Anti-sintering cavitation-damage-resistant copper alloy and processing method thereof

A processing method and anti-cavitation technology, applied in the field of material processing, to achieve the effects of good anti-sintering, strong environmental protection, and high fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

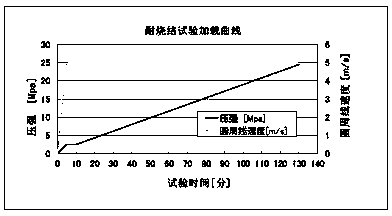

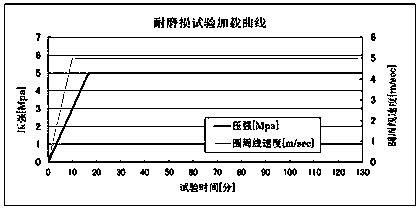

[0034] Such as figure 1 As shown, the present invention discloses a sintering-resistant and cavitation-resistant copper alloy applicable to the manufacture of mechanical parts. Specifically, a sintering-resistant and cavitation-resistant copper alloy, the composition and mass percentage of which are——

[0035] Cu: 64.0% to 72.0%;

[0036] Al: 1.0% to 3.0%;

[0037] Ni: 2.5% to 4.0%;

[0038] Si: 0.5% to 2.0%;

[0039] Mn: 0.5%~2.0%;

[0040] Fe: 0.2% ~ 1.0%;

[0041] The balance is Zn.

[0042] Here, it should be noted that, due to unavoidable reasons in the processing process, certain impurities must be contained in the final product, and the impurities will be referred to by others hereinafter. The composition and mass percentage of impurities in the final product are 0.2% to 0.5%.

[0043] A set of measurement data is listed below to further prove the mechanical properties of the anti-sintering and cavitation-resistant copper alloy of the present invention:

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com