Method for recycling heavy sludge and enhancing nitrogen and phosphorus removal

A technology for nitrogen and phosphorus removal and sludge removal, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of increased operating costs, poor removal effect, and activated sludge concentration Low-level problems, to achieve the effect of strong impact load resistance, increased sludge specific gravity, and rapid sludge settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

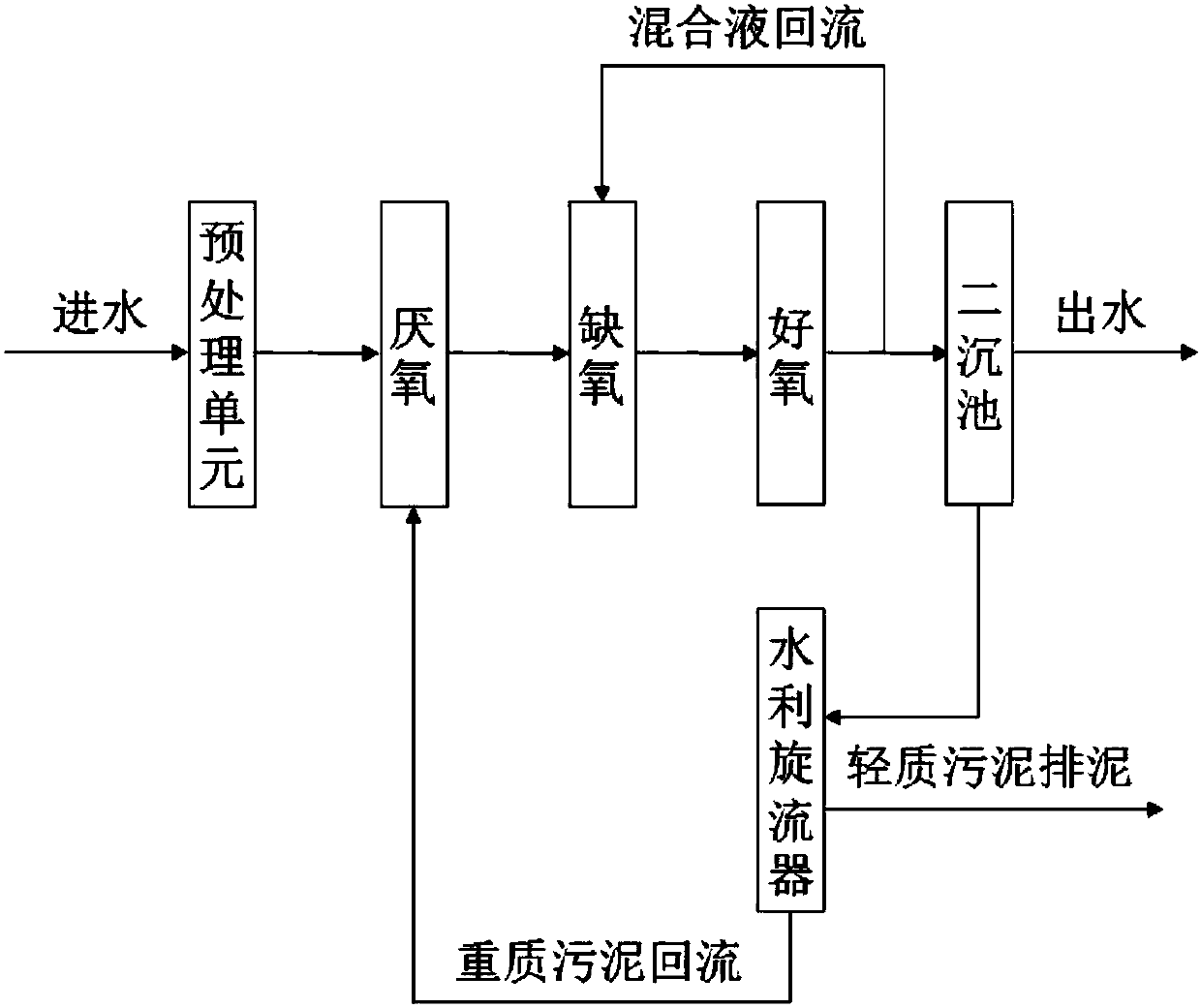

[0026] like figure 1 As shown, a method for heavy sludge recovery and enhanced denitrification and phosphorus removal is realized by the following device, which is made of plexiglass, including an anaerobic tank, anoxic tank, and an aerobic tank connected in sequence. Gas tank and secondary sedimentation tank, the volume ratio of the anaerobic tank, anoxic tank, and aerobic tank is 1:2:5, and the total effective volume is 52.5L, the effective volume of the secondary sedimentation tank is 26L, and the anaerobic tank Stirring and mixing with the anoxic tank is adopted, and the aerobic tank is fixed at the bottom to supply oxygen and promote liquid mixing at the same time. The inflow, sludge and nitrification liquid return are all controlled by peristaltic pumps; The influent water is connected to the back pipe of the pretreatment unit; part of the mixed liquid in the aerobic tank is returned to the anoxic tank through the mixed liquid return pipe; The sludge output end, the hyd...

Embodiment 2

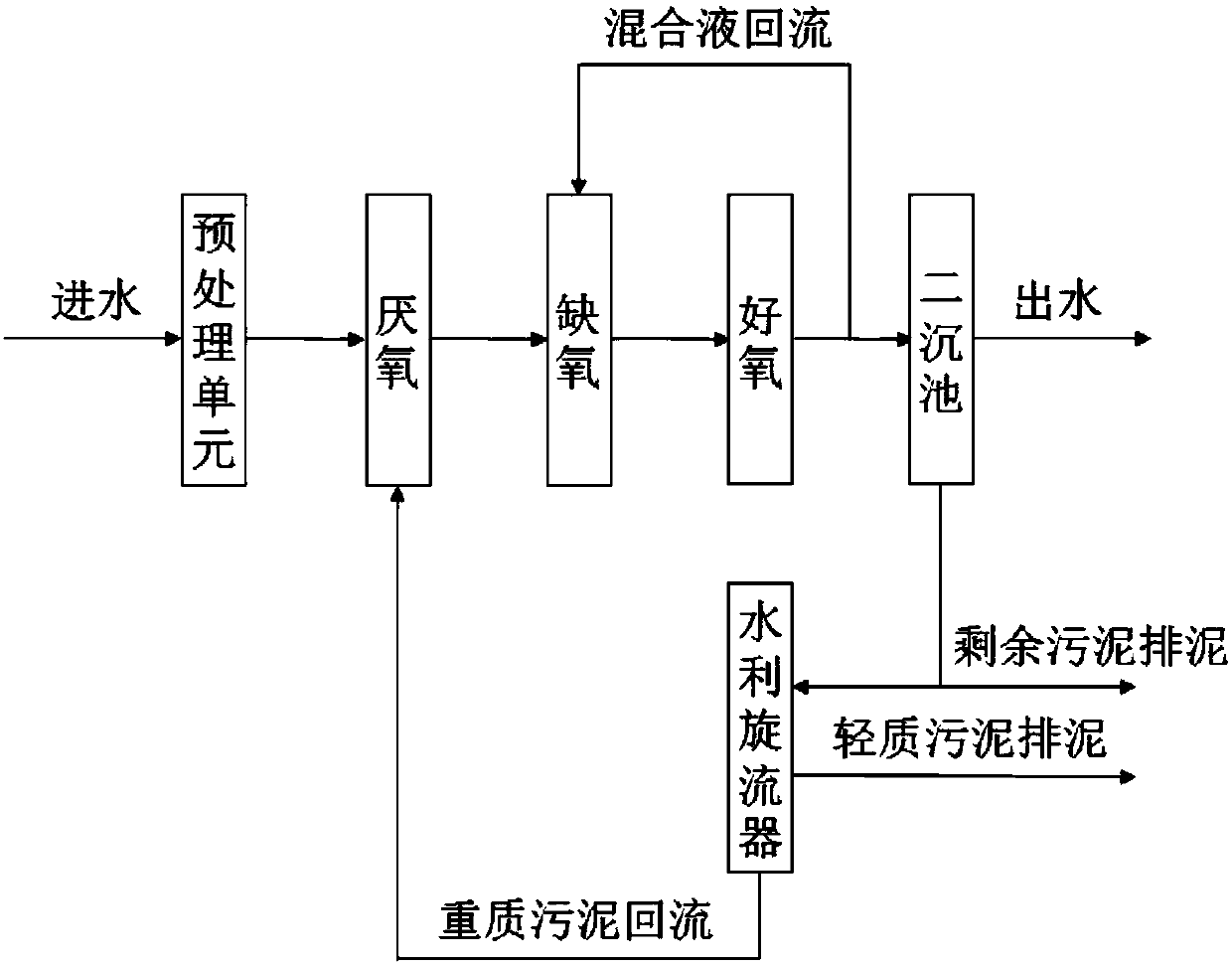

[0039] like figure 2 As shown, a method for heavy sludge recovery and enhanced denitrification and phosphorus removal is characterized in that the method is realized by the following devices, including an anaerobic tank, an anoxic tank, an aeration tank as an aerobic tank and In the secondary settling tank, the sewage input end of the anaerobic tank is connected with the sewage influent through the rear pipeline of the pretreatment unit; part of the mixed liquid in the aerobic tank is returned to the anoxic tank through the mixed liquid return pipeline; the bottom of the secondary settling tank is set There is a return sludge output end, and the secondary settling tank is connected to the anaerobic tank through the return sludge output end, hydrocyclone or centrifuge, heavy sludge return pipeline connected in sequence, and the secondary settling tank is also equipped with an outlet pipe, so The excess sludge discharge pipe is set on the output end of the return sludge, when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com