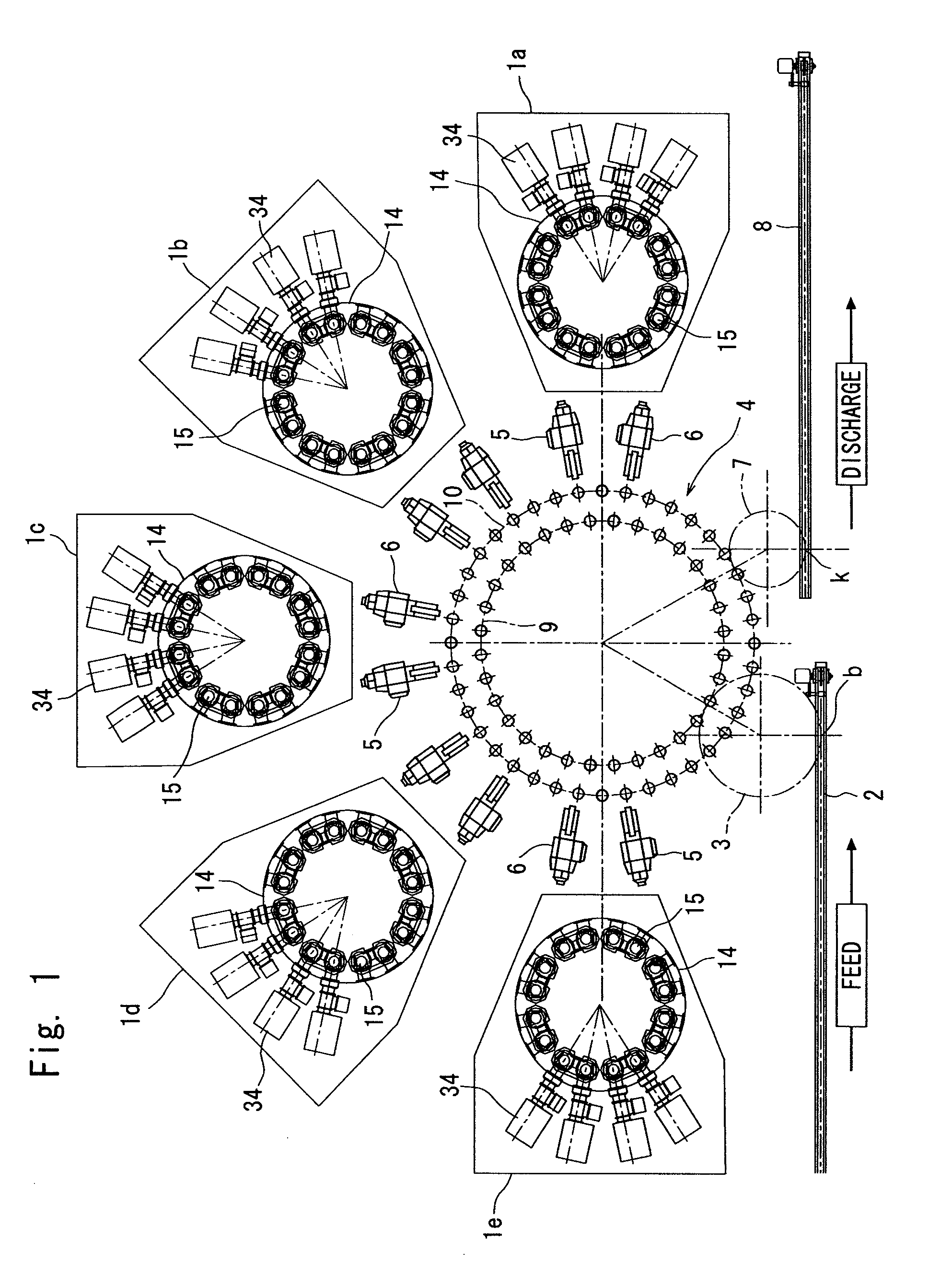

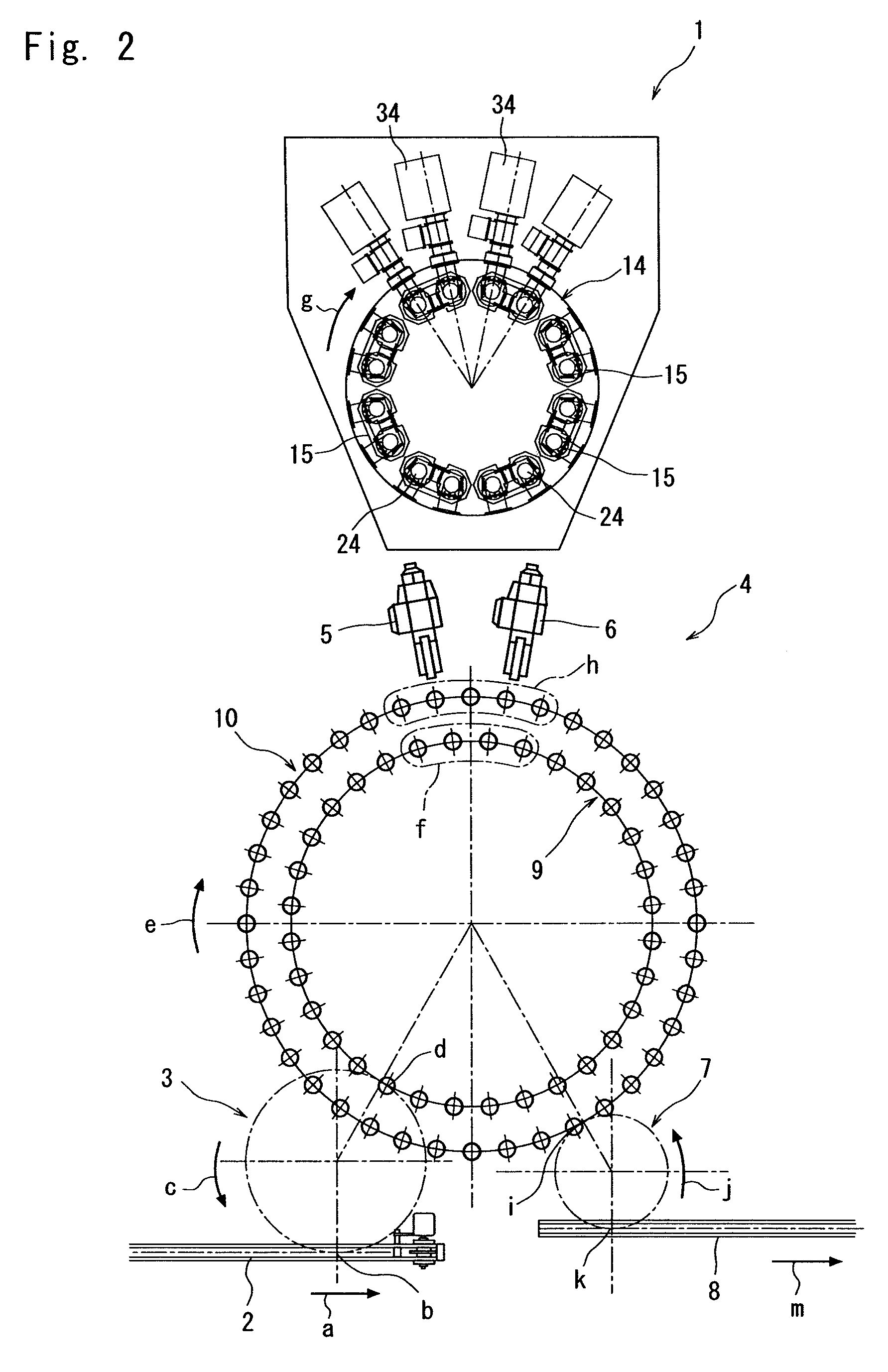

Container conveyer device

InactiveUS20100163367A1Shorten the timeIncrease delivery speedChemical vapor deposition coatingConveyor partsEngineeringMechanical engineering

[Problems] To decrease the area for installing a container conveyer passage that has container hand-over devices on the way of the conveyer passage.[Means for Solution] A container conveyer device including a conveyer passage that has a container feed position d where containers are received and a container discharge position i where the containers are handed over, and for conveying the containers from the container feed position d up to the container discharge position i, the container conveyer device, further, having container hand-over positions f, h where the containers that are once taken out from the conveyer passage are returned back again to the conveyer passage on the way of the container conveyer passage. A conveyer wheel 4 includes an inner conveyer passage 9 and an outer conveyer passage 10 that rotate about a rotary shaft, and conveyer hand-over means 5, 6 that hand over the containers between the inner conveyer passage 9 and the outer conveyer passage 10, and works to return the containers back to the outer conveyer passage 10 at the hand-over position h after the containers are taken out from the inner conveyer passage 9 at the container hand-over position f.

Owner:TOYO SEIKAN KAISHA LTD

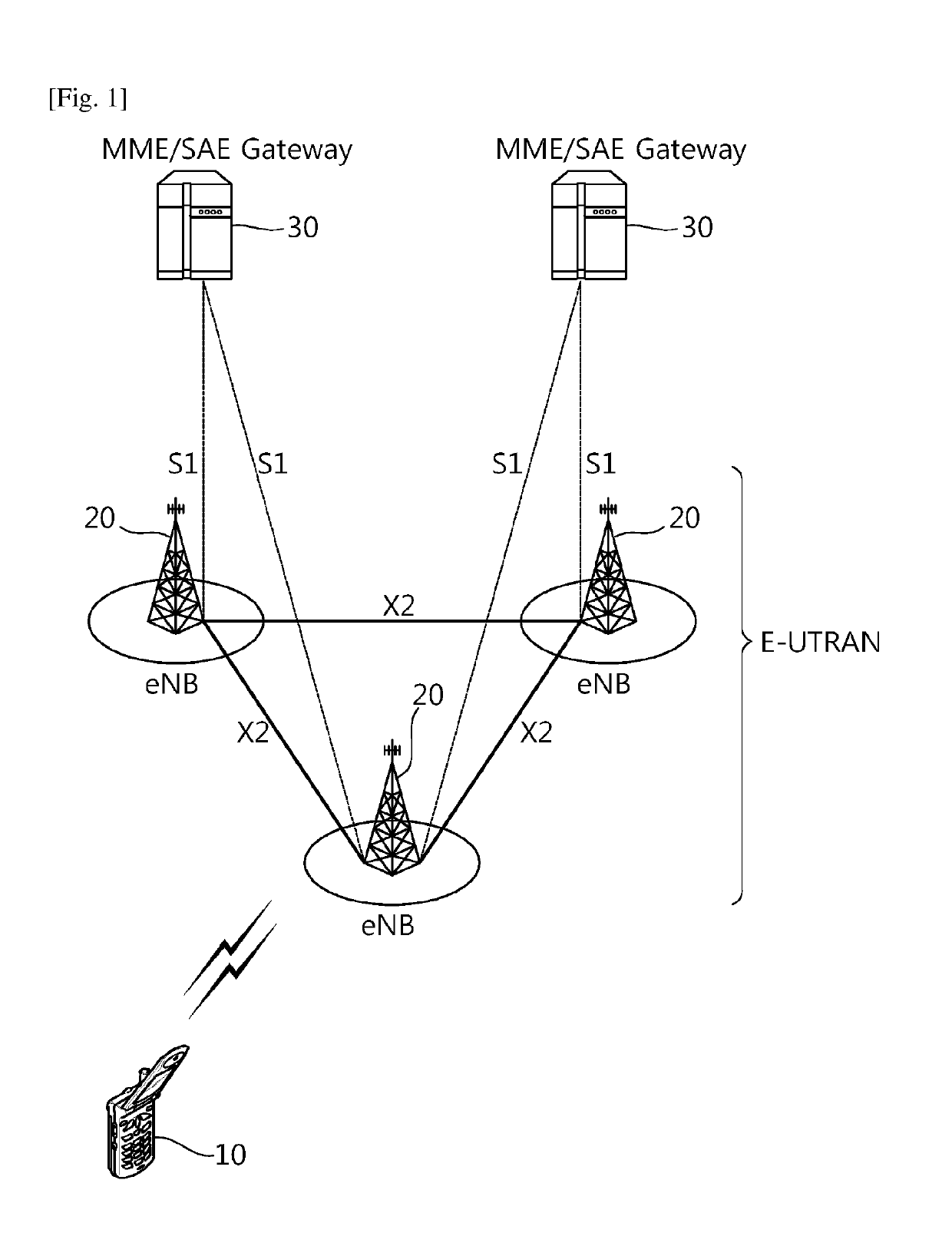

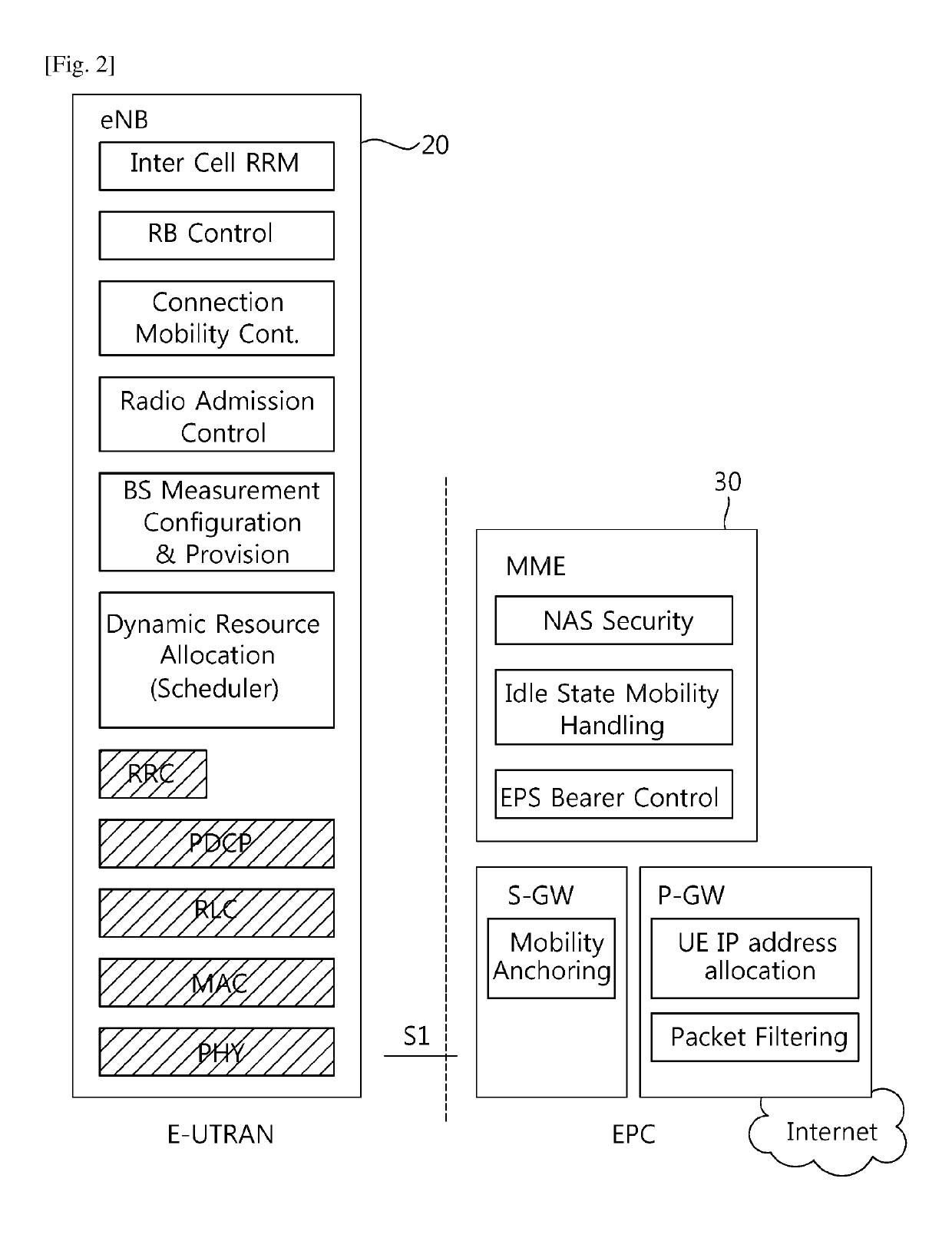

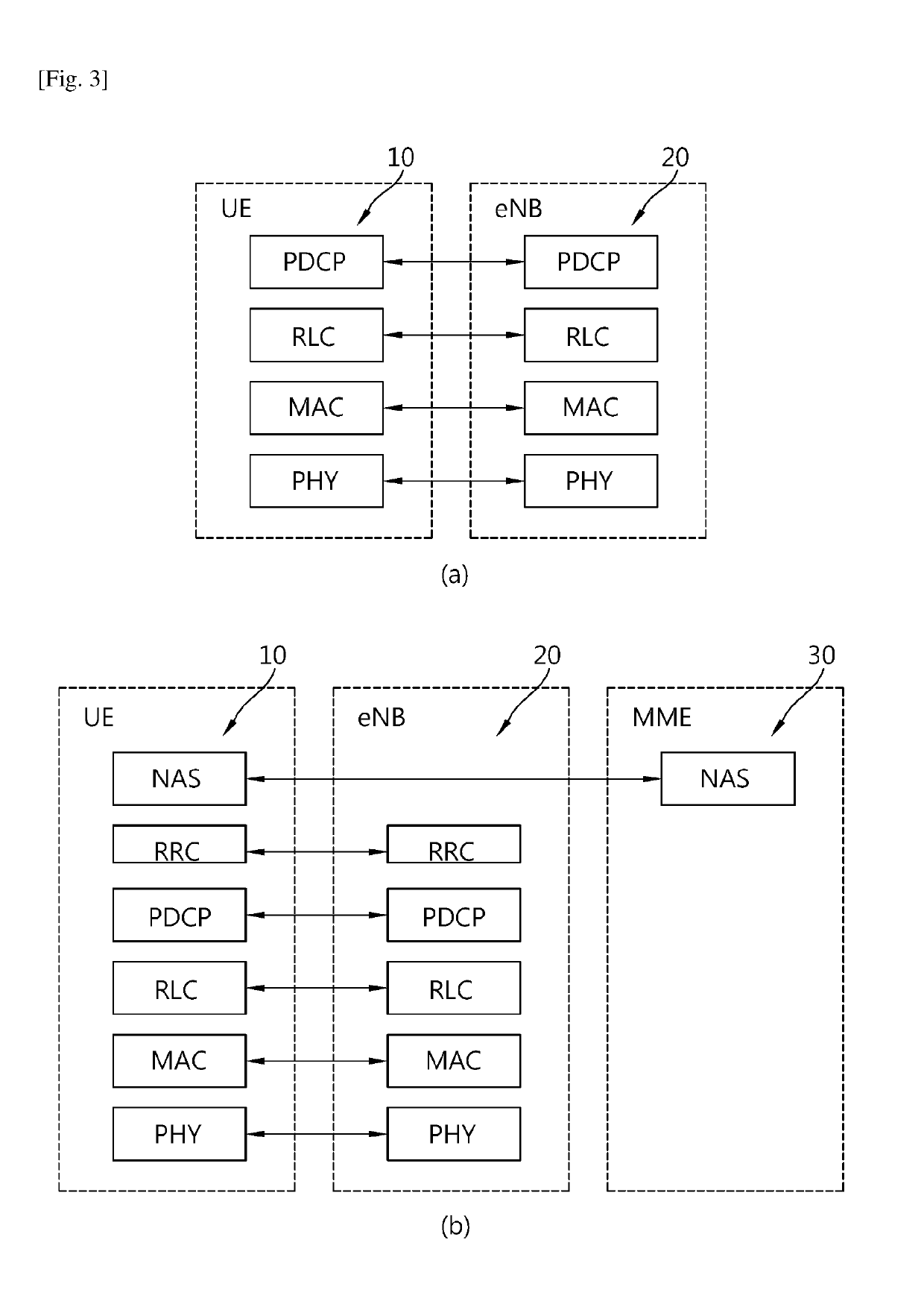

Method and apparatus for performing handover procedure in wireless communication system

ActiveUS10412649B2Utilization areaEfficient networkingConnection managementTelecommunicationsCommunications system

A method for performing a handover procedure in a wireless communication system is provided. A first eNodeB (eNB) of a 3rd generation partnership project (3GPP) long term evolution (LTE) system receives information on an access point (AP) of a wireless local area network (WLAN) system, which is located at neighborhood of a second eNB, to which data of the first eNB can be offloaded, from a user equipment (UE) or a second eNB, and decides whether to handover the UE to the second eNB based on the received information on the AP.

Owner:LG ELECTRONICS INC

Method of manufacturing 3-D semiconductor device

ActiveUS10636699B2Reduce in quantityUtilization areaSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A method of manufacturing three-dimensional semiconductor device, comprising the steps of: a) forming a device unit on a substrate, the said device includes a plurality of stack structures composed of the first material layer and the second material layer stacked along a direction perpendicular to the substrate surface; b) forming a contact lead-out region around the said device unit, the contact lead-out region comprises a plurality of sub-partitions, each of the sub-partitions respectively exposes a different second material layer; c) forming a photoresist on said substrate, covering said plurality of sub-partitions, exposing a portion of said second material layer; d) using the photoresist as a mask, simultaneously etching the portion of the second material layer exposed by said plurality of sub-partitions, until another second material layer beneath said second material layer is exposed; e) slimming the size of the photoresist to expose a portion of said another second material layer; f) repeating said steps d and step e, until all of the second material layers are exposed; g) forming contact leads, connecting each of the plurality of the second material layers. In accordance with the method of the present invention, the total number of etching process steps is reduced dramatically and the area utilization is improved effectively by selectively etching each of the sub-partitions.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com