A method for preparing micro-nano composite structure coating by liquid material plasma spraying

A micro-nano composite structure, plasma technology, applied in metal material coating process, coating, fusion spraying and other directions, can solve problems such as failure and coating performance degradation, achieve good high temperature resistance, fine coating structure, The effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

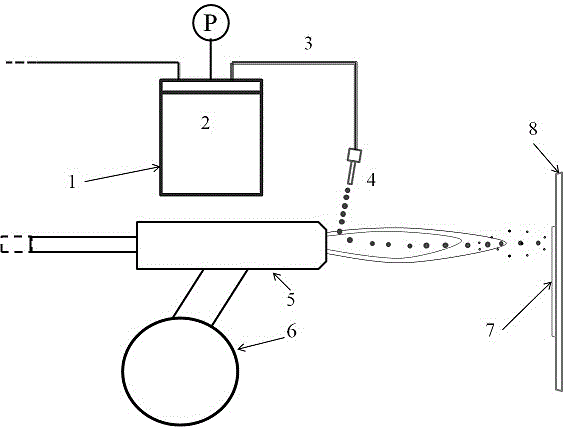

Method used

Image

Examples

Embodiment 1

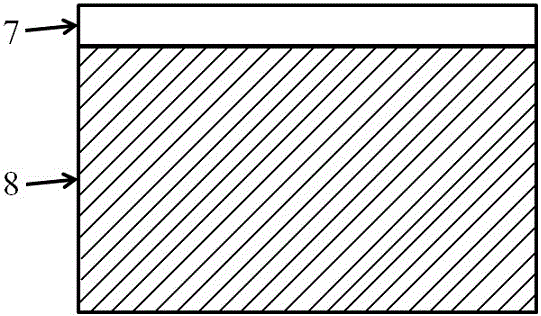

[0045] Weigh 50g tungsten chloride WCl 6 powder, dissolved in 250 ml of absolute ethanol to obtain a blue transparent solution. 25 g of tungsten oxide WO with an average particle size of 1 µm 3 Powder added to blue WCl 6 solution, and use magnetic stirring to mix evenly to obtain a suspension.

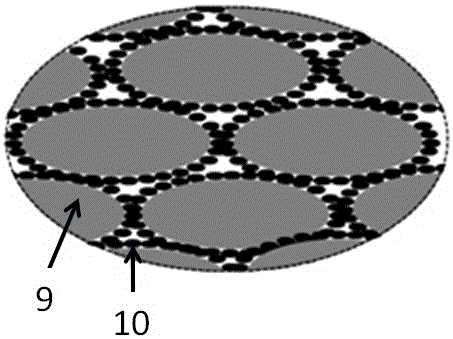

[0046] The prepared suspension liquid was fed into the flame flow generated by the F4MB plasma spray gun through a non-atomizing nozzle with a diameter of 0.5 mm, and 2 o 3 WO 3 Composite coating. The coating was analyzed by X-ray diffraction analysis (XRD) and field emission scanning electron microscope (FE-SEM). The results showed that the coating showed a monoclinic phase WO 3 , the microstructure is a nano-submicron composite structure.

Embodiment 2

[0048] Weigh 50g crystalline zinc acetate Zn (CH3COO)2 2H2O, dissolved in 500 ml deionized water to obtain a colorless transparent solution. Add 50 g of ZnO powder with an average particle size of 2.5 µm to the blue Zn(CH3C0O) 2 solution, and use magnetic stirring to mix evenly to obtain a suspension.

[0049] The prepared suspension liquid was fed into the flame flow generated by the F4MB plasma spray gun through a nozzle with a diameter of 0.75 mm, and a ZnO composite coating was obtained on the Fe substrate. The coating is analyzed by XRD and SEM, and the results show that the coating presents a hexagonal wurtzite structure, and the microstructure is a nano-micro composite structure.

Embodiment 3

[0051] Weigh 50g tin dichloride (SnCl 2 ) powder, dissolved in 500 ml deionized water to obtain a colorless transparent solution. Add 50 g of tin oxide powder with an average particle size of 0.5 μm into the tin dichloride solution, and use magnetic stirring to mix evenly to obtain a suspension.

[0052] The prepared suspension liquid was fed into the flame flow generated by the F4MB plasma spray gun through a non-atomizing nozzle with a diameter of 0.25 mm, and 2 o 3 SnO 2 Composite coating. The coating was analyzed by X-ray diffraction analysis XRD and field emission scanning electron microscope FE-SEM analysis, the results showed that SnO 2 The coating presents a rutile structure, and the microstructure is a nano-submicron composite structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com