Artificial leather surface layer material for home building materials, and preparation method and application thereof

A surface layer, artificial leather technology, applied in the field of artificial leather, can solve the problems of poor weather resistance, heat resistance and mechanical properties, soft hardness can not meet the requirements of furniture and building materials, affecting comfort, etc. Easy to loop, easy to reuse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

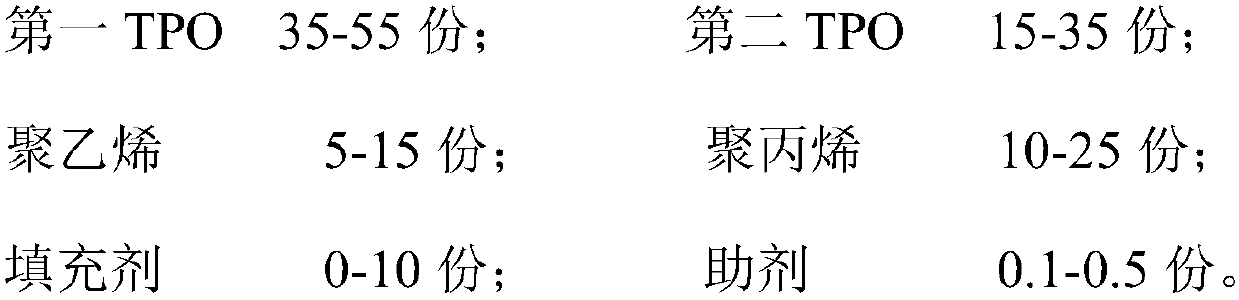

Method used

Image

Examples

preparation example Construction

[0051] A method for preparing an artificial leather surface layer material for furniture and building materials, comprising the following steps: weighing the first TPO, the second TPO, polyethylene, polypropylene, fillers and auxiliary agents, and putting them into an internal mixer for internal mixing , the banburying temperature of setting internal mixer is 160-190 ℃, the initial electric current of banburying is 260-320A, the electric current when unloading is 180-240A, obtains final product.

[0052] The internal mixing of raw materials under this condition can strengthen the internal mixing and shorten the mixing cycle. At the same time, the heat generated at this speed will not be too high, which will have little effect on the viscosity of the raw materials and will not reduce the mechanical shearing effect. It is conducive to the full dispersion of each component; in addition, there will be no raw material burning phenomenon, and there will be no raw material crushing ph...

Embodiment 1-4

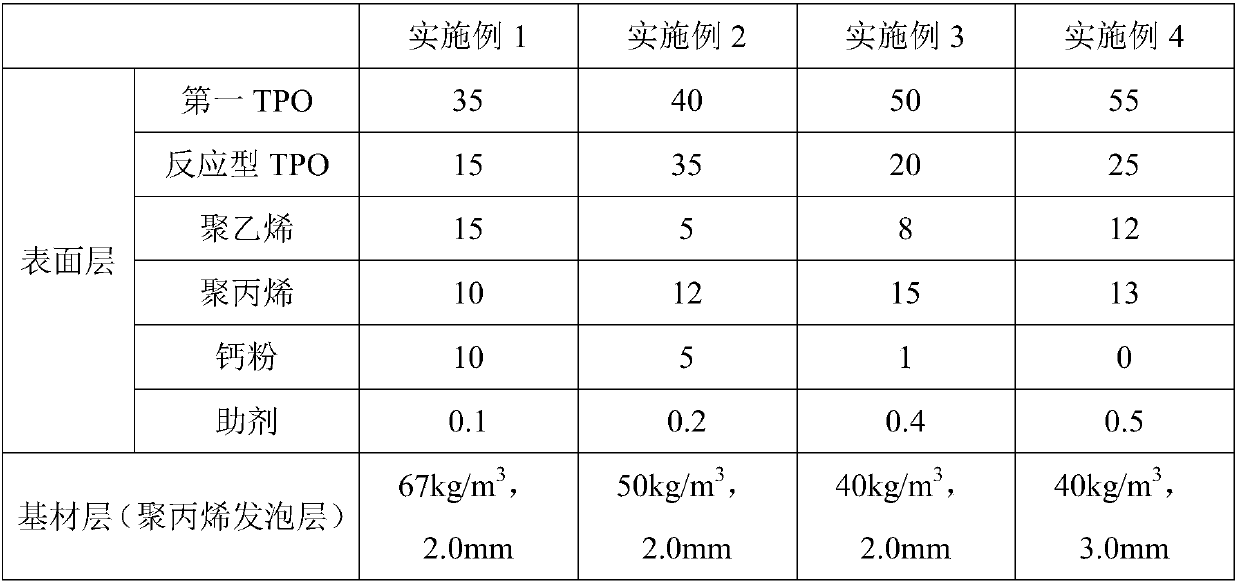

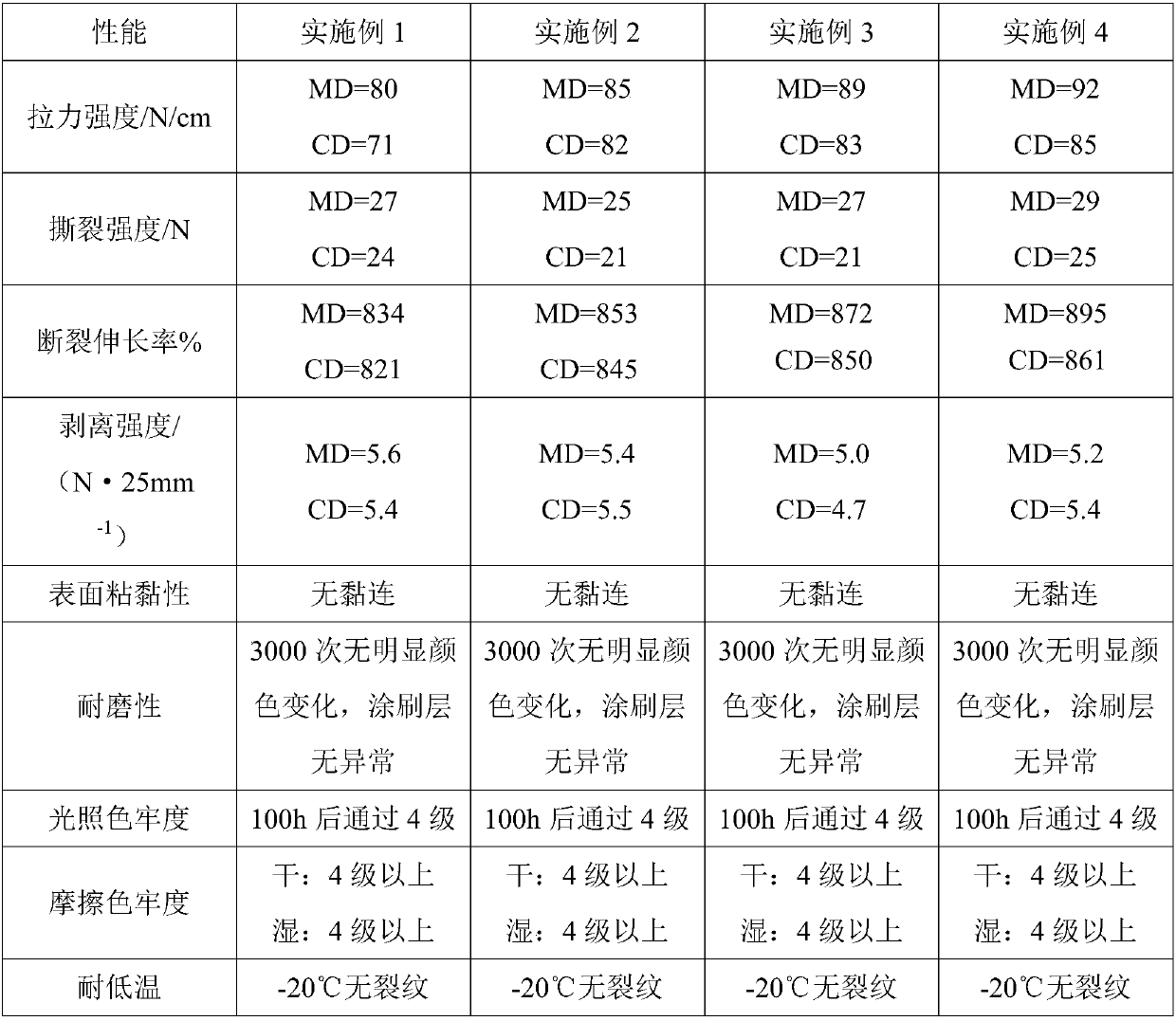

[0065] An artificial leather comprising a surface layer and a substrate layer bonded upper and lower. The composition and dosage (parts by weight) of the artificial leather of Examples 1-4 are shown in Table 1 below.

[0066] The formula table of the artificial leather of table 1 embodiment 1-4

[0067]

[0068] A kind of preparation method of artificial leather, comprises the following steps:

[0069] Mixing step: Weigh the first TPO, the second TPO, polyethylene, polypropylene, fillers and additives in the formula, put them into the internal mixer for internal mixing, set the internal mixing temperature of the internal mixer to 160-190 ℃, the initial current of banburying is 260-320A, and the current during unloading is 180-240A to obtain the raw material of the first surface layer;

[0070] Milling step: unload the raw materials of the first surface layer into the mill, set the temperature of the mill to 160-190°C, further knead and plasticize, and obtain the raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com